Method and device for recording the straightness of elongated products

A measuring device and straightness technology, applied in the direction of measuring device, length measuring device, optical device, etc., can solve the problem of friction affecting roller table contact uncertainty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

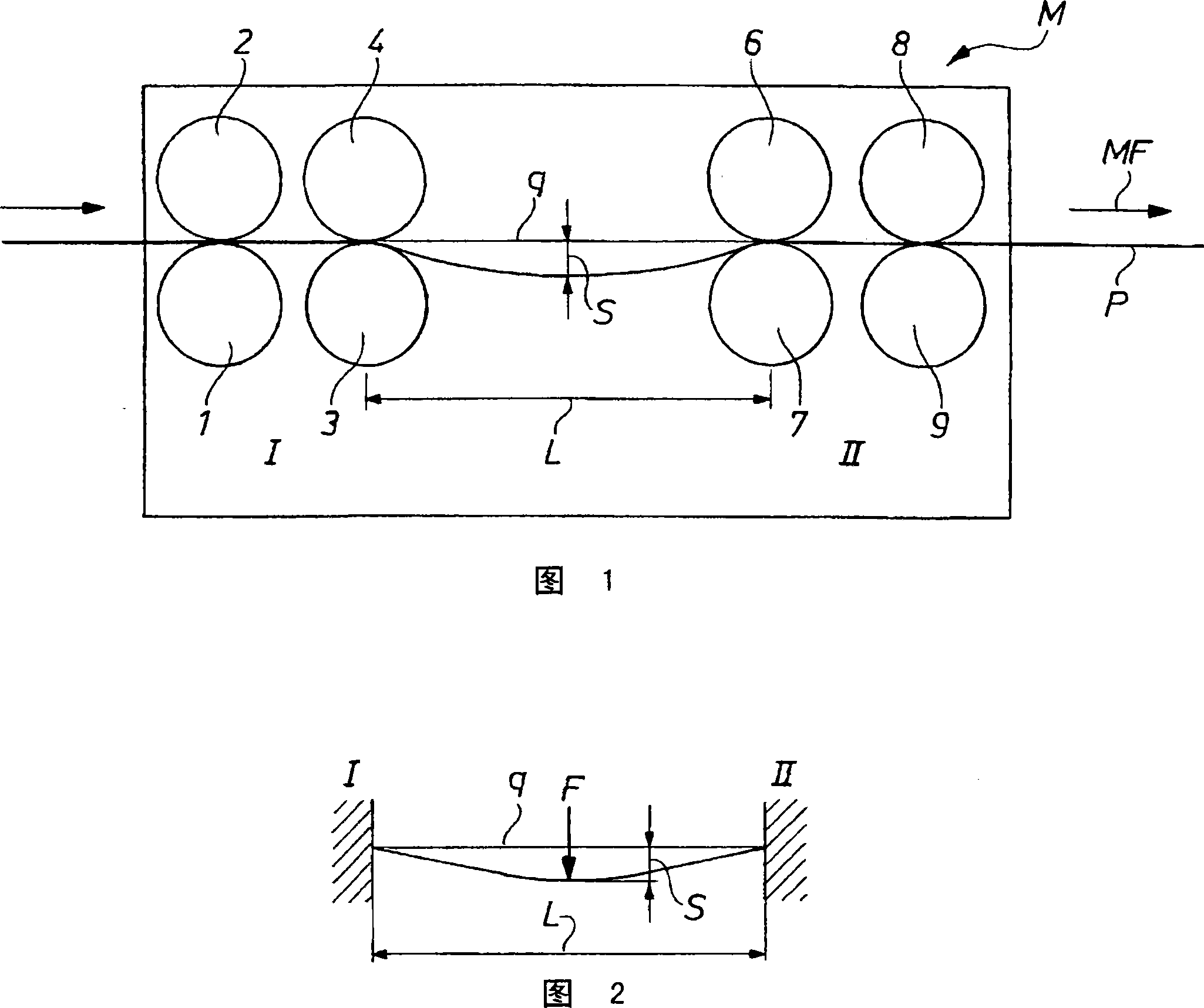

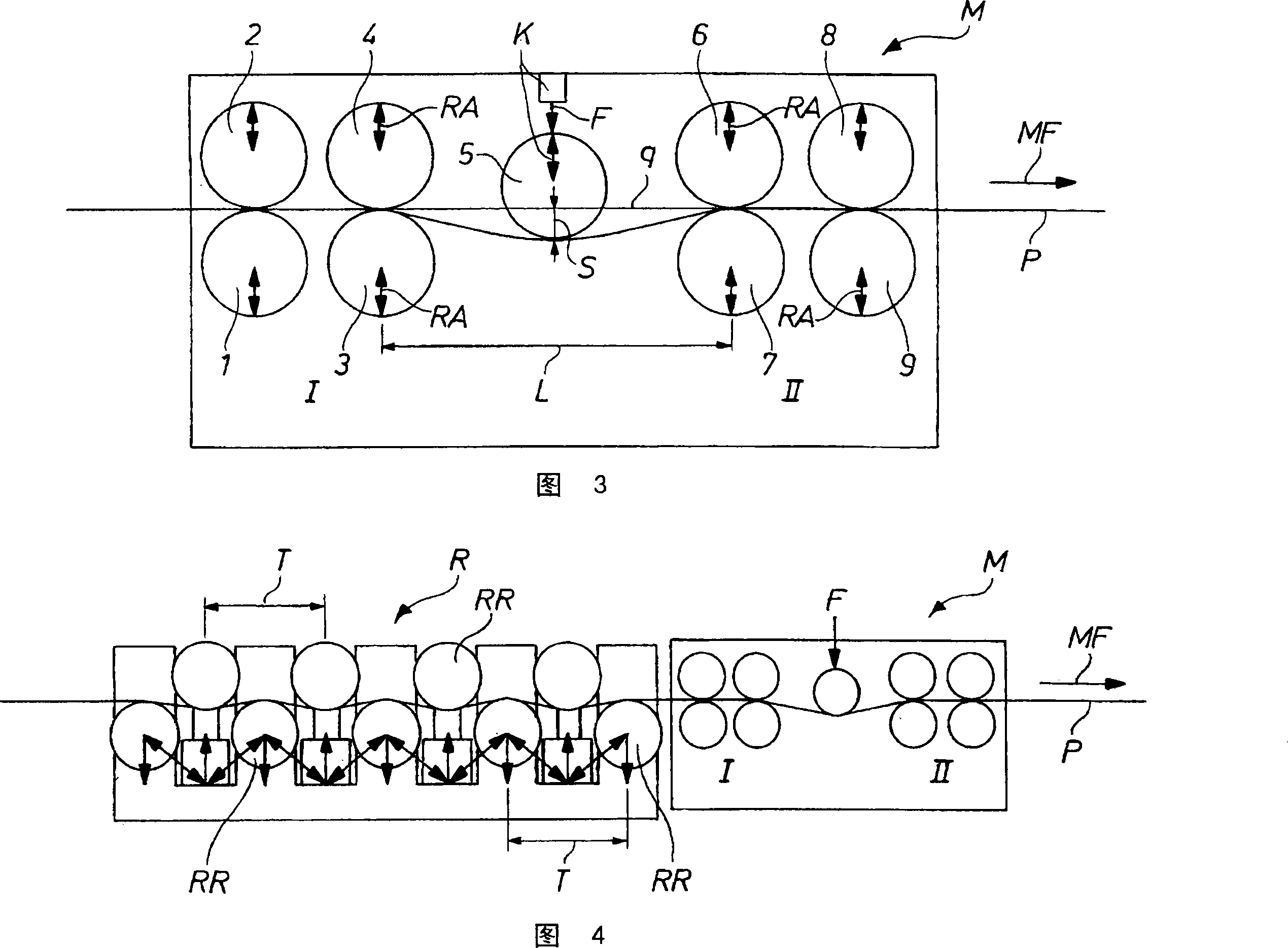

[0018] Measuring device M according to FIG. 1 comprises two groups spaced apart from each other, each having two roller pairs, wherein the upper rollers 2, 4, 6 and 8. These two roller pairs form clamping areas I and II for elongated products P, such as rolled steel beam profiles or rails, which pass continuously through the measuring device M in the flow direction MF. The continuously passing elongated product P occupies a defined unsupported overhang length L between the roller pairs or clamping regions I, II. In the region of this unsupported clamping length, the elongated product experiences a deflection S due to its own weight, which deflection S can be represented expediently as an elastic deformation by applying a force F. A chord q placed in perfect straightness on the unsupported extension length L allows the deflection S and the resulting force to be determined with suitable measuring equipment (not shown) and as a function of S and F. Identify the string. The mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com