Furnace hearth flame detecting method based on intelligent-control computer vision technology

A technology of computer vision and flame detection, which is applied in the direction of combustion methods, safety devices of combustion chambers, combustion chambers, etc., can solve the problems of small field of view of flame detectors, inability to further judge flame combustion, and affect the detection effect of furnace flames, etc. achieve efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

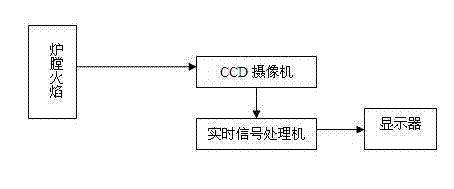

[0037] Such as figure 1 Shown, the furnace flame detection method based on the computer vision technology of wavelet packet and BP neural network, comprises the following steps:

[0038] (1) Image acquisition: use a CCD camera to take pictures of the furnace flame through an optical fiber image sensor, and transmit the signal of the collected image information to a real-time signal processor;

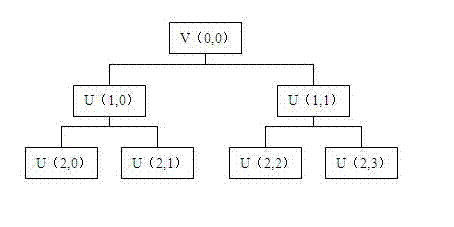

[0039] (2) Signal denoising processing of wavelet packet algorithm: adopt wavelet packet algorithm to carry out signal denoising processing on image information in the signal processor;

[0040] (3) Use BP neural network model to detect and recognize images: use BP design network to detect and recognize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com