Noise measuring system for engine accessory system in hemi-anechoic room

An accessory system and noise testing technology, applied to vibration measurement in solids, measuring vibration, measuring devices, etc., can solve the problems of high cost of noise test bench, interference of noise test results, long cycle, etc., and achieve accurate and reliable test results , low cost and short implementation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

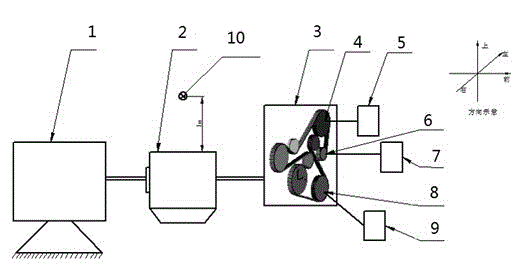

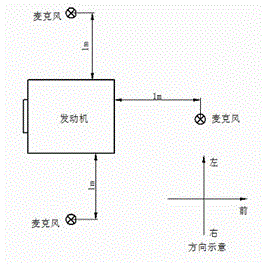

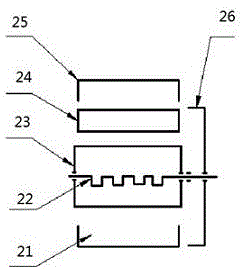

[0025] Combine below Figure 1 to Figure 3 , the present invention is further described:

[0026] Such as figure 1 As shown, the accessory system 3 is normally installed on the test engine 2, the cooling water pipeline on the engine is normally installed, and the test engine 2 is normally installed on the bench in the semi-anechoic chamber. The test engine 2 is driven by the dynamometer 1 through the transmission shaft, and the test engine 2 drives the accessory system 3 to work through the crankshaft pulley and the accessory belt. The power steering pump load 5 is applied to the power steering pump 4 in the accessory system 3, the generator load 7 is applied to the generator 6 in the accessory system 3, and the air compressor load 9 is applied to the air compressor 8 in the accessory system 3 superior. The rotation speed of the dynamometer 1 is adjusted through the console, and the test engine 2 is driven by the dynamometer 1, so that the accessory system 3 works at differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com