Internal combustion engine with a lubricating, cooling and starting system

A technology of lubricating system and cooling system, applied in the field of internal combustion engine, can solve the problems of prolonged assembly time, troublesome pre-installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

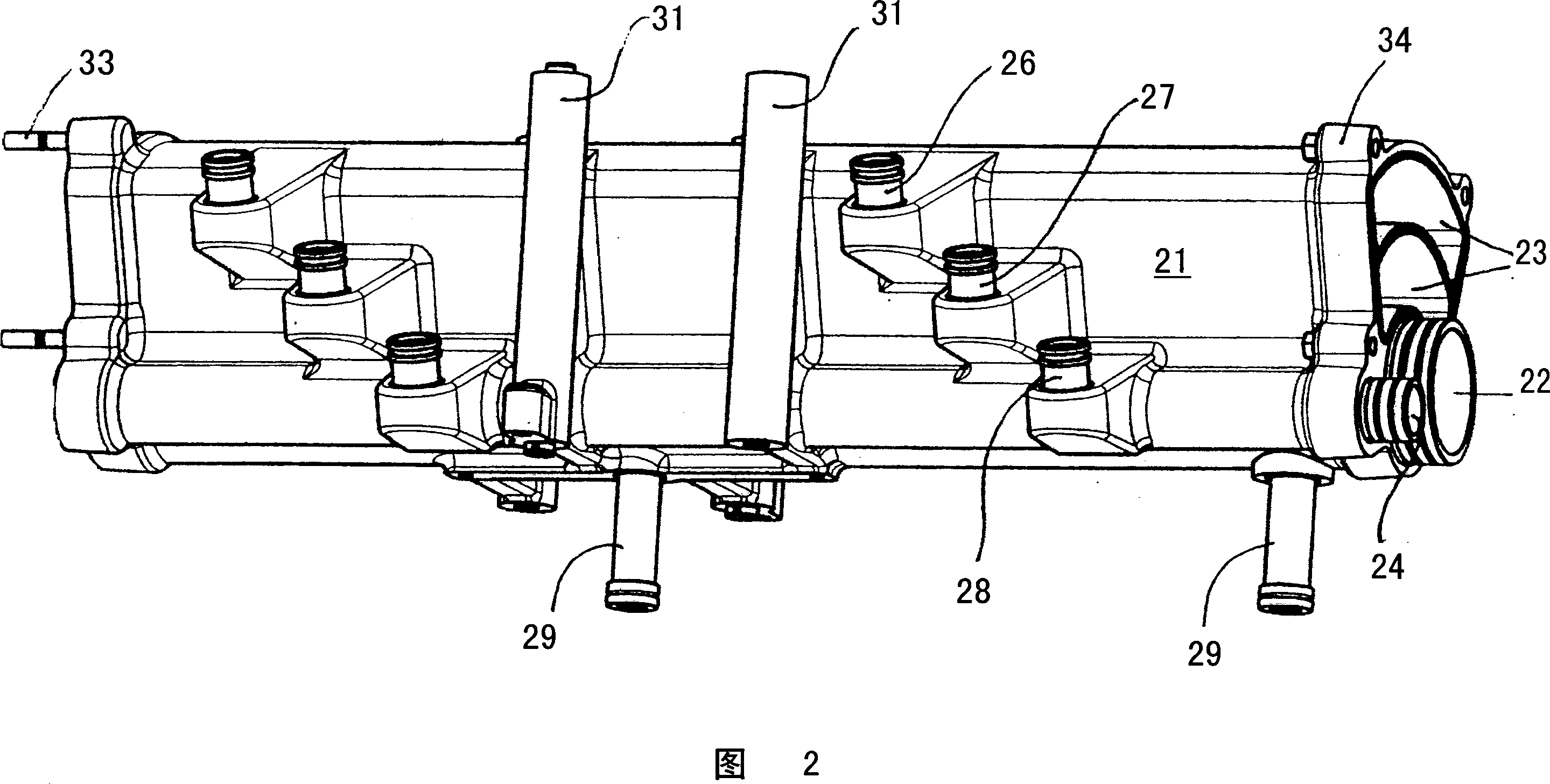

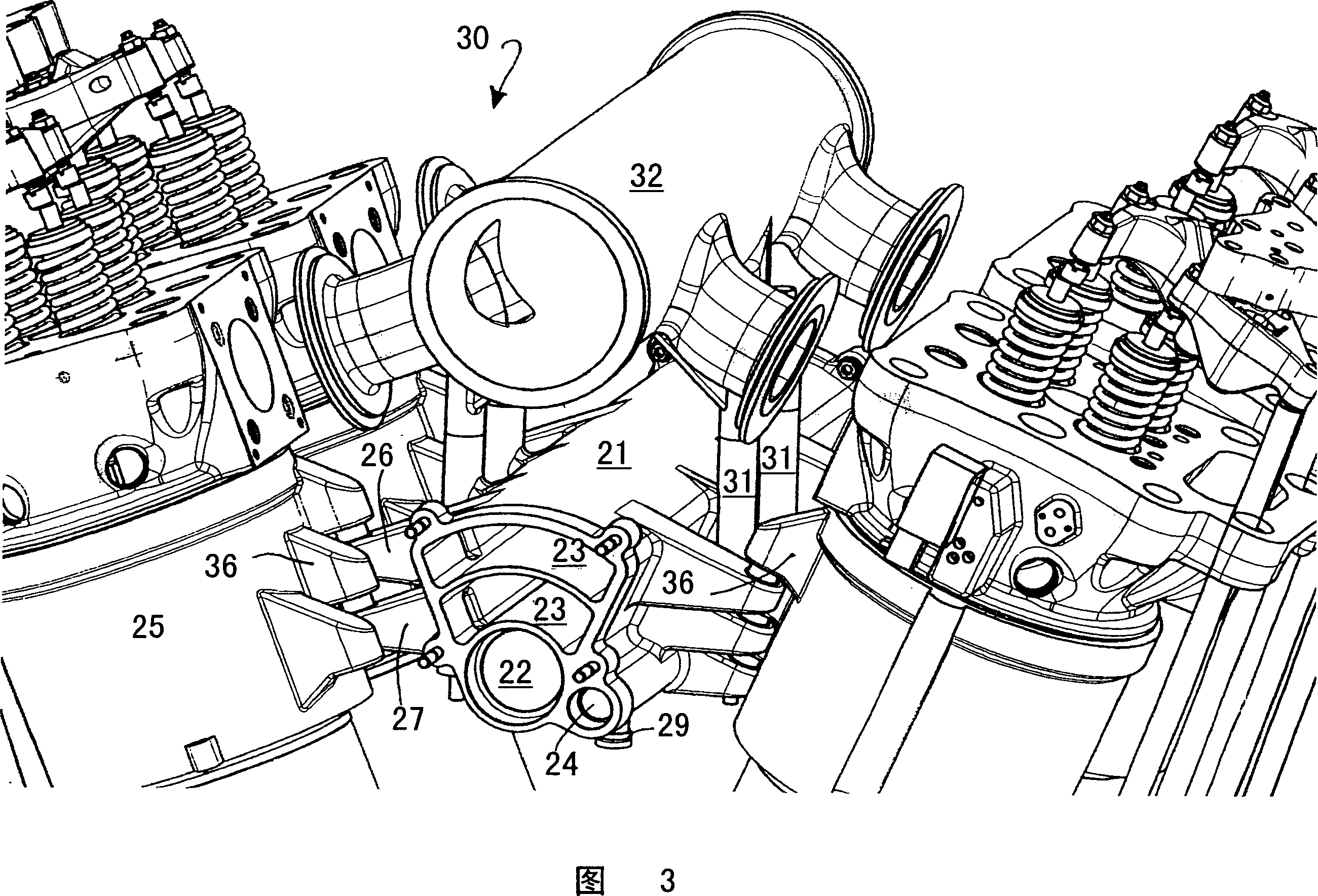

[0020] Corresponding parts are identified with the same reference numerals in FIGS. 2 and 3 .

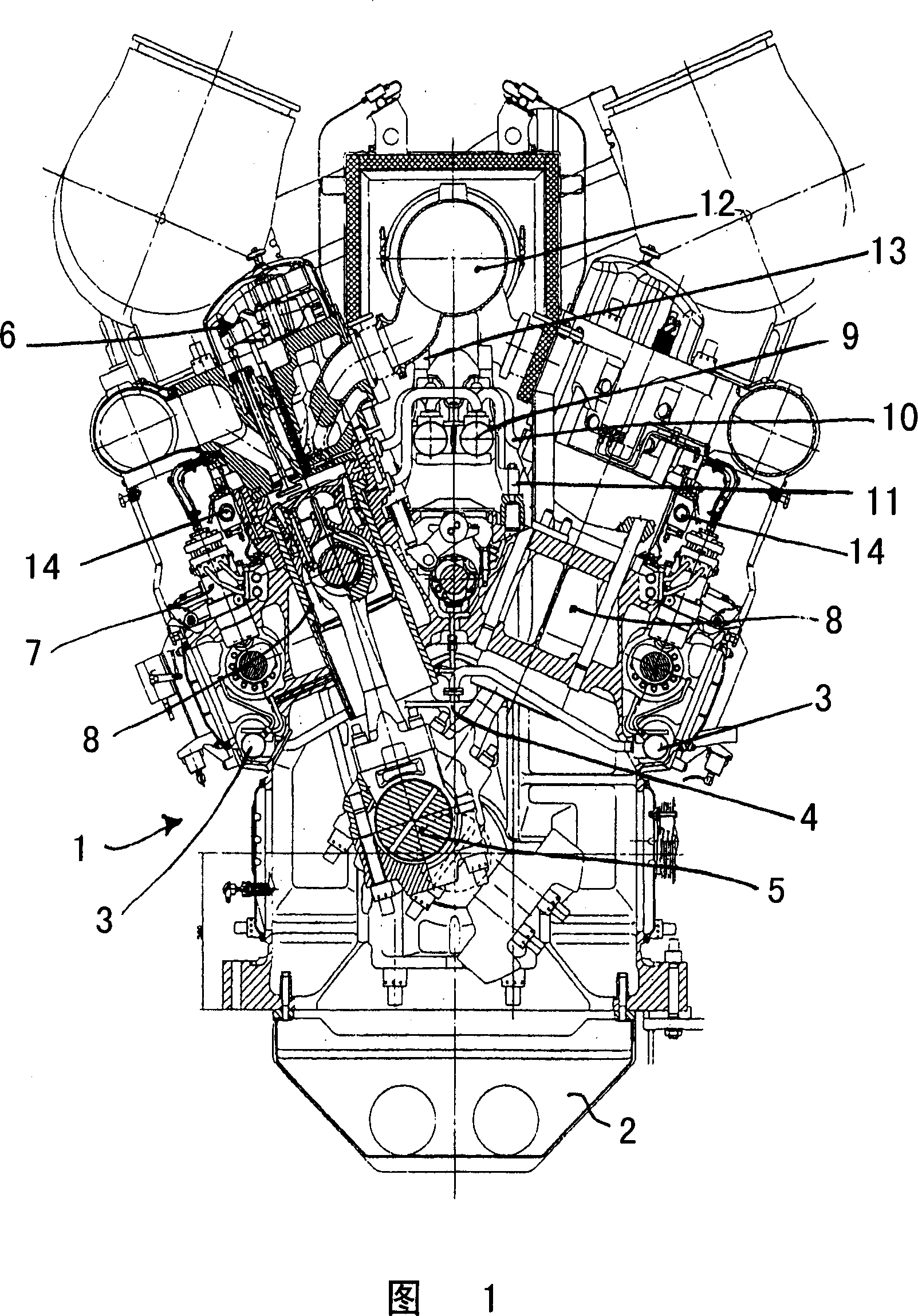

[0021] FIG. 1 shows a V-shaped engine, wherein the engine block 1 has an oil sump 2 in the lower part. Lubricating oil distribution lines 3 are provided along both outer sides of the engine block 1 , from which branch lines 4 for oil supply to the crankshaft 5 lead off.

[0022] A lubricating oil pump, not shown here, delivers the oil from a reserve oil tank in a known manner into the distribution line 3, from which branch pipes 4 lead to each crankshaft bearing and to the oil perforations in the crankshaft 5. to the position to be lubricated.

[0023] In addition, oil flows from distribution line 3 to valve drive 6 and to the roller tappets of fuel injection pump 7 .

[0024] Between the cylinders 8 of the V-engine, the inflow and outflow are arranged in the form of distribution lines 9 of the cooling system. The branch 10 leads to the internal duct of the engine block 1 in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com