Balancing shaft

A technology for balancing shafts and balancing weights, applied in the field of balancing shafts, can solve problems such as the reduction of motion quality, and achieve the effect of improving operation stability and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

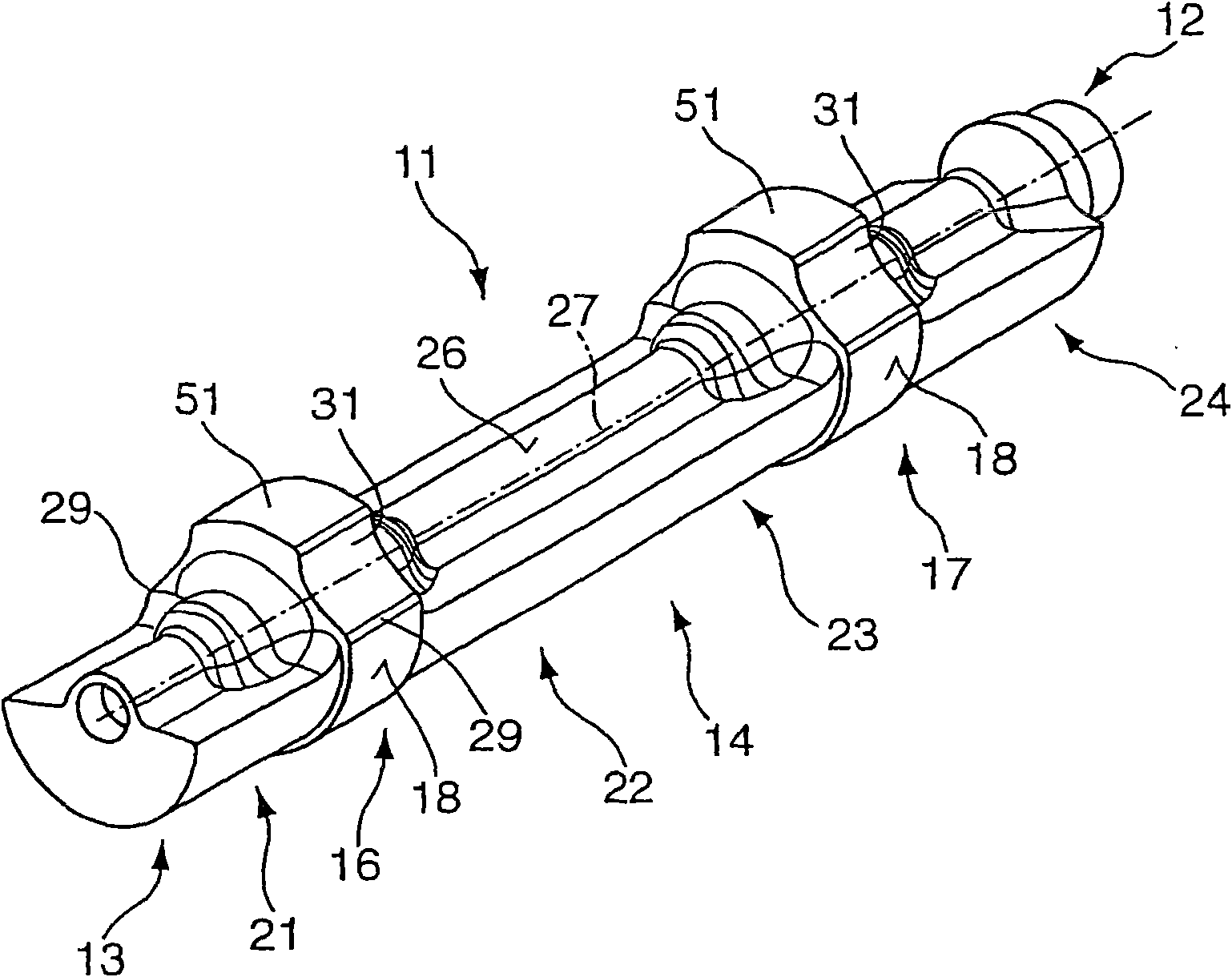

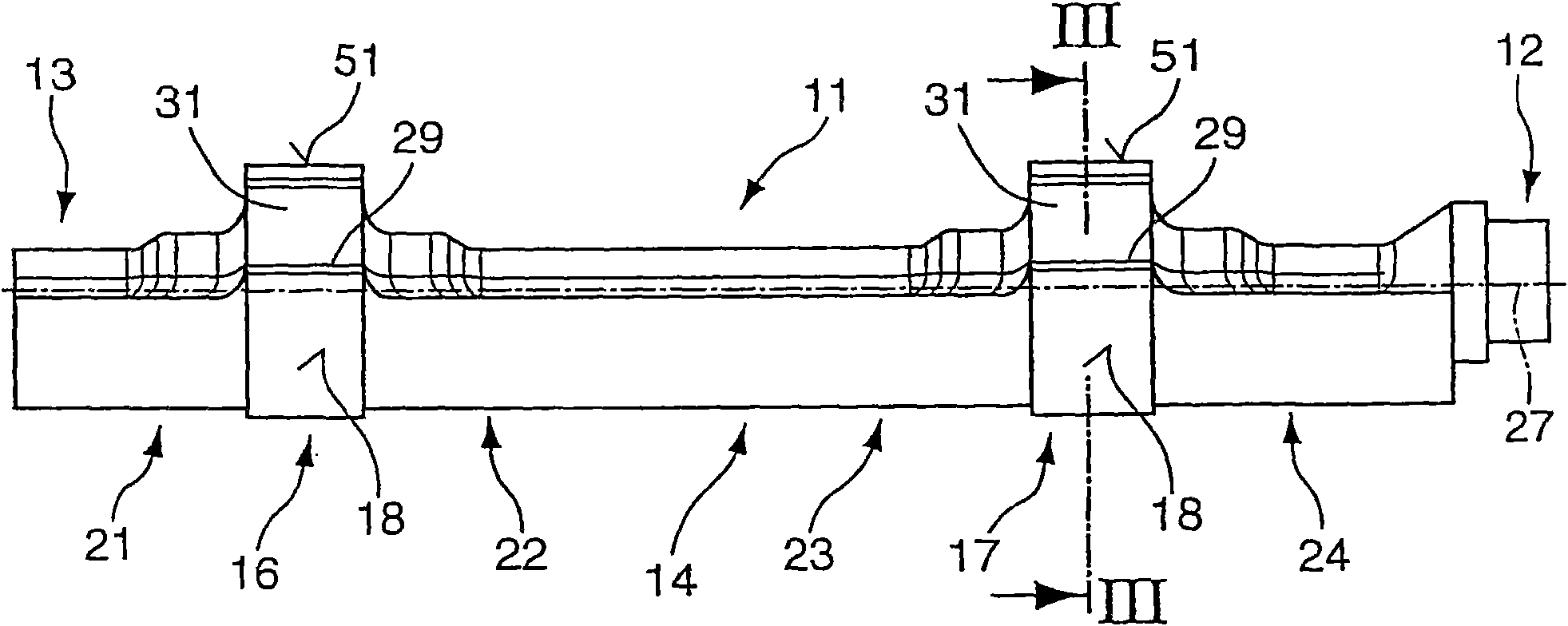

[0044] figure 1 A first embodiment of the balancing shaft 11 according to the invention is shown in perspective in the middle. Such a balancing shaft 11 is provided, for example, for a multi-cylinder engine and serves to balance second-order inertial forces. Usually two balancing shafts are arranged offset relative to each other, which then rotate counter to each other at double the engine speed.

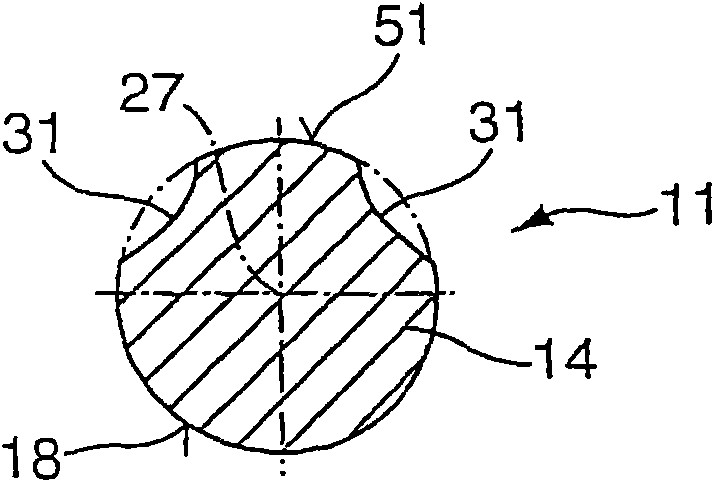

[0045] exist figure 1 On the rear end section 12 shown in , the balancing shaft 11 is provided with a drive (not shown in detail), for example a sprocket, which drives the balancing shaft 11 . This end section 12 can form a fixed bearing for the balancing shaft 11 . The balancing shaft 11 comprises a base body 14 on which first and second bearing points 16 , 17 are arranged. These bearing points serve to support the balancing shaft 11 in the engine block. The bearing points 16 , 17 have a running surface 18 whose boundary length is designed to be greater than the boundary lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com