Rib plate type retaining wall and construction method thereof

A technology of retaining walls and ribs, which is applied in construction, underwater structures, infrastructure engineering, etc., can solve problems such as uneconomical, self-heavy, and large wall sectional volume, so as to reduce the workload of excavation, The effect of reducing the amount of temporary support works and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

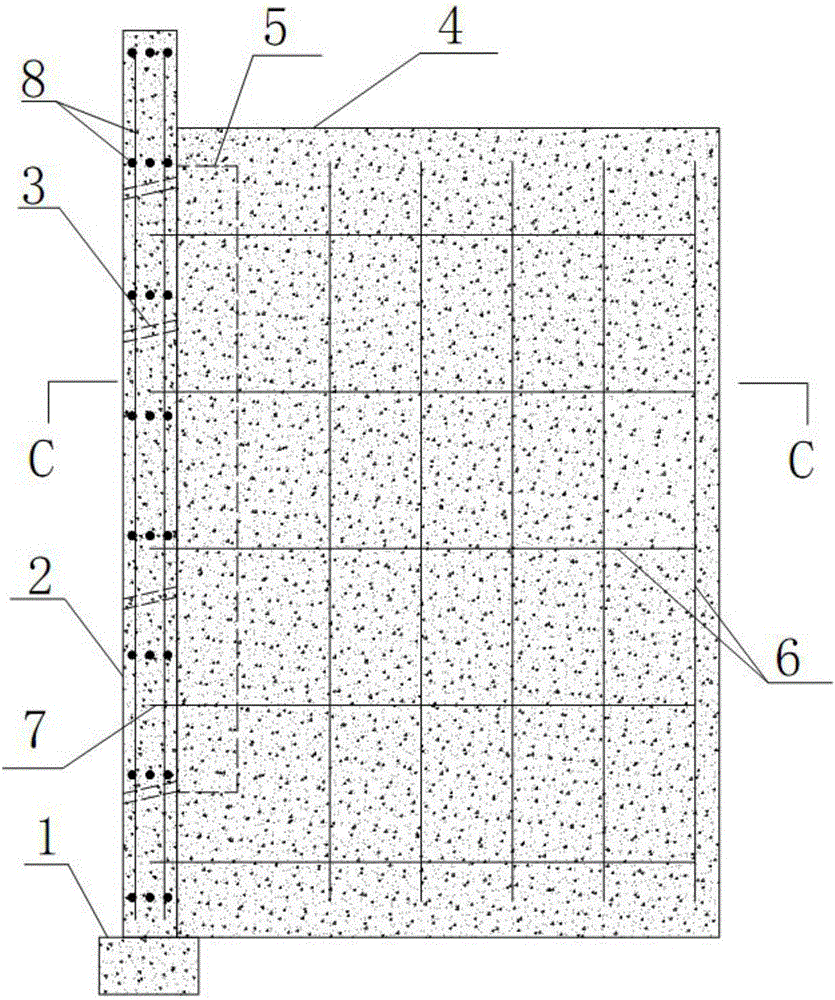

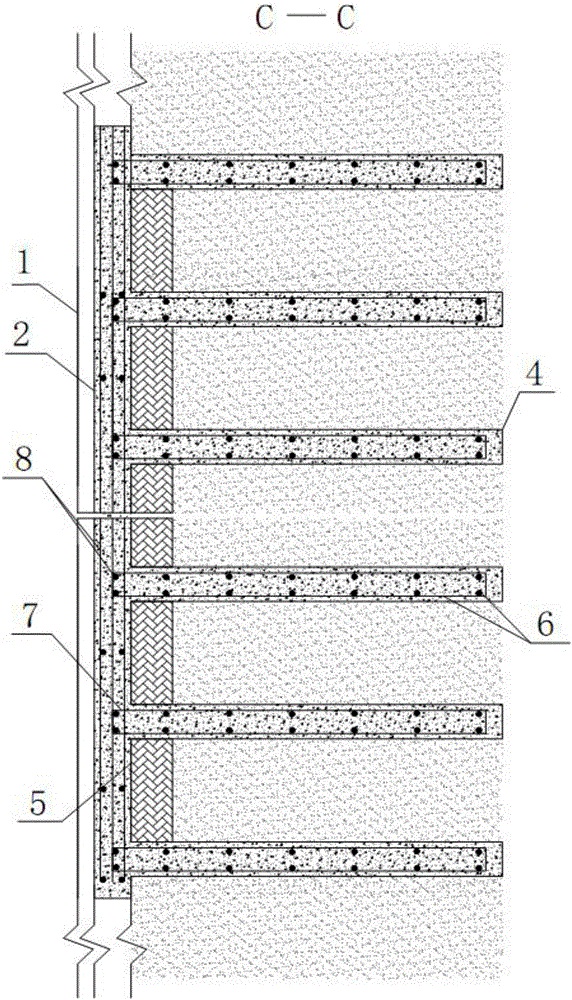

[0024] figure 1 , figure 2 It is shown that a specific embodiment of the present invention is a ribbed retaining wall, comprising a foundation 1, a wall panel 2 on the foundation 1, and a drain hole 3 on the wall panel 2, and its structural characteristics are as follows: The wall panel 2 facing the soil surface is consolidated with vertical ribs 4 at equal intervals, and the part of the wall panel 2 facing the soil surface between the ribs 4 is provided with an anti-filter layer 5 .

[0025] A construction method of the ribbed retaining wall of this example, the steps are:

[0026] a. Excavate a vertical groove matching the rib plate 4 in the slope soil body;

[0027] b. Bind the rib plate steel bar 6 in the vertical groove of step a and reserve the connecting steel bar 7 connecting the wall panel, then pour concrete in the vertical groove to form the rib plate 4 of the exposed connecting steel bar 7;

[0028] c. Excavate the foundation groove of the wall panel 2, and bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com