Controlling, adjusting and remote monitoring system for fuel gas-fired boiler

A remote monitoring system and technology for gas boilers, which are used in the control of combustion, combustion methods, and regulation of fuel supply, etc., can solve the problems of electronic combustion control and regulation systems that are rarely studied and not seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

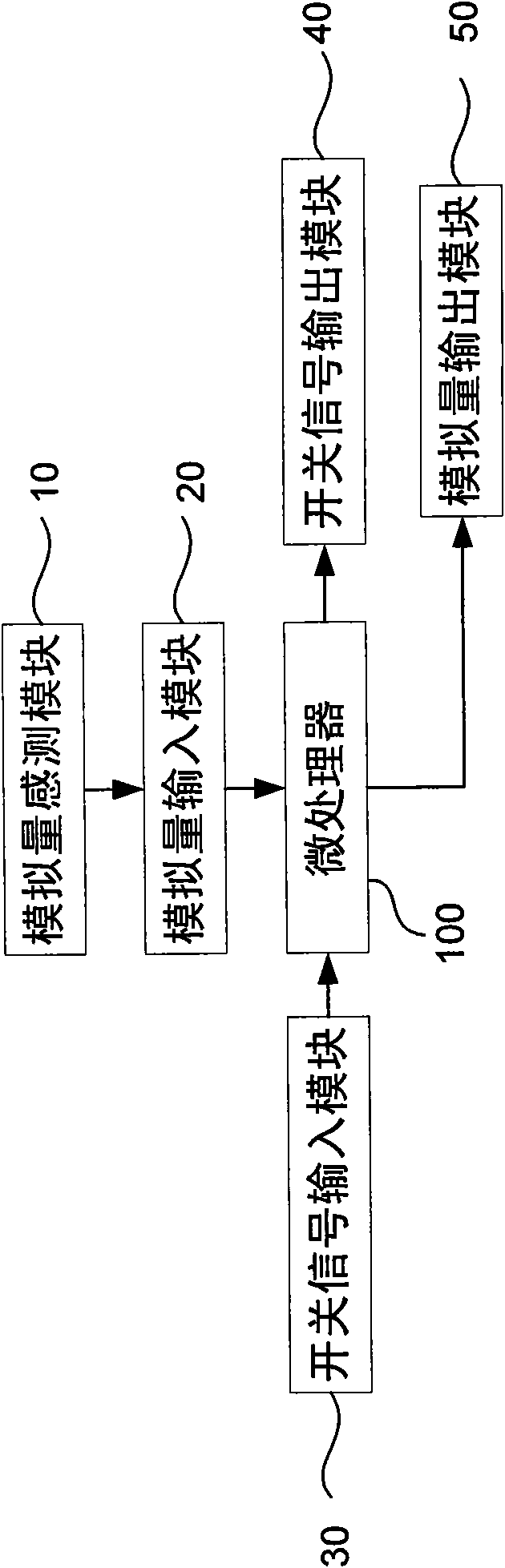

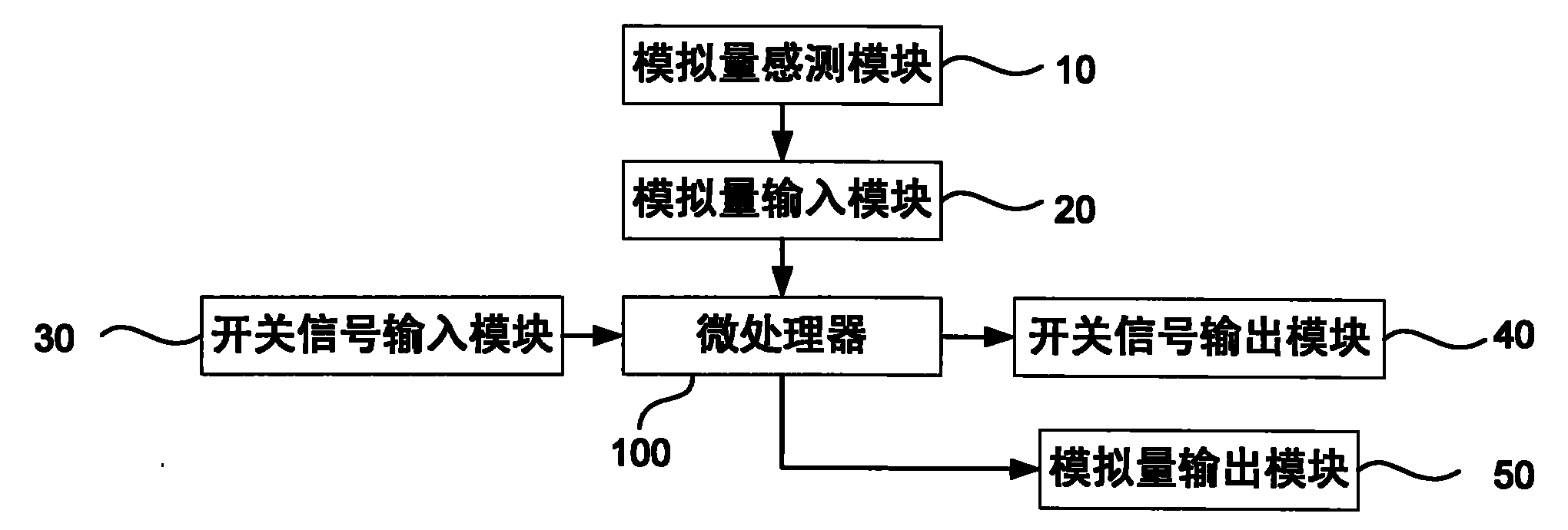

[0026] Please see attached figure 1 As shown, the fuel gas boiler control adjustment and remote monitoring system of the present invention includes a microprocessor 100, an analog sensing module 10 and an analog input module 20, a switch signal input module 30, a switch signal output module 40 and an analog output module 50 . Wherein, the output end of the analog quantity sensing module 10 is connected with a signal input end of the microprocessor 100 through the analog quantity input module 20, and this sensing module 10 is used for sensing and spot sampling the present oxygen amount in the boiler, and temperature or The pressure signal is then sent to the microprocessor 100 after the analog-to-digital conversion is carried out by the analog input module 20, and the output end of the switch signal input module 30 is connected to a control input end of the microprocessor 100, which is used to control the microprocessor 100 when the pressure signal is satisfied. Including that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com