Biomass horizontal type cyclone burning boiler

A biomass and cyclone technology, applied in the direction of combustion methods, blast equipment, combustion equipment, etc., can solve problems such as furnace blockage, boiler black smoke, fuel cannot be fully burned, etc., and achieve the effect that is conducive to high temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

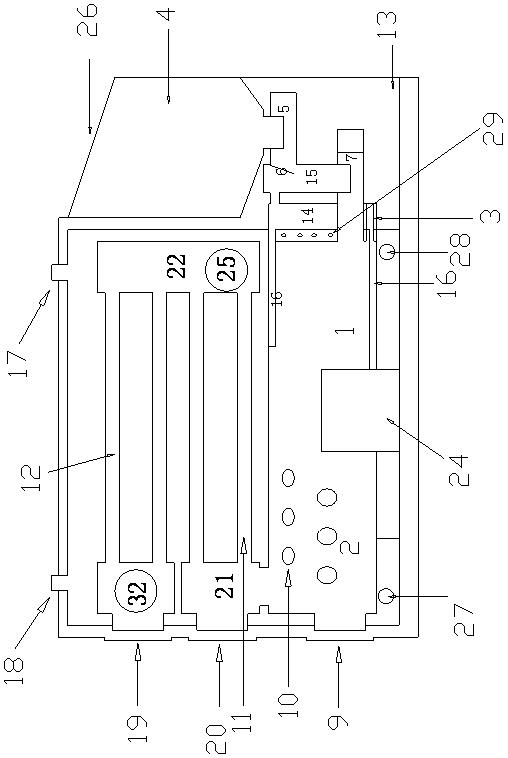

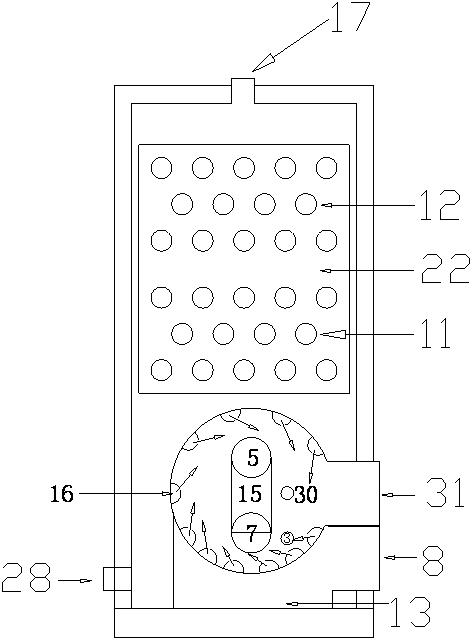

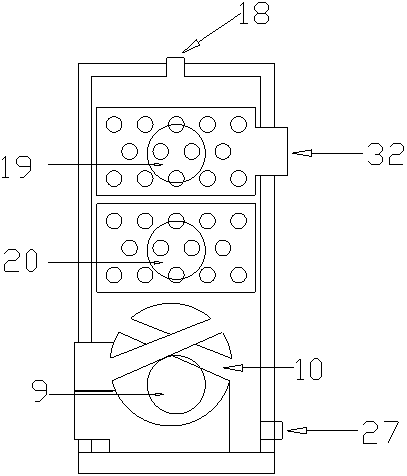

[0021] The specific implementation manner of the present technology will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 In the shown biomass horizontal cyclone boiler, the combustion chamber 1 includes the combustion chamber 1 and the combustion chamber 2 connected. The inner wall of the combustion chamber 1 is provided with a horizontal cyclone air duct. The horizontal cyclone air duct 16 is semi-cylindrical, the right end (front end) is closed, and the left end (rear end) passes through the jacket layer 29 and communicates with the blast air distribution cavity 14 . The rear end of the combustion chamber 1 is provided with a jacket layer 29 which is isolated from the blast air distribution chamber 14, and the side wall on the right side of the jacket layer 29 forms the combustion chamber back plate. The jacket layer communicates with the water chamber 33 through holes. The first fuel feed channel passes through the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com