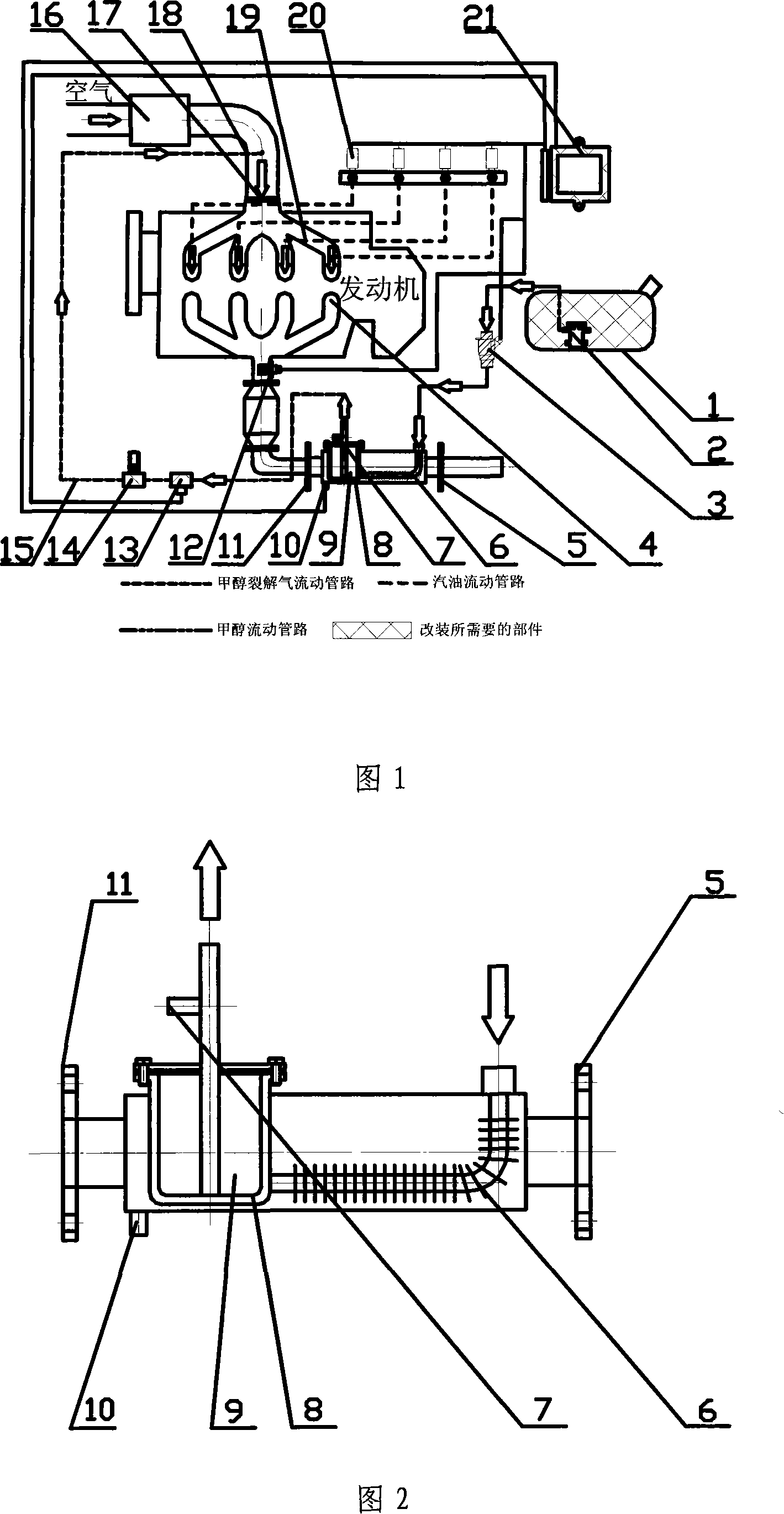

Ignition type engine directly burning methanol cracking product and control method thereof

A methanol cracking and engine technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of large latent heat of vaporization, high aldehyde emissions, incomplete methanol combustion, etc., to eliminate aldehyde emissions and improve power performance. , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

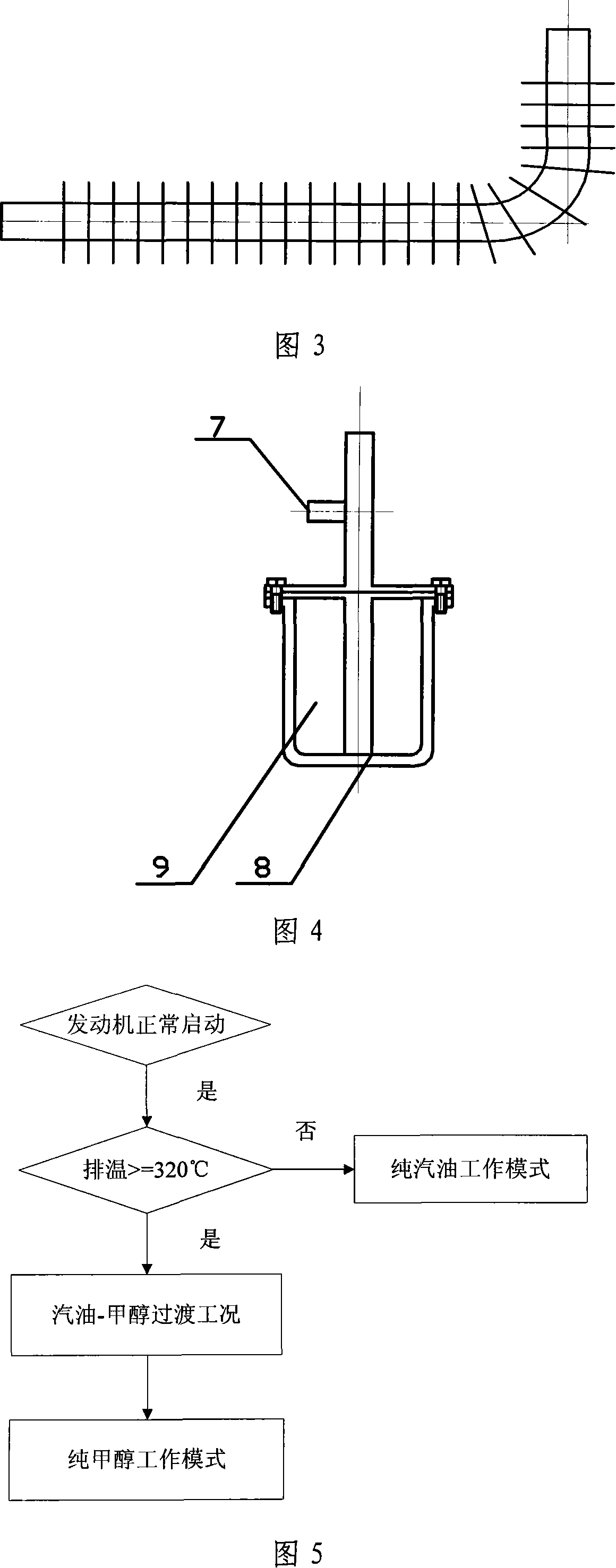

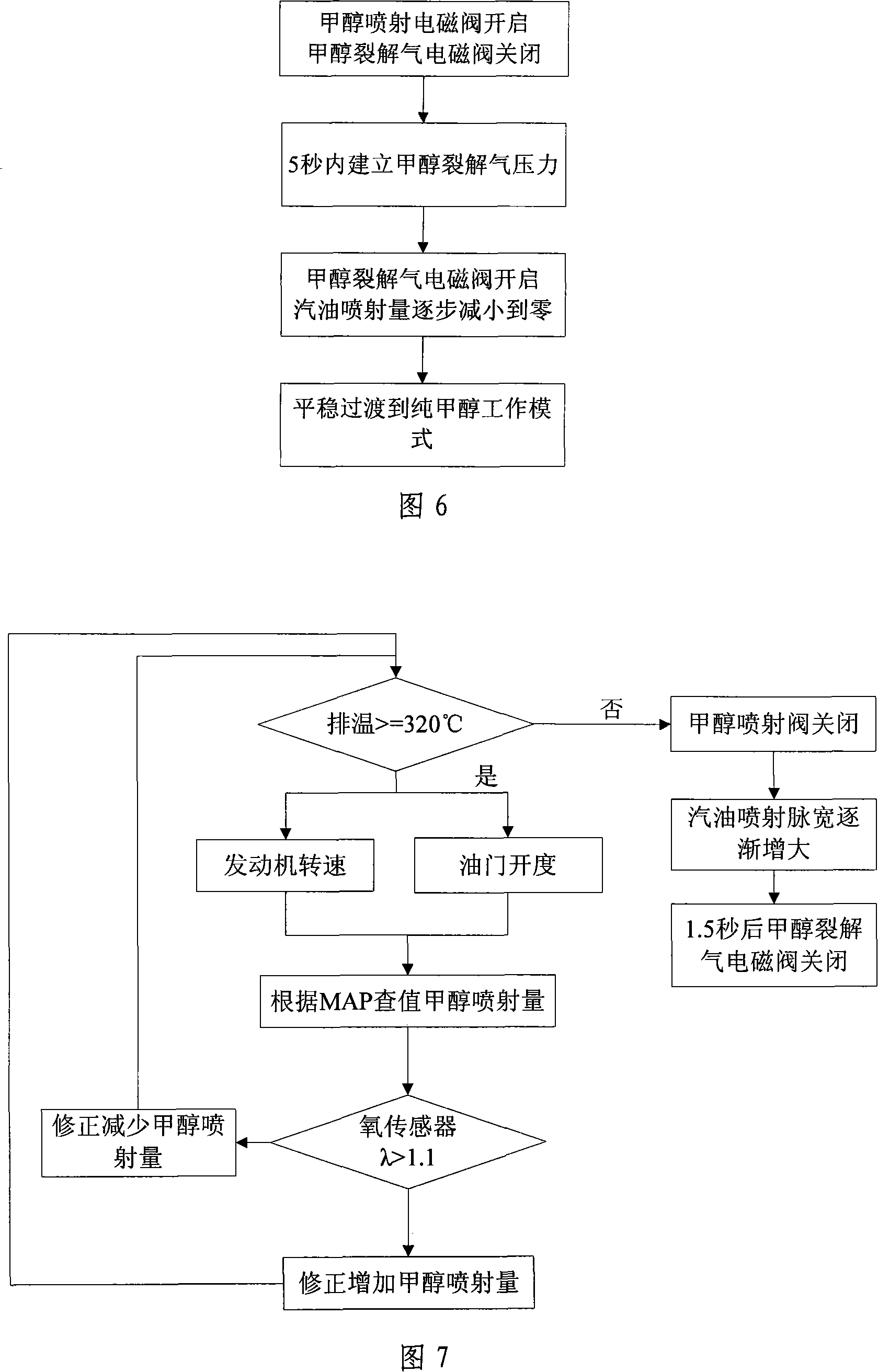

Method used

Image

Examples

Embodiment

[0054] The main technical parameters of the original gasoline engine of the engine are shown in Table 1; the performance comparison of the engine directly burning methanol cracking products and the original gasoline engine is shown in Table 2; the emission comparison of the engine directly burning methanol cracking products and the original gasoline engine is shown in Table 3.

[0055] Table 1:

[0056] manufacturer

model

the form

Displacement L

Bore x stroke (mm x mm)

Dongfeng Nissan

HR16DE

inline four cylinder

9.8

1.598

78×83.6

Rated power / speed(kW / rpm)

Maximum torque / speed (N m / rpm)

80 / 6000

153 / 4400

[0057] Table 2:

[0058] Rotating speed

(rpm)

torque

(N·m)

the power

(kW)

Pure burning methanol consumption

(kg / h)

Pure gasoline consumption

(kg / h)

replacement ratio

2000

111.2

23.3

9.2

5.7

1.614...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com