Mining roadway frame style advanced support bracket

A technology of advanced support and mining roadway, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of easily damaged roadway roof bolt support, small support area, low operation efficiency, etc. Compact, supportive and mobile stable, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

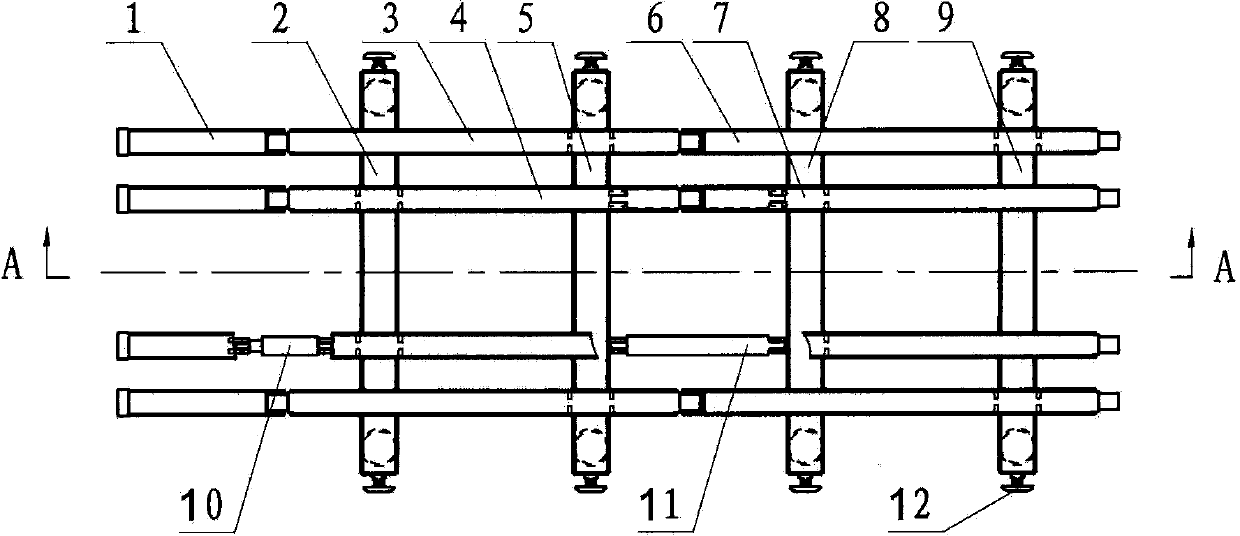

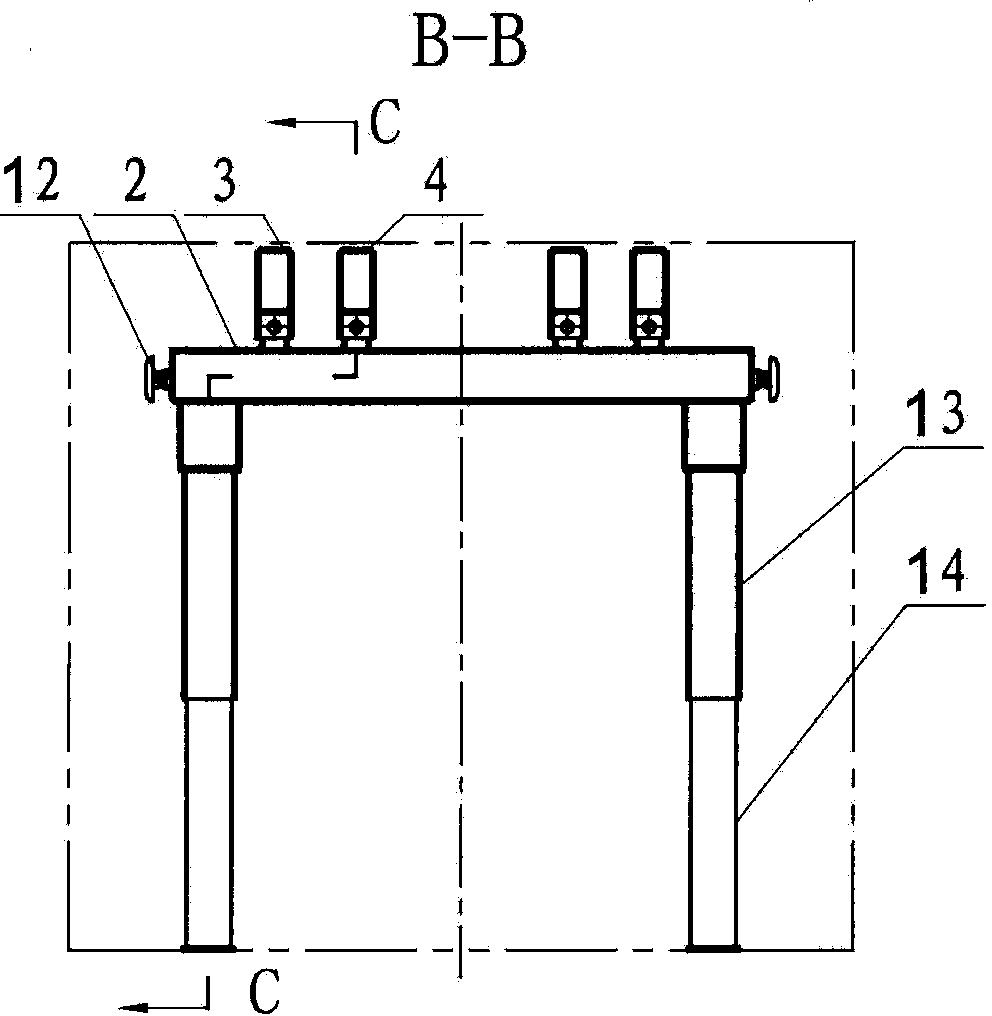

[0020] according to Figure 1~6 The specific structure of the present invention will be described in detail. The mining roadway frame-type advance support bracket includes components such as crossbeams assembled into frames, along beams, and hydraulic columns 14 as supports hinged at the bottom of the crossbeams. The frame is composed of two sets of integral main frames and auxiliary frames which move synchronously respectively.

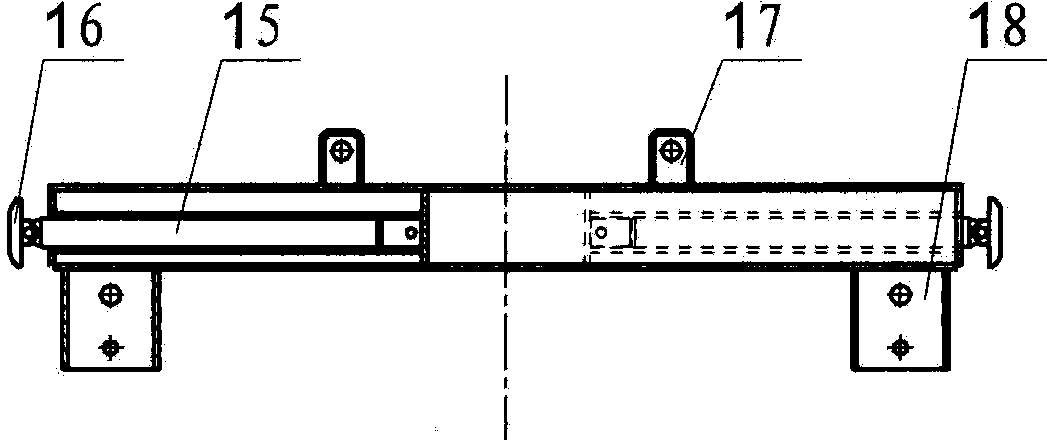

[0021] The main frame includes components such as the main front beam 5, the main rear beam 9, the hydraulic column 14, the main front beam 3 and the main rear beam 6. The main front crossbeam 5 and the main rear crossbeam 9 are provided with an upper connecting seat 17 and a lower connecting seat 18 respectively, and the bottoms of the main frontal beam 3 and the main rearward beam 6 are respectively provided with connecting ear plates 19 . Piston rod guard cover 13 tops that are hinged with the piston rod end of hydraulic column 14 tops are hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com