Method for cooling a hot strip wound to a hot strip bundle, a device for cooling a hot strip, a control and/or regulating device, and metal strip

A hot-rolled strip and driving device technology, applied in the direction of workpiece cooling devices, metal rolling, forging and pressing devices, etc., can solve the problem of reducing the cooling rate of the outermost layer of hot-rolled strip coils, so as to achieve deviation, reduce Bias, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

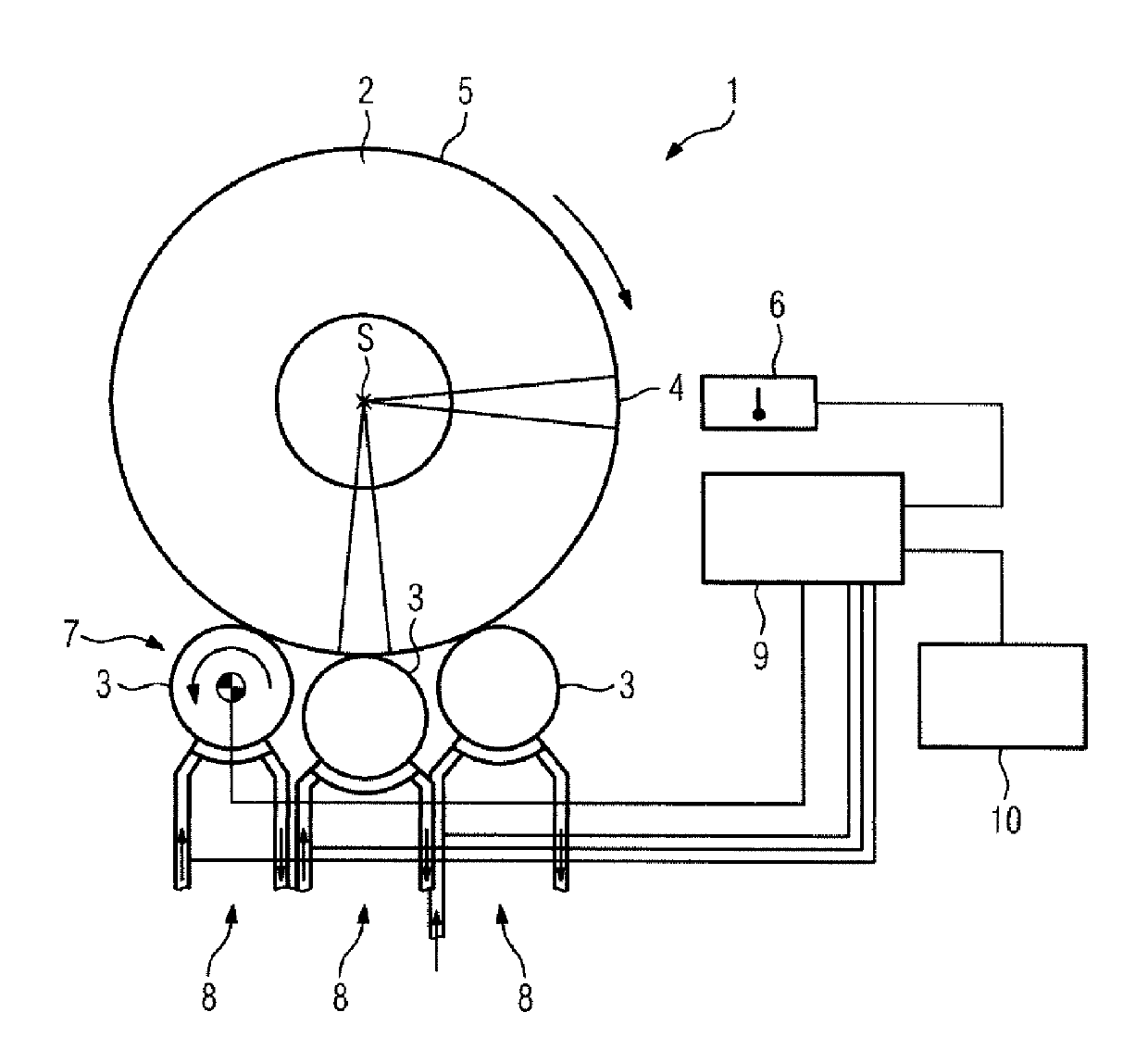

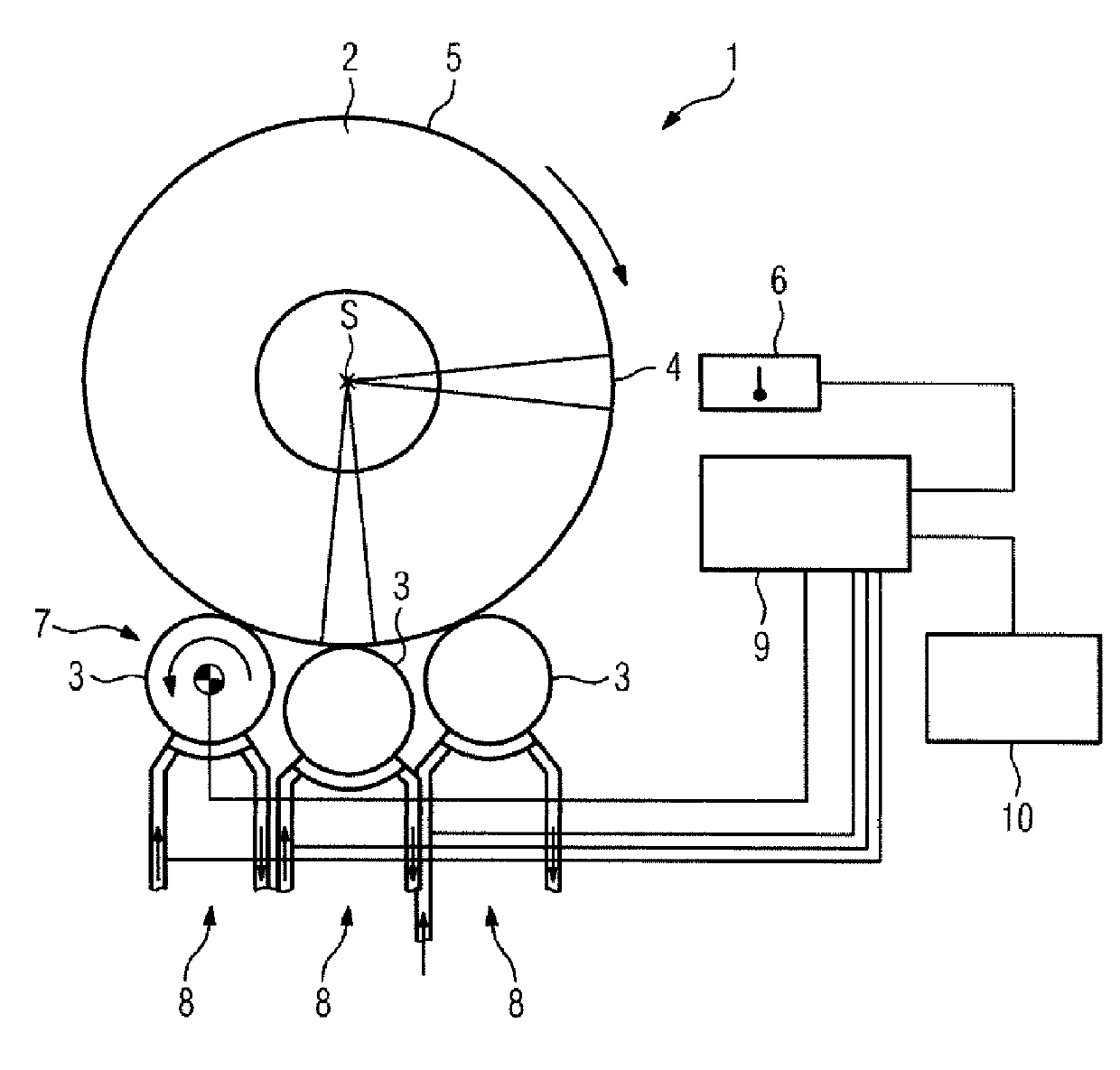

[0027] figure 1 A hot-rolled strip coil 1 consisting of a coiled hot-rolled strip 2 is shown. The hot strip coil 1 has an axis S of symmetry. The axis of symmetry S runs perpendicular to the plane of the drawing through the center of the hot-rolled strip coil 1 .

[0028] The hot strip coil 1 is supported on three movable rollers. exist figure 1 One of these rollers is configured as drive roller 7 . The other two rollers are designed as passive, rotatably mounted support rollers 3 . Both the drive roll 7 and the other two support rolls 3 are solid elements which are in contact with a part of the side face 5 of the hot strip coil 1 . The hot strip coil 1 can be rotated about its axis of symmetry S by means of the drive roll 7 . Roller 3 or 7 is designed such that its side height is at least as large as the side height of hot-rolled strip coil 1 in the exemplary embodiment, that is to say said roller is on the side face 5 of hot-rolled strip coil 1 on the whole side height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com