First intermediate roll swing arm type bracket system of twenty-high roll mill

A 20-high rolling mill and 20-high rolling technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of difficult assembly and debugging, big drawbacks, long time for roll change, etc. Fast and efficient roll change, easy operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

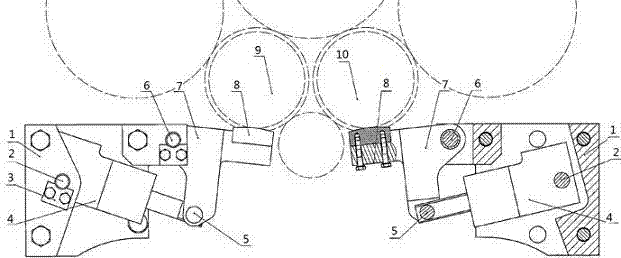

[0017] This embodiment provides a swing-arm bracket system for the first intermediate roll of a 20-high rolling mill, which consists of two swing-arm brackets that are vertically symmetrical about the center of the 20-high rolling mill and arranged under the two first intermediate rolls device composition;

[0018] The swing arm bracket device includes a swing arm bracket 7 arranged below the first intermediate roller, a fixed bracket 1 connected to the swing arm bracket 7 through a swing arm hinge shaft 6, and the fixed bracket 1 is arranged on the twenty-roller On the transmission side of the press frame, the fixed bracket 1 is provided with a swing arm cylinder 4, the tail of the swing arm cylinder 4 is hingedly mounted on the fixed bracket 1 through the cylinder hinge shaft 2, and the rod end of the swing arm cylinder 4 passes through the cylinder rod The connecting shaft 5 is hinged with the swing arm bracket 7 .

[0019] The implementation process of this embodiment:

...

Embodiment 2

[0022] On the basis of Embodiment 1, a lock plate 3 is provided at one end of the cylinder hinge shaft 2 of the swing arm oil cylinder 4, which can realize axial limit. A cushion block 8 is provided at the junction of the swing arm bracket 7 and the first intermediate roller, so that the cushion block 8 directly contacts the left first intermediate roller 9 and the right first intermediate roller 10 to avoid wear of the two first intermediate rollers .

Embodiment 3

[0024] This embodiment provides a figure 1 In the swing arm bracket system of the first intermediate roller of the twenty-roller press shown, a swing arm bracket 7 is arranged under each first intermediate roll, and a spacer 8 is fixedly installed on each swing arm bracket 7. The spacer 8 is in direct contact with the first left middle roller 9 and the first right middle roller 10, the swing arm bracket 7 is hinged with the rod end of the swing arm oil cylinder 4, and the stretching of the oil cylinder rod drives the swing arm bracket 7 to swing around the swing arm hinge shaft 6 , the tail of the swing arm oil cylinder 4 is hingedly mounted on the fixed bracket 1 through the cylinder hinge shaft 2, and one end of the cylinder hinge shaft 2 has a lock plate 3 axially limited, and the fixed bracket 1 is fixedly installed on the transmission side of the rolling mill frame. The first left middle roller 9 and the first right middle roller 10 are each supported by the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com