Fastening element and adapted cylinder cover of a fluid-actuated working cylinder

A technology for fastening elements and working cylinders, which is applied in the directions of fluid pressure actuation devices, supporting machines, mechanical equipment, etc., and can solve the problems of lack of versatility of fastening devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

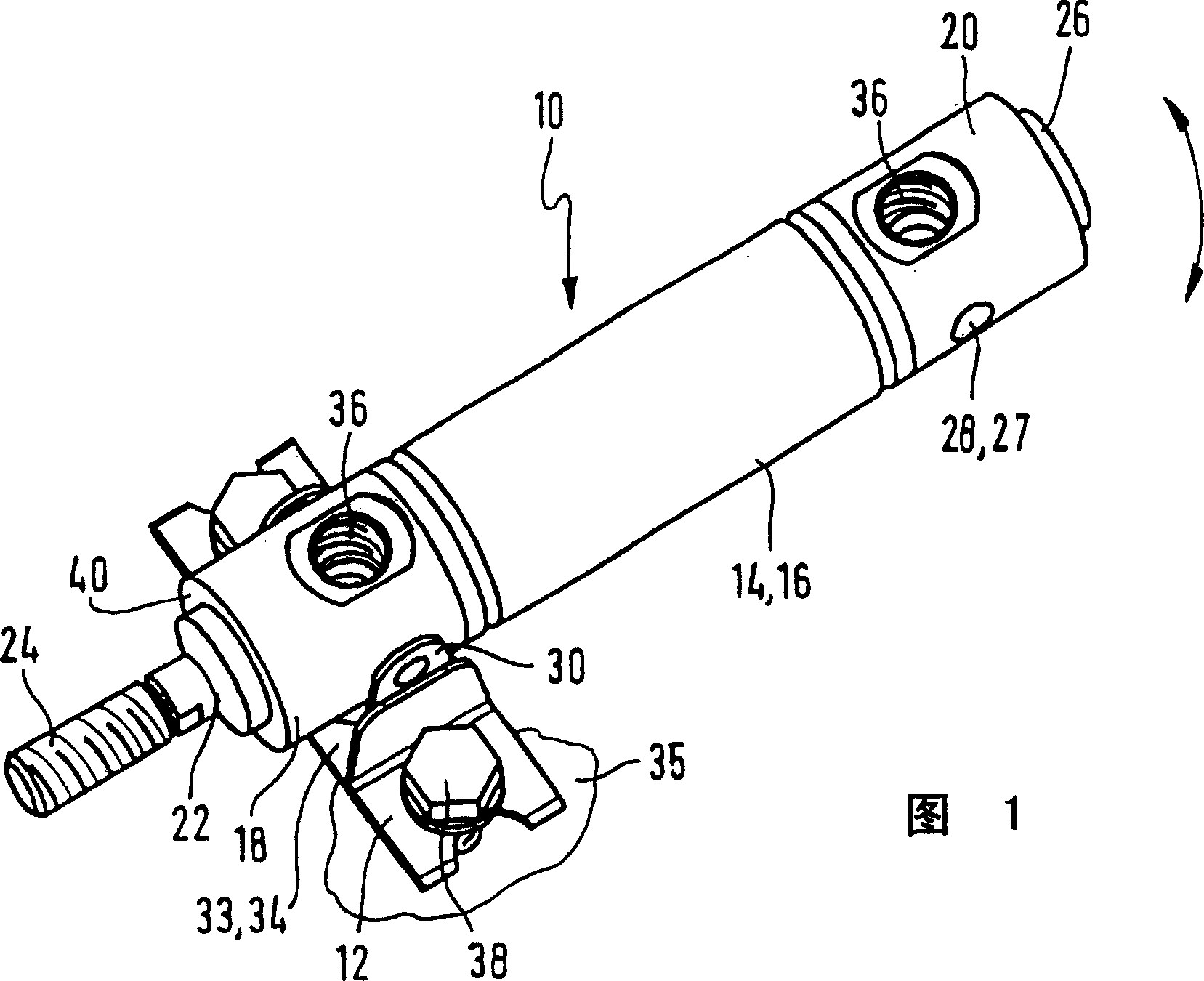

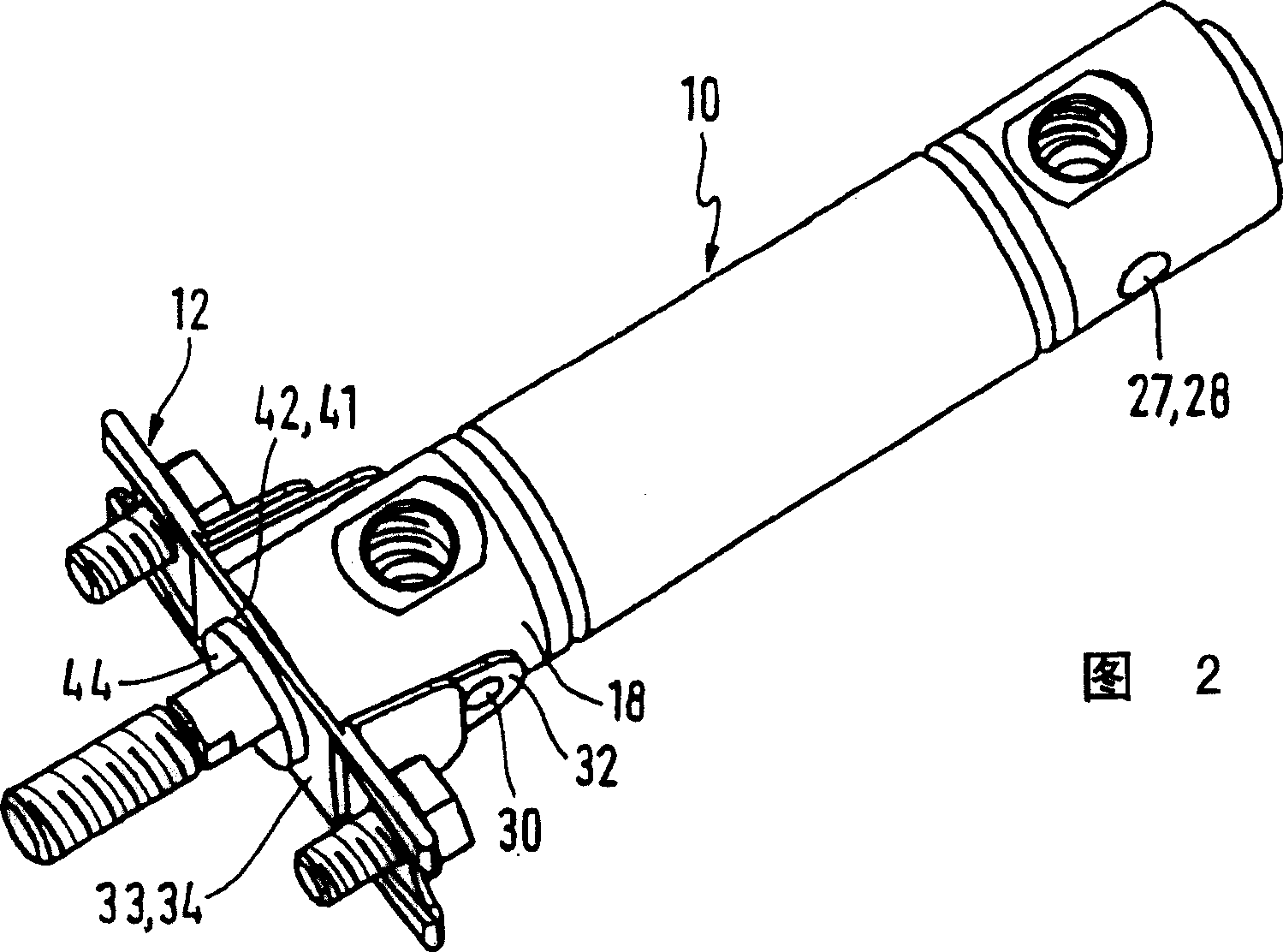

[0031] Figure 1 shows a working cylinder 10 which is supported on the side of a cylinder housing 14 by means of a fastening element 12 according to the invention. The working cylinder 10 mainly includes a cylinder liner 16 with cylinder heads 18 and 20 fastened on both ends. The cylinder heads 18 and 20 can be fastened to the cylinder liner 16 by screwing and / or pressing and / or by flanges, for example at the ends.

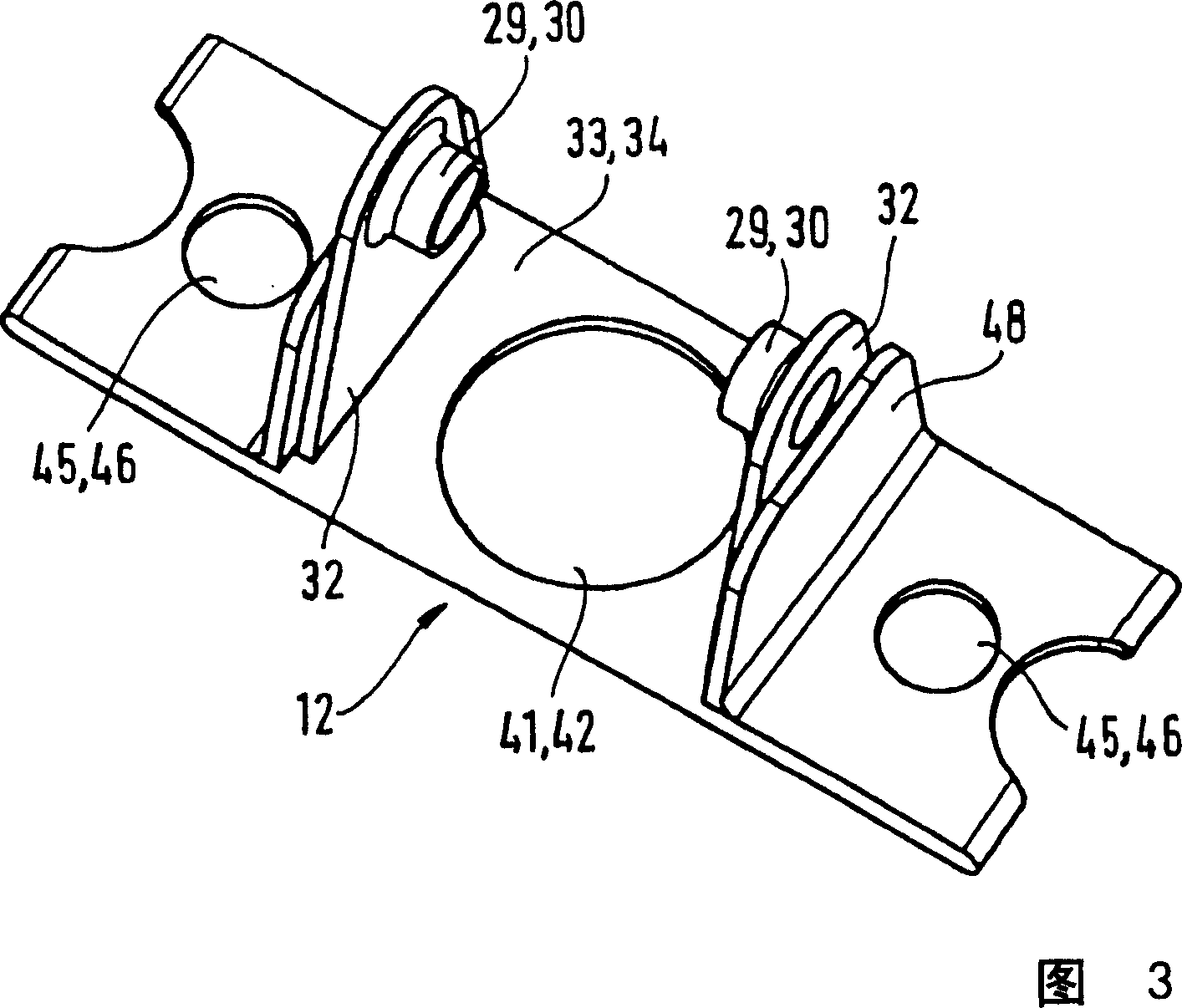

[0032]A front cylinder head 18 has a hollow cylindrical hole 22 for the piston rod 24 of the working cylinder 10 to pass therethrough. The working cylinder 10 has a one-way or two-way linear transmission function. For a rear cylinder head 20 of substantially the same design, the hole 22 is closed by a plug 26 screwed in or inserted in other ways. On the opposite sides of the cylindrical sides of the cylinder heads 18 and 20, a circular socket 28 serving as the first supporting device 27 can be seen, and the corresponding matching journal 30 can be assembled in it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com