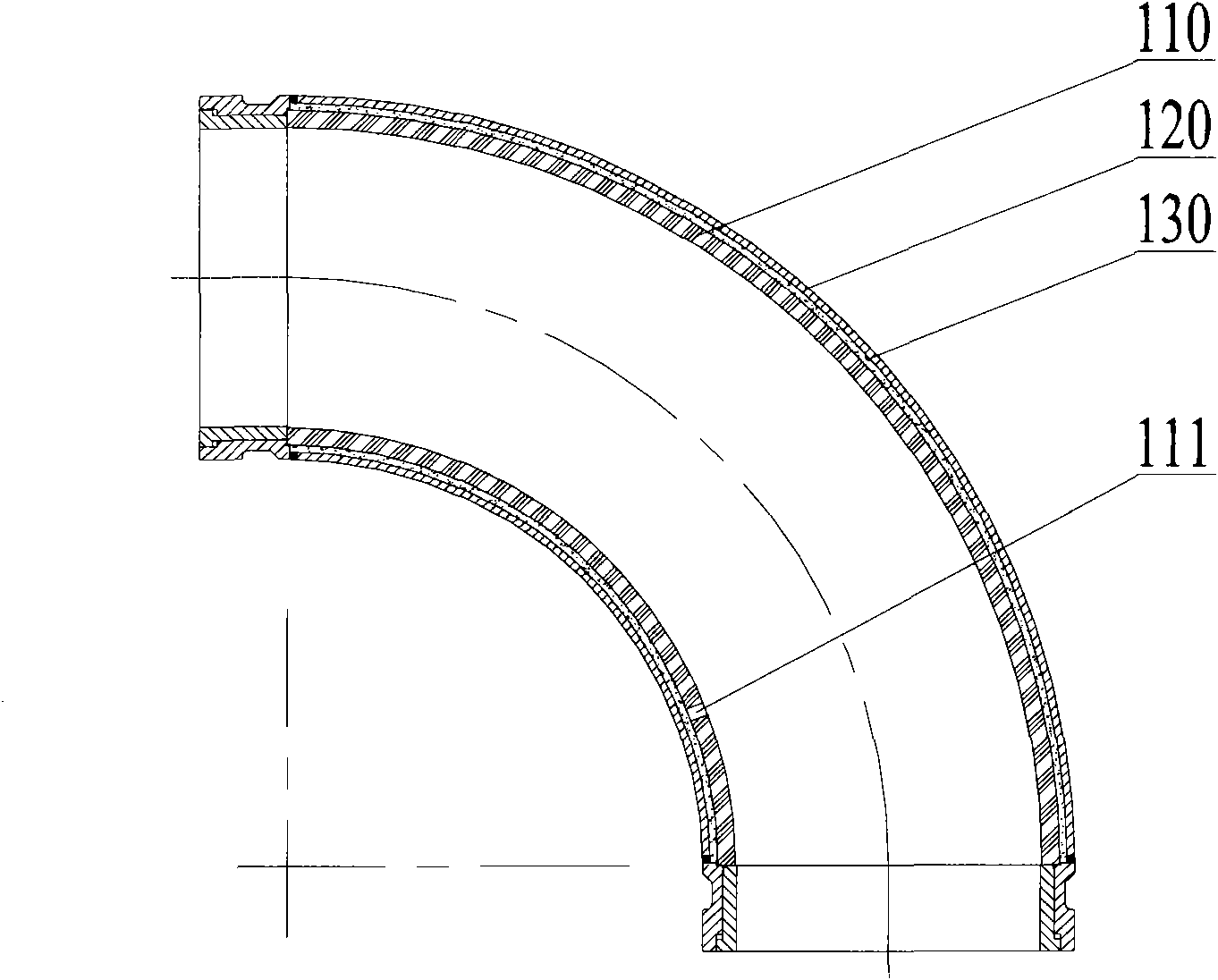

Conveying bent pipe, concrete conveyer and manufacturing method of same

A technology of bending pipes and inner pipes, which is applied in the production field of concrete conveying machinery and conveying curved pipes. It can solve the problems of heavy weight of filling layer 130, high manufacturing cost, and increased use cost of bending pipes, so as to reduce manufacturing cost and use cost. , reduce production costs, reduce the effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

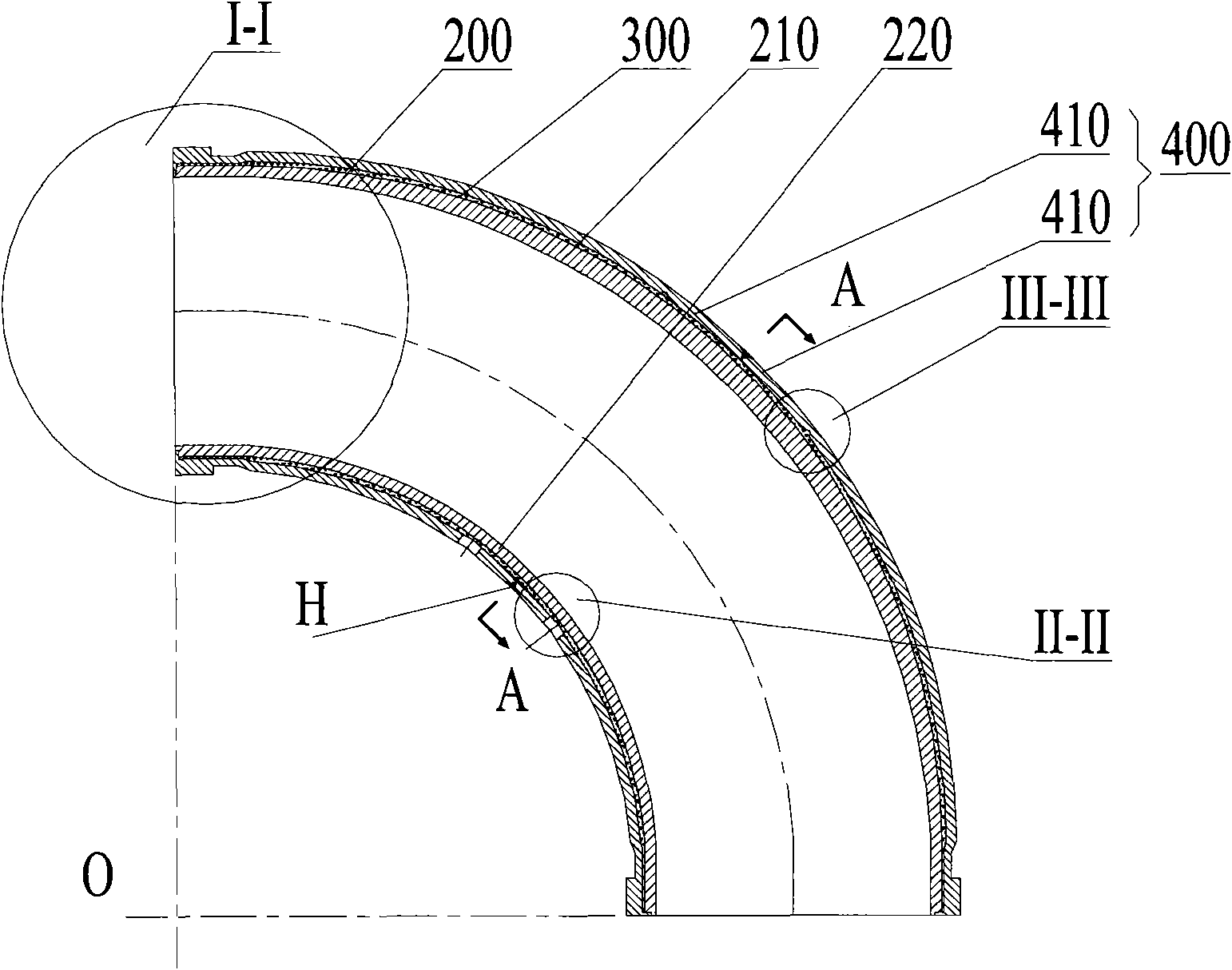

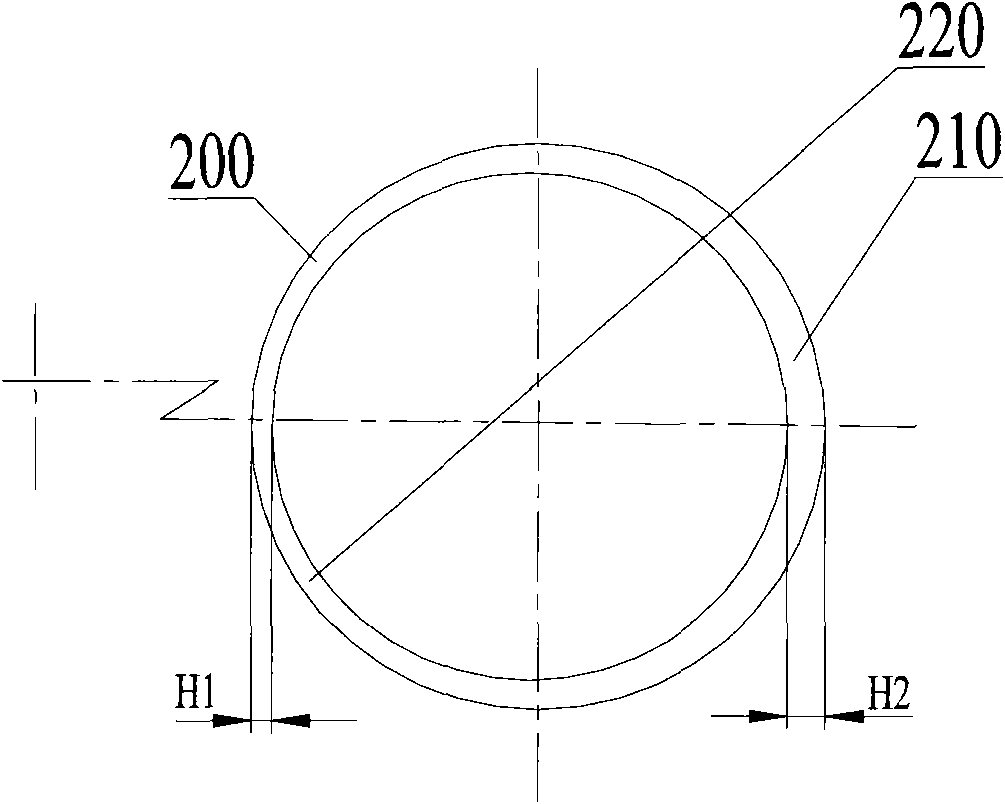

[0056] In the first embodiment, the outer tube 400 of the conveying elbow includes two support tubes 410. Therefore, during installation, the support tube 410 can be easily sleeved outside the inner tube 200 to form the outer tube 400 to realize the conveying bend. Manufacturing of the tube; since the two support tubes 410 can be respectively sheathed outside the inner tube 200 from both ends, the outline dimension of the middle part of the outer surface of the inner tube 200 may be larger, and may not be parallel to its inner surface, so that the inner Each part of the pipe wall of the pipe 200 has different thicknesses, so as to conform to the wear rule of the inner pipe 200 and realize the equal life design of the inner pipe 200 .

[0057] Making each part of the inner pipe 200 have different thicknesses, the realization of the equal-life design mainly includes two aspects, one is the design of unequal thickness of the radial pipe wall; the other is the pipe wall thickness a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com