Telescopic protective covering

A technology for a protective cover and a cover segment, which is applied in the field of protective covers, can solve the problems of high cost and cost-intensive manufacturing of protective covers, and achieve a simple method and the effect of supporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

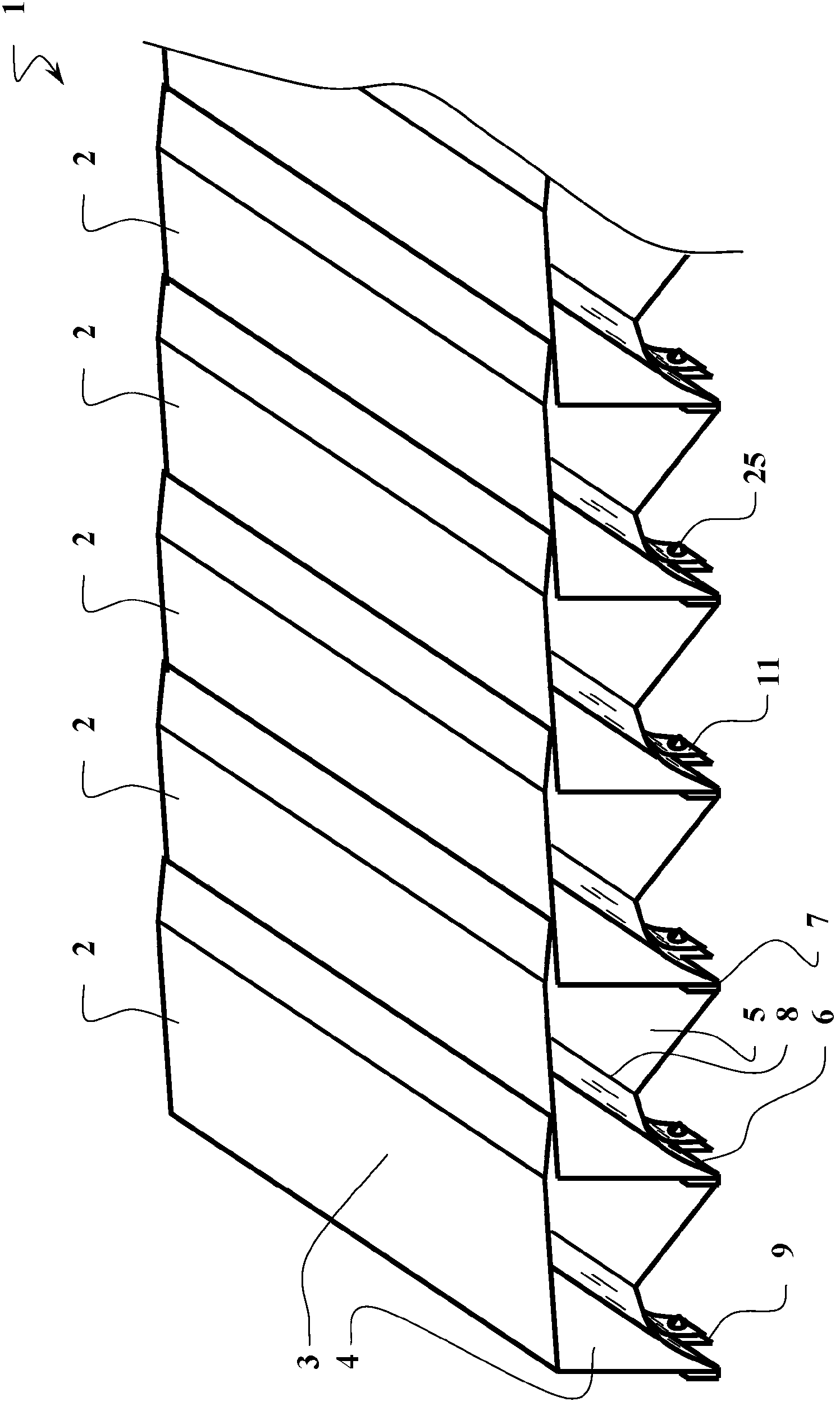

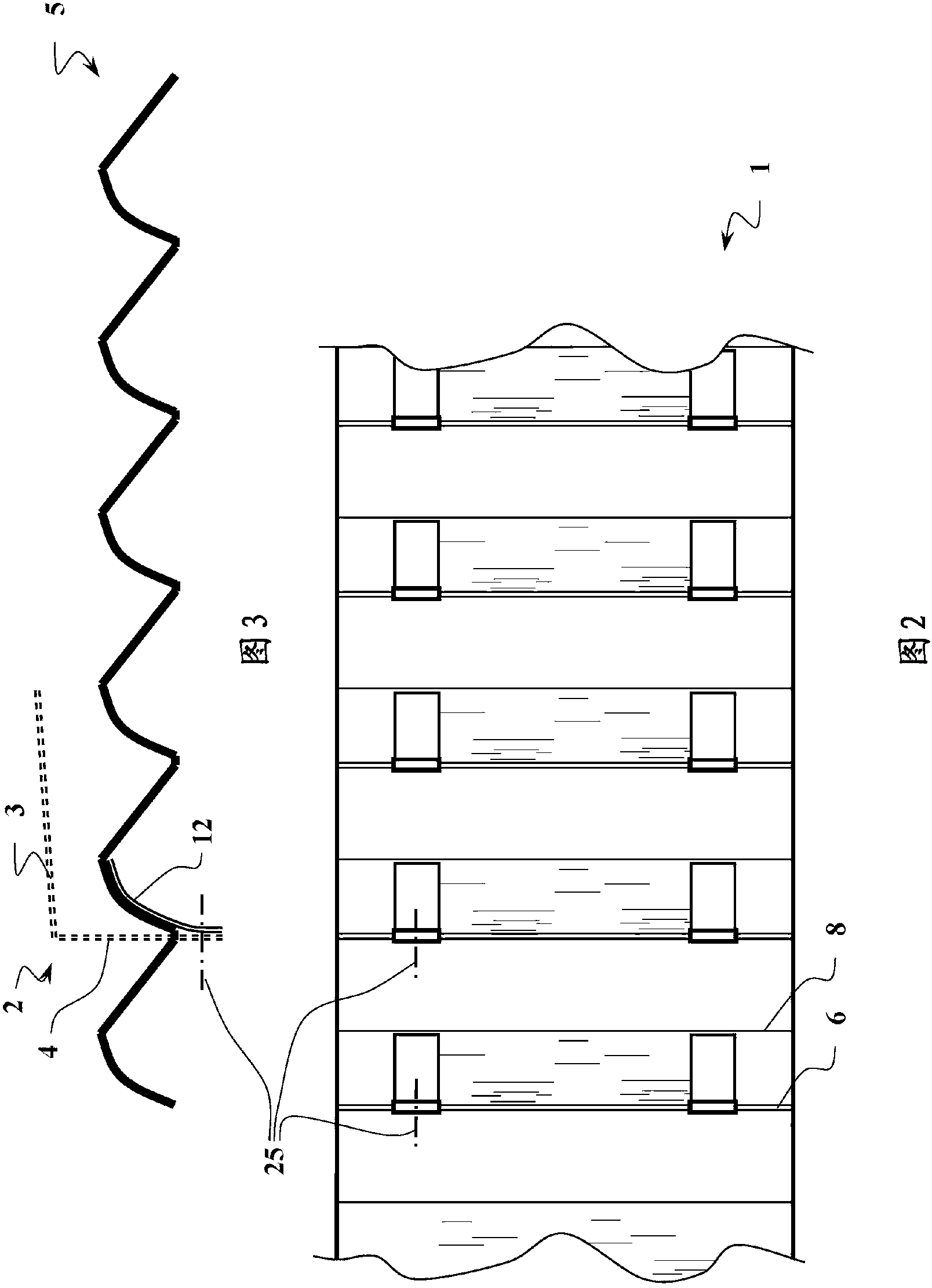

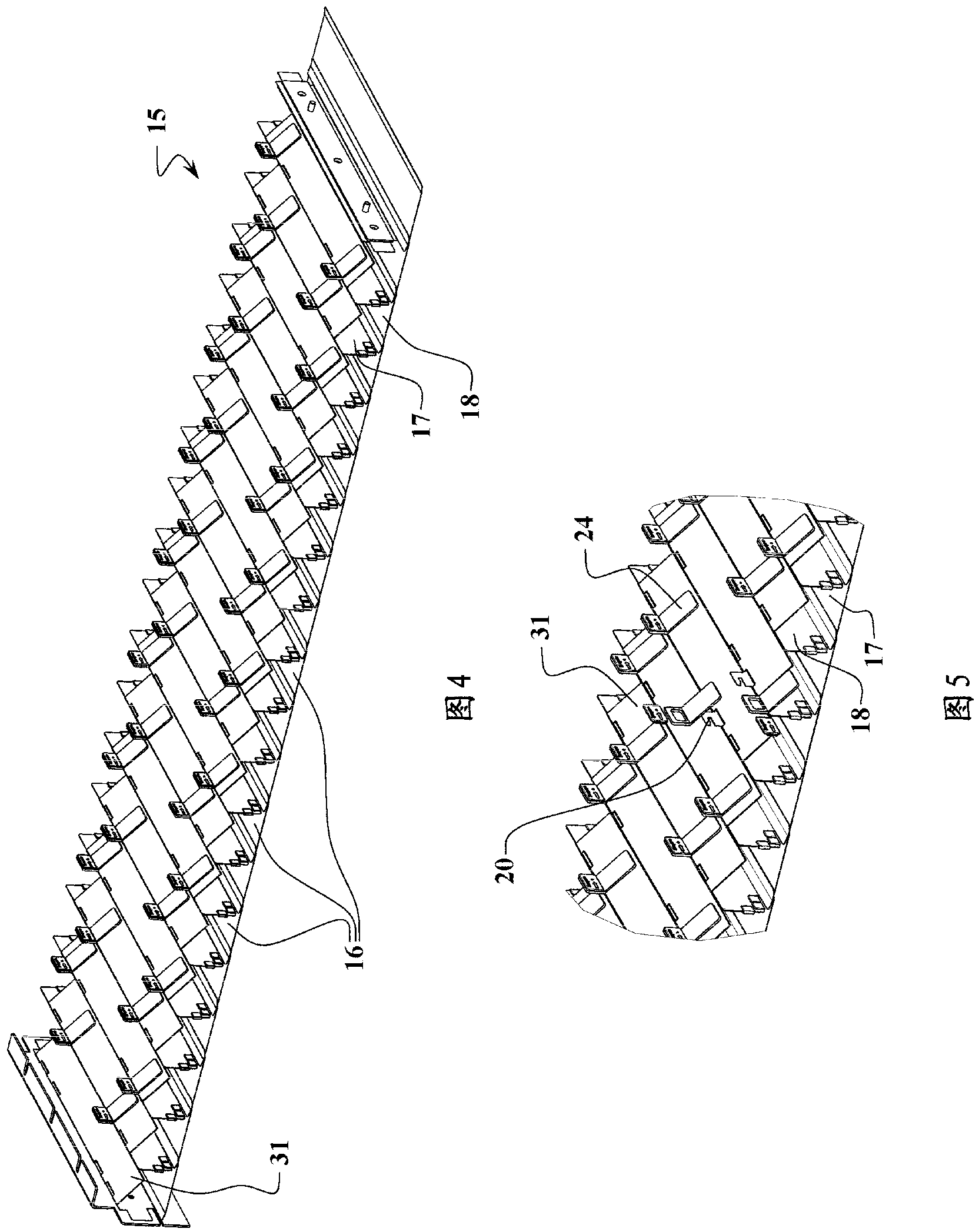

[0039] exist figure 1 The protective hood 1 shown in has a plurality of protective hood segments 2 , which are produced from sheet metal, for example stainless steel. The protective hood segments 2 are each substantially L-shaped and each have a covering leg 3 and a supporting leg 4 . In this case, the protective hood segments 2 are arranged relative to one another in such a way that they can be moved telescopically relative to one another, wherein the covering legs 3 of adjacent protective hood segments 2 correspondingly form an overall substantially closed surface. lean against each other.

[0040] In the illustrated embodiment, the boot segments 2 are connected via flexible connecting elements 5 in the form of rails made of an inherently rigid plastic material, in particular polypropylene (PP), so that in the event of a tensile load, The protective hood segments 2 move when the protective hood 1 is lengthened or shortened, wherein the connecting element 5 simultaneously s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com