Housing, in particular outer housing for low-pressure steam turbine

A technology for steam turbines and outer casings, applied in mechanical equipment, engine components, engine manufacturing, etc., can solve problems such as high assembly costs and high costs, and achieve the effects of low-cost manufacturing and assembly, reduced complexity, and fast costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

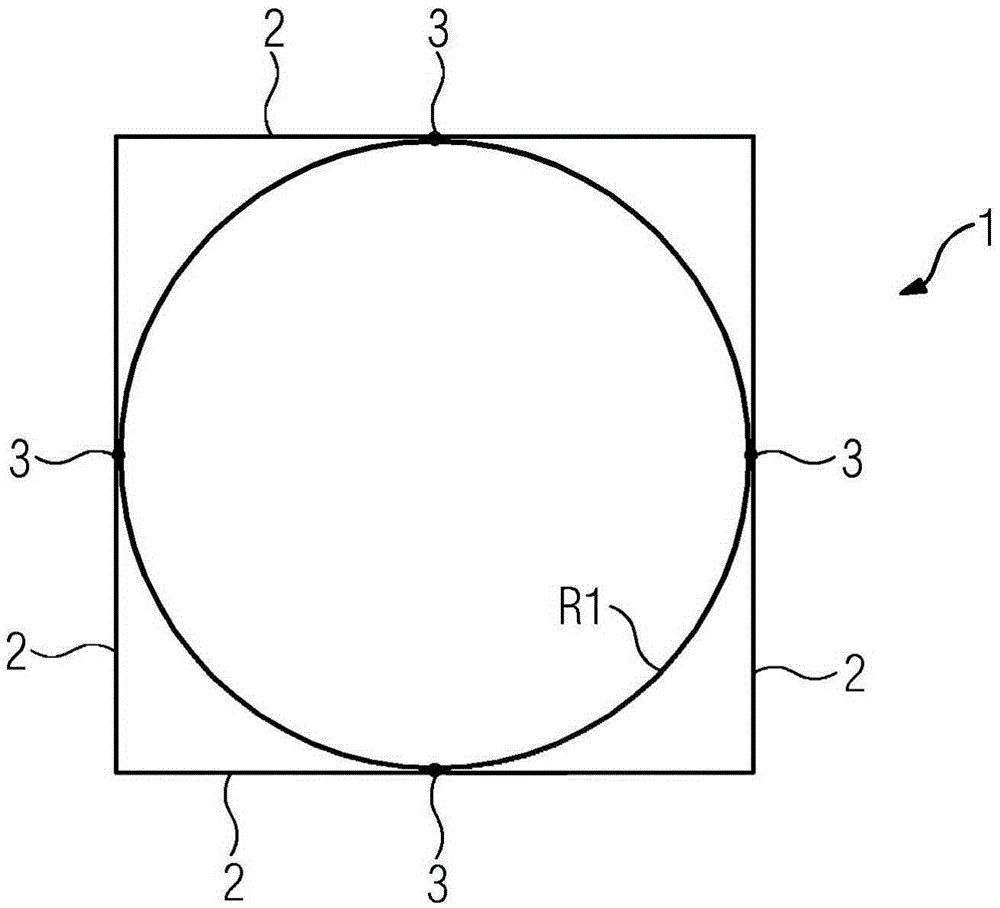

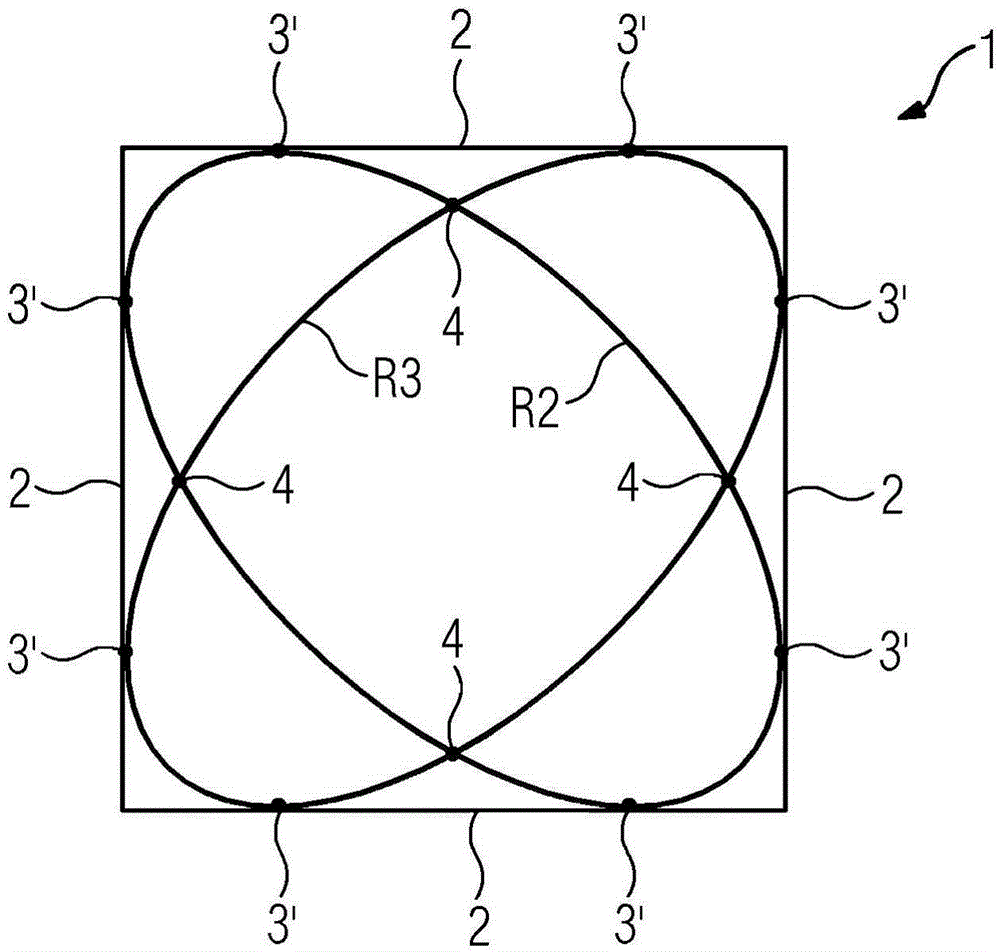

[0013] figure 1 A plan view of the lower part 1 of the housing of the welded condenser with the low-pressure steam turbine is shown. The large-area lateral panel walls 2 on the bottom of the rectangle—here a square—delimit the volume of the lower part and together with the upper part form the housing of the low-pressure steam turbine. The four side panel walls 2 are welded to each other and to the base plate at their respective edges. The panel wall 2 itself does not have sufficient inherent stiffness due to its large-area sheet metal construction. As a result, indentations can occur due to large pressure differences between the environment and the non-metallic volume, so that safe operation of the low-pressure steam turbine is no longer guaranteed.

[0014] According to the invention, therefore, an annular reinforcement element R1 is provided for the reinforcement of a large-area panel wall, which at the same time also has the simplest possible construction and low costs an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com