Patents

Literature

144results about How to "Realize support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

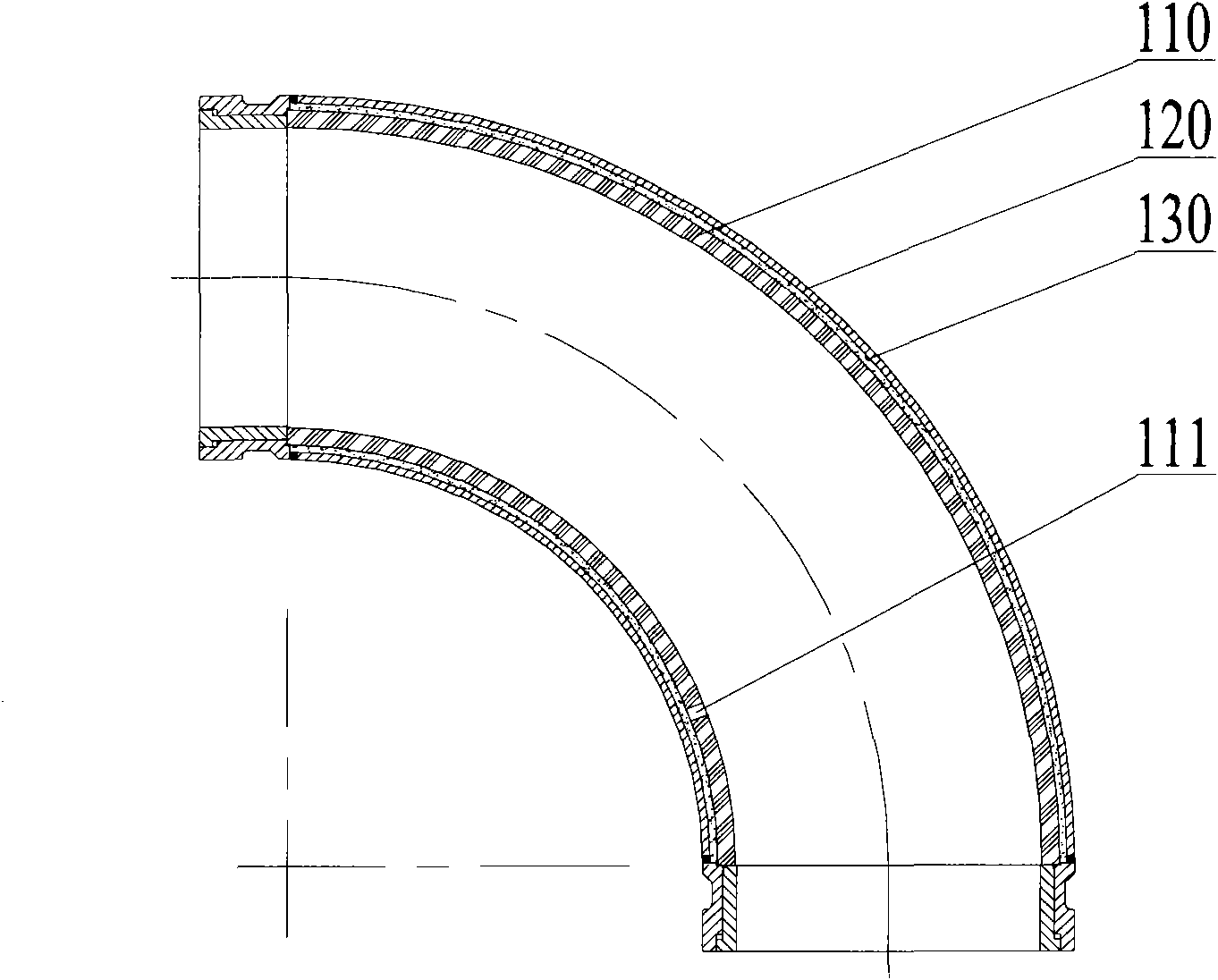

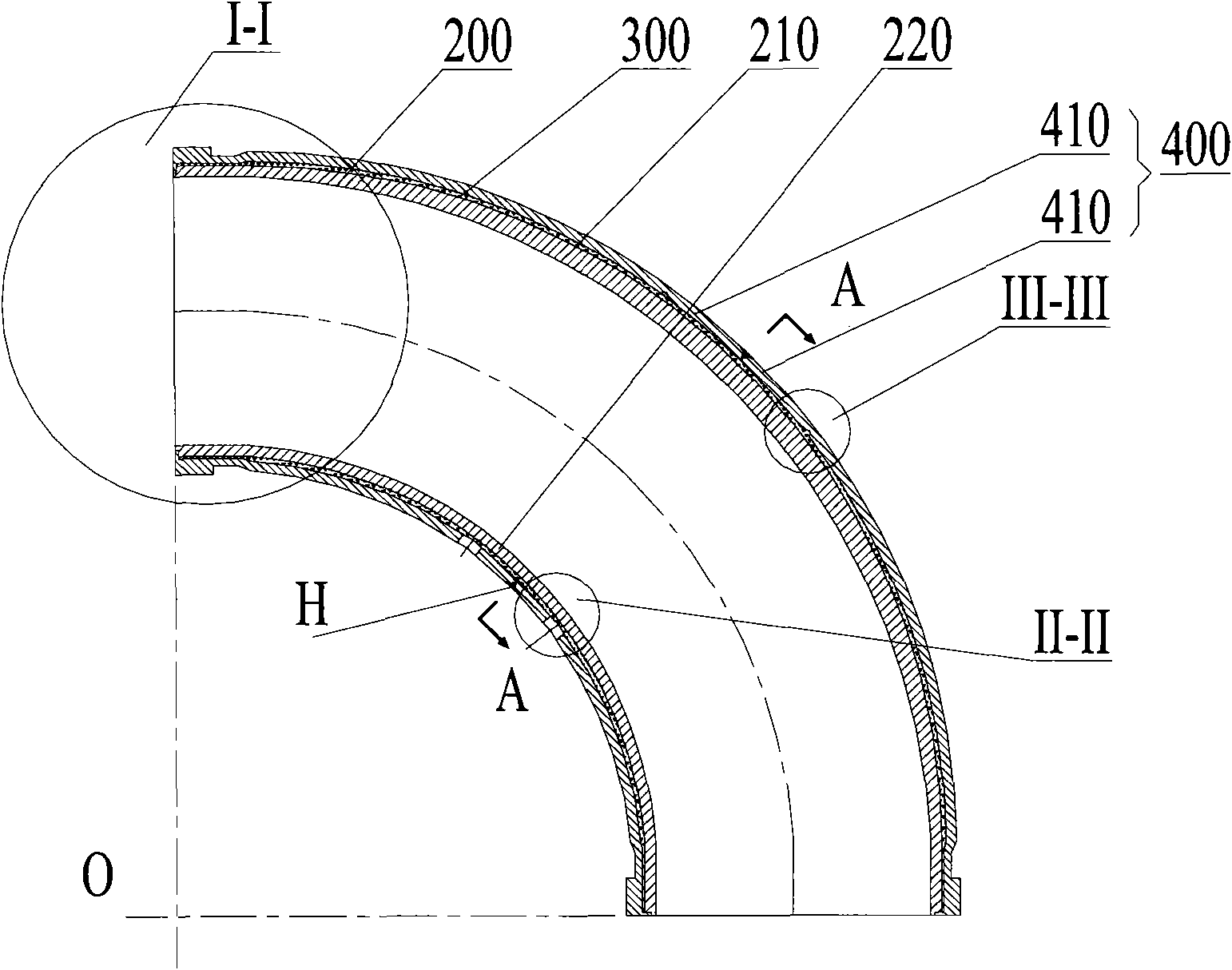

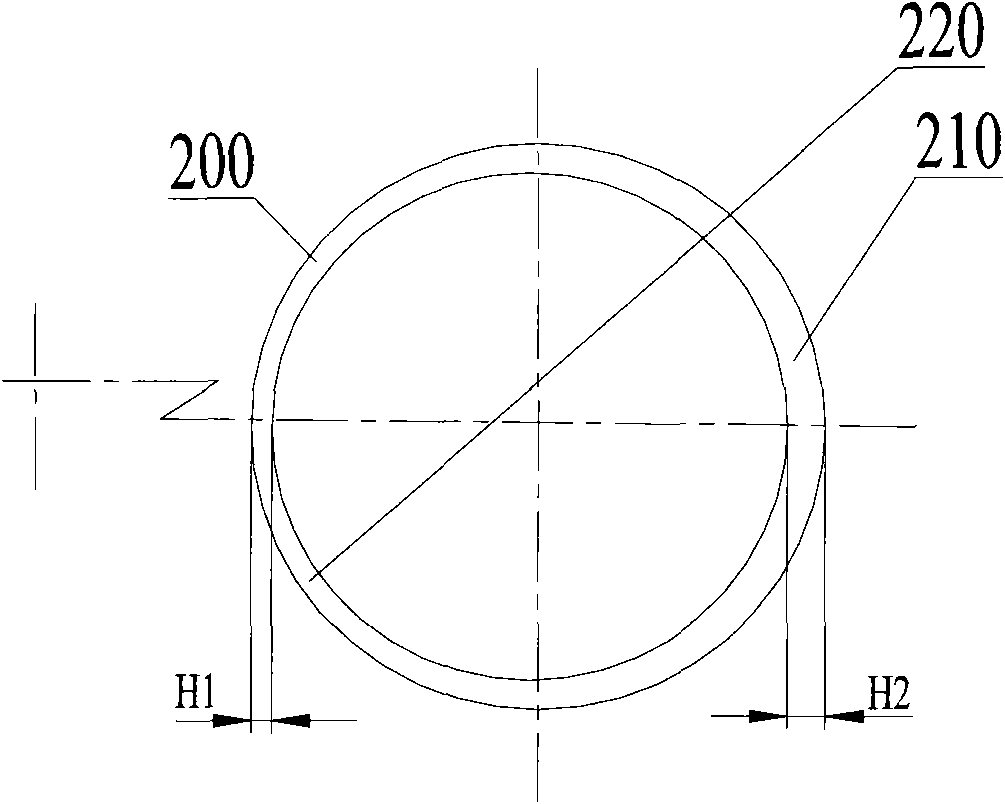

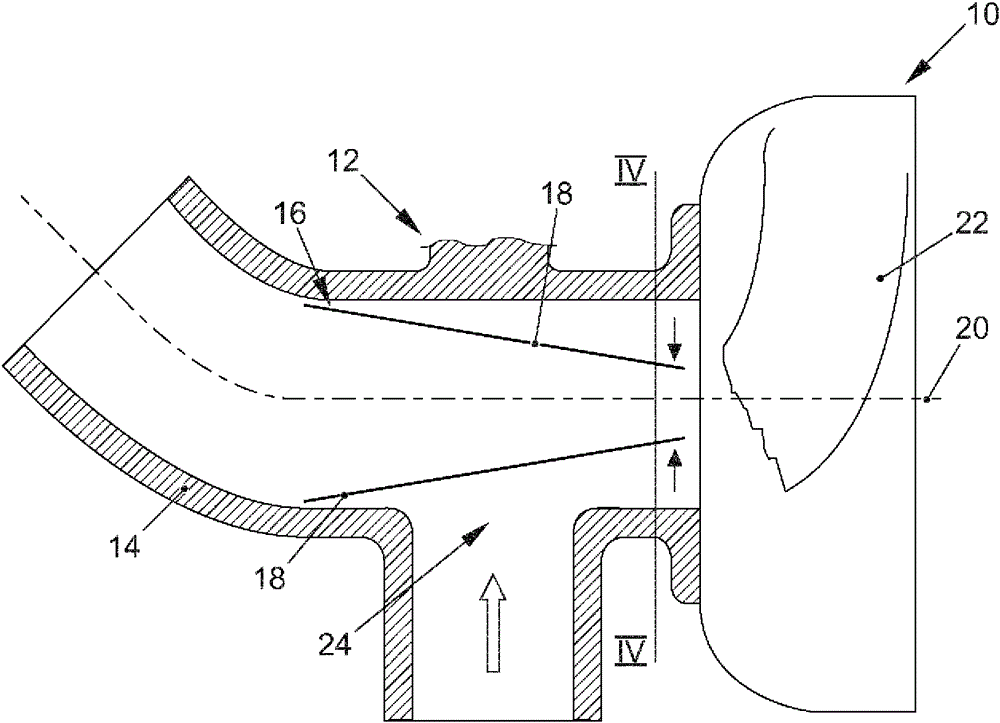

Conveying bent pipe, concrete conveyer and manufacturing method of same

InactiveCN101625060AReduce manufacturing costEasy to processBulk conveyorsRigid pipesManufacturing technologyEngineering

The invention discloses a conveying bent pipe, a concrete conveyer and a manufacturing method of the conveying bent pipe. The disclosed sequentially comprises an inner pipe, an outer pipe and a filling layer, and the outer pipe at least comprises two supporting pipes which are sequentially connected; the outer pipe of the conveying bent pipe has a split type structure and comprises two or more than two supporting pipes, thereby reducing the cost of the conveying bent pipe under the condition that the wearing resistance, the strength, the high toughness and the impact resistance are ensured. In an optimized technical scheme, the inner pipe and outer pipe are fixed by an adhesive layer to transfer the acting force of the inner pipe to the outer pipe, the supporting and protecting function of the inner pipe by the outer pipe is ensured, and safety of the conveying bent pipe can be increased. Because the inner pipe and the outer pipe can be mutually positioned by matching with an inner convex body and an inner notch, the manufacturing method of the conveying bent pipe not only can simplify a manufacturing technology in a conveying bent pipe manufacturing process, but also can reduce auxiliary mechanisms and reduce the manufacturing cost of the conveying bent pipe.

Owner:SANY HEAVY IND CO LTD (CN)

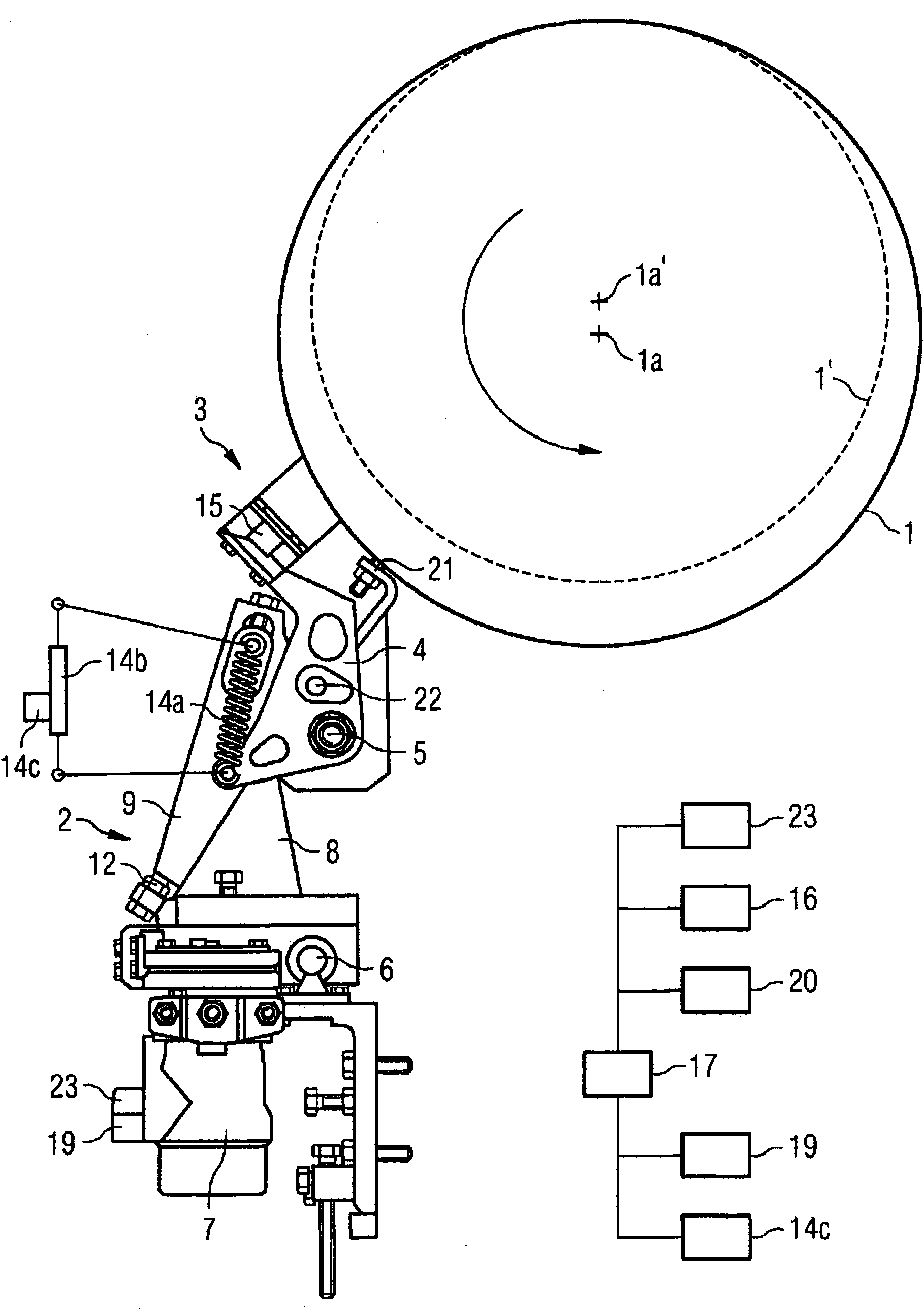

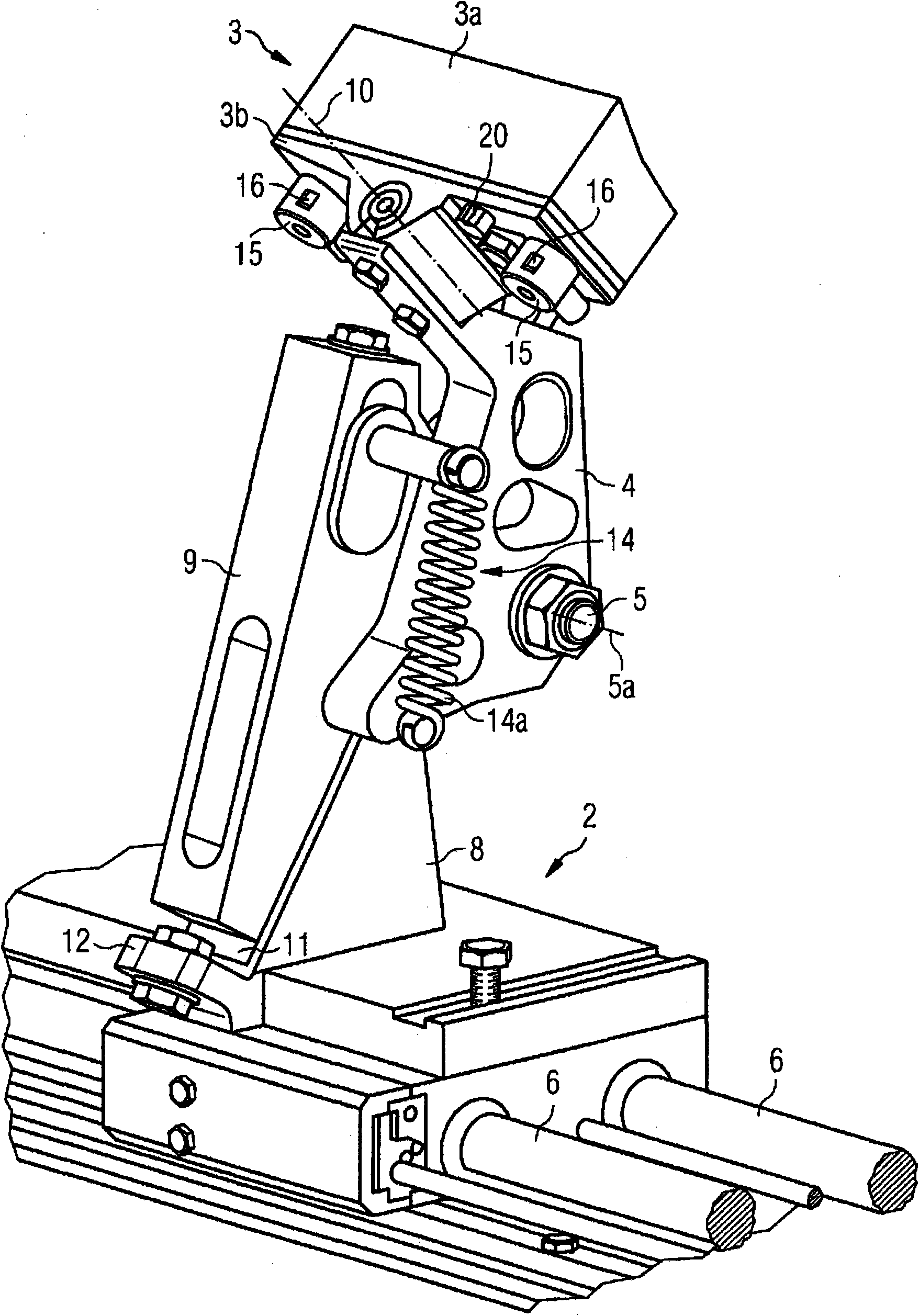

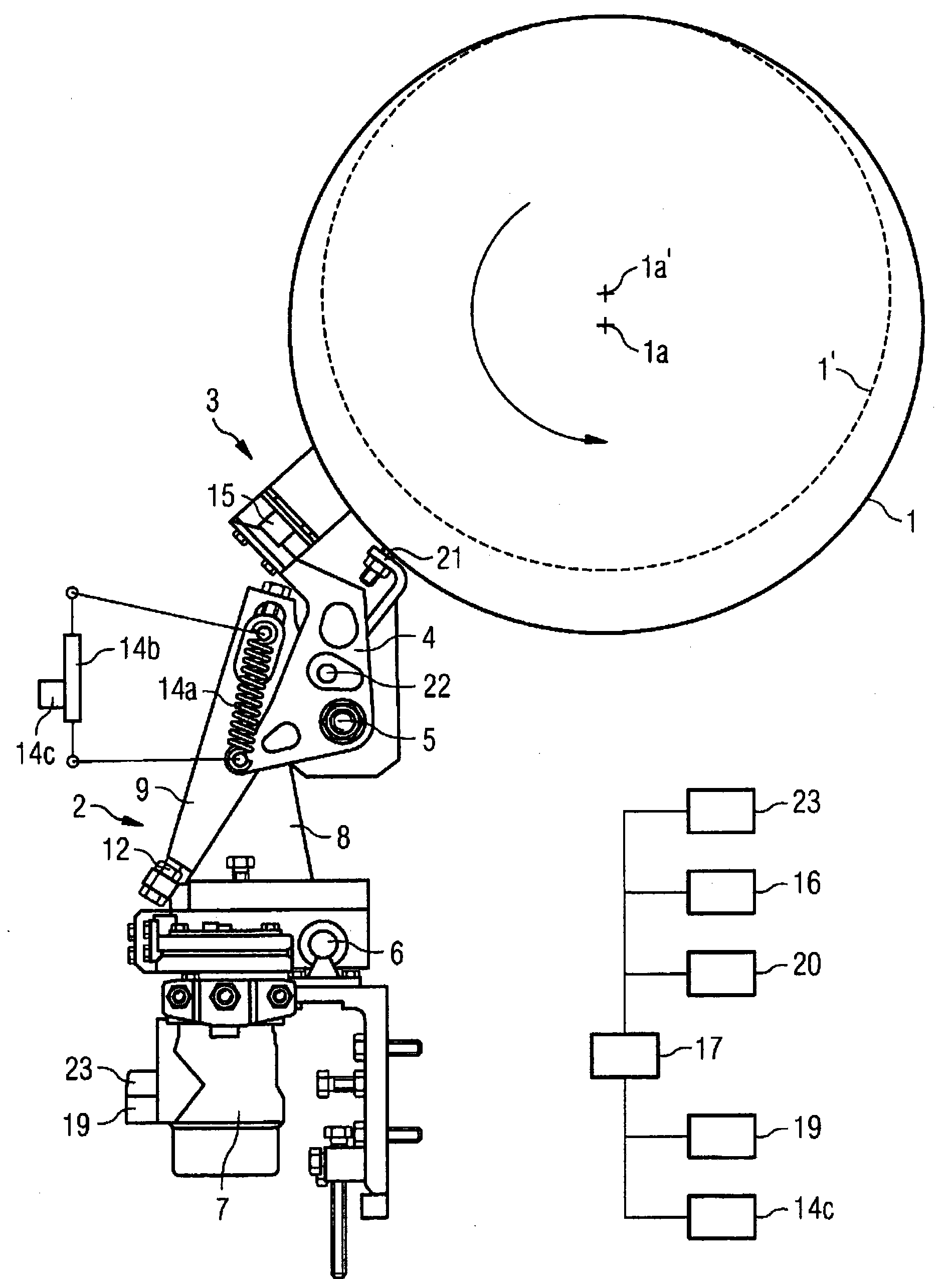

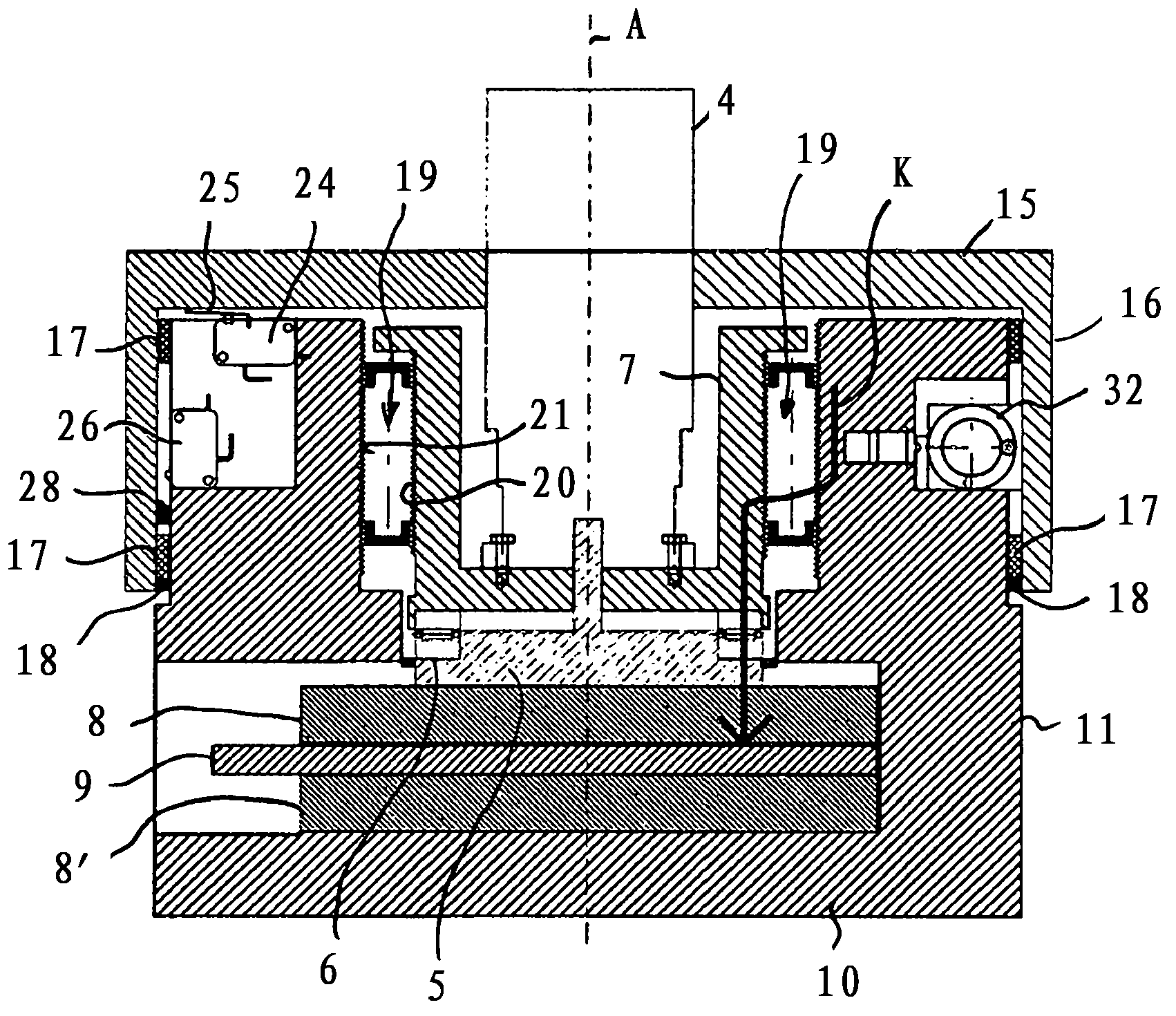

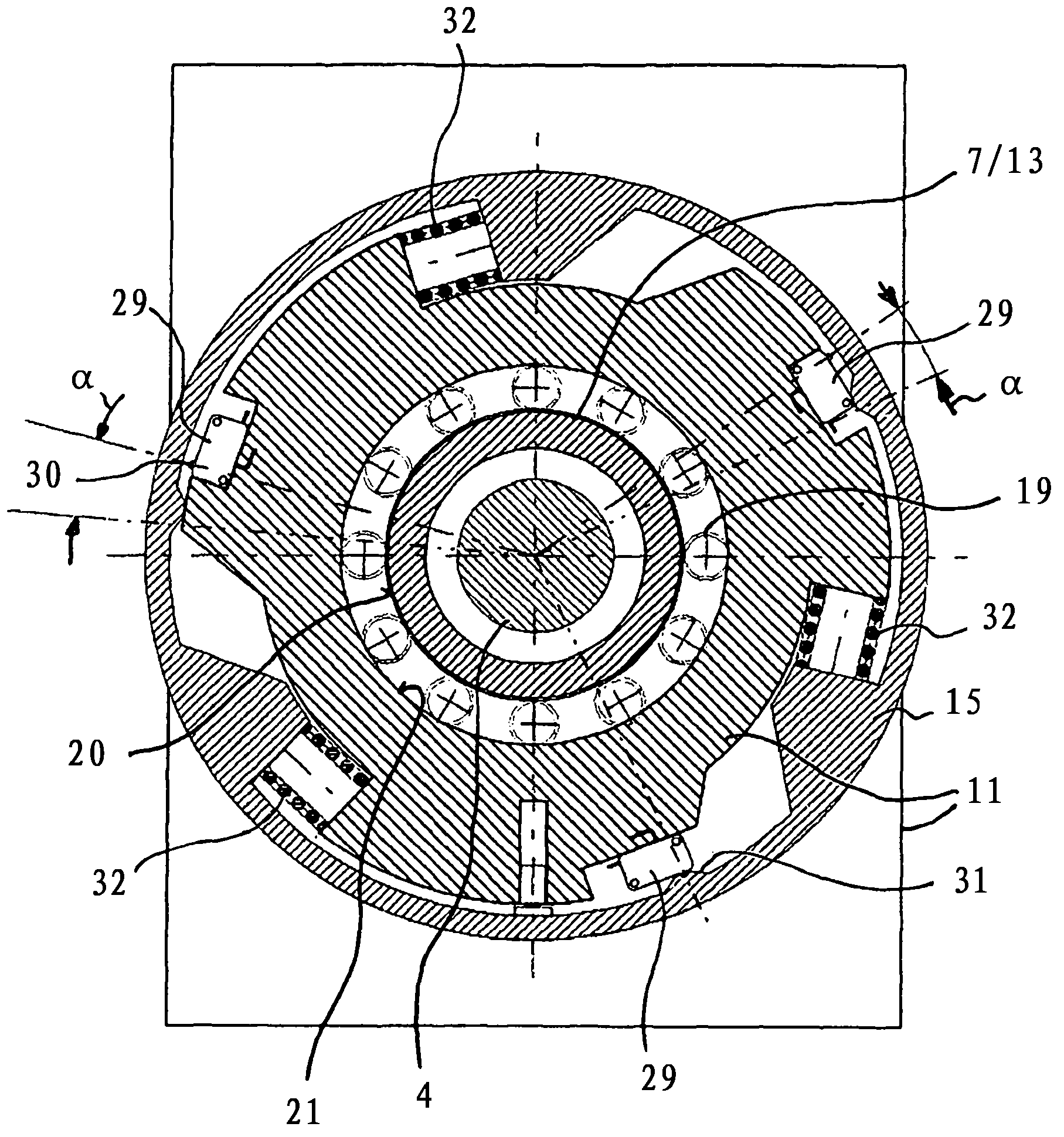

Method and device for cleaning the outer surface of roll or roller

InactiveCN101821027AClean thoroughlyEasy to useRevolution surface grinding machinesRolling equipment maintainenceEngineeringMechanical engineering

The invention relates to a method for cleaning the outer surface of a roll or roller (1) in strip-producing and strip-conditioning equipment, wherein deposits on the shell surface of the roll or roller are detected using a detection device (15), a cleaning tool (3), which can be placed against the outer surface of the roll or roller, is moved along said surface and the deposits are removed from the rotating roll or roller. In order to achieve an automatic cleaning process, it is suggested that the detection device (15) is guided along the outer surface of the roll or roller along with the cleaning tool (3), and the deposit detected by the detection device (15) on the shell surface of the roll or roller is removed using the cleaning tool (3).

Owner:PRIMETALS TECH AUSTRIA GMBH

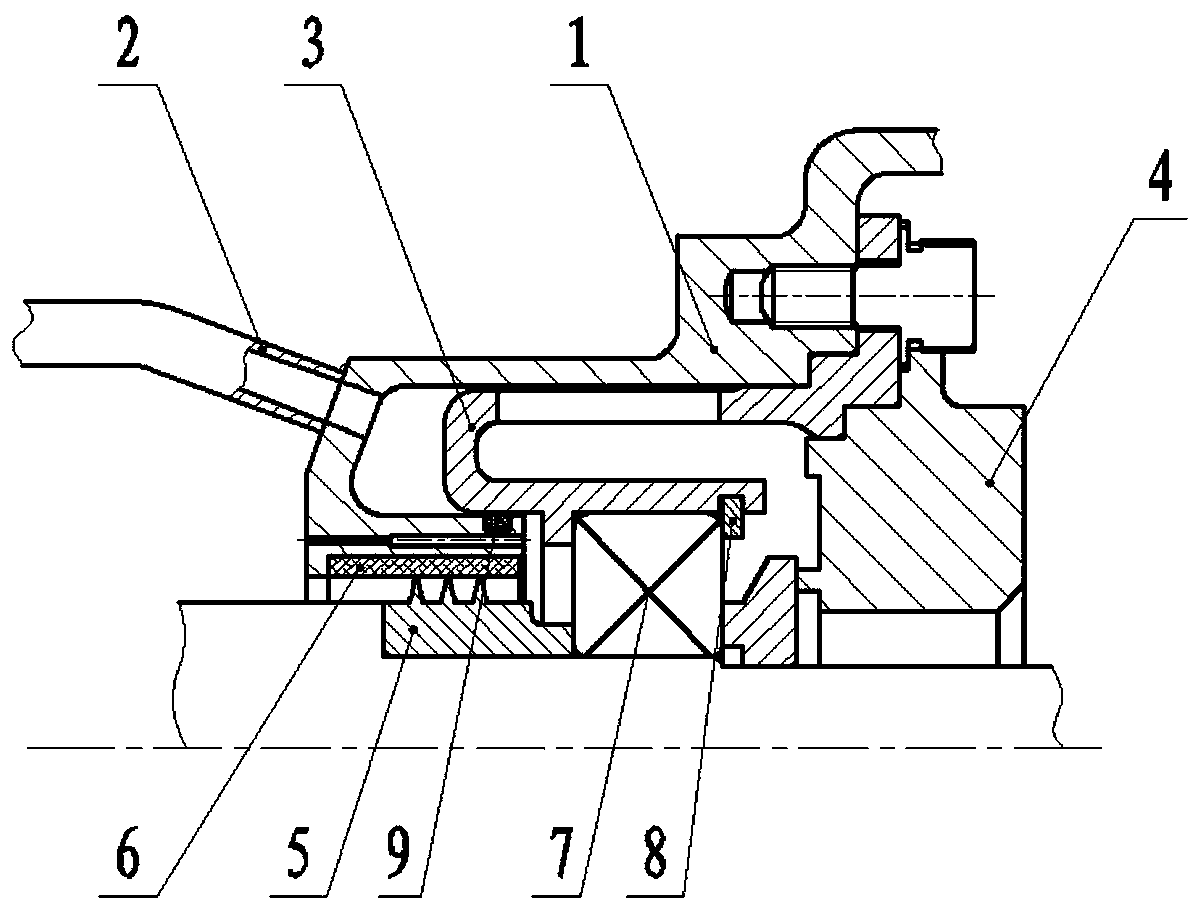

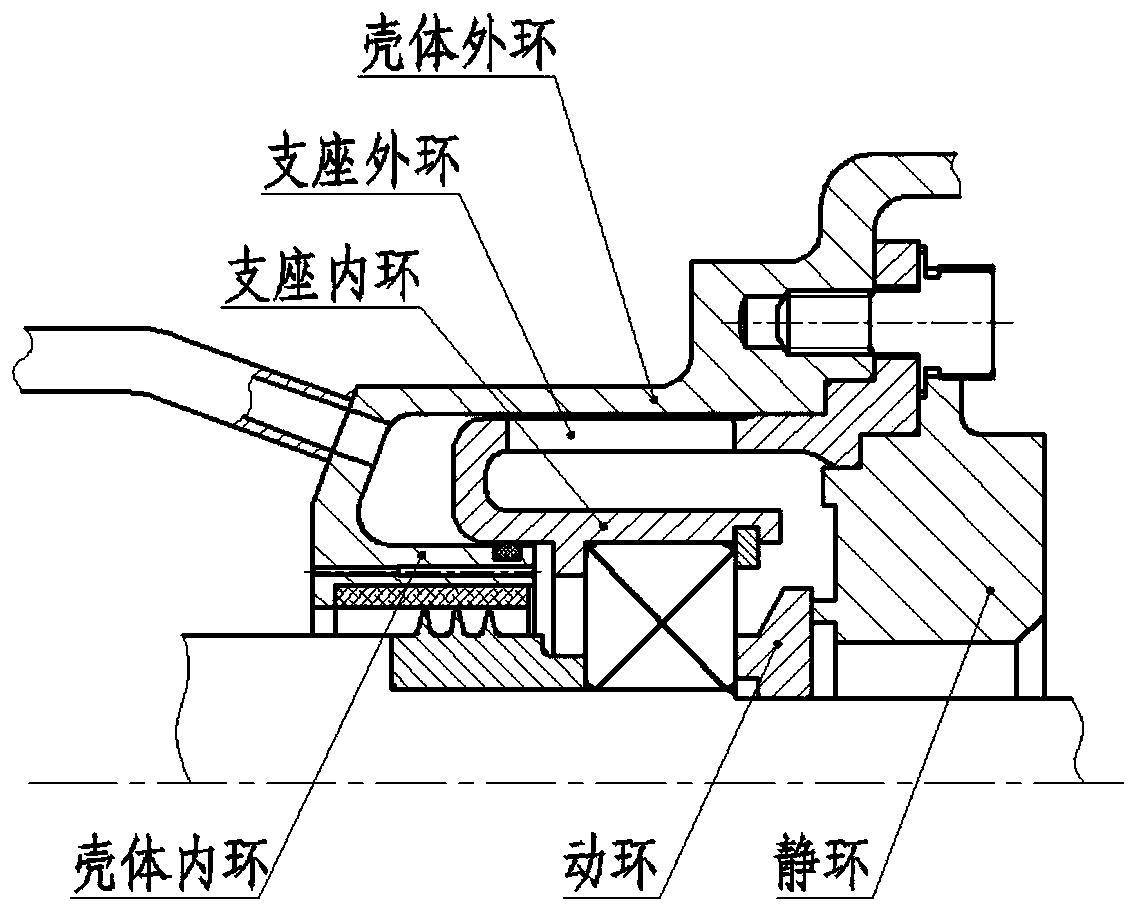

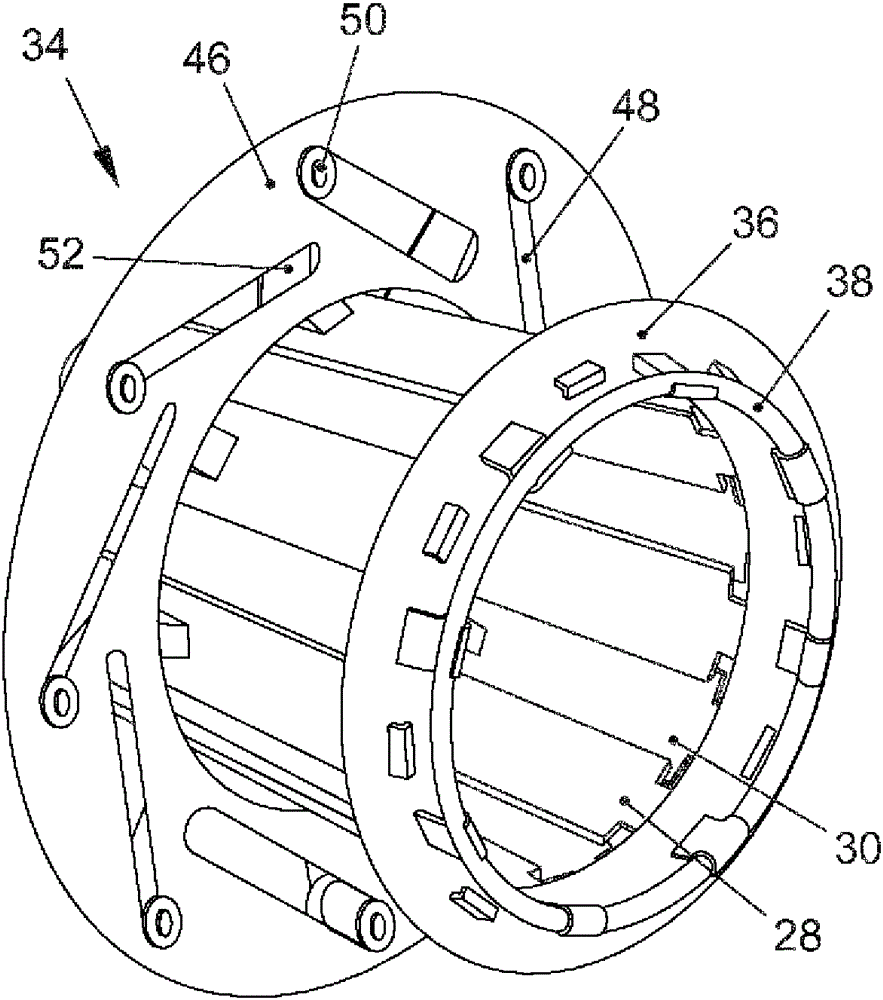

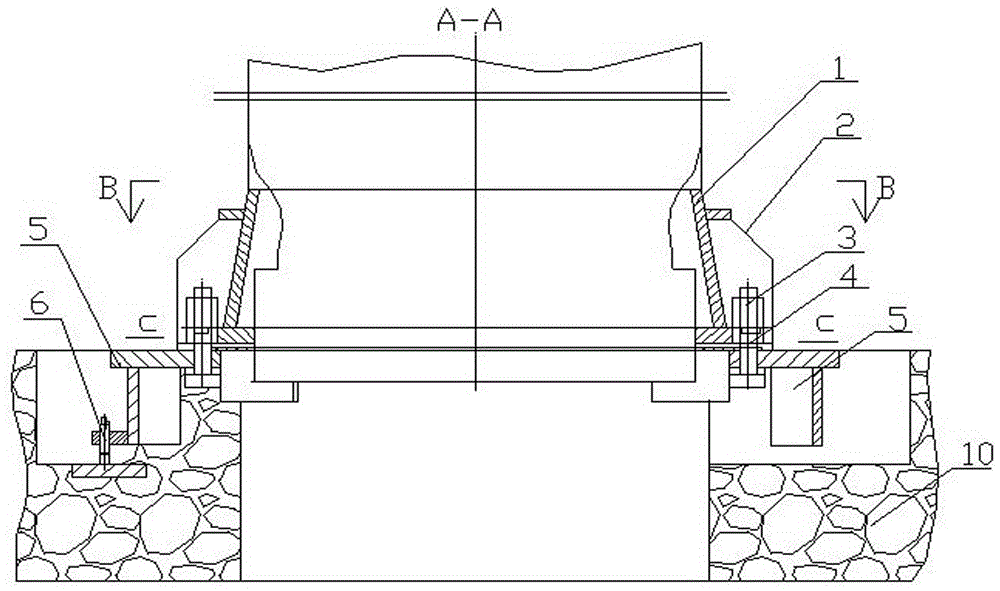

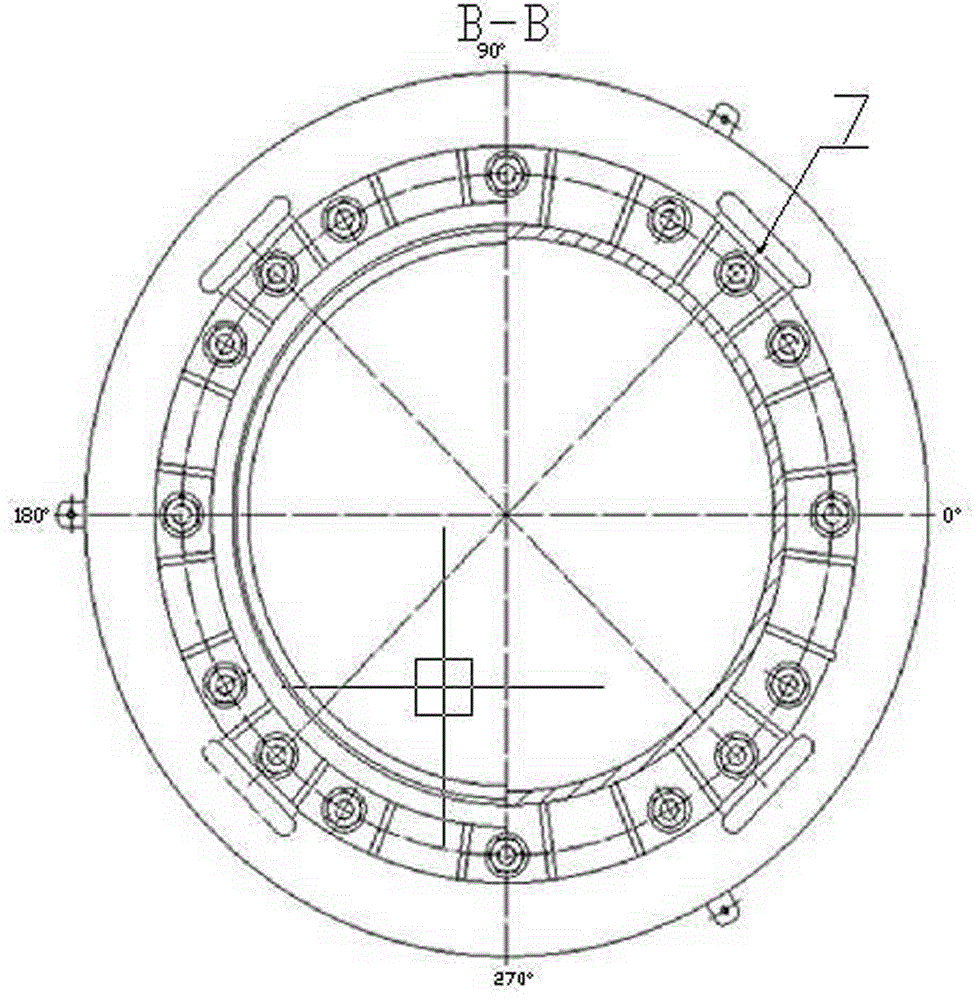

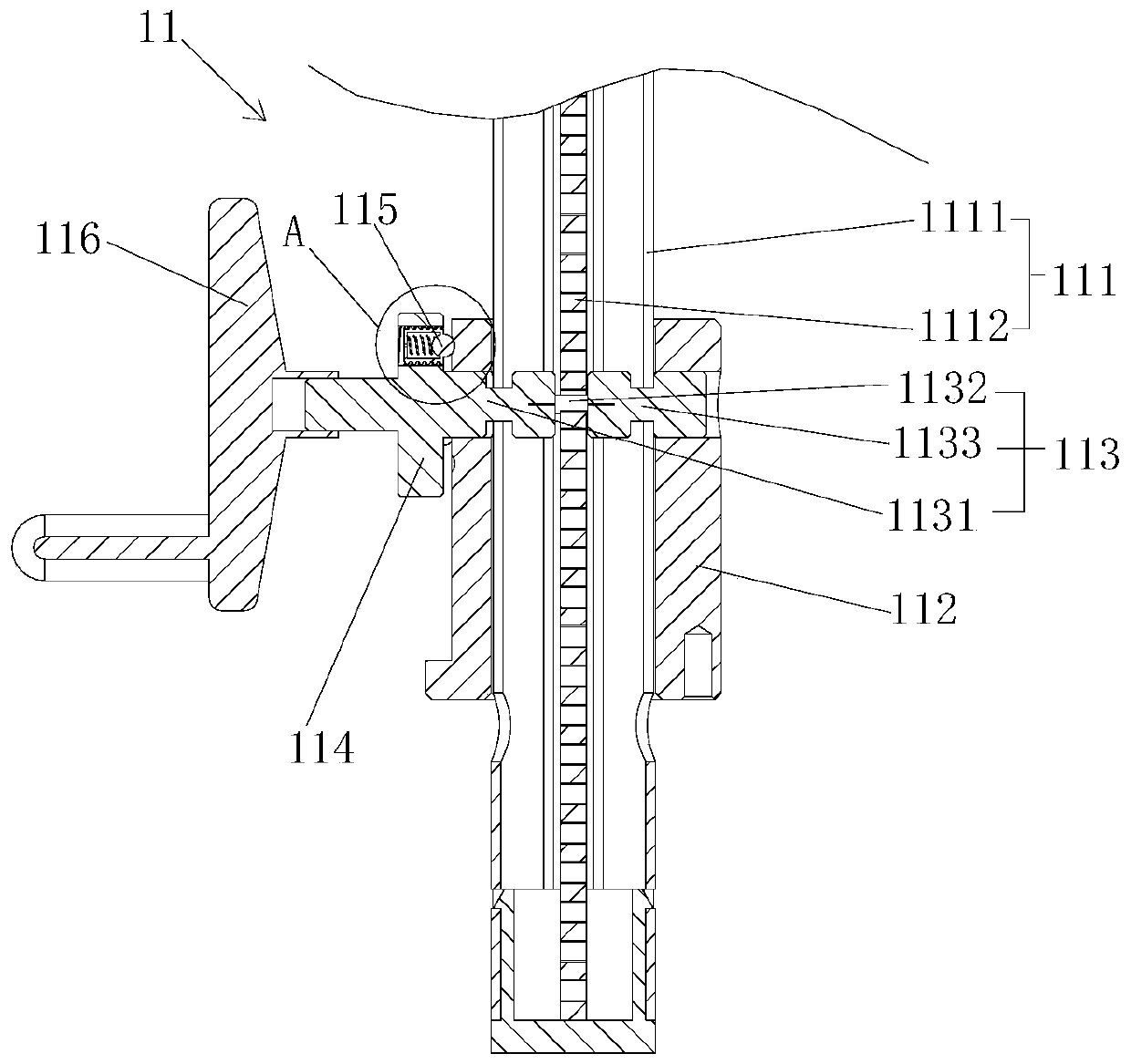

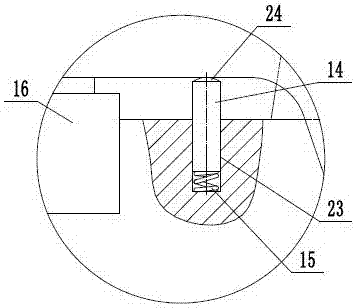

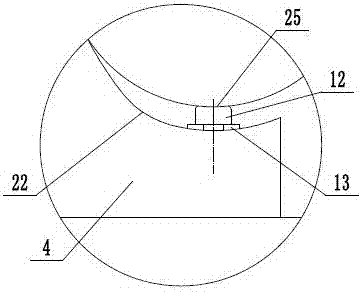

Mouse cage elastic support bearing cavity structure

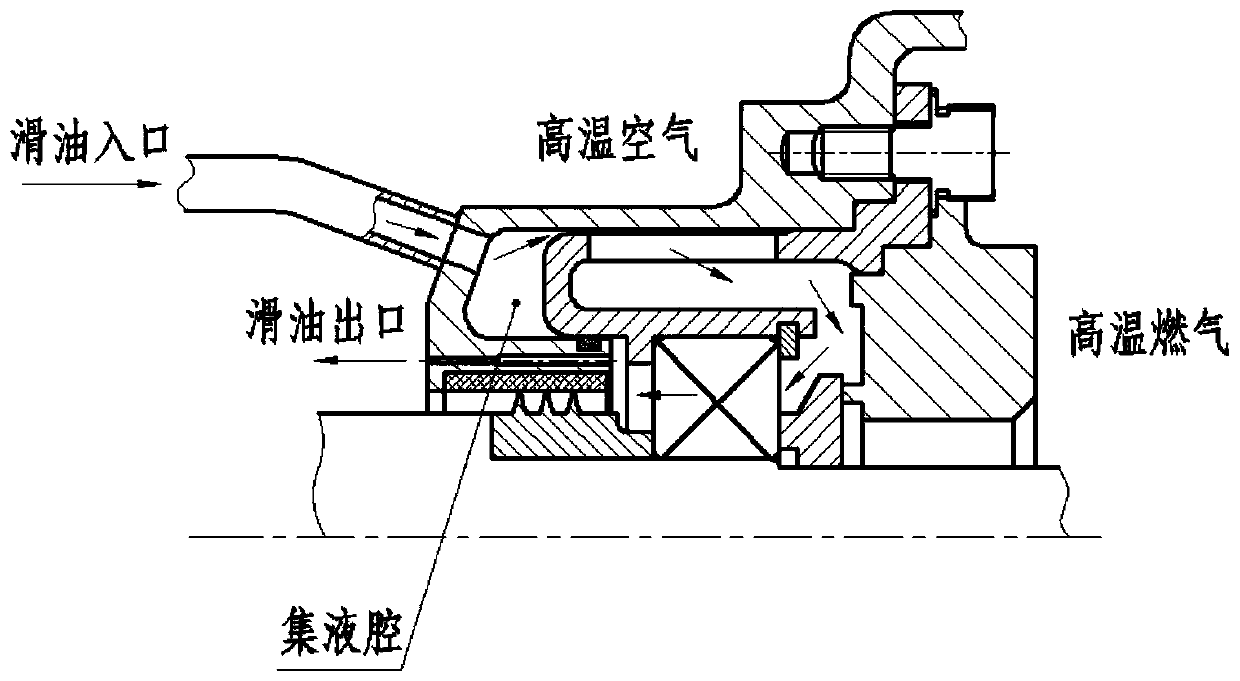

ActiveCN110005545ACompact sizeGuaranteed to workEngine componentsRocket engine plantsEngineeringSmall hole

The invention relates to a mouse cage elastic support bearing cavity structure. The mouse cage elastic support bearing cavity structure comprises a shell provided with an oil inlet pipe, and a returntype mouse cage elastic support, a contact type end face sealing device, sliding oil seal grate teeth, a graphite ring, a bearing, a clamping ring, a rotating shaft and the like that are arranged in the shell; the return type mouse cage elastic support is installed in a ring groove of the shell, and the inner ring of the shell is provided with a plurality of small holes uniformly distributed in the circumference; and the contact end face sealing device is hermetically arranged at one end of the bearing cavity structure. In the working state, high-pressure lubricating oil enters the bearing cavity through the oil inlet pipe arranged on the shell, the contact-type end face sealing device and the bearing are sequentially cooled according to a preset flow path, and the cooled lubricating oil is discharged out of the bearing cavity through the small holes arranged in the inner ring of the shell, the bearing cavity is filled with lubricating oil under the throttling effect of the small holes, positive pressure of 0.6-0.7 MPa is formed, and therefore, the pressure condition of normal working of the contact type end face seal is met, the external high-temperature gas is isolated, and the normal working of the bearing cavity is ensured.

Owner:XIAN AEROSPACE PROPULSION INST

Telescopic protective covering

ActiveCN103260822AFirmly connectedConnection can be releasedMaintainance and safety accessoriesMechanical engineeringEngineering

Owner:ARNO ARNOLD

Method and device for recording the straightness of elongated products

InactiveCN101226055ARealize supportHigh measurement accuracyMeasuring devicesUsing optical meansMechanical engineeringPhysics

Owner:SMS MEER

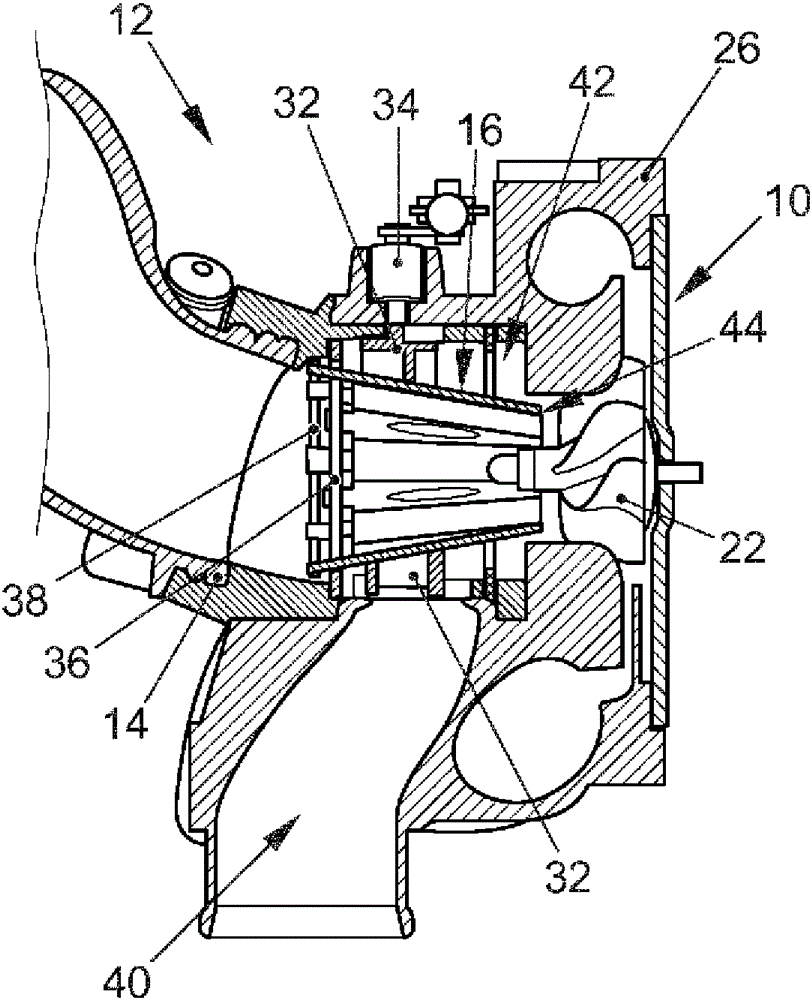

Internal combustion engine

ActiveCN105026743AAchieve regulationSimple structureEngine manufactureNon-fuel substance addition to fuelCombustion noiseTurbocharger

The invention relates to an internal combustion engine with a combustion engine, an exhaust gas line, a fresh gas line, a turbocharger with a turbine integrated into the exhaust gas line, a compressor integrated into the fresh gas line, and a trim plate (12), by means of which the cross section of the compressor inflow can be adjusted. The internal combustion engine is characterized by a low-pressure exhaust gas recirculation system, by means of which exhaust gas downstream of the turbine is removed from the exhaust gas line and can be introduced into the fresh gas line upstream of the compressor, wherein an opening of the low-pressure exhaust gas recirculation system is arranged in the region of the trim plate (12).

Owner:VOLKSWAGEN AG

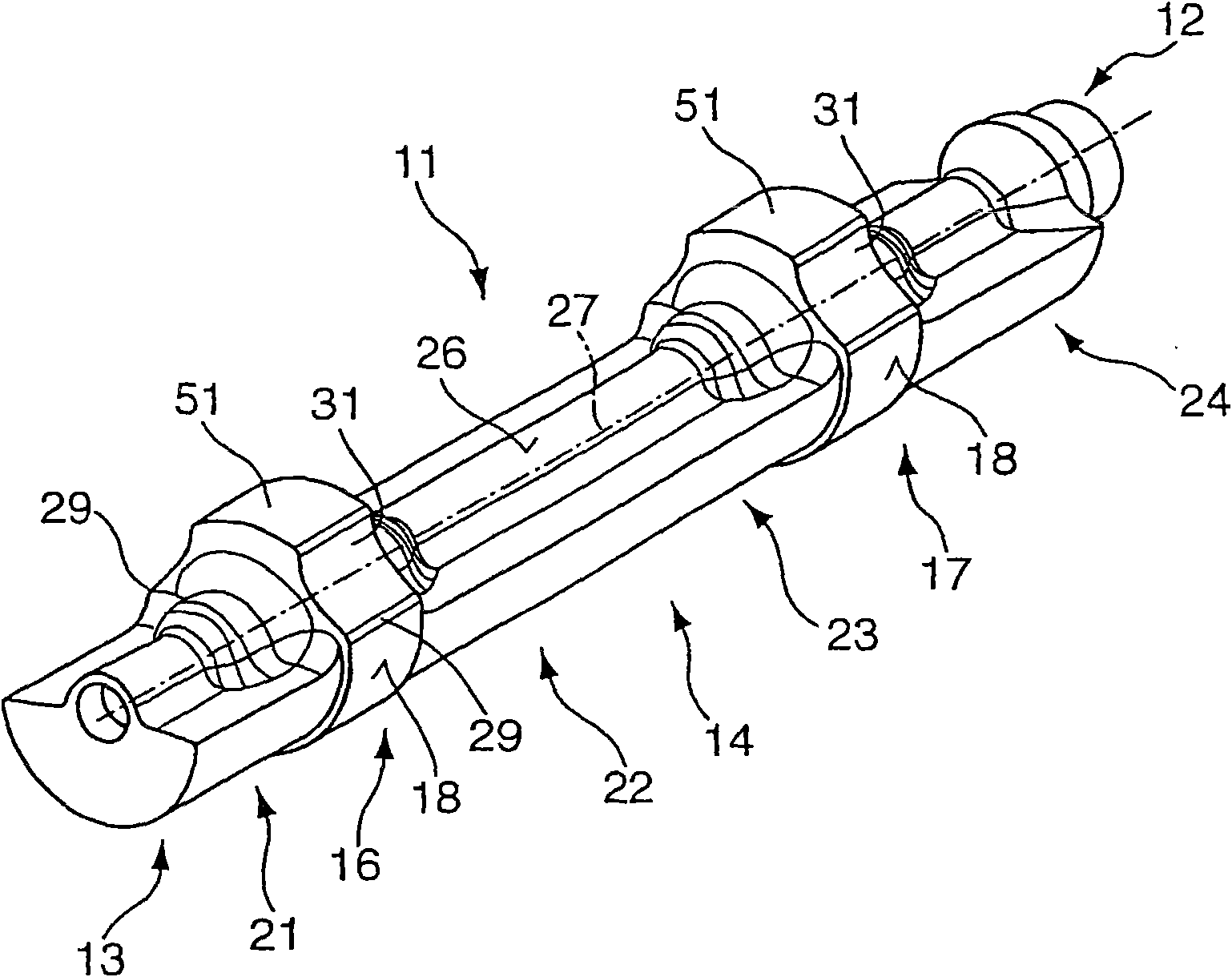

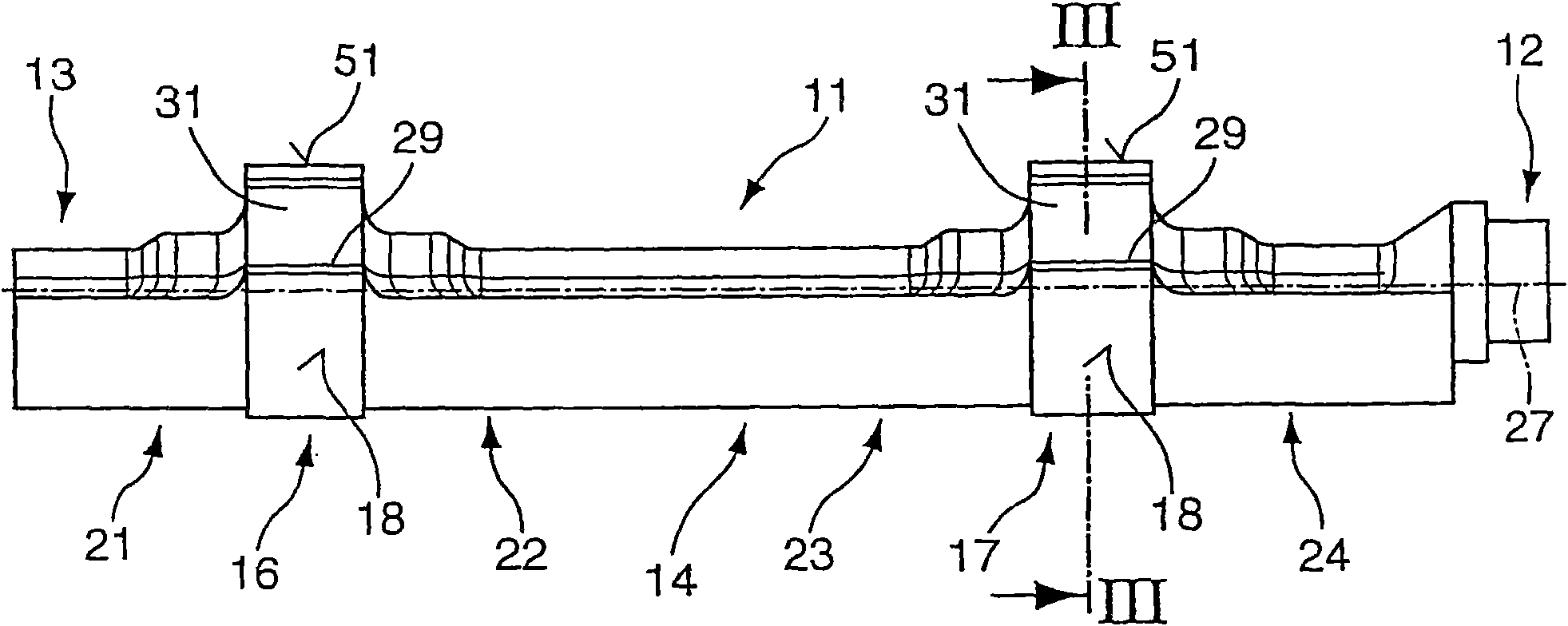

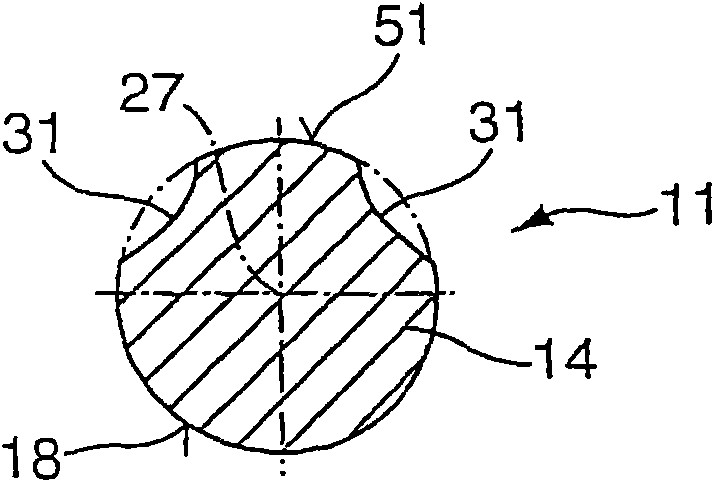

Balancing shaft

ActiveCN101680507ACheap manufacturingLow costInertia force compensationShaftsEngineeringSingle-cylinder engine

The invention relates to a balancing shaft for a single- or multi-cylinder motor having at least one unbalanced weight section (21, 22; 23, 24) and at least one bearing point (16, 17), wherein the at least one unbalanced weight section (21, 22; 23, 24) is allocated to the bearing point (16, 17) and the bearing point has a radial contact surface (18) that extends only partially over a circumference of the bearing point (16, 17) and a centrifugal force resulting from the rotation of the balancing shaft (11) lies inside a region of the bearing point (16, 17) formed by the contact surface (18) extending partially over the circumference of the bearing point (16, 17), wherein at least one support surface (51) is provided that is provided partially over the circumference of the bearing point (16, 17) and separately from the contact surface (18).

Owner:HERZOG INTERTEC GMBH

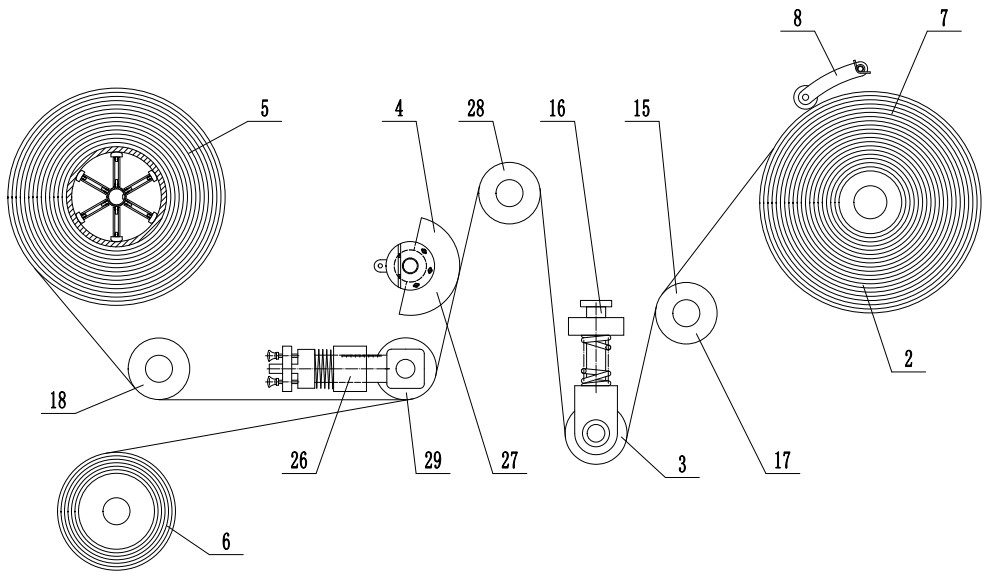

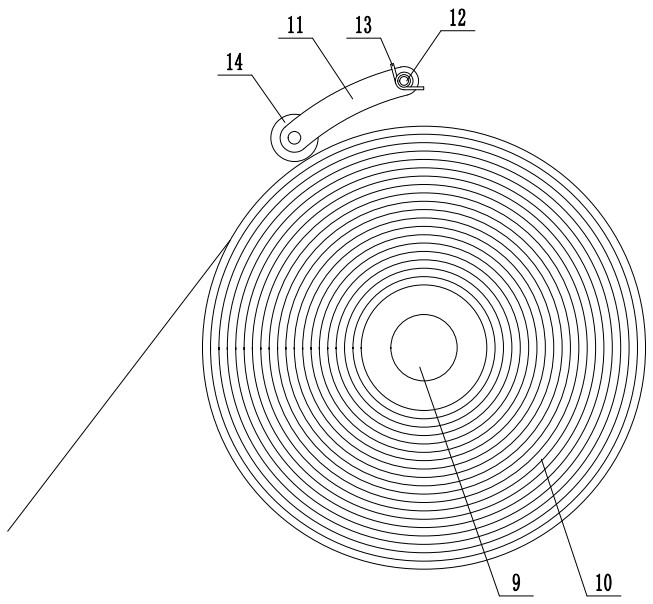

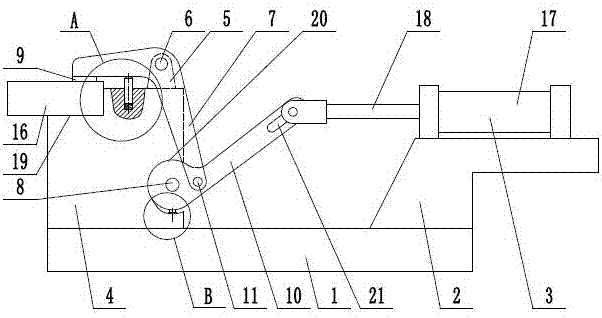

Adjustable cutting equipment for melt-blown cloth

ActiveCN111910418AAdjustable cutting widthGood width adjustment accuracySevering textilesWebs handlingEngineeringMechanical engineering

Owner:桐乡市中瑞环保科技有限公司

Electric brake

InactiveCN103109104ALow reduction ratioIncrease pressureEngine fuctionsGearingElectrical driveMechanical engineering

The invention relates to a brake, comprising at least one brake actuating element, which is operatively connected to a planetary-roller threaded unit and to an electrical drive in order to move the brake actuating element between a braking position and an axially offset non-braking position of the brake actuating element, wherein the planetary-roller threaded unit has a plurality of threaded roller elements distributed in the circumferential direction, the threaded roller elements being in threaded engagement with a spindle element connected in a rotationally fixed manner to the electrical drive and with a stationary housing, and wherein the threaded roller elements are rotatably arranged about the axes thereof, which are each arranged parallel to an axis of the spindle element, and about the axis of the spindle element, wherein the brake actuating element is coupled only to the spindle element.

Owner:HANNING ELECTRO WERKE GMBH & CO KG

Fragile product carrying device

The invention provides a fragile article handling device, which belongs to the technical field of fragile article processing. It includes the left clamping finger, the right clamping finger, the lifting support at the lower end of the lifting piston rod of the lifting cylinder, the guide components are evenly arranged between the fixed frame and the lifting support, and the supporting base can slide forward and backward through the slider and set on the guide rail. , the screw rod and the screw nut are threadedly connected, the left jaw can be slidably set on the left guide rod, the right jaw can be slidably set on the right guide rod, the right end of the left piston rod is connected with the left air piston, and the left end of the right piston rod It is connected with the right air piston, the left buffer plate is installed at the right end of the left clamp finger, the right buffer plate is installed at the left end of the right clamp finger, the micro switch is installed in the left clamp finger and the right clamp finger, and the micro switch and the left buffer plate , the right buffer plate fit, the invention not only utilizes the incompressibility of the liquid and the damping characteristics of the damping cylinder to realize the flexible clamping of fragile products in the clamping process, avoiding excessive clamping force, but also realizes the flexible clamping of fragile products. Product handling and delivery.

Owner:嵊泗县东升水产冷冻厂

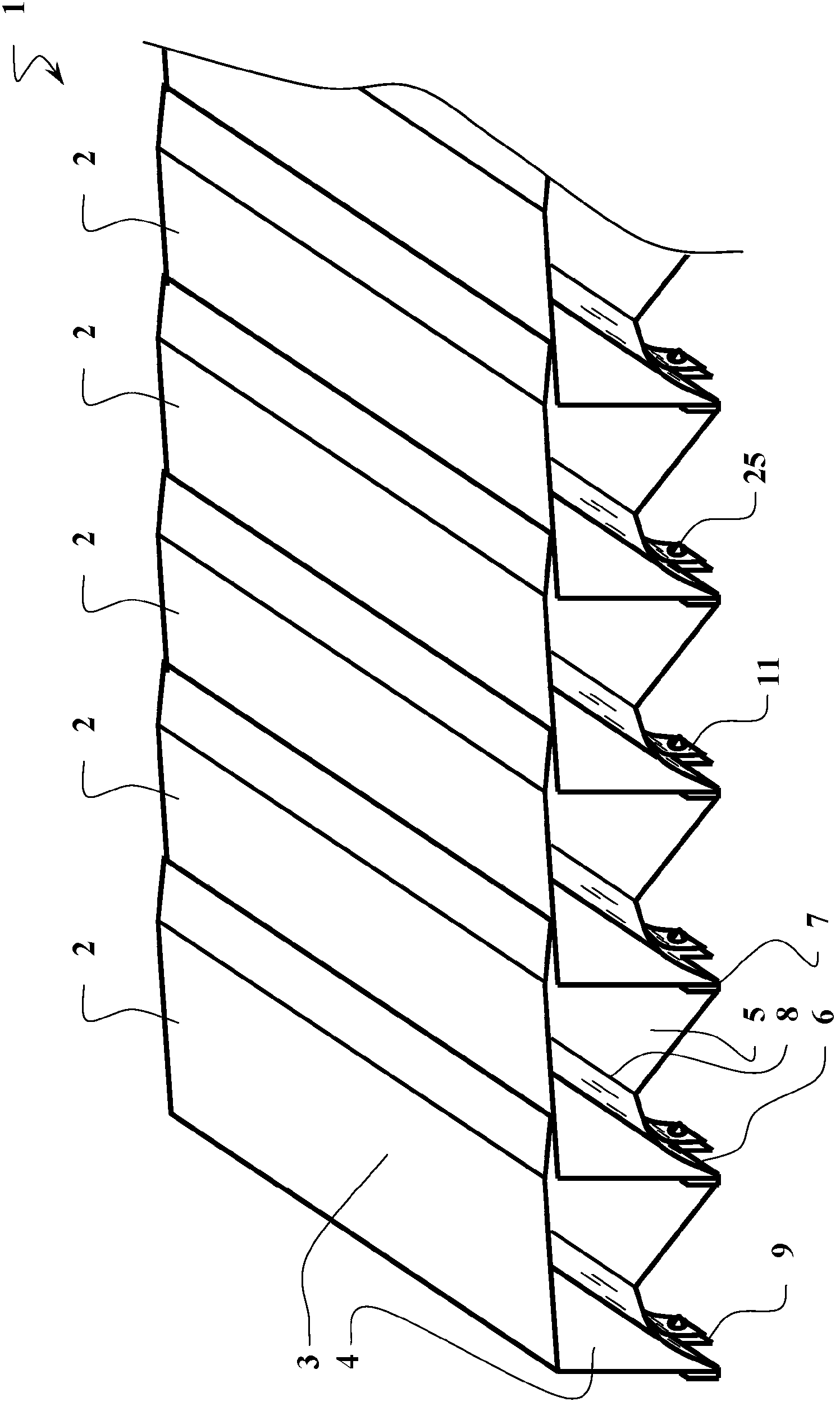

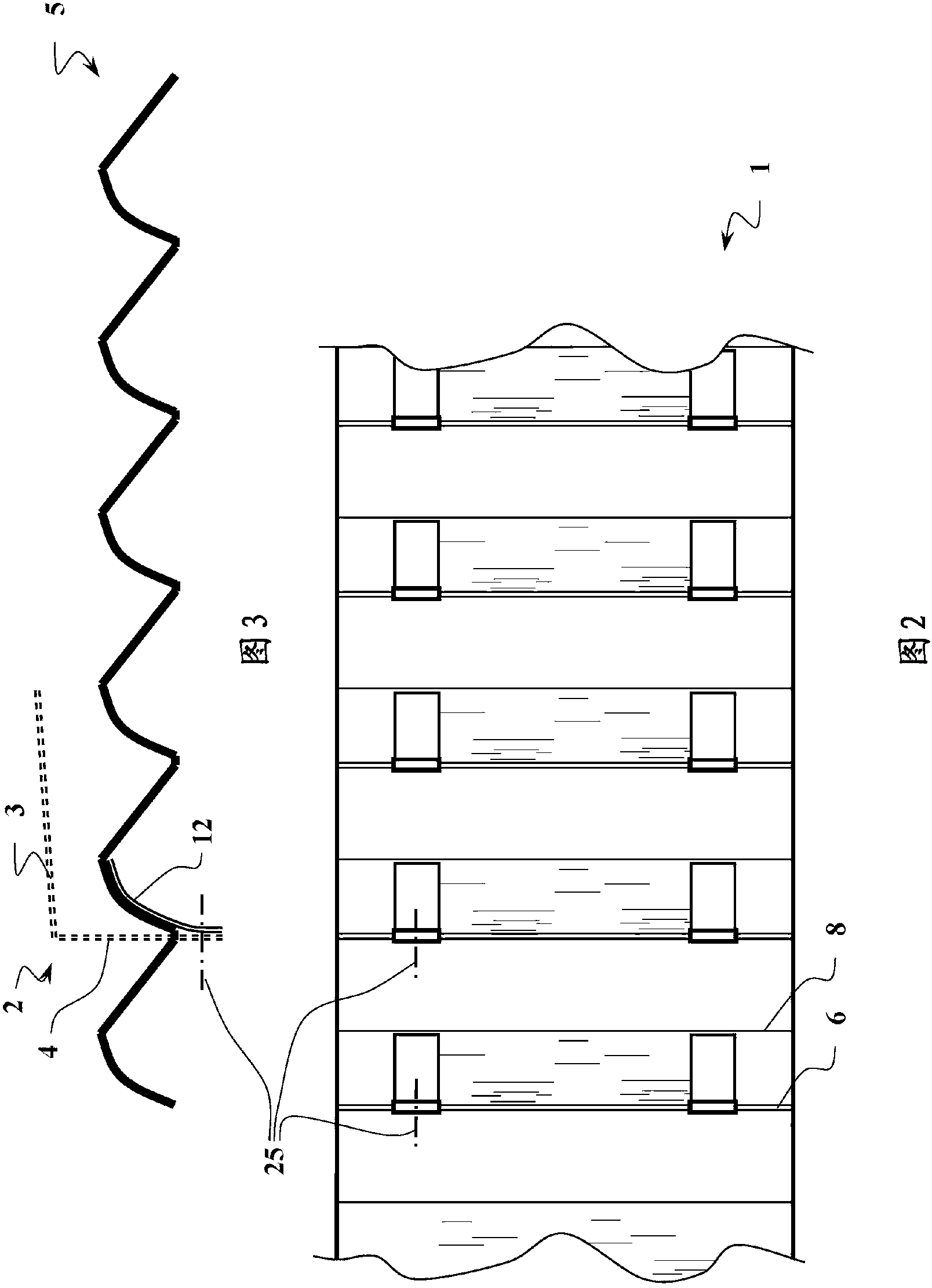

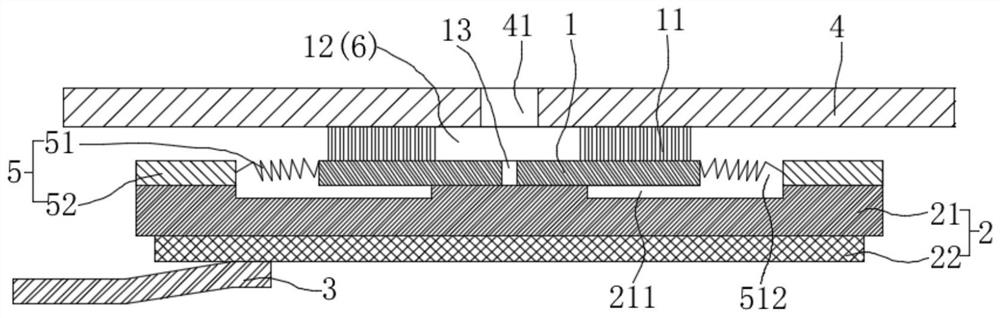

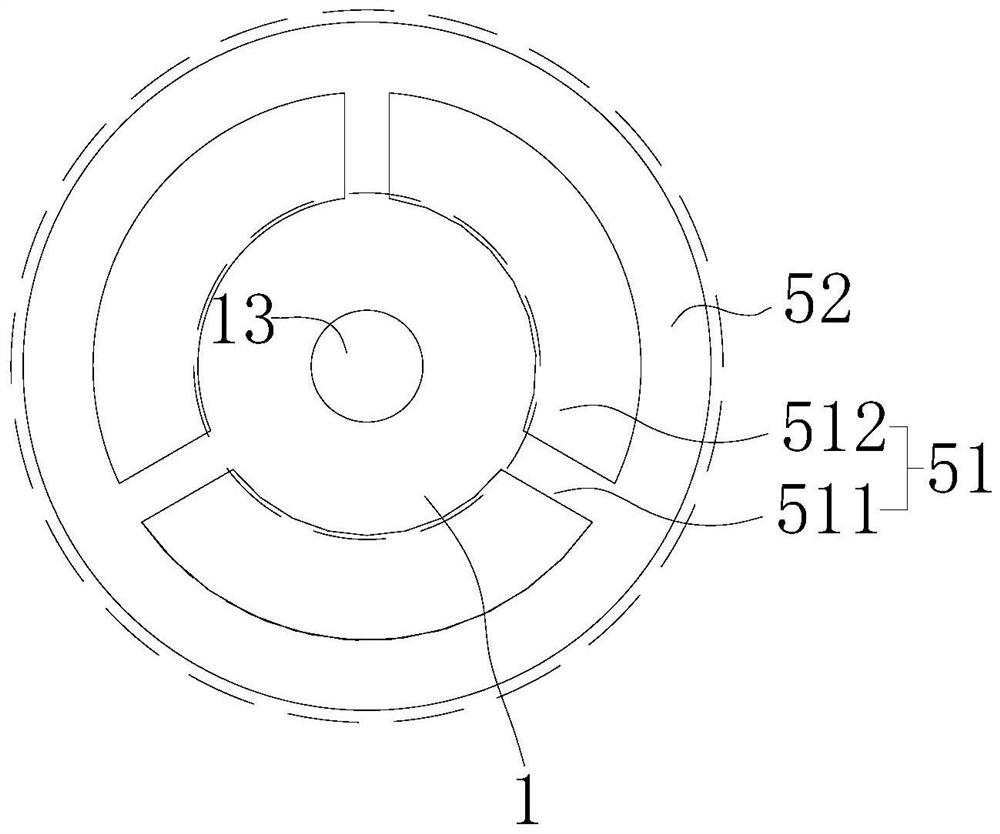

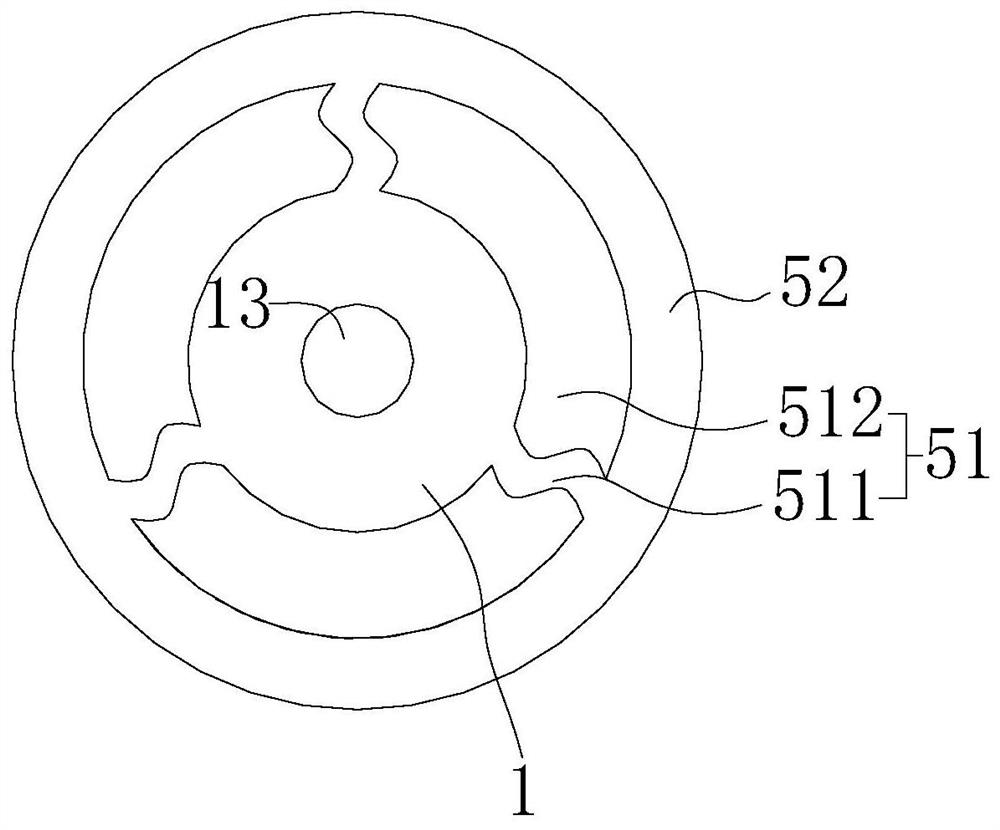

Staggered-layer supporting structure of piezoelectric micropump and gas control device

PendingCN111980887AMiniaturizationThe structure is reduced or even eliminatedPositive displacement pump componentsFlexible member pumpsEngineeringMicropump

The invention belongs to the technical field of fluid conveying equipment, and particularly relates to a staggered-layer supporting structure of a piezoelectric micropump and a gas control device. Thestaggered-layer supporting structure of the piezoelectric micropump comprises the piezoelectric micropump and a supporting plate, wherein the piezoelectric micropump comprises a resonance plate, a piezoelectric vibrator and an electrode assembly, the resonance plate and the piezoelectric vibrator are sequentially arranged in a stacked mode, and the electrode assembly is connected to the side, away from the resonance plate, of the piezoelectric vibrator; and the side, away from the piezoelectric vibrator, of the resonance plate is supported by the supporting plate, a gap is formed between theresonance plate and the supporting plate so as to form a gas inlet cavity, and the supporting plate is used for supporting and restraining the piezoelectric micropump. The gas control device comprisesthe staggered-layer supporting structure of the piezoelectric micropump and a shell. The technical problems that in the prior art, a piezoelectric micropump needs to be connected to a peripheral supporting part through a connecting part extending in the circumferential direction, the supporting part is laminated and fixed, and the size of the piezoelectric pump is greatly increased are solved.

Owner:常州威图流体科技有限公司

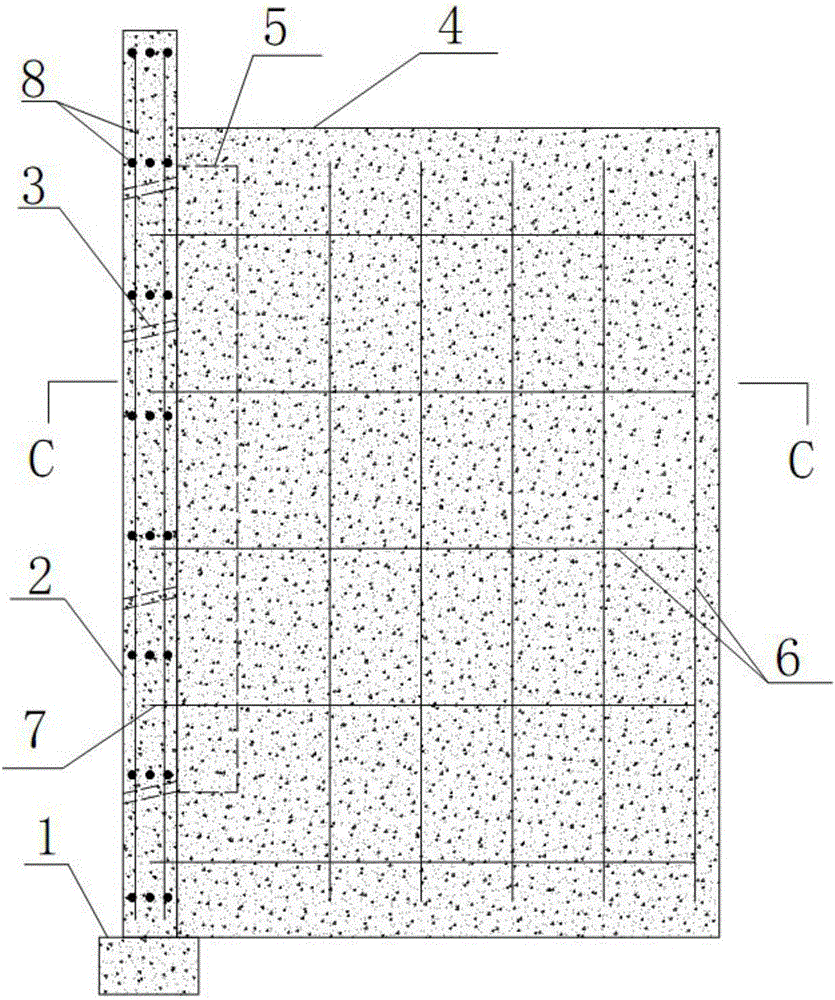

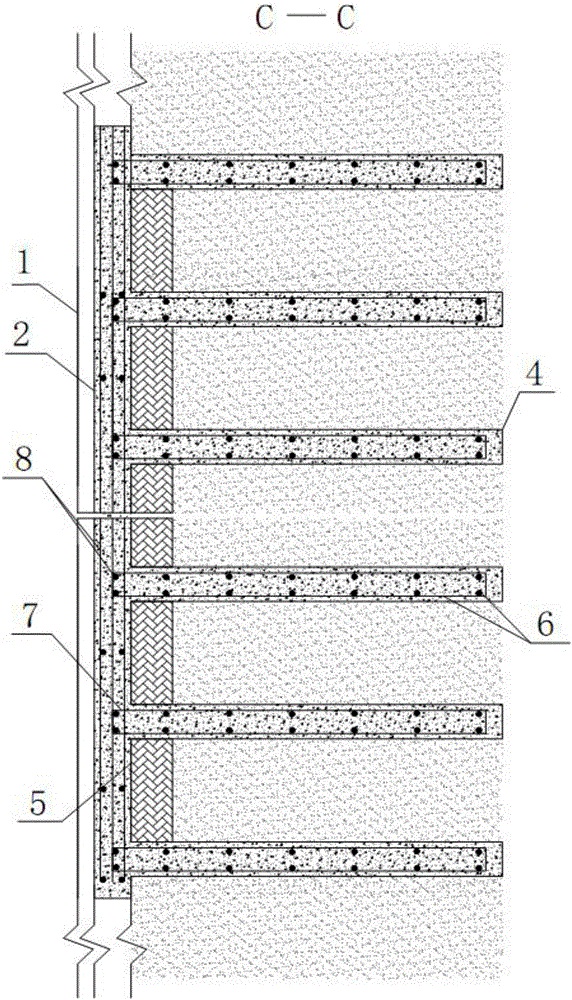

Rib plate type retaining wall and construction method thereof

ActiveCN104988948ARealize supportStrong support abilityArtificial islandsUnderwater structuresSteep slopeEngineering

The invention provides a rib plate type retaining wall and a construction method thereof. The retaining wall comprises a foundation, a wall panel on the foundation and drain holes in the wall panel. The retaining wall is structurally characterized in that vertical rib plates are fixedly connected to the soil adjacent face of the wall panel at equal intervals, and an inverter filter is arranged at the portion, between the rib plates, of the soil adjacent face of the wall panel. The construction method of the retaining wall includes the steps that a, vertical grooves matched with the rib plates are dug in slope soil mass; b, rib plate rebars are bound into the vertical grooves in the step a, connecting rebars connected with the wall panel are reserved, and concrete is poured into the vertical grooves to form the rib plates; c, the foundation is constructed; d, wall panel rebars are bound to the foundation, the wall panel rebars and the connecting rebars are connected, a wall panel formwork is erected, drain hole pipes are embedded, and concrete is poured into the wall panel formwork to form the wall panel; e, the inverted filter is laid at the portion, between the rib plates, of the soil adjacent face of the wall panel, and soil mass is backfilled between the inverted layer and a slope and compacted till the wall top. The retaining wall is suitable for supporting and retaining steep slopes or embankment sections or cutting steep slope sections, and is low in construction cost and easy to popularize.

Owner:SOUTHWEST JIAOTONG UNIV

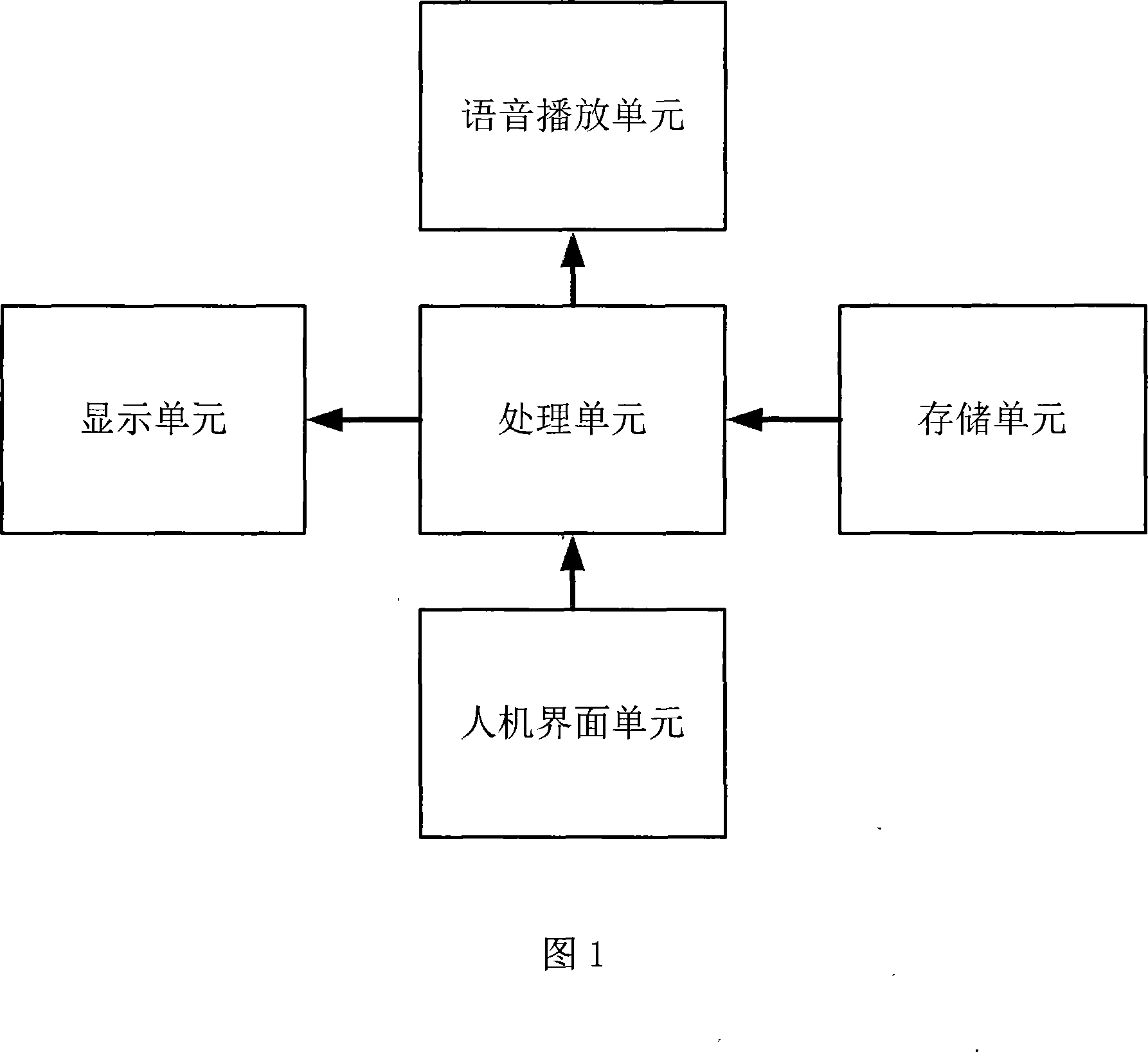

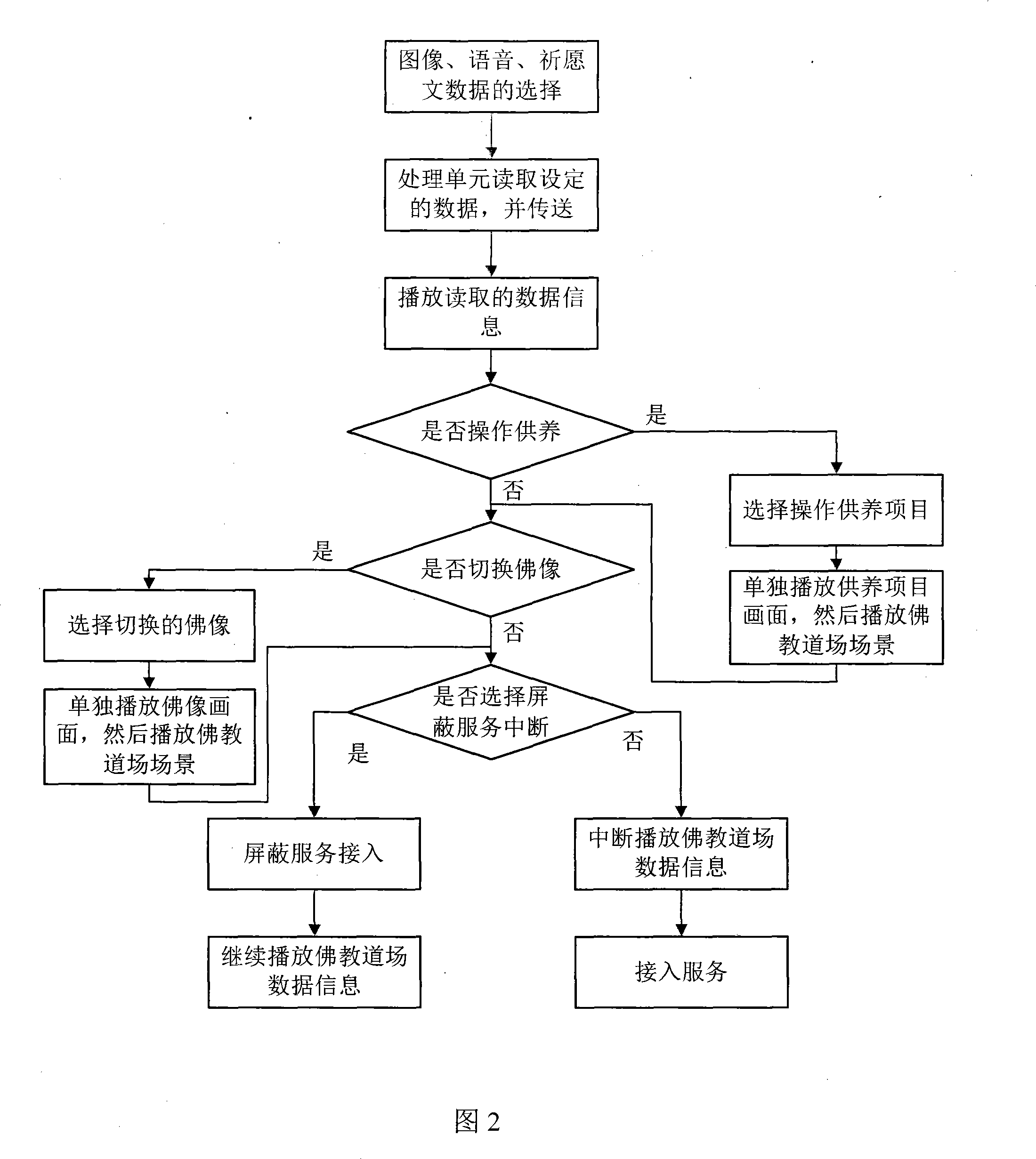

Video terminal, display method and storage medium for providing buddhism bodhimandala scene

InactiveCN101219029ARealize switchingRealize supportElectrophonic musical instrumentsCathode-ray tube indicatorsSprayerComputer terminal

The invention discloses a visible terminal, a display method and a storage medium for Buddhism worship scenes, wherein, the visible terminal at least comprises a storage unit, a voice play unit, a display unit and a processing unit; the storage unit stores at least a set of Buddhism worship image data and at least a set of Buddhism voice data, oblation image data, Buddha image data and Buddhism prayer data; the voice play unit can play the voice data of the Buddhism worship; the display unit can display the image data and the sprayer data; the processing unit is connected with the storage unit, the voice play unit and the display unit, the voice play unit and the display unit and is used for reading the voice data, the image data and the sprayer data from the storage unit and sending the voice data to the voice play unit to play or sending the image and the sprayer data to the display unit to display. By adopting the invention, the visible terminal user can start the terminal to play the stored virtual worship information at any time and select different Buddha images for oblation.

Owner:徐航 +1

Skirt-type supporting device provided with embedded parts and used for reactor pressure vessel

InactiveCN106297912AConvenient in-service inspectionEffective supportNuclear energy generationContainmentReactor pressure vesselEngineering

The invention discloses a skirt-type supporting device provided with embedded parts and used for a reactor pressure vessel. The skirt-type supporting device comprises a skirt-type supporting base, the embedded parts and stopping blocks, the upper end of the skirt-type supporting base is connected with the reactor pressure vessel, the lower end of the skirt-type supporting base is fixed to the embedded parts, and the stopping blocks penetrate through the embedded parts to be embedded into a concrete foundation. According to the skirt-type supporting device provided with the embedded parts and used for the reactor pressure vessel, the skirt-type supporting base is arranged, the upper end of the skirt-type supporting base and the reactor pressure vessel are welded, the lower end of the skirt-type supporting base is fixed to the embedded parts at the bottom of a reactor through foundation bolts, the pressure vessel can be effectively supported and fixed, the outer surface of the reactor pressure vessel is exposed to the maximum degree, in-service inspection is conveniently carried out on the pressure vessel when the reactor runs, and the requirement for supporting the periphery of the pressure vessel is met.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

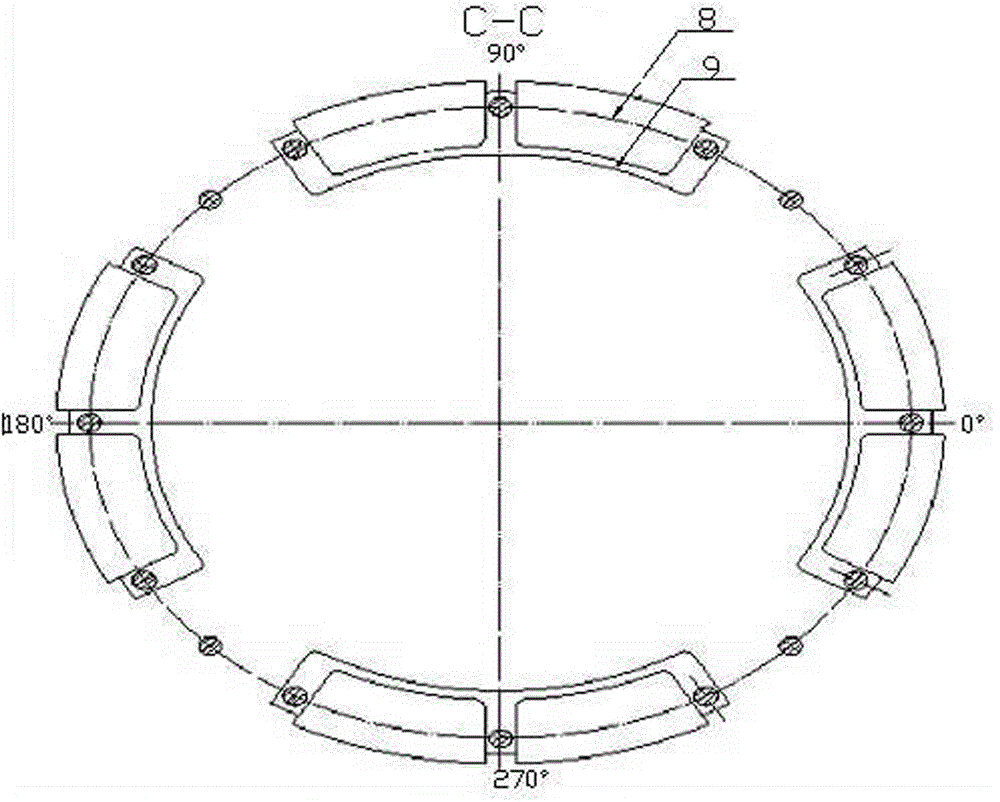

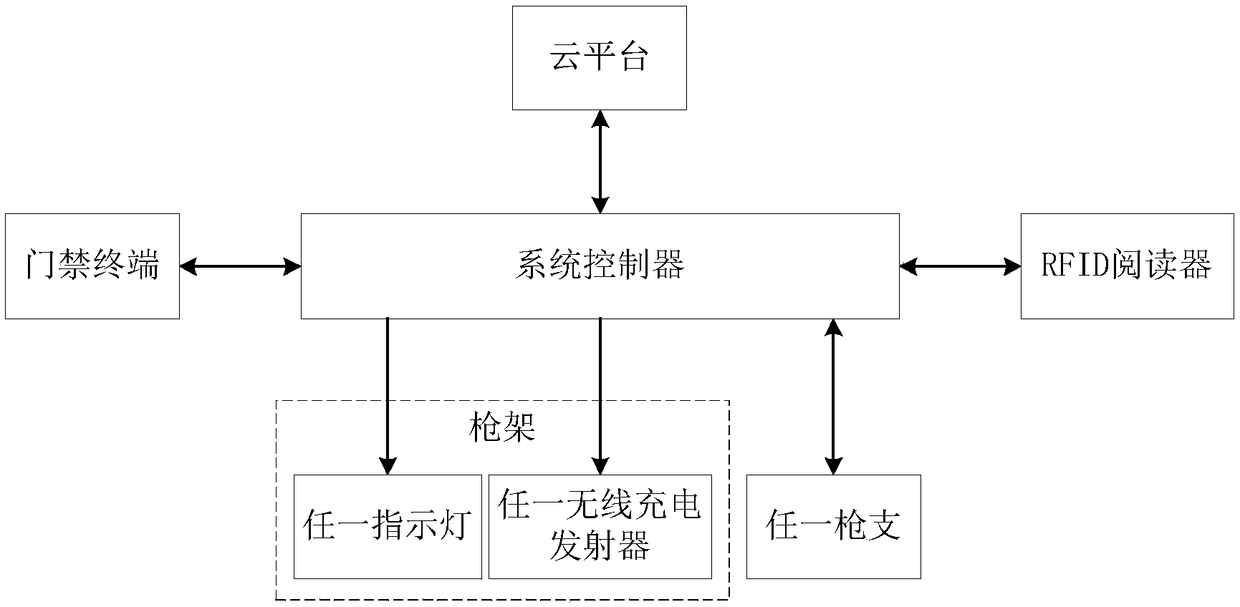

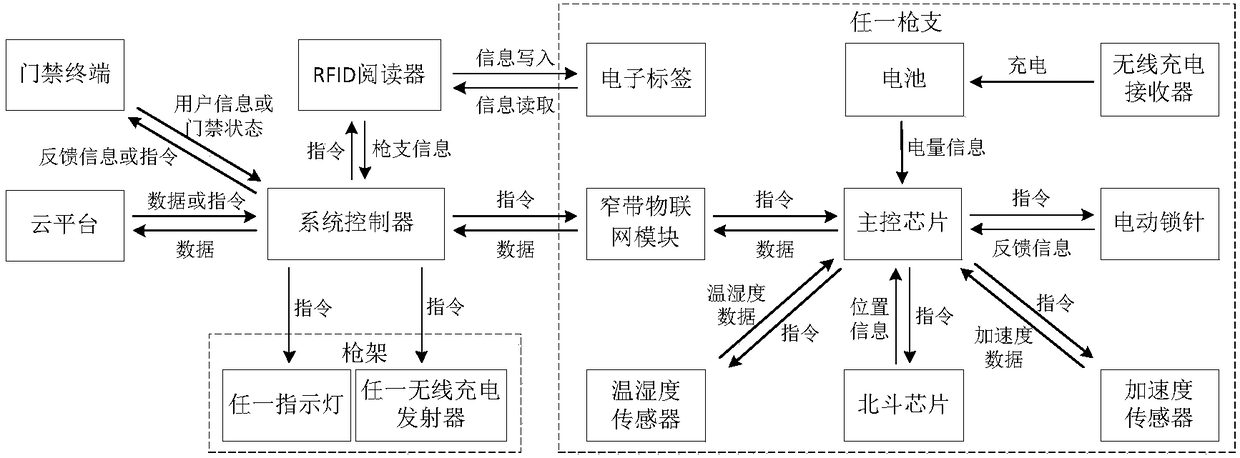

Firearm management system and method thereof

InactiveCN108520585AEasy to manageComplete and compact designIndividual entry/exit registersTransmissionLogistics managementNetworked system

The invention discloses a firearm management system and method thereof. The firearm management system is reasonable in design, and during management of a firearm storehouse, functions including unattended supervision, automatic identification and collection of firearm information, automatic recording of firearm borrowing and returning operation, real-time statistics of the firearm position state,orderly storage and placement of firearms and the like are achieved. Meanwhile, the position of each firearm can be located in real time, and temperature and humidity data of each firearm in the environment is obtained; through system allocation and a cloud platform, a national network system can be formed, and high-level sharing of data is achieved. The system achieves visible management and control over the firearms in real time all day long in all weather conditions, the work efficiency and the accuracy and timeliness of information are improved greatly; additionally, data such as positioninformation provided by a Beidou chip and shooting and bullet quantity information provided by an acceleration sensor has a considerably high unexpected reference value in the aspects such as maneuvers, combat command, logistics supply and firearm maintenance.

Owner:HEFEI MADAO INFORMATION TECH CO LTD

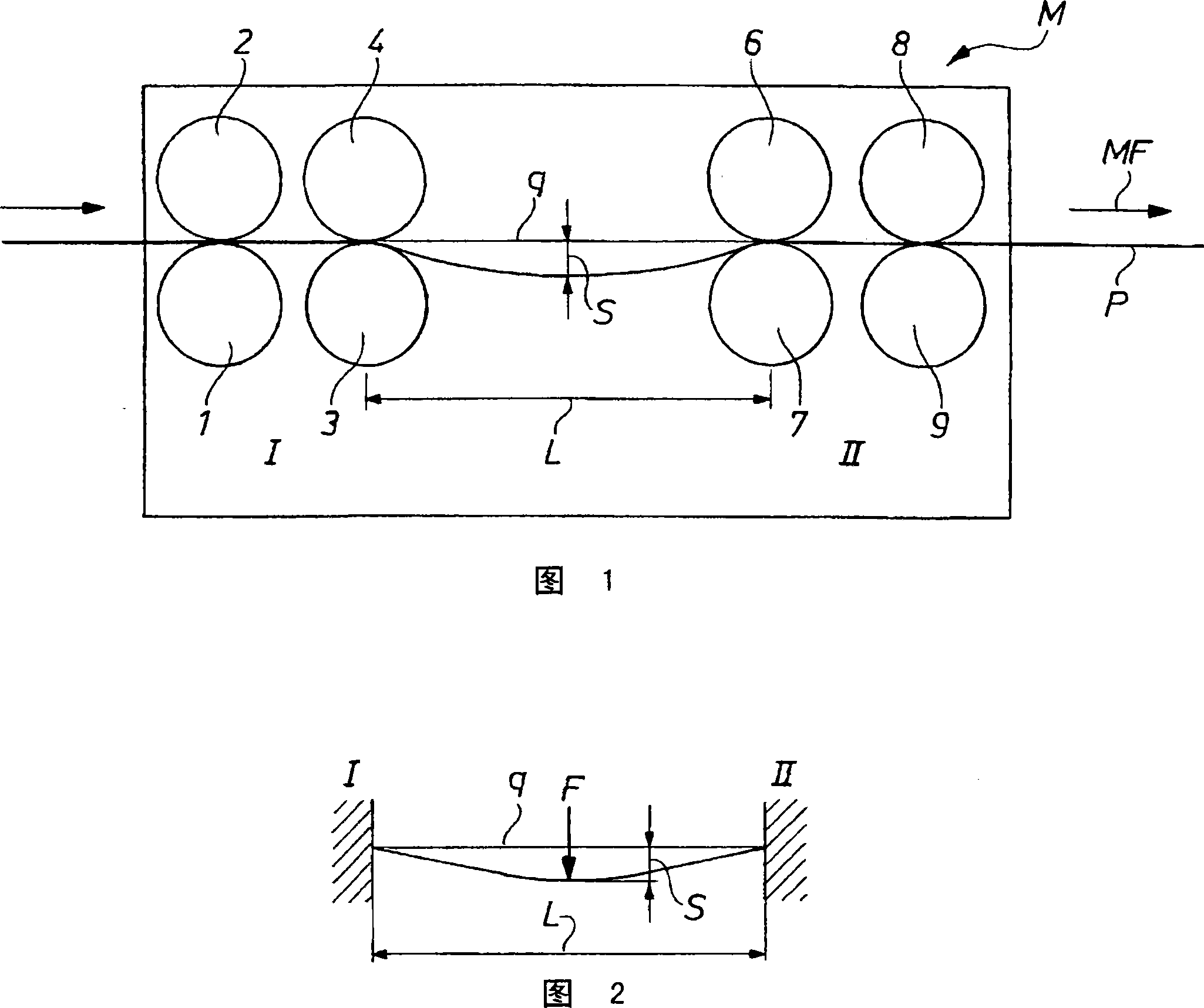

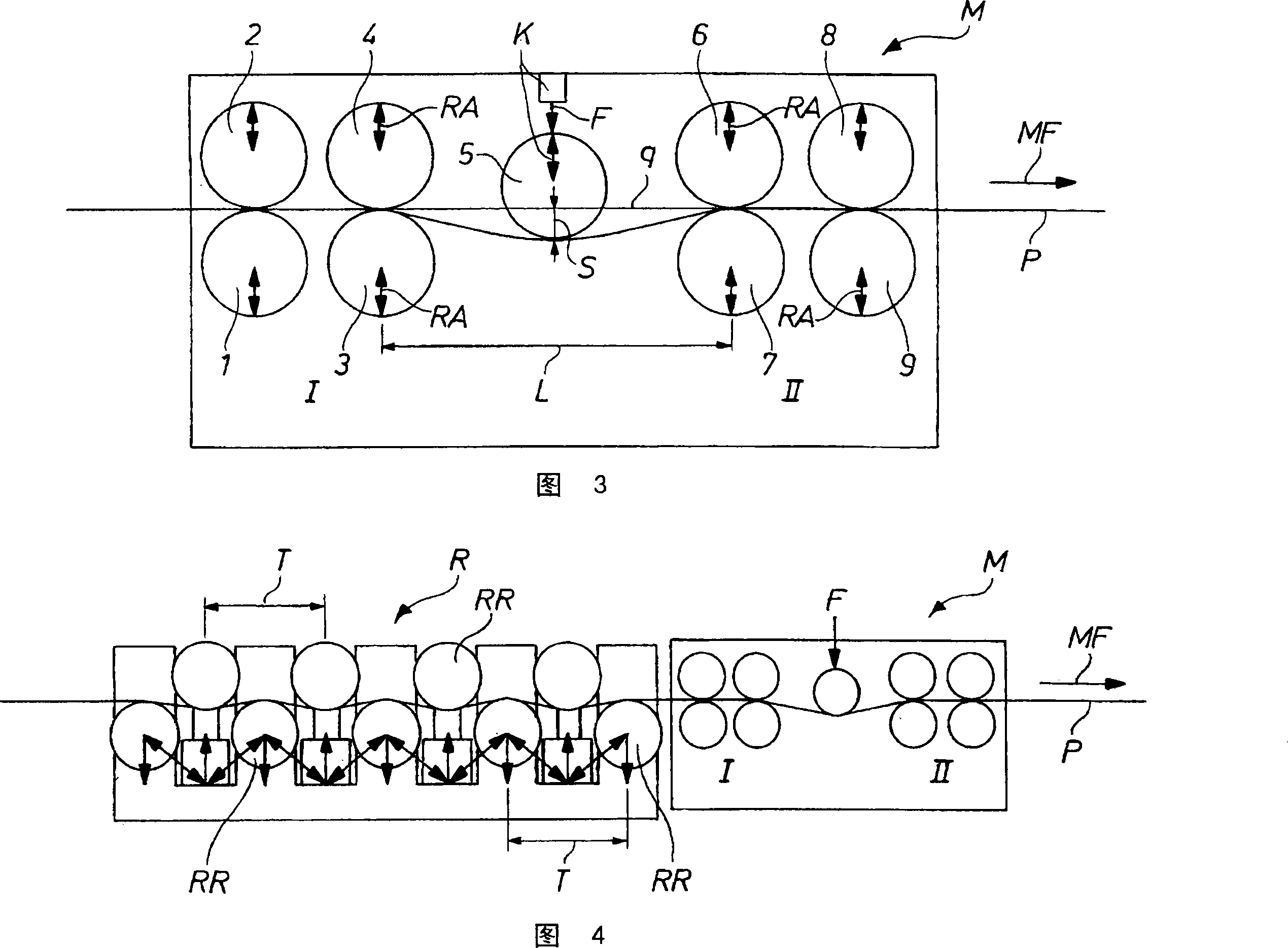

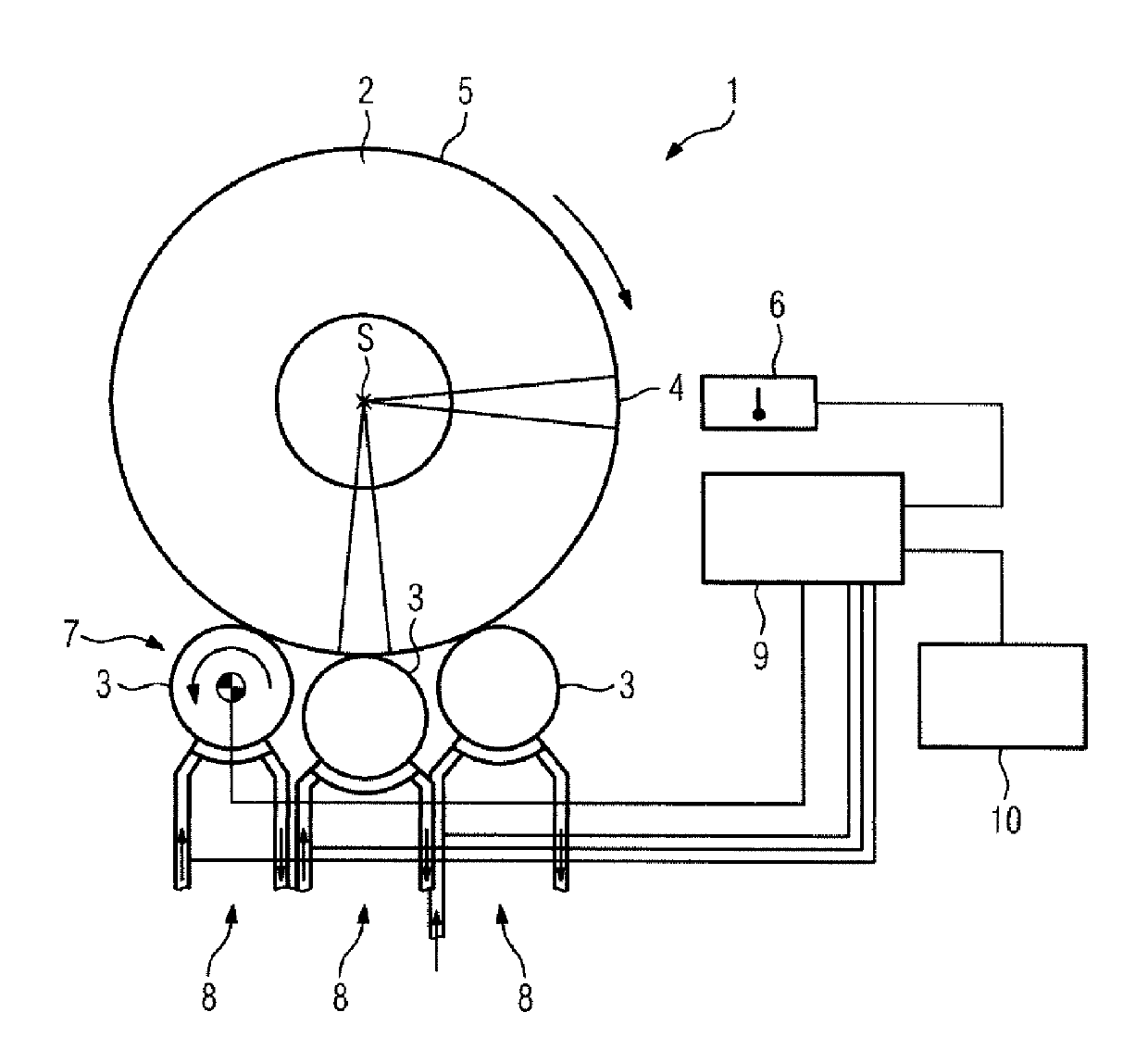

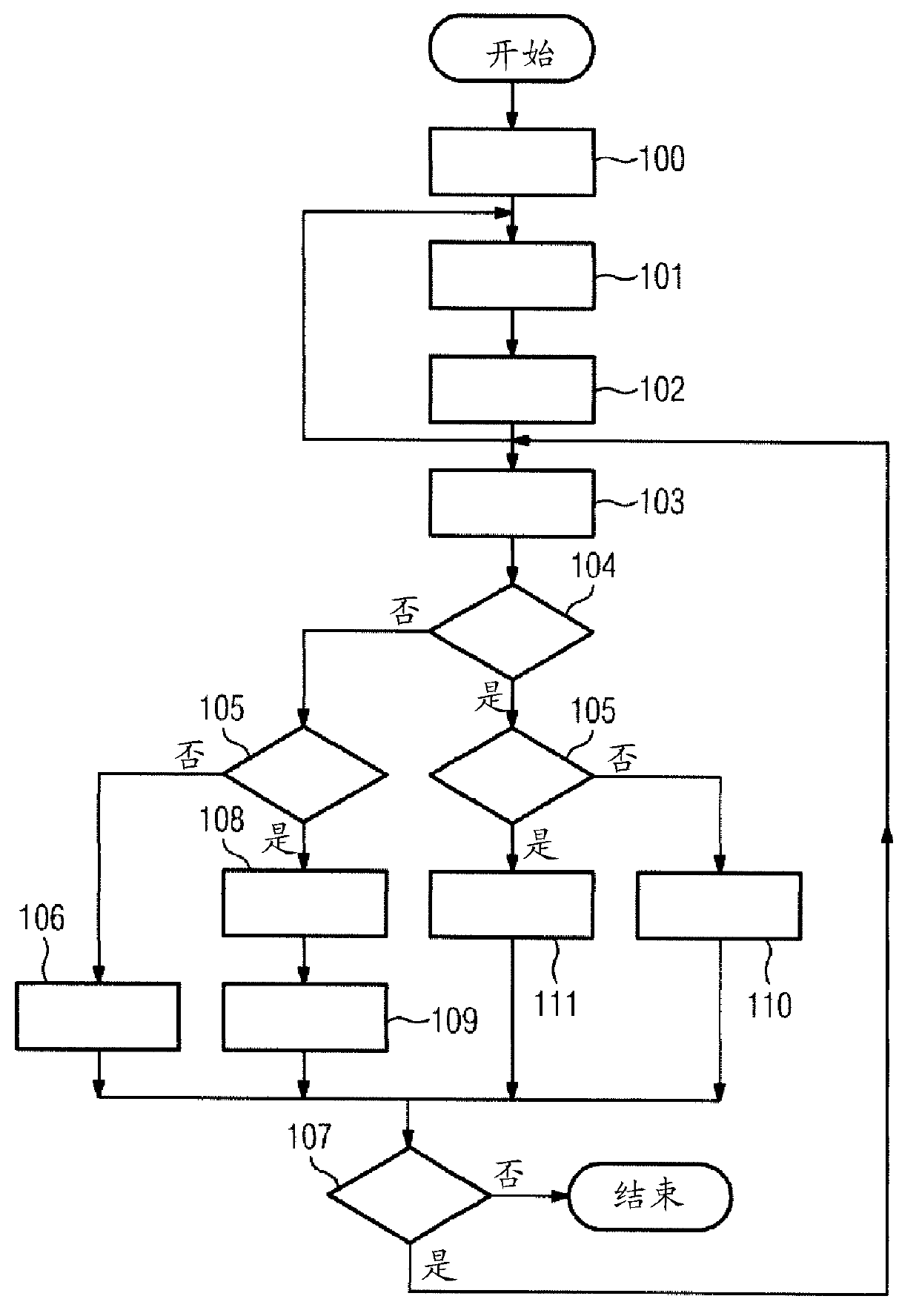

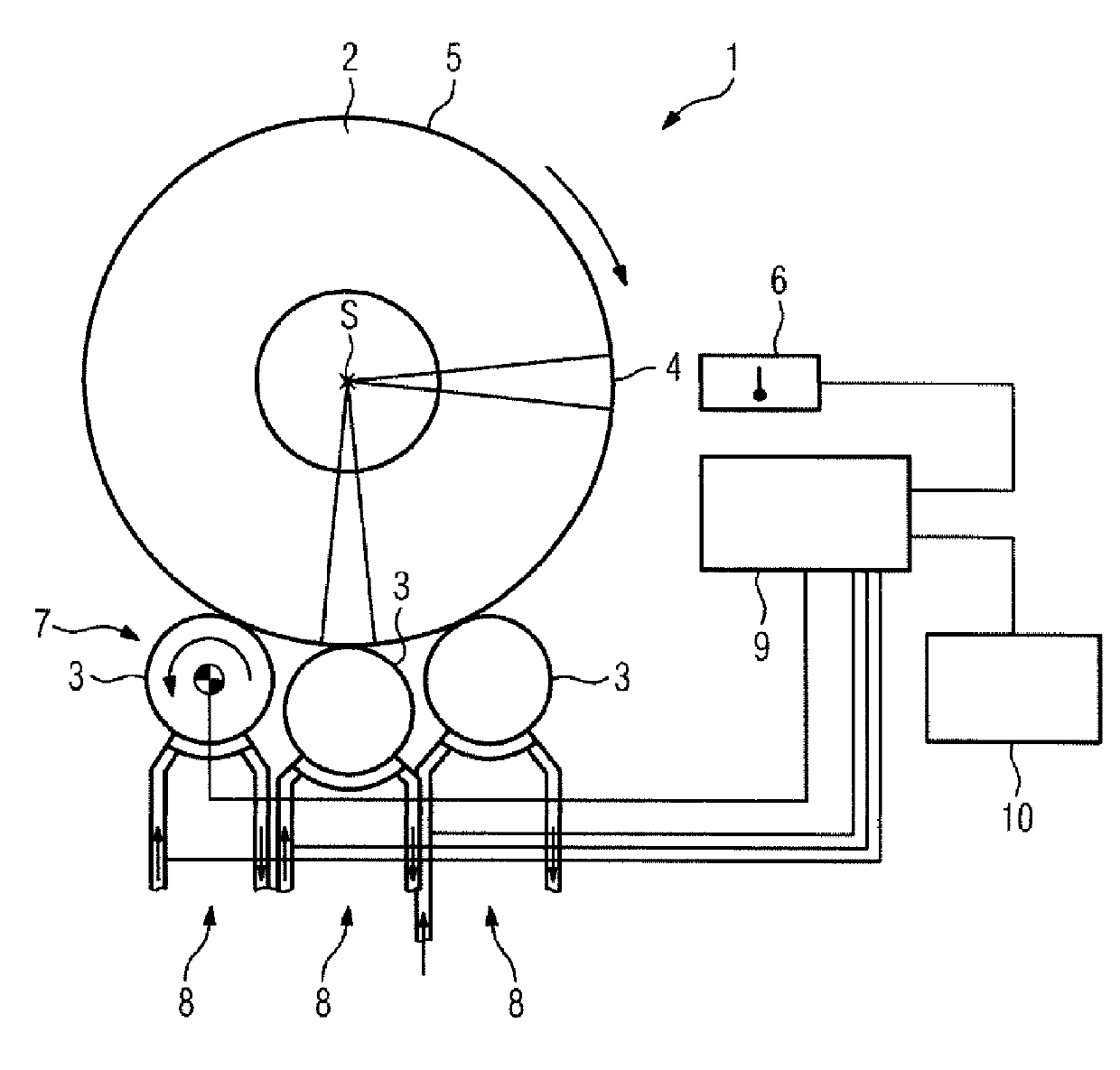

Method for cooling a hot strip wound to a hot strip bundle, a device for cooling a hot strip, a control and/or regulating device, and metal strip

InactiveCN102089091AReduce biasHigh precisionForging/pressing devicesTemperature control deviceAxis of symmetryEngineering

The invention relates to a method for cooling a hot strip wound to a hot strip bundle, a device for cooling a hot strip bundle, a control and / or regulating device, and a metal strip. The invention relates to a device for cooling a hot strip bundle (1), a metal strip, a control and / or regulating device for a device for cooling a hot strip bundle (1), and to a method for cooling a hot strip (2) wound to a hot strip bundle (1), wherein the hot strip bundle (1) is twisted (100) and cooled by means of contact of the lateral surface (5) thereof with at least one element (3, 7). By twisting the hot strip bundle (1) about the axis of symmetry (S) thereof, a method and a device can be provided by means of which homogenous strip properties may be obtained for a cooling hot strip bundle in a compact manner.

Owner:PRIMETALS TECH GERMANY

Anti-corrosion concrete special for building and production system thereof

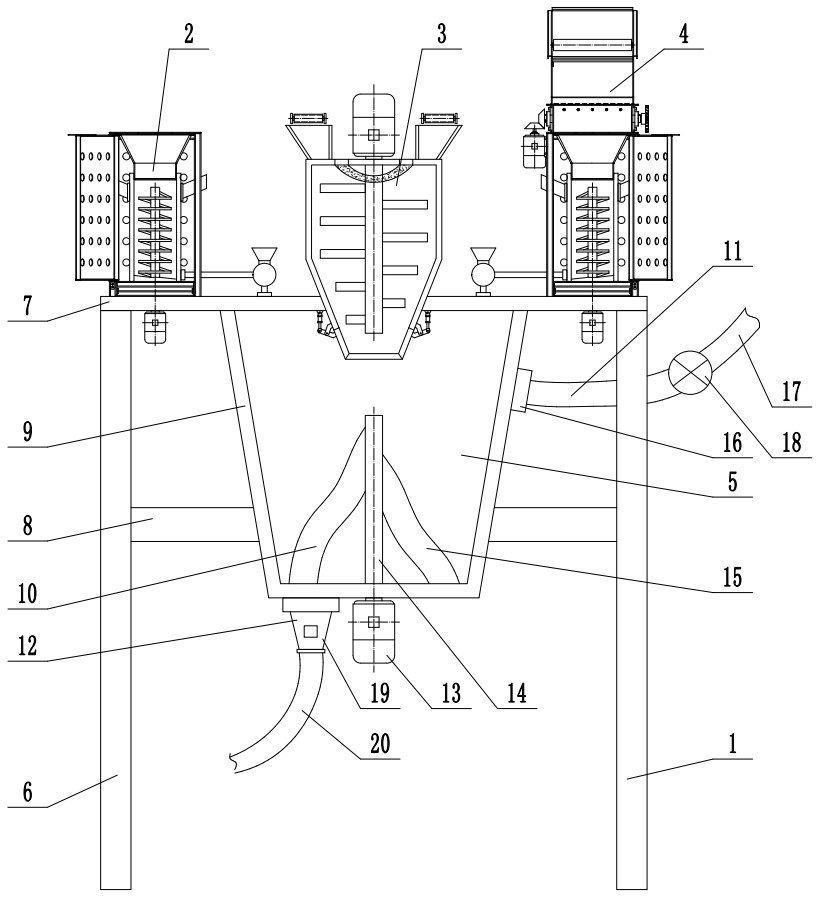

ActiveCN112358253AImprove fusion effectImprove compactnessSolid waste managementMixing operation control apparatusArchitectural engineeringStructural engineering

The invention provides an anti-corrosion concrete special for a building, and belongs to the technical field of concrete. The anti-corrosion concrete is prepared by stirring the following components in parts by weight: 95-105 parts of an anti-corrosion concrete gel base material, 375-412 parts of an anti-corrosion concrete base material, 10-17 parts of an anti-corrosion concrete filling base material and 40-45 parts of water. A production system of the anti-corrosion concrete special for a building comprises a production rack device, an anti-corrosion concrete gel base material production device, an anti-corrosion concrete base material production device, an anti-corrosion concrete filling base material production device and a mixing and stirring device. The corrosion resistance of the concrete is greatly improved, the service life of a building is greatly prolonged, the production system is reasonable in structure, continuous processing of the anti-corrosion concrete special for a building is facilitated, and the automation degree is high.

Owner:桐乡市钟大建材有限公司

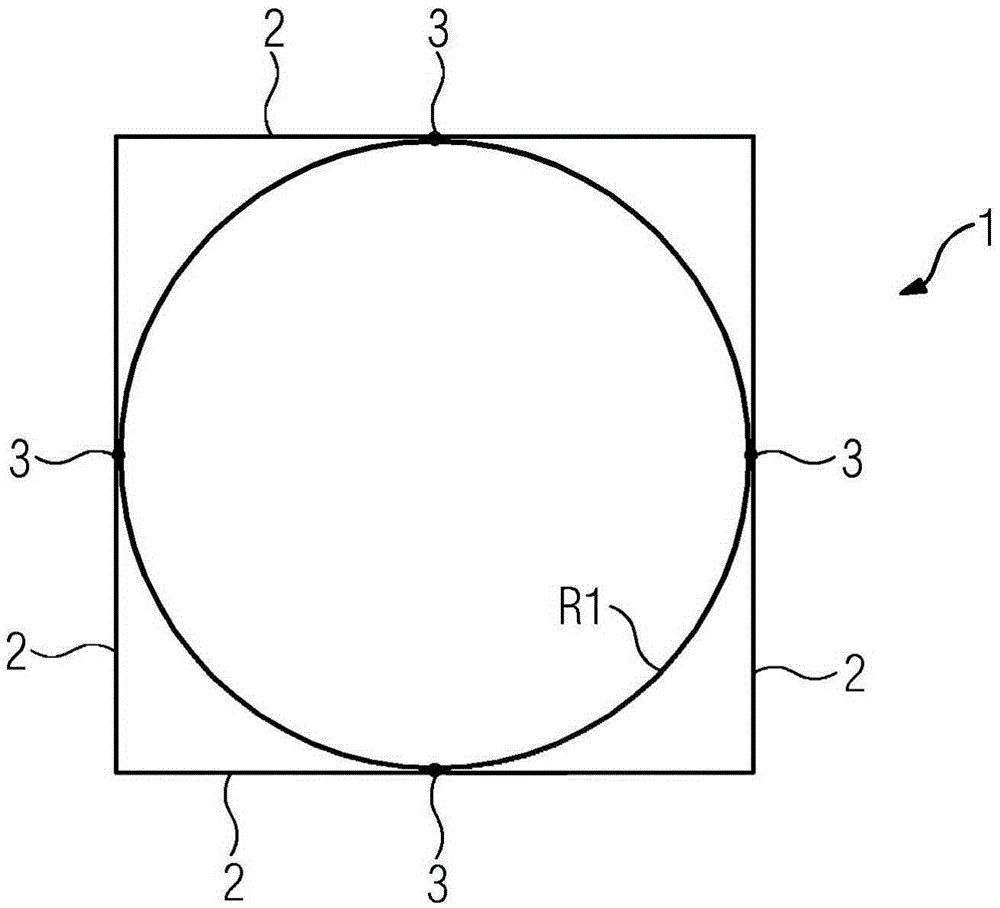

Housing, in particular outer housing for low-pressure steam turbine

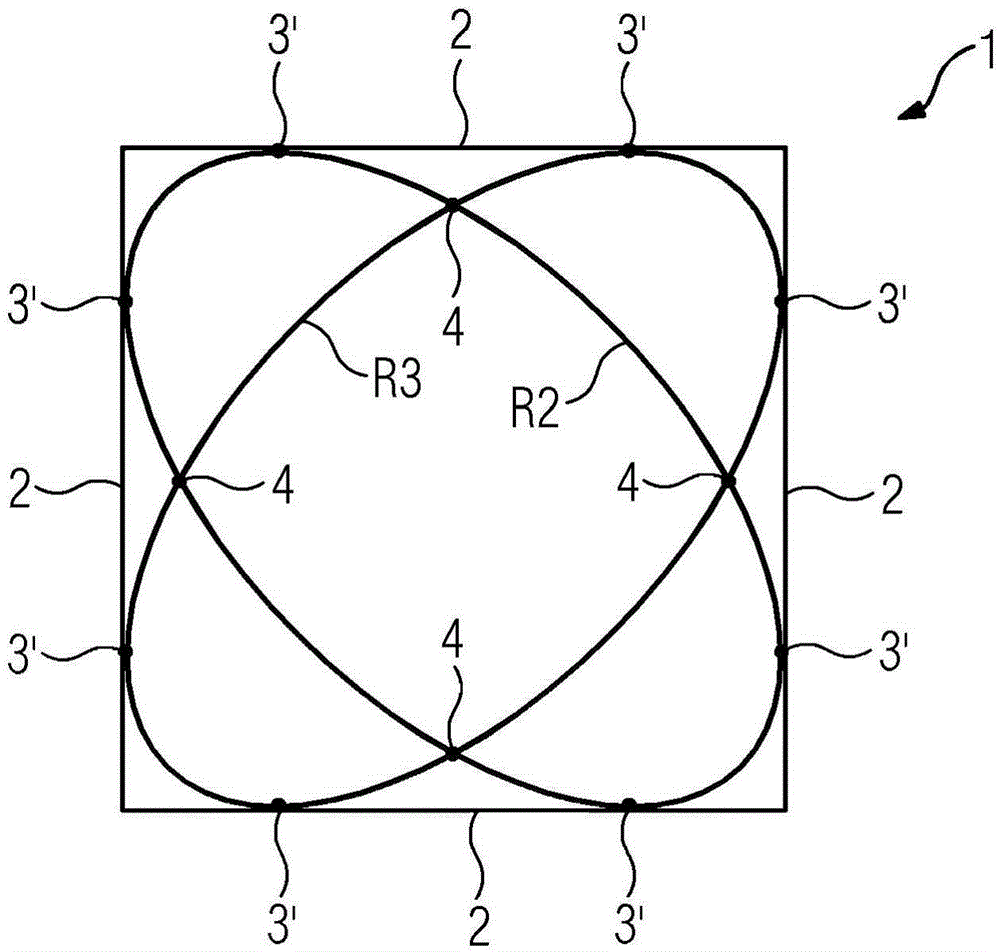

The invention relates to a housing, in particular an outer housing for a low-pressure steam turbine, which has, in its main surface, a substantially rectangular cross-section and in which the surfaces of lateral sheet metal walls (2) form parts of the housing. To reinforce the sheet metal walls (2), at least one annular reinforcing element (R1, R2, R3) is inserted and designed in such a way that it supports the sheet metal walls at points of the surfaces (3, 3').

Owner:SIEMENS AG

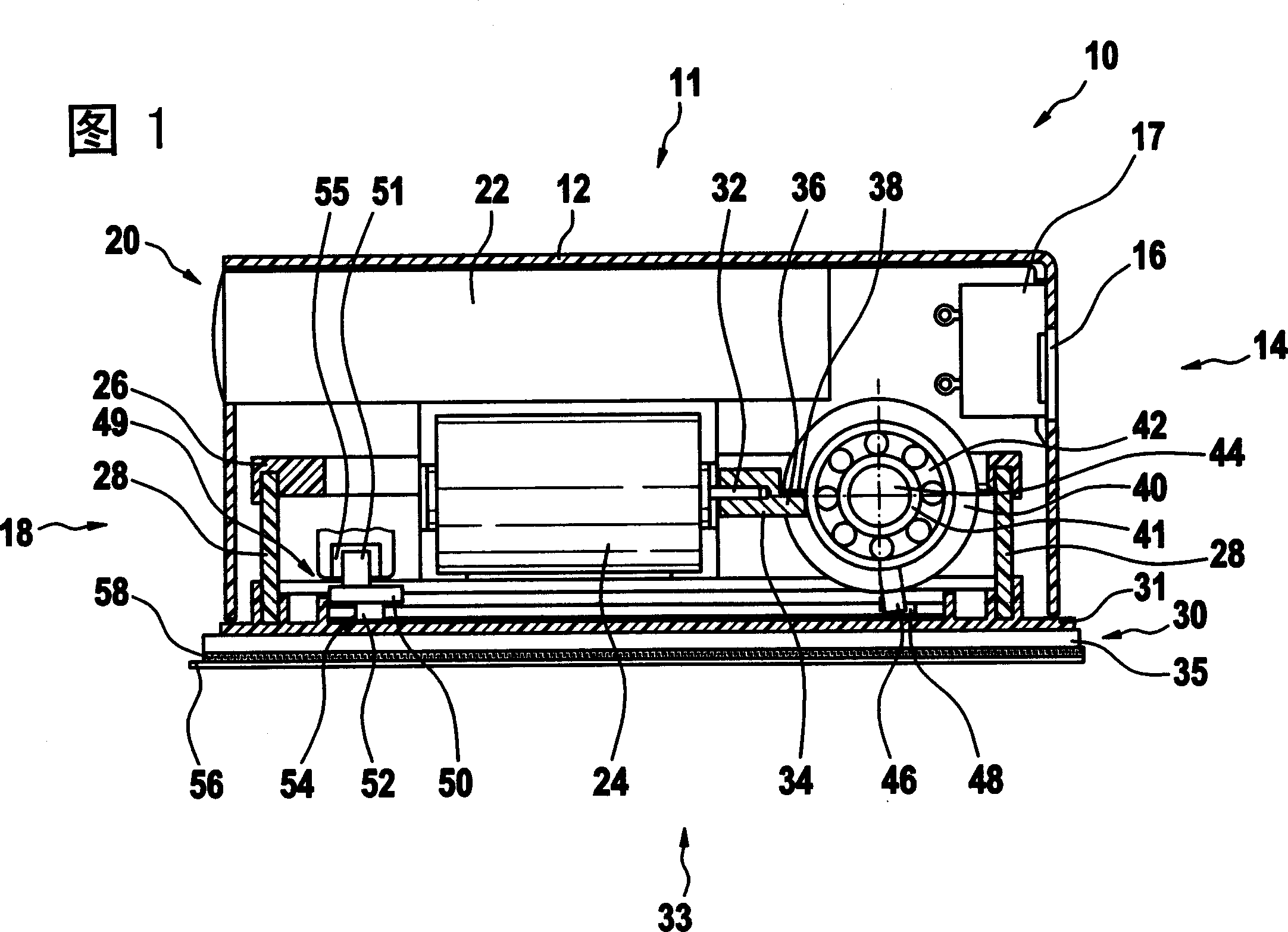

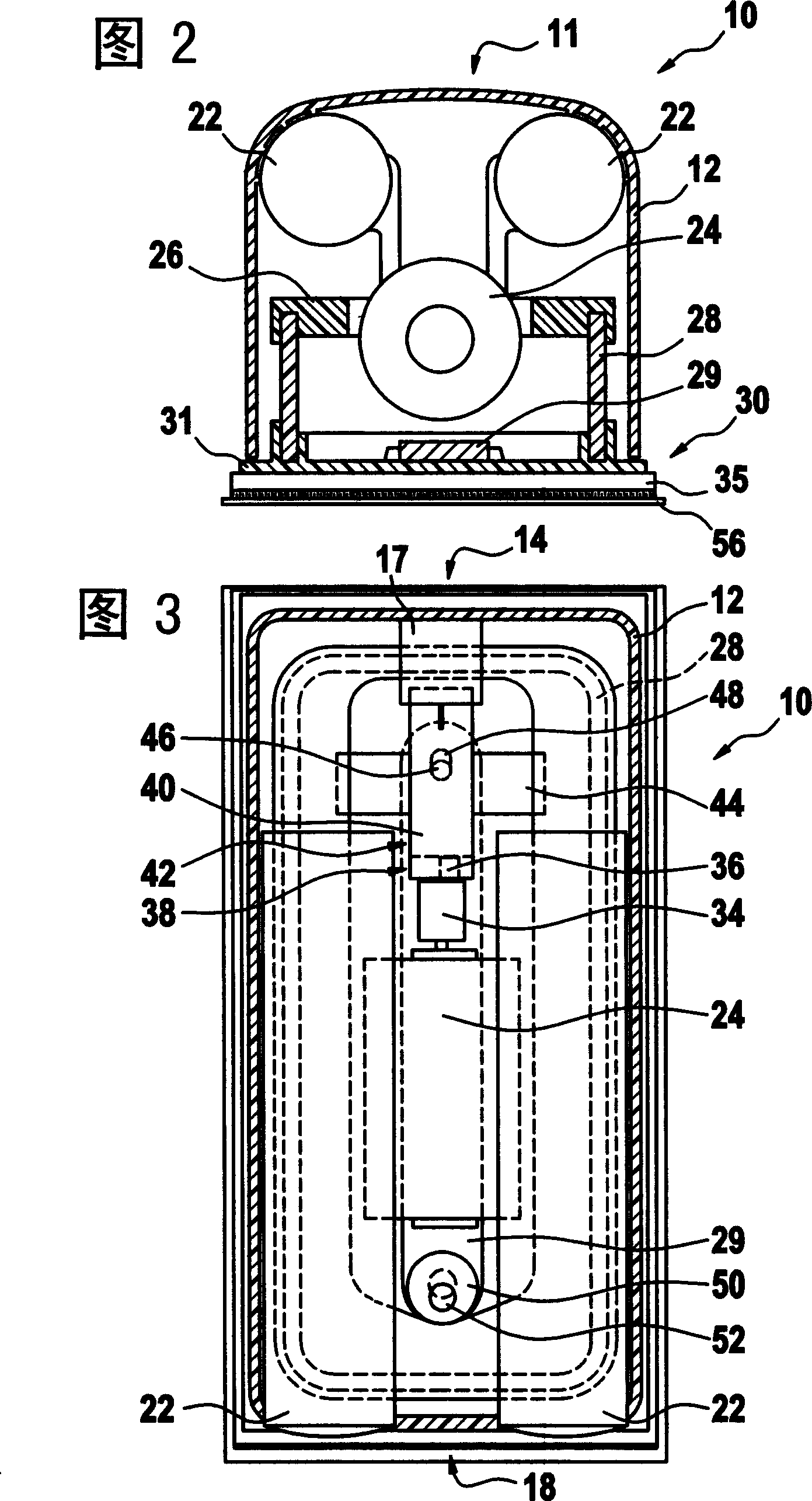

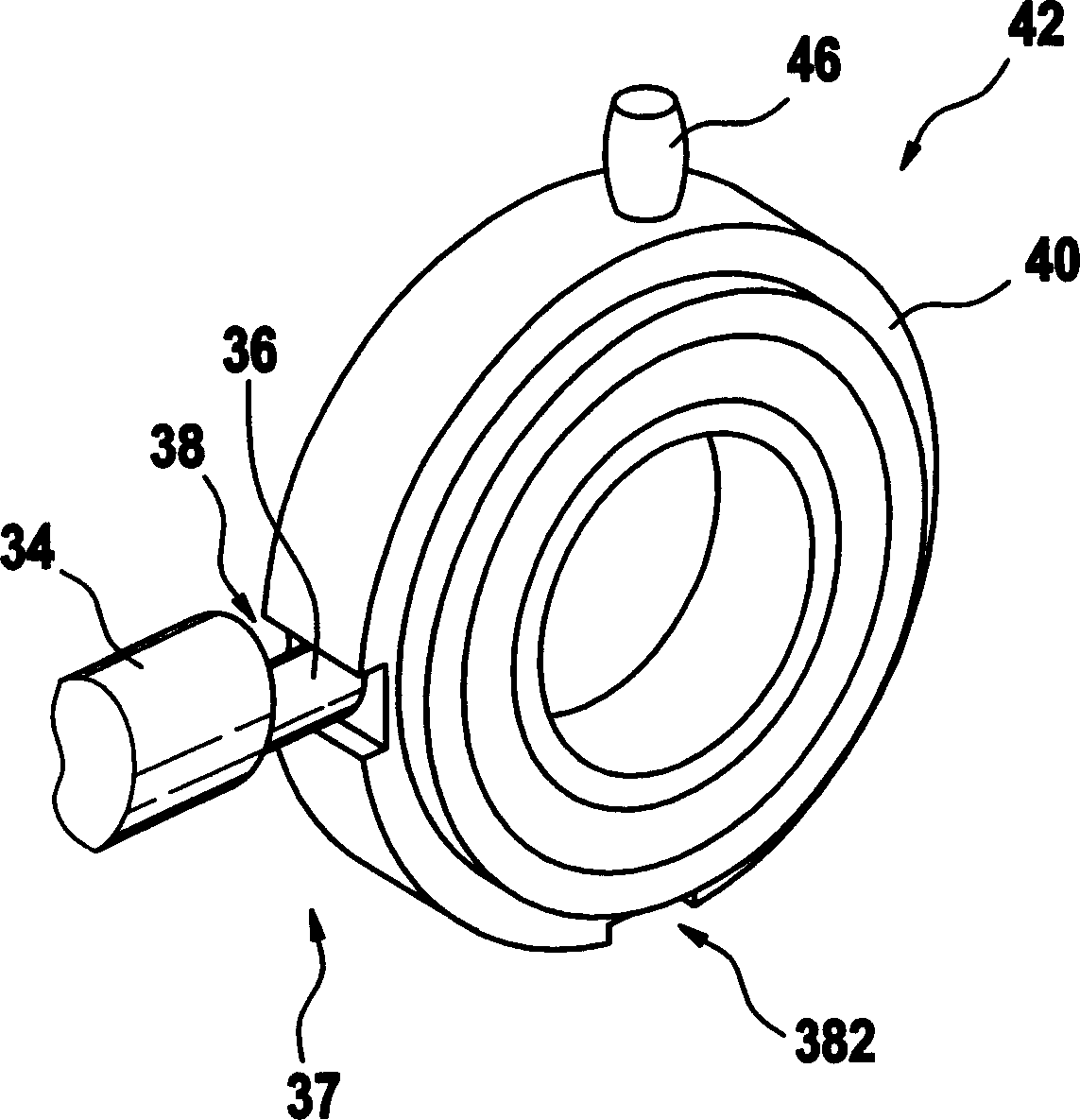

A hand-held machine tool

InactiveCN1636675ALow costSave construction spaceGrinding drivesGearingReciprocating motionHand held

A hand-held power tool (10) has a housing (12), on the lower side of which a grinding blade (56) is movably arranged, which can be passed through an angle transmission device (37 ) A grinding disc (30) driven by an electric motor, wherein the angular transmission (37) consists of an eccentric (34) that drives a swing rod (42) to reciprocate around a swing axis (44). The swing axis (44) extends parallel to the grinding disc (30), wherein the swing link (42) is constructed as an angle bar, one of its lever arms moves up and down around the swing axis (44), and its other lever arm moves toward the The lower deflection is angled and imparts a horizontal back and forth reciprocating motion to the grinding disc (30) or one other tool.

Owner:ROBERT BOSCH GMBH

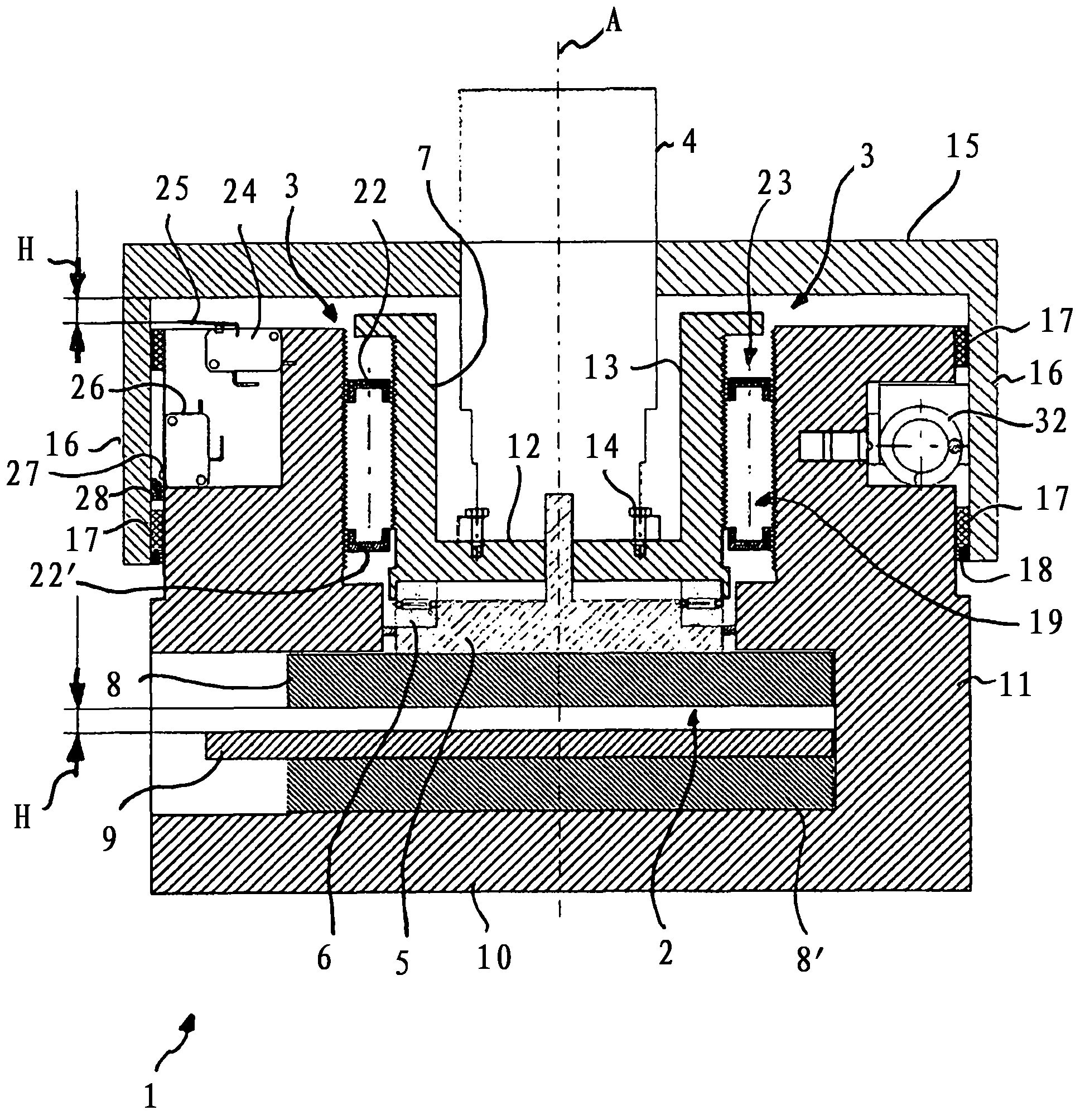

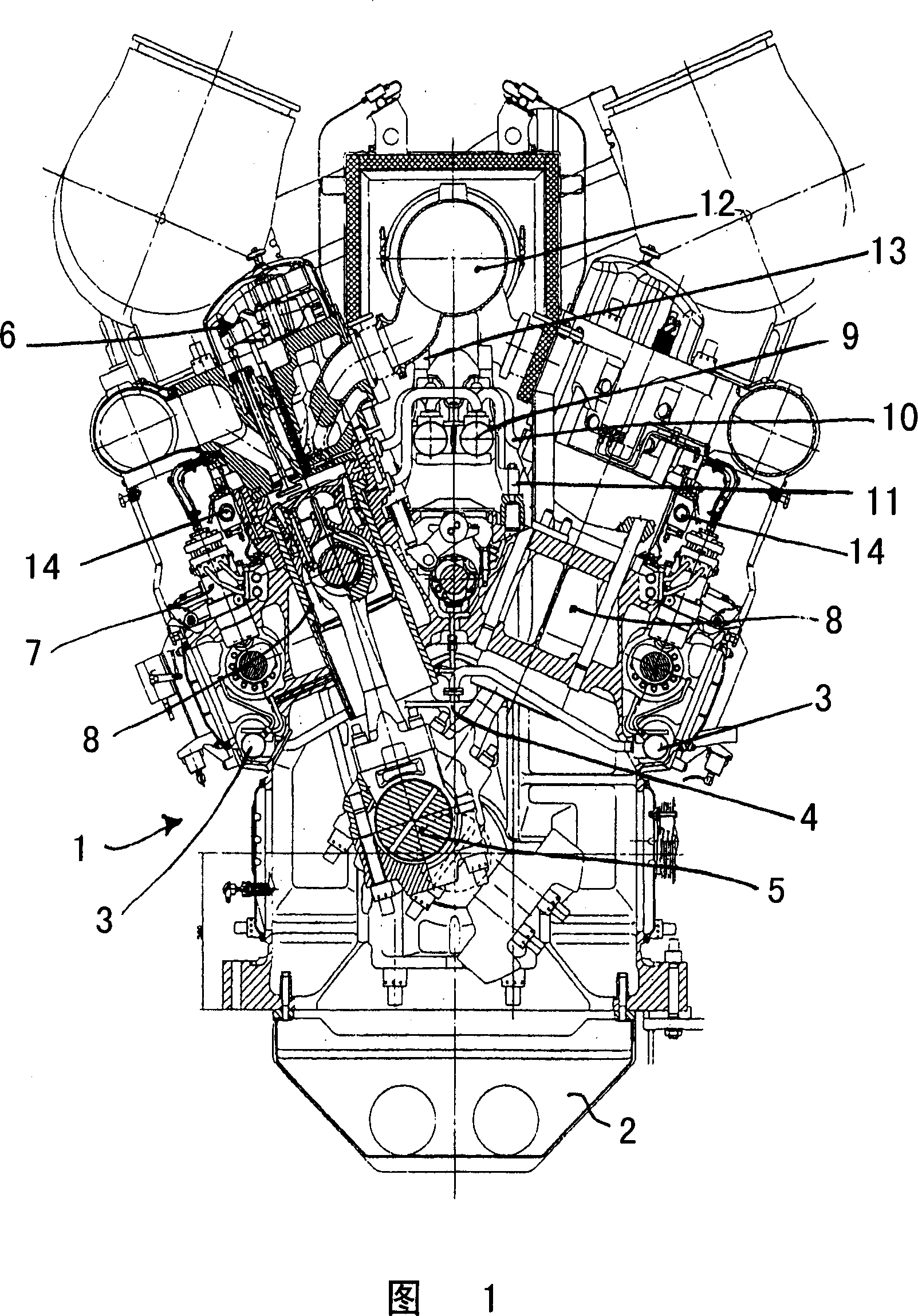

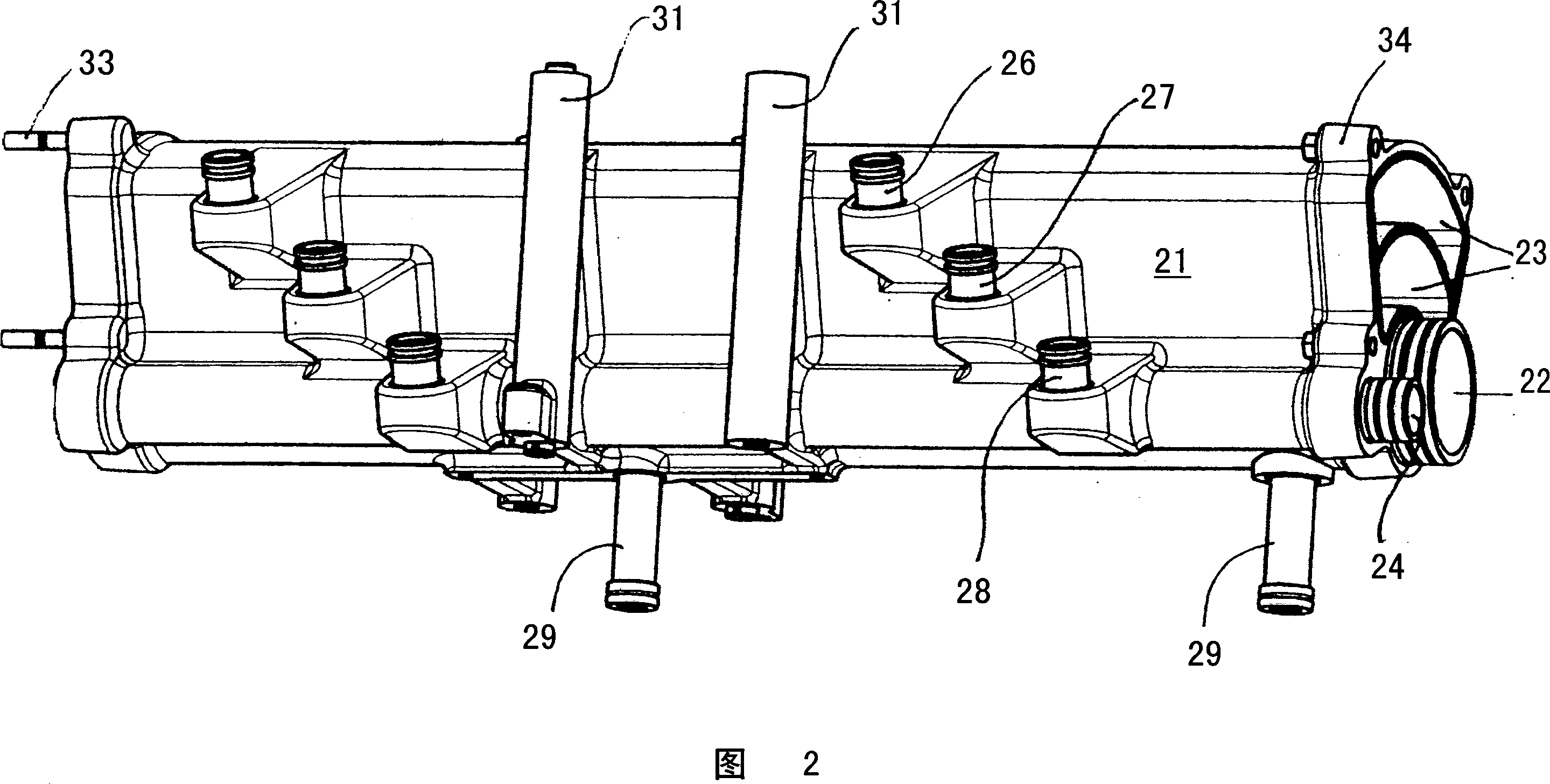

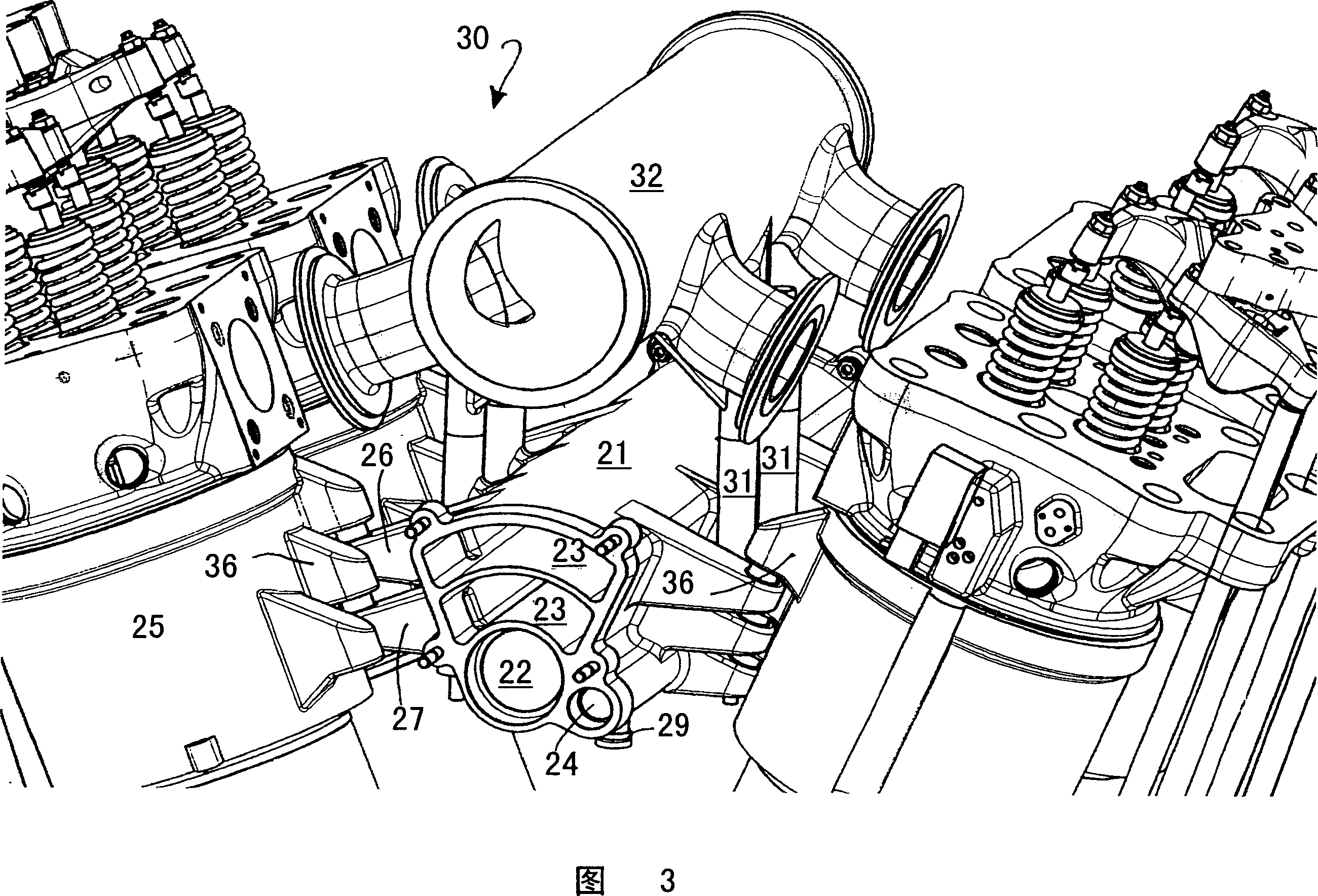

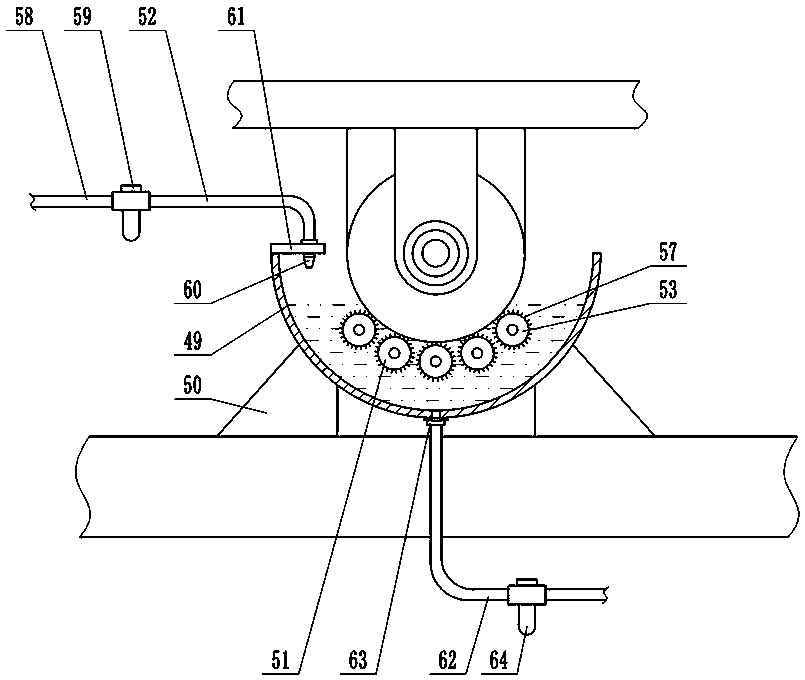

Internal combustion engine with a lubricating, cooling and starting system

InactiveCN1975119ARealize supportReduce in quantityLiquid coolingPower operated startersExternal combustion engineEngineering

The invention relates to a method for supplying lubricant, coolant and air inlet for start-up capable of reducing the assembly cost. The distributing pipes of the lubricant system, cooling system and start-up system are assembled in a common structure unit which is constituted by a plurality of dusting sections 21 for forming lubricant ducting, cooling water ducting and air inlet ducting for start-up, and is arranged along the engine block so as to connect the internal engine pipeline corresponding to the lubricant system, cooling system and start-up system by means of the separate transmitting ducting 26 to 29.

Owner:MAN ENERGY SOLUTIONS SA

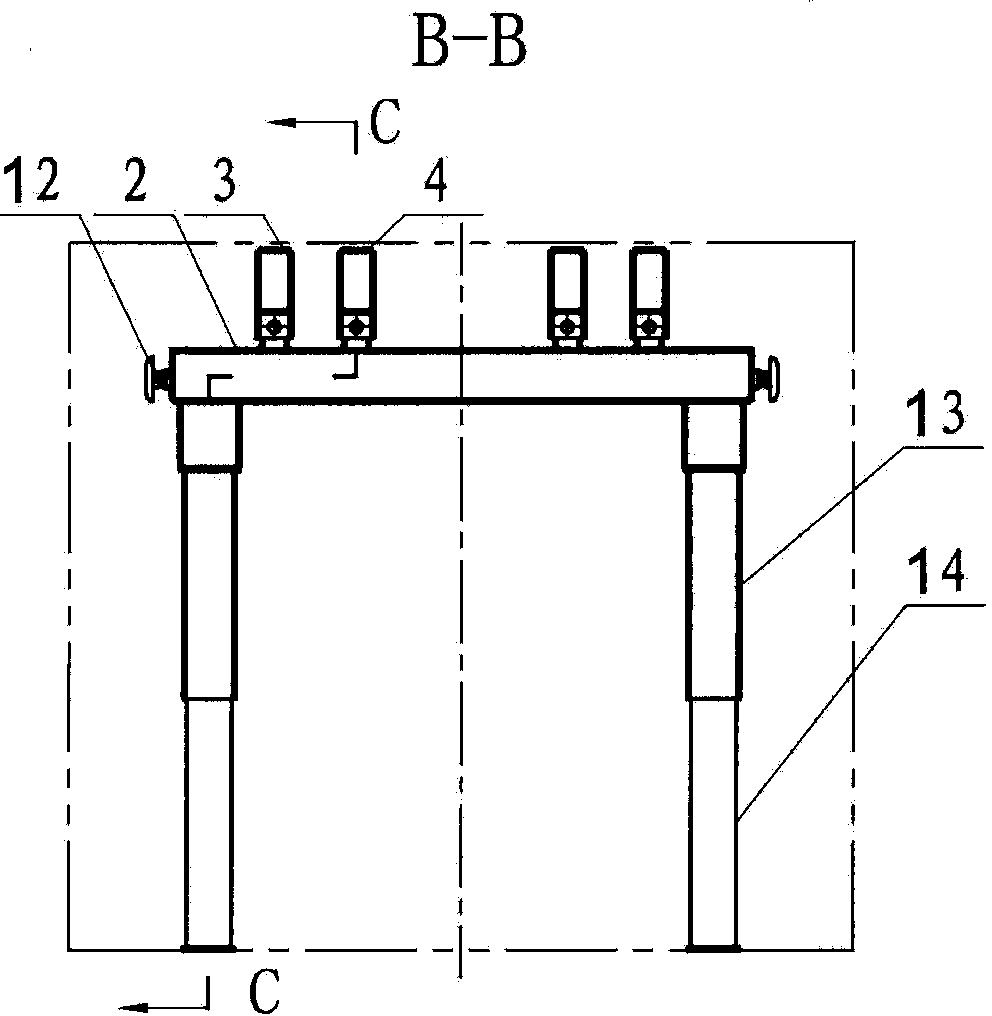

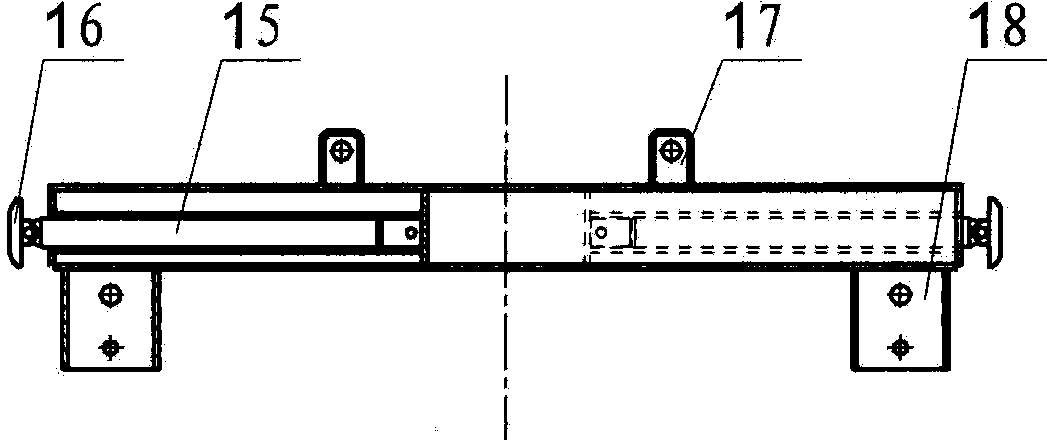

Mining roadway frame style advanced support bracket

InactiveCN104047627AReasonable designCompact structureMine roof supportsCoal miningStructural engineering

A mining roadway frame style advanced support bracket solves the problems that in the prior art, a support area is small, an anchor rod support on the top of a roadway is prone to being damaged, a bracket is slow to move, operation is complex and work efficiency is low. The mining roadway frame style advanced support bracket comprises beams, longitudinal beams and hydraulic upright columns hinged to the bottoms of the beams and serving as a support, wherein the beams, the longitudinal beams and the hydraulic upright columns are assembled to form a frame. The bracket is technically characterized in that the frame is composed of an overall main frame body and an auxiliary frame body, and the overall main frame body and the auxiliary frame body move synchronously; a frame moving hydraulic cylinder hinged between a main front beam of the main frame body and an auxiliary rear beam of the auxiliary frame body drives the main frame body or the auxiliary frame body to move synchronously as a whole; the two ends of the main front beam and a main rear beam and the two ends of an auxiliary front beam and the auxiliary rear beam are respectively connected with lateral telescopic mechanisms in a hinged mode. The mining roadway frame style advanced support bracket is reasonable in design, compact in structure, easy and convenient to operate, stable in supporting and moving and safe and reliable, occupies little space in the roadway, can achieve mechanical advanced support for continuously supporting a roadway top plate according to different geological conditions and roadway sectional shapes, and remarkably improves support quality and production efficiency of a coal mining working face.

Owner:SHENYANG TIAN AN TECH CO LTD

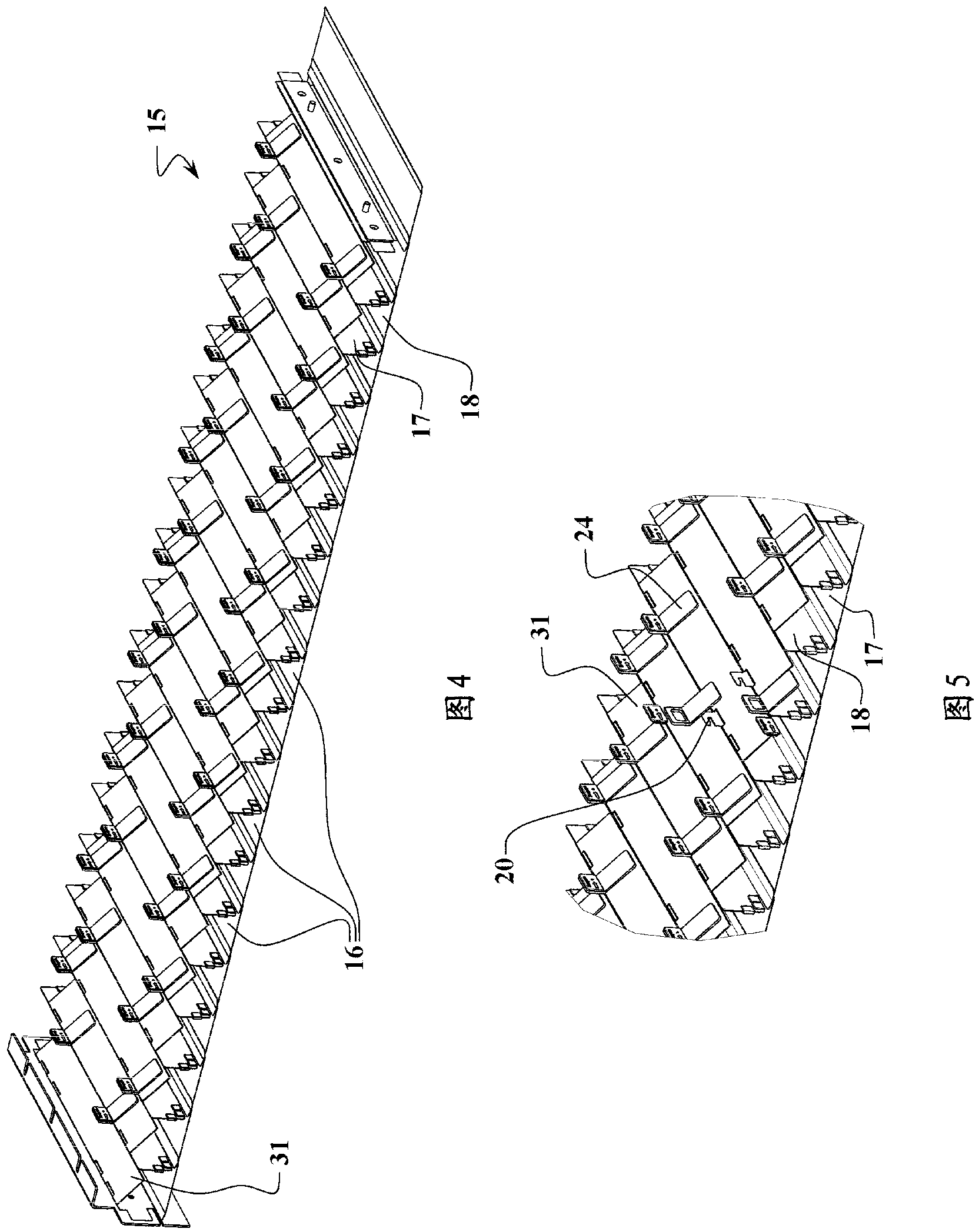

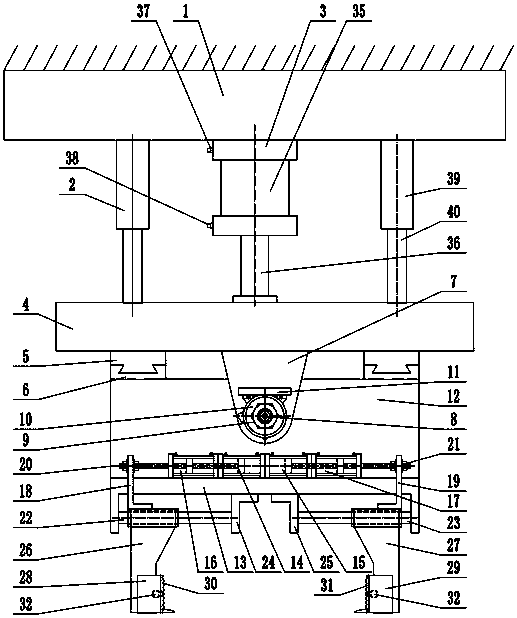

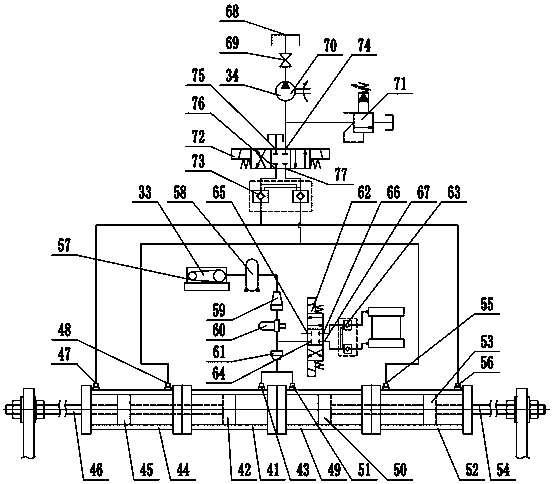

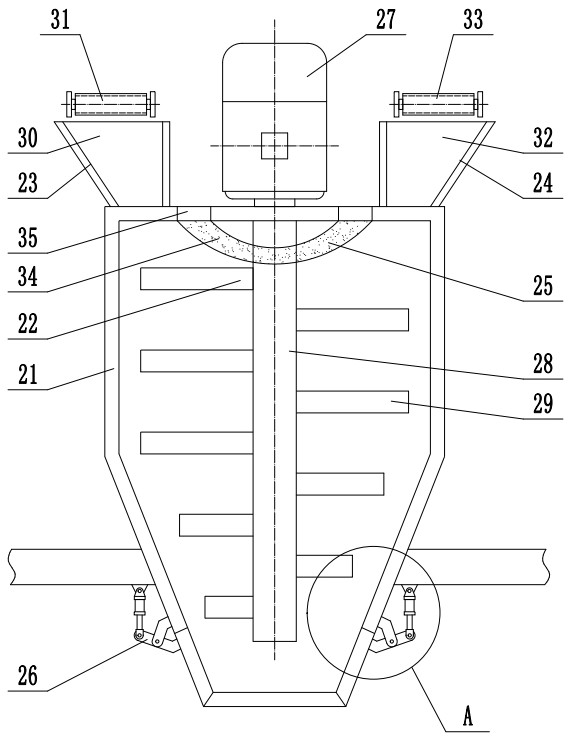

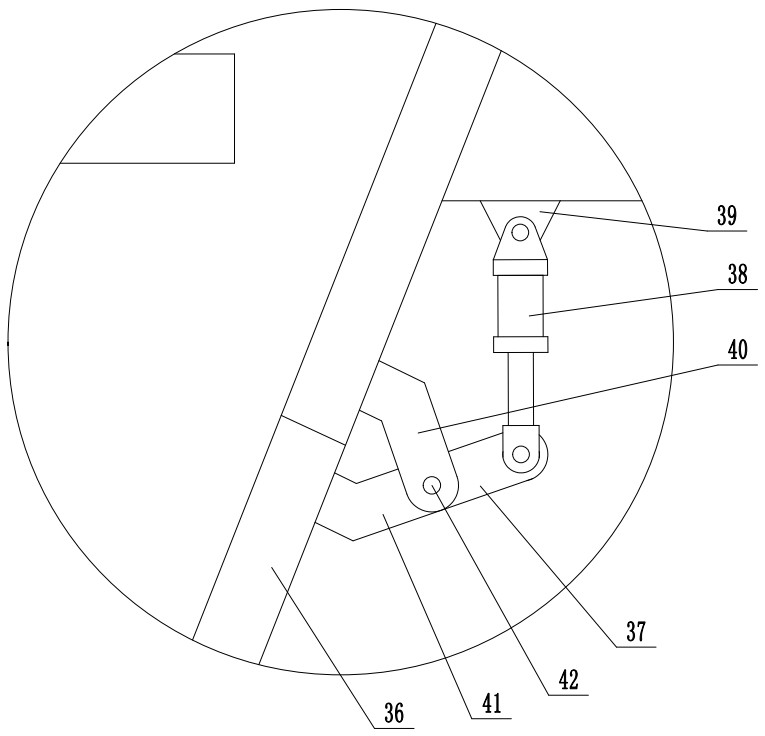

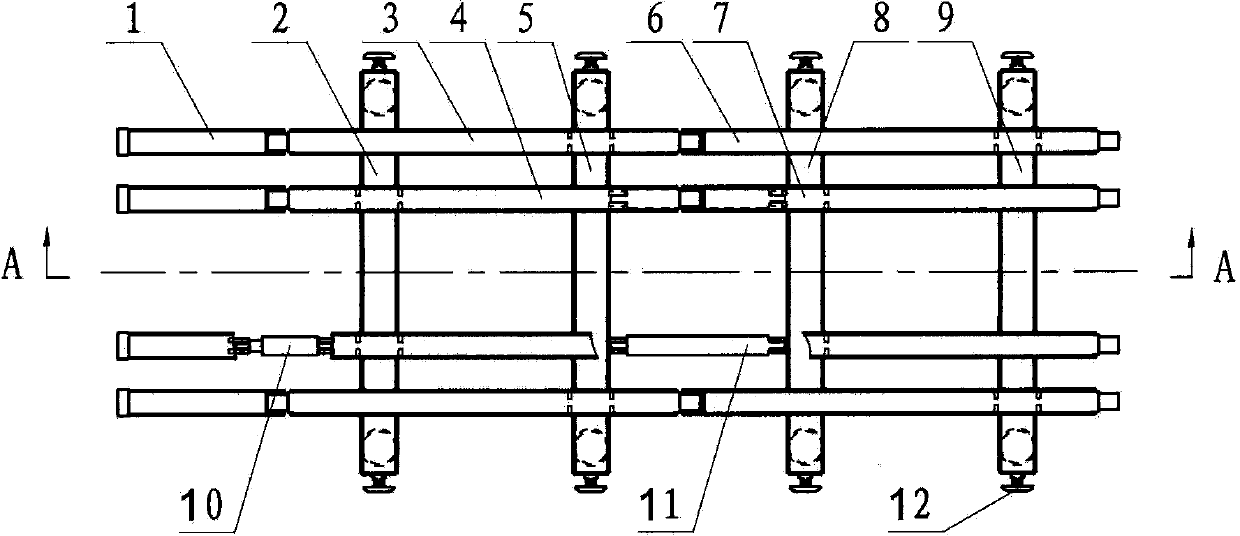

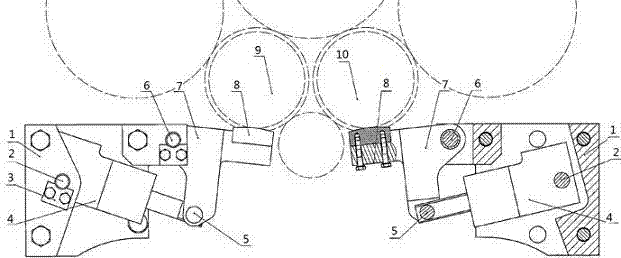

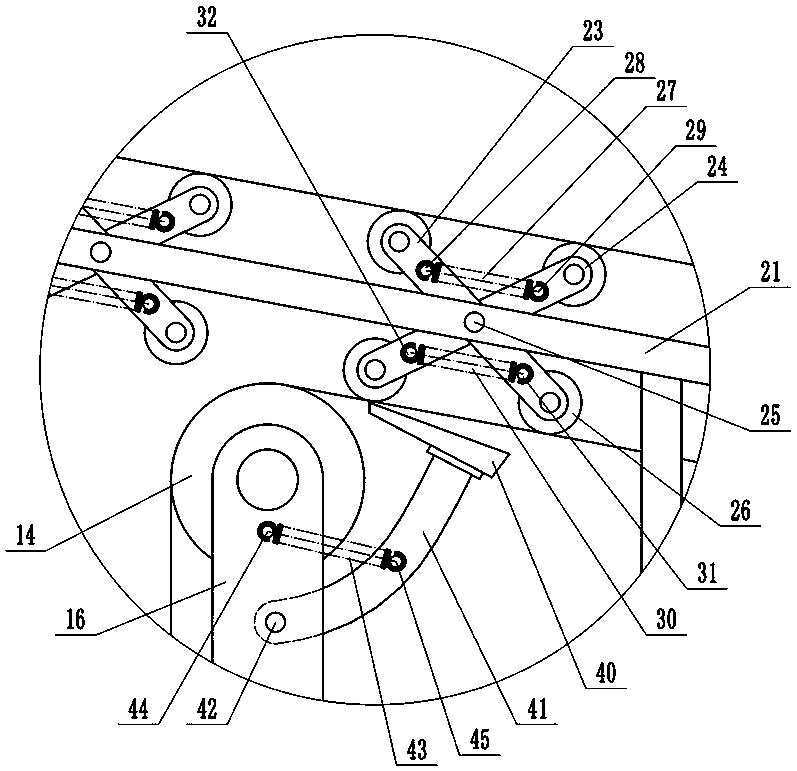

First intermediate roll swing arm type bracket system of twenty-high roll mill

ActiveCN104772336AQuick and efficient roll changeAvoid wear and tearMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The invention belongs to the technical field of plate and strip rolling, and specifically relates to a first intermediate roll swing arm type bracket system of a twenty-high roll mill. The system consists of two swing arm type bracket devices which are vertically symmetric about the center of the twenty-high roll mill and arranged below two first intermediate rolls, and the swing arm type bracket devices comprise swing arm brackets arranged below the first intermediate rolls and fixed supports which are connected with the swing arm brackets by virtue of swing arm hinged shafts; the fixed supports are arranged on a driving side of a twenty-high roll mill rack, the fixed supports are provided with swing arm oil cylinders, the tail parts of the swing arm oil cylinders are articulated with the fixed supports by virtue of cylinder body hinged shafts, and rod ends of the swing arm oil cylinders are hinged with the swing arm brackets by virtue of cylinder rod connection shafts. The bracket system can swing the brackets during roll replacement, the intermediate rolls are enable to fall without performing manual operation on the mechanism at the driving side of the twenty-high roll mill by workers, and the intermediate roll replacement is rapidly and efficiently realized.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

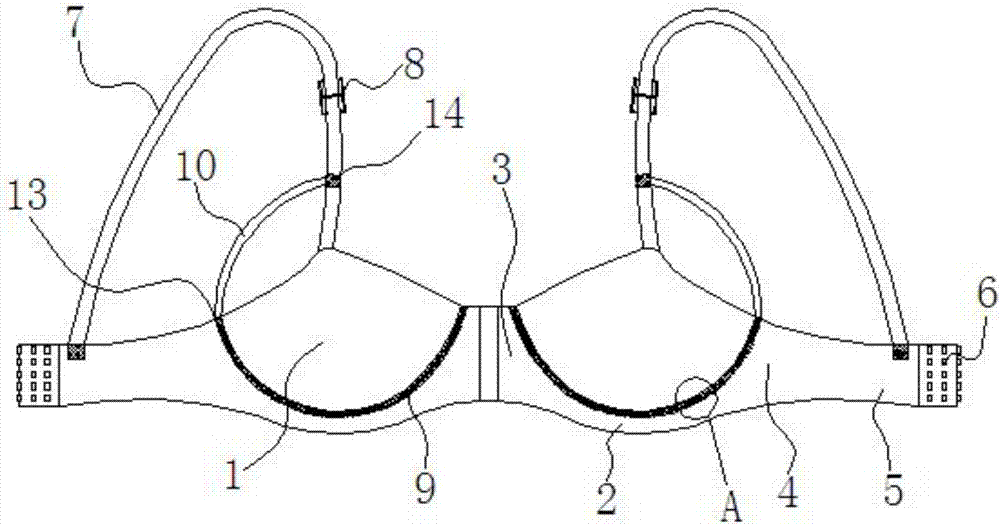

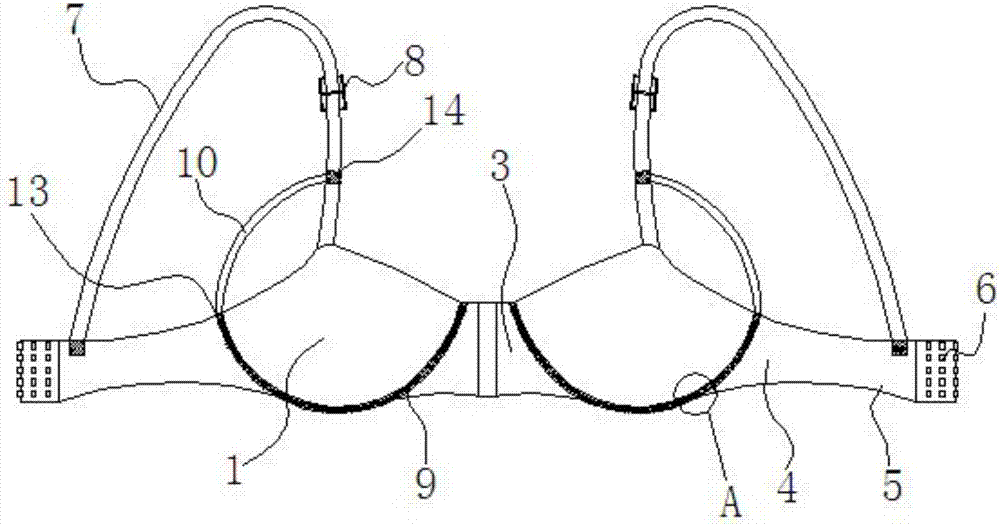

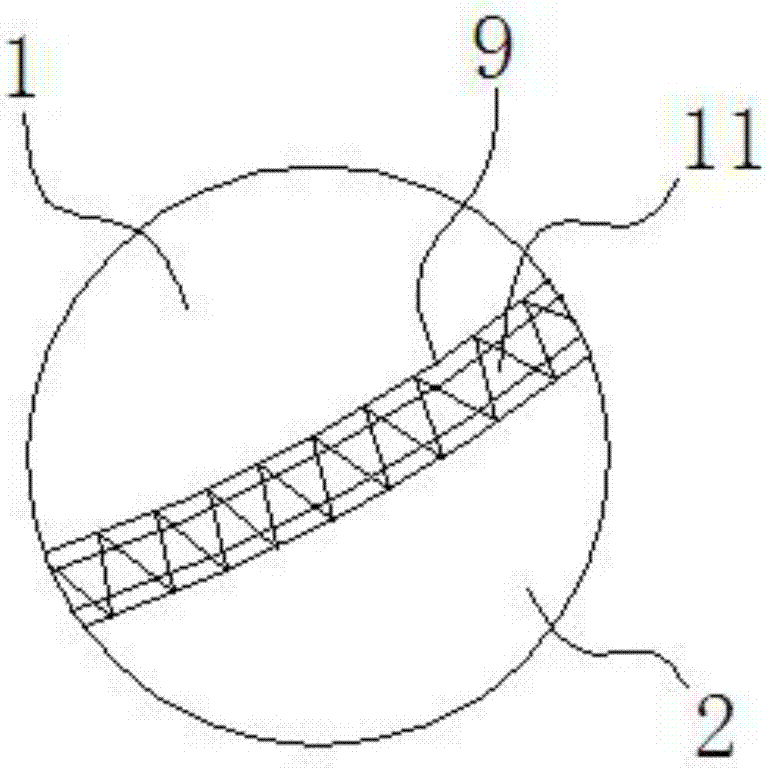

Linglong wireless bra

Owner:何丹彤

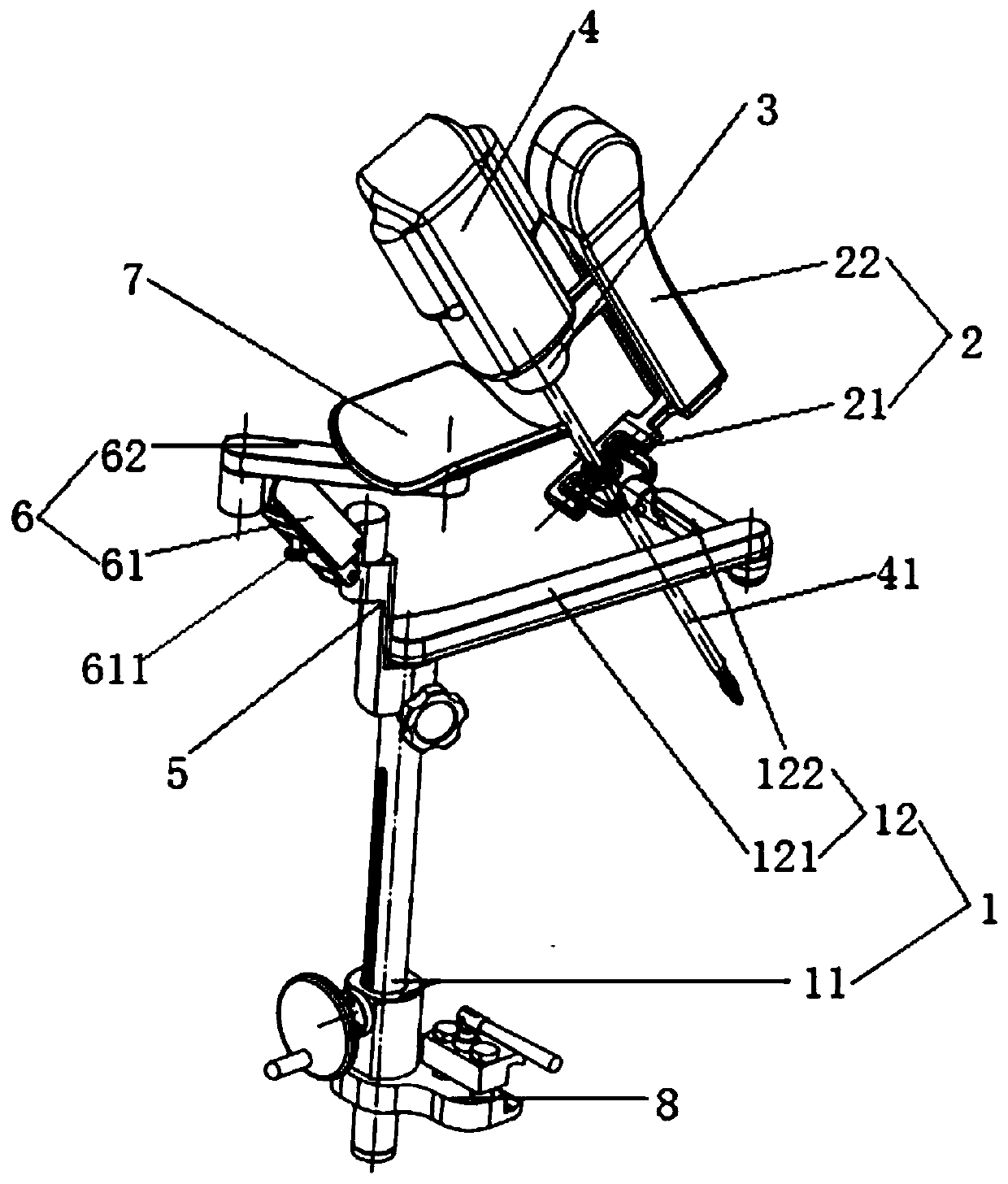

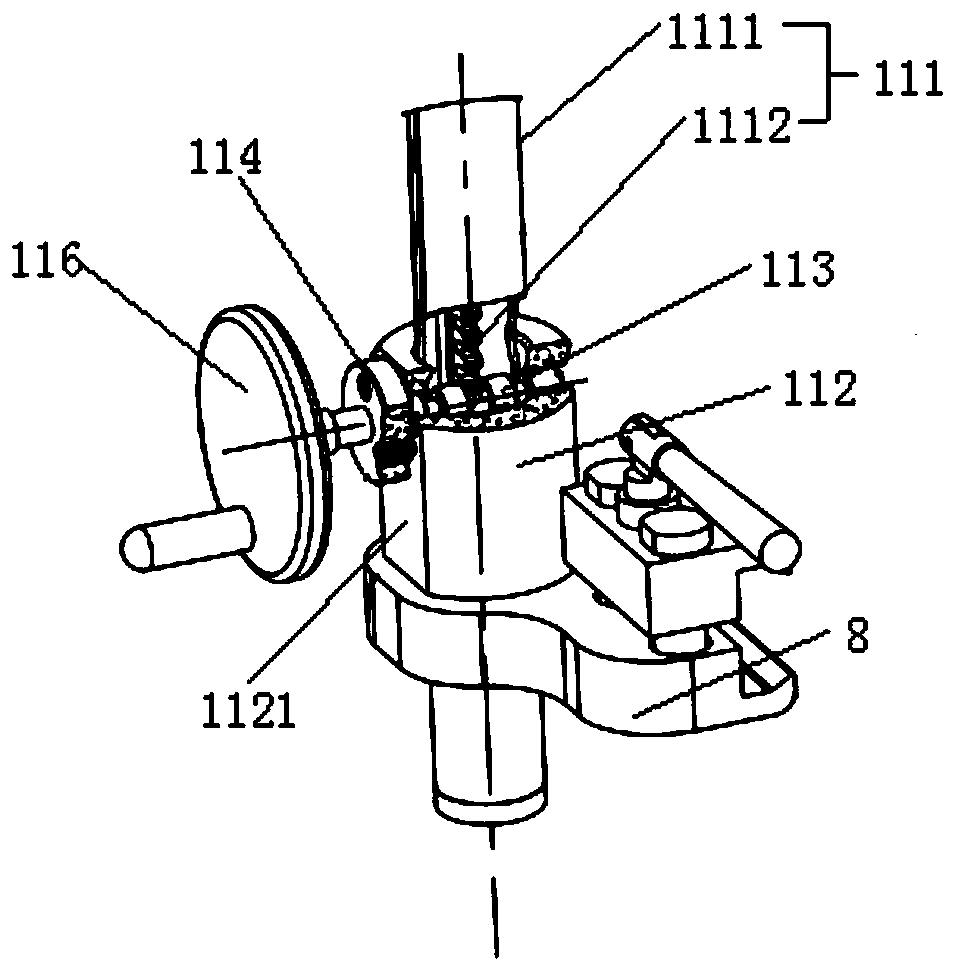

Auxiliary device for surgical robot

The invention relates to the technical field of medical instruments, in particular to an auxiliary device for a surgical robot. The auxiliary device comprises a positioning assembly, a first adjustment assembly which comprises a first swinging unit and a first lifting unit, and a supporting base, wherein the first swinging unit is rotatably connected with a free end of the positioning assembly andis used for driving the first lifting unit to be swung; and the supporting base is connected with the first lifting unit, the first lifting unit is used for driving the supporting base to be moved, and the surgical robot is supported on the support base. Through arrangement of the first adjustment assembly based on the positioning assembly, the positioning assembly is connected with the supporting base through the first adjustment assembly, and the supporting base is used for supporting the surgical robot; and after the positioning assembly realizes positioning, the surgical robot arranged onthe positioning assembly can be further flexibly moved, so that the the surgical robot can flexibly be moved to a required position according to operation intention of a doctor. According to the auxiliary device for the surgical robot disclosed by the invention, the problem that the surgical robot in the prior art is heavier so as not to provide convenience for a surgery doctor to operate for a long time is solved.

Owner:锐志微创医疗科技(常州)有限公司

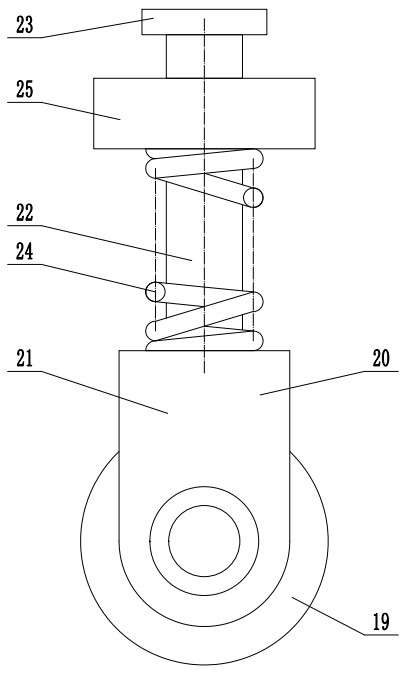

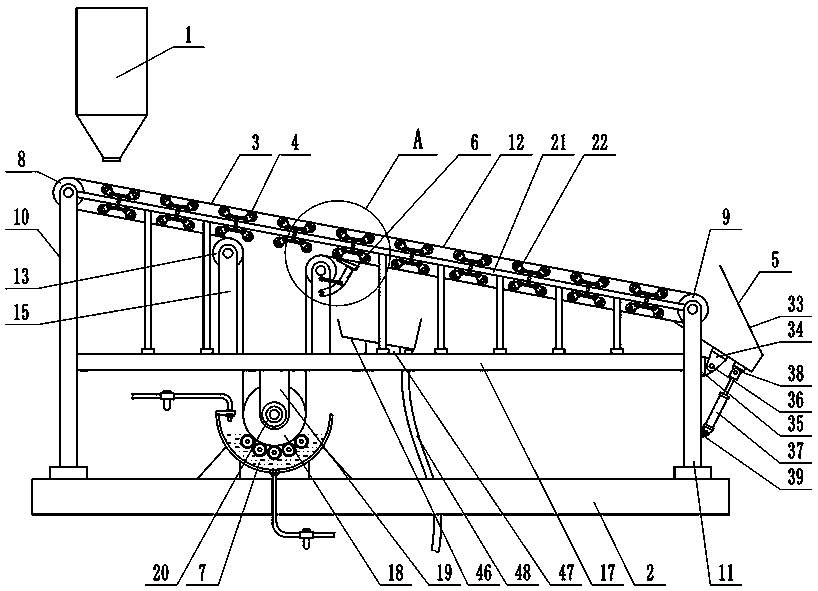

Material conveying device for concrete production

PendingCN110356781AImprove the support effectPrevent saggingConveyorsCleaningWater circulationEngineering

The invention provides a material conveying device for concrete production, and belongs to the technical field of concrete production. The material conveying device comprises a conveying mechanism, asupporting tensioning mechanism, a discharging mechanism, a material scraping mechanism and a cleaning mechanism, wherein a conveying belt of the conveying mechanism winds around a first conveying roller, a second conveying roller, a second conveying supporting guide roller, a conveying belt outward-turning roller and a first conveying supporting guide roller; supporting tensioning assemblies of the supporting tensioning mechanism are uniformly distributed on a supporting tensioning frame; the lower end of a material scraping swing rod of the material scraping mechanism is hinged with a secondconveying supporting guide roller frame through a material scraping swing rod pin shaft; a material scraping tongue is arranged at the upper end of the material scraping swing rod; the cleaning mechanism comprises a cleaning assembly and a water circulation assembly; and cleaning brushes are uniformly distributed on cleaning rollers of the cleaning assembly. According to the material conveying device, the stable conveying of concrete can be ensured, the concrete is prevented from being condensed on the conveying belt; and the conveying belt is good in supporting and tensioning effect and longin service life.

Owner:桐乡市钟大建材有限公司

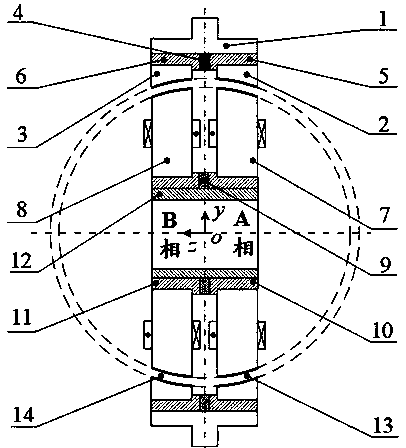

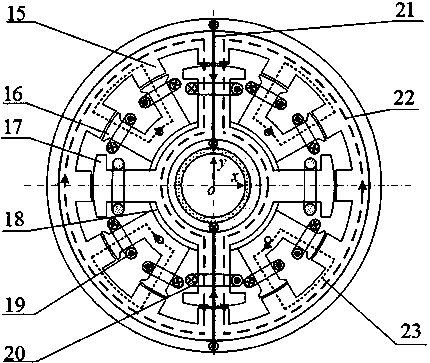

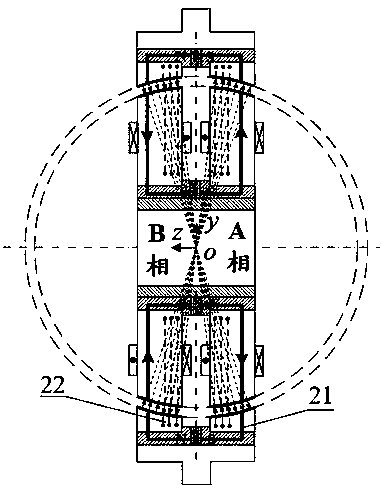

Axial permanent magnet spherical surface magnetic levitation flywheel motor

PendingCN110011440AEasy to integrateIncrease stiffnessMagnetic circuit rotating partsMagnetic circuit stationary partsFlywheelPhysics

The invention relates to an axial permanent magnet spherical surface magnetic levitation flywheel motor, belonging to the technical field of magnetic levitation motors. The axial permanent magnet spherical surface magnetic levitation flywheel motor comprises a flywheel, a rotor and a stator. The flywheel and the rotor form an integral body, the stator and the rotor are divided into an A phase anda B phase in an axial direction, and axial reverse magnetizing permanent magnets are respectively clamped between a rotor A-phase magnetic conducting ring and a rotor B-phase magnetic conducting ringand between a stator A-phase magnetic conducting ring and a stator B-phase magnetic conducting ring; the rotor comprises a rotor A-phase spherical surface iron core, a rotor B-phase spherical surfaceiron core, a rotor permanent magnet, the rotor A-phase magnetic conducting ring and the rotor B-phase magnetic conducting ring; the stator comprises a stator A-phase spherical surface iron core, a stator B-phase spherical surface iron core, a stator permanent magnet, the stator A-phase magnetic conducting ring, the stator B-phase magnetic conducting ring and a stator sleeve; each-phase stator spherical surface iron core is provided with a wide-tooth suspension poles, narrow-tooth torque poles and magnetic isolating bodies, and the suspension poles and the torque poles employ pole shoe structures and are respectively wound with suspension control coils and torque control coils. The axial permanent magnet spherical surface magnetic levitation flywheel motor improves the global uniformity ofair gap magnetic density, achieves the shaftless support of the flywheel and inhibits the gyroscopic effect; meanwhile, the system integration level, the operation efficiency and the reliability are improved, and the decoupling of the suspension magnetic circuit and the torque magnetic circuit is achieved.

Owner:NANJING INST OF TECH

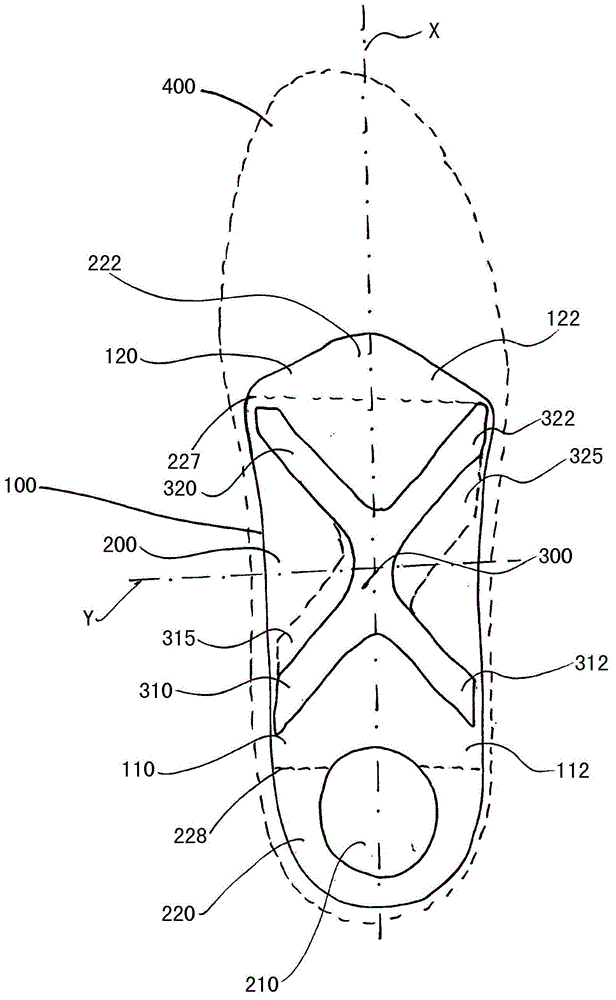

Supporting brace for footwear inserts

Owner:BAUERFEIND GMBH & CO

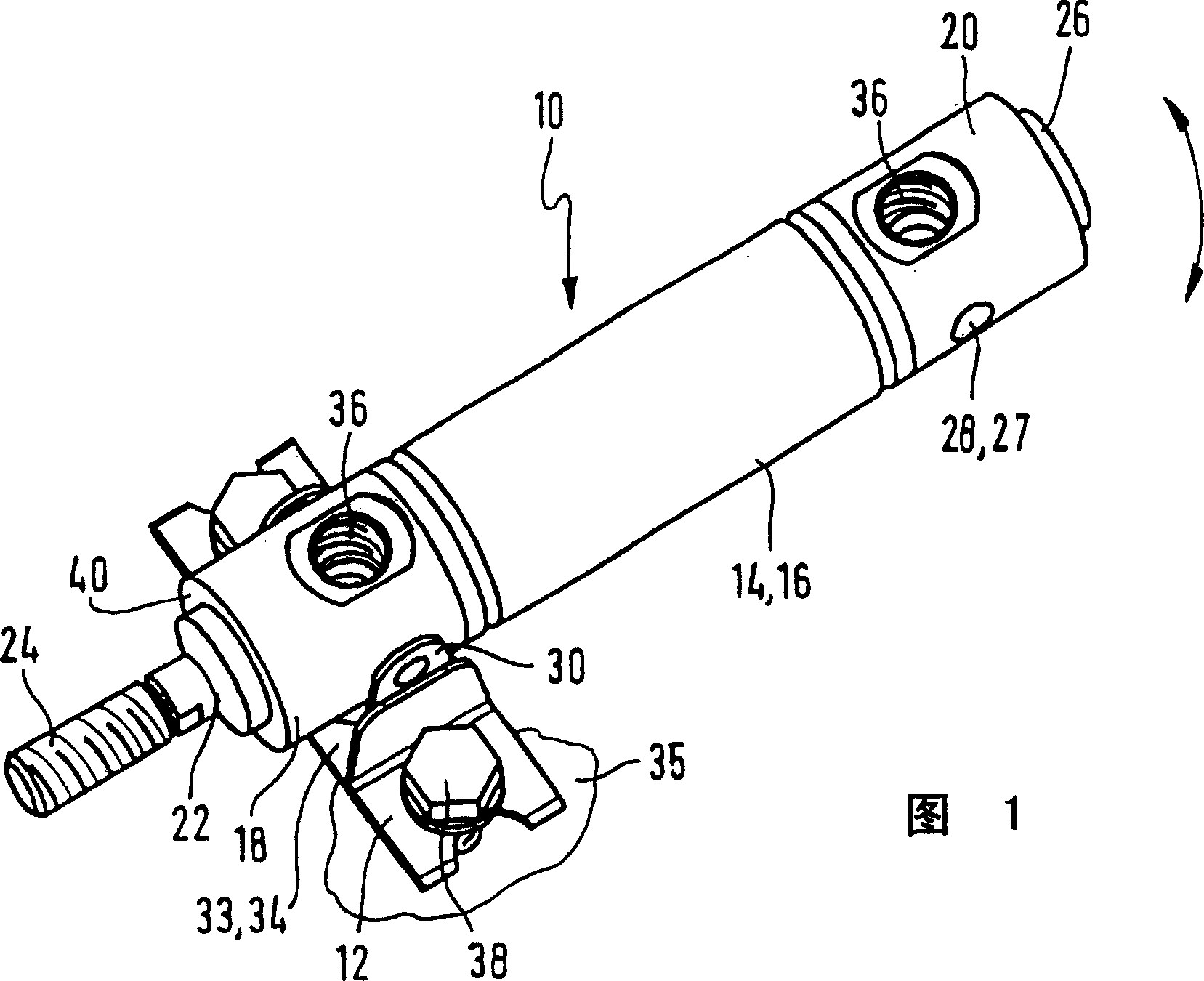

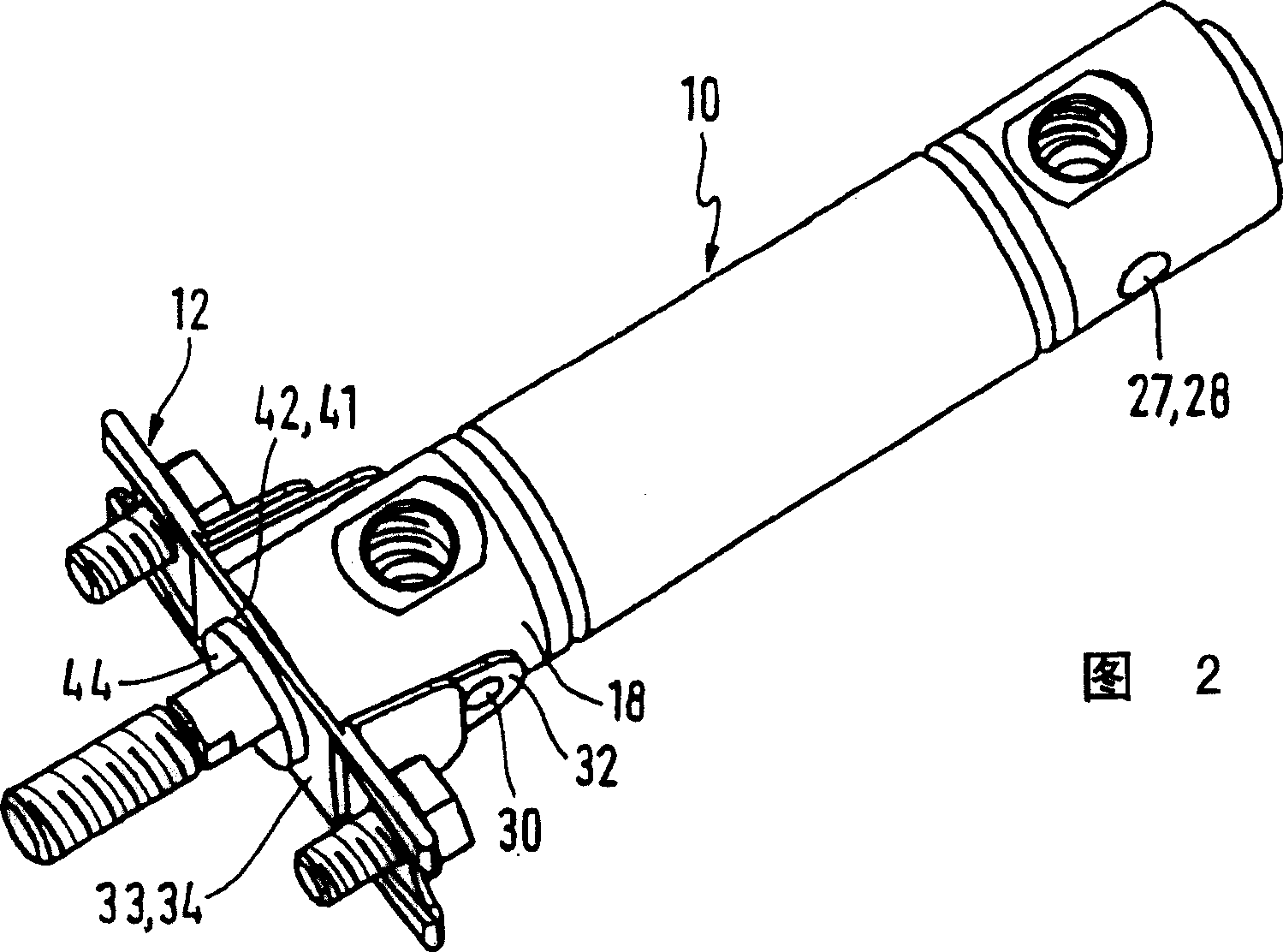

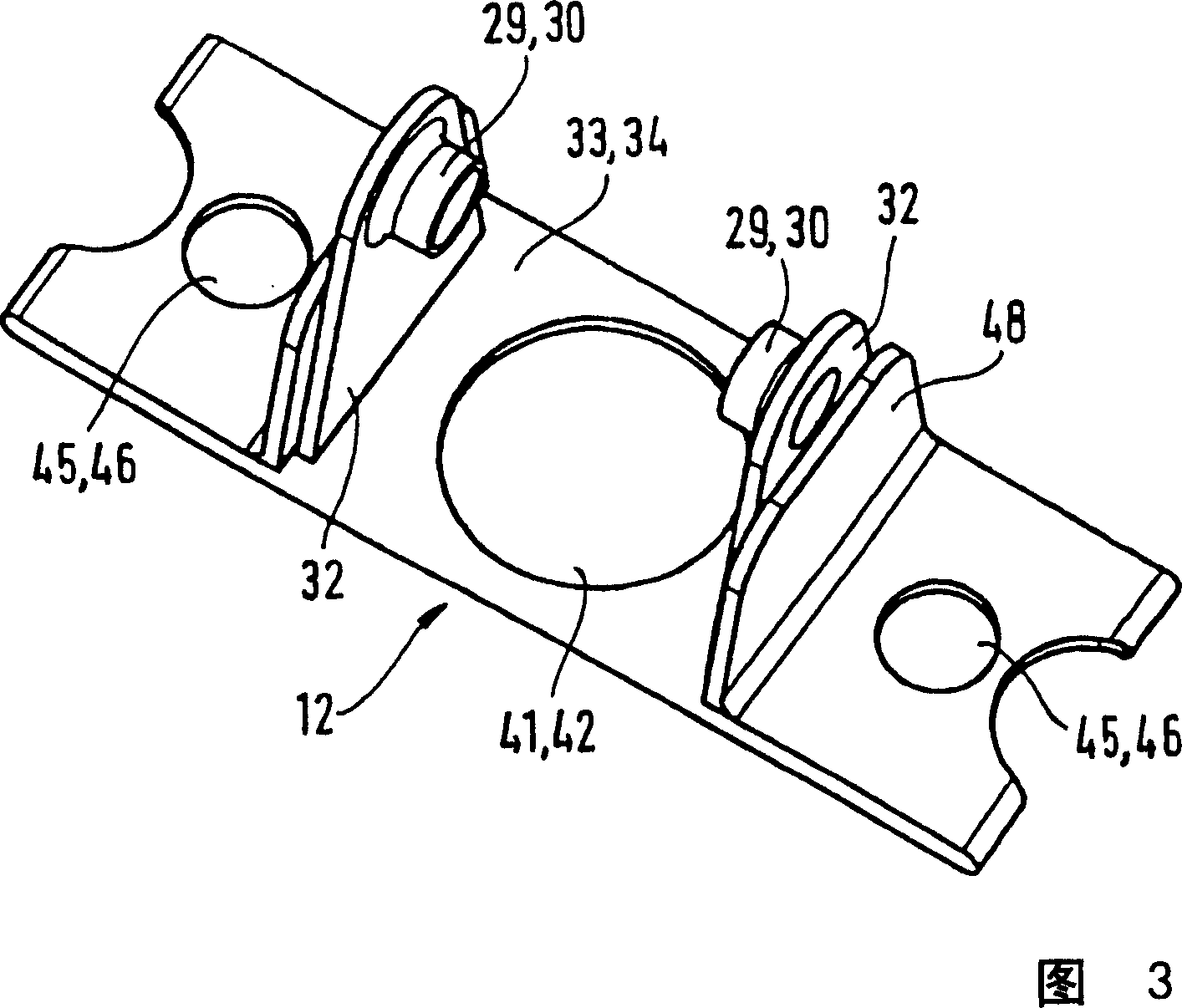

Fastening element and adapted cylinder cover of a fluid-actuated working cylinder

InactiveCN100347455CRealize supportCutting costsFluid-pressure actuatorsStands/trestlesFixed bearingEngineering

Owner:FESTO AG & CO KG

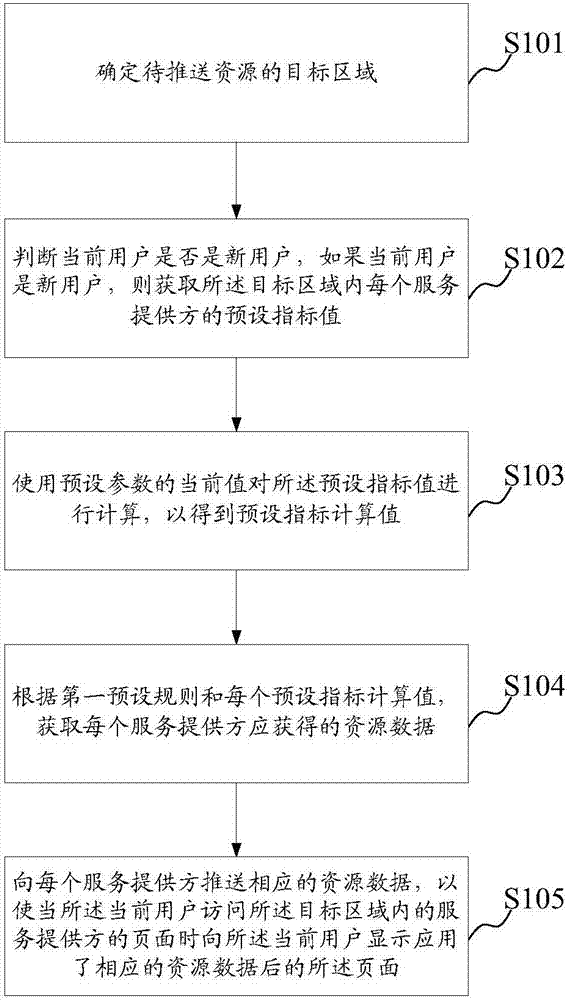

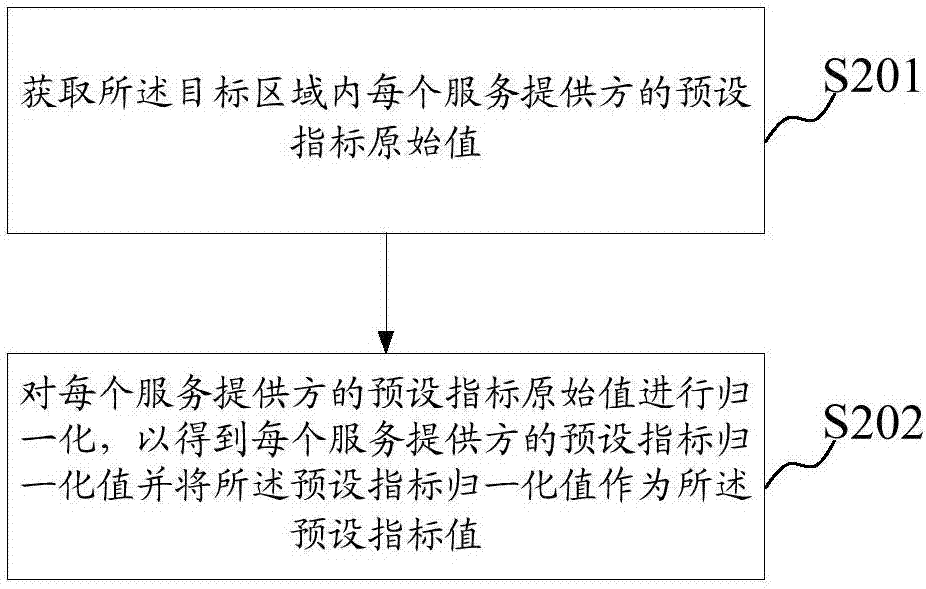

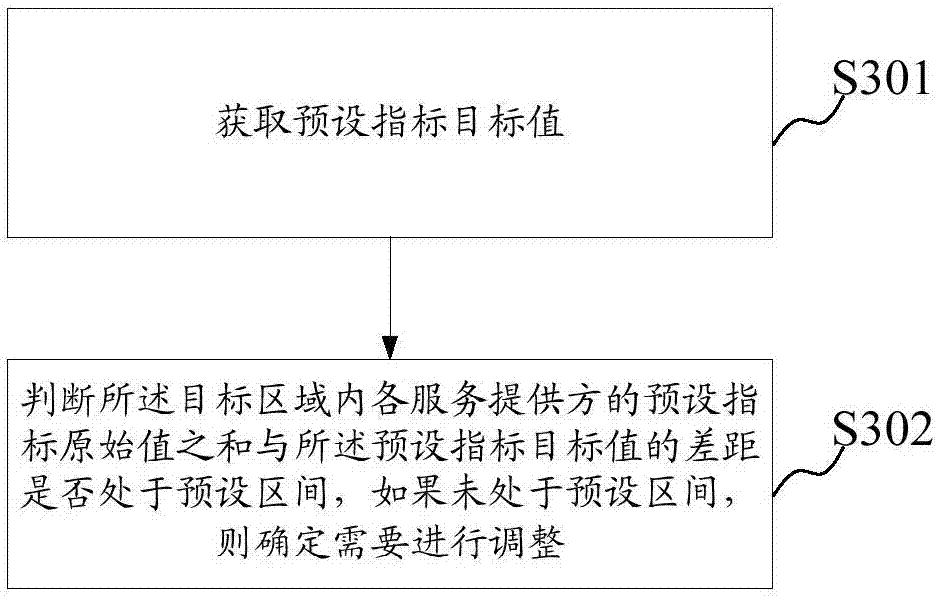

Resource pushing method and apparatus

ActiveCN107092612AImprove retentionImprove efficiencySpecial data processing applicationsWeb data retrieval using information identifiersService provisionData mining

The invention provides a resource pushing method and apparatus. The method comprises the steps of determining a target region of a to-be-pushed resource; judging whether a current user is a new user or not, and if the current user is the new user, obtaining a preset index value of each service provider in the target region; calculating the preset index values by using current values of preset parameters to obtain preset index calculated values; according to a first preset rule and each preset index calculated value, obtaining resource data supposed to be obtained by each service provider; and pushing the corresponding resource data to each service provider, thereby displaying a page after the corresponding resource data is applied, to the current user when the current user accesses the page of the service provider in the target region. According to the method and the apparatus, finite resources can be pushed to the valuable service provider, so that platform resources can be better transmitted to the new user, the new user can be stimulated more effectively, and the retention rate of the new user is increased.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

Carton marking device

Owner:ZHEJIANG HONGFENG WARP & WEFT KNITTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com