Heating device using solid fuels

A heating device and solid fuel technology, which is applied to solid heating fuel, stoves/stoves with convection heating devices, stoves/stoves with hot water devices, etc., which can solve the problem of inability to achieve low emissions and inaccurate control of the combustion process , Combustion efficiency needs to be improved, etc., to achieve the effect of improving heating effect, saving materials, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

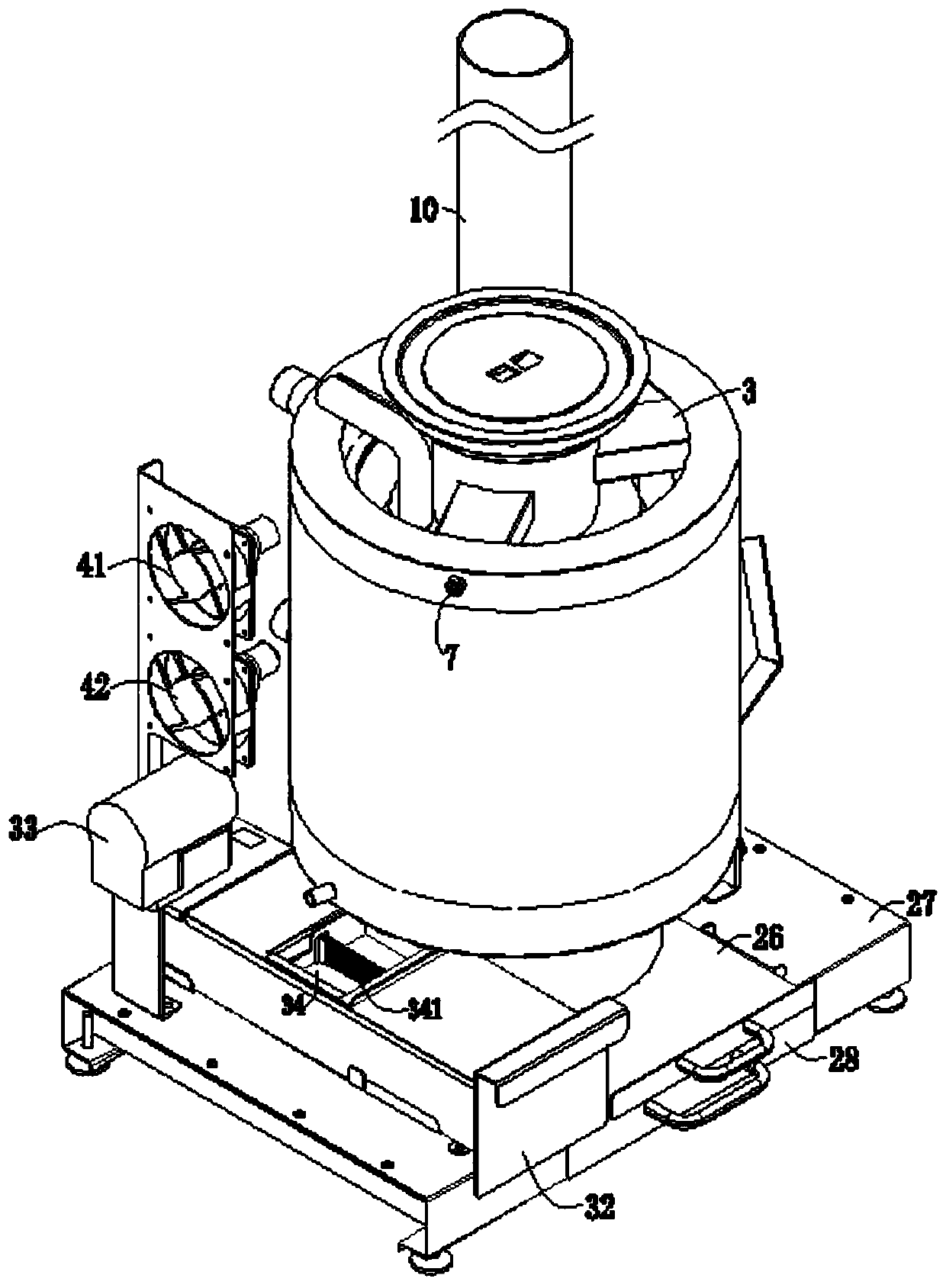

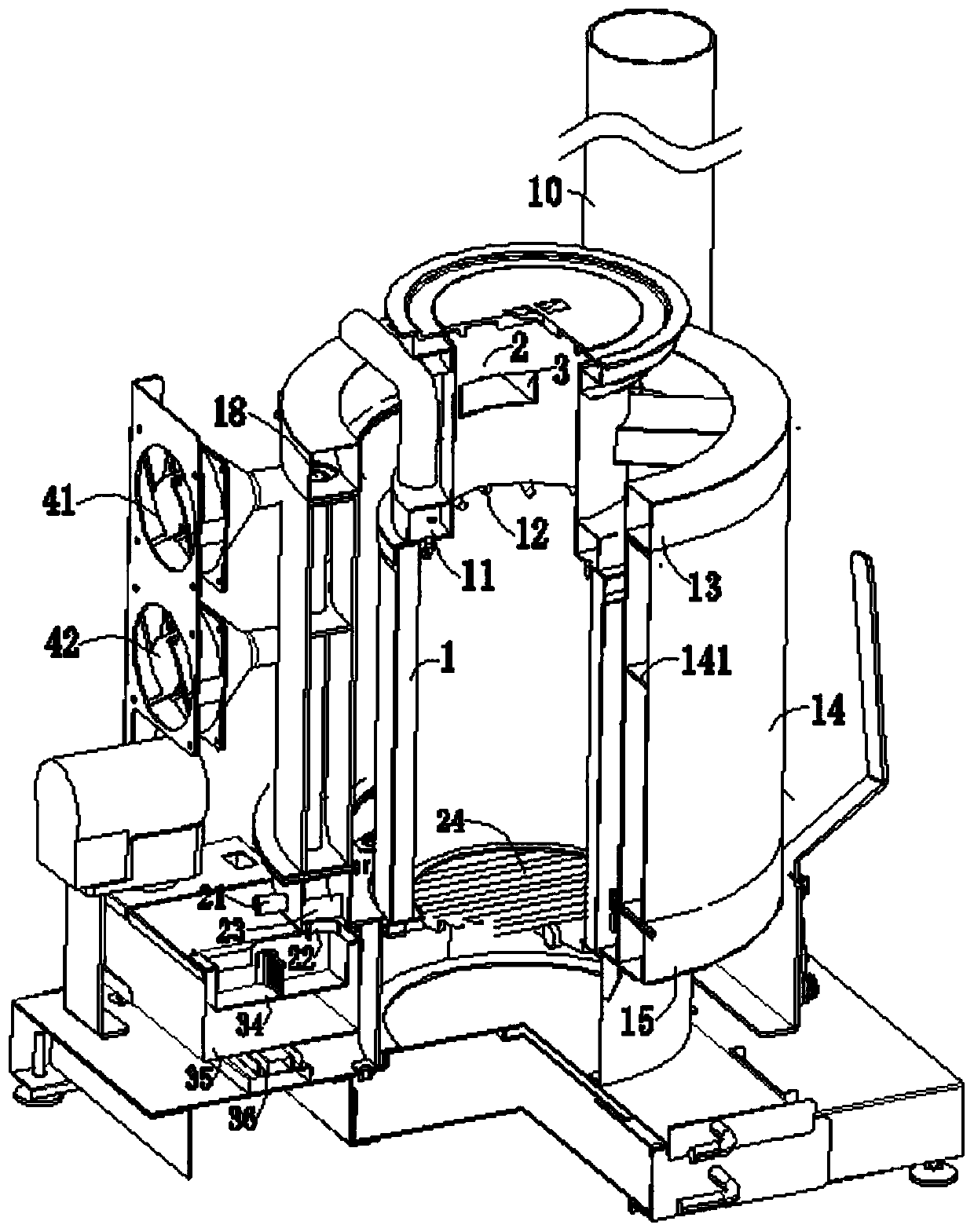

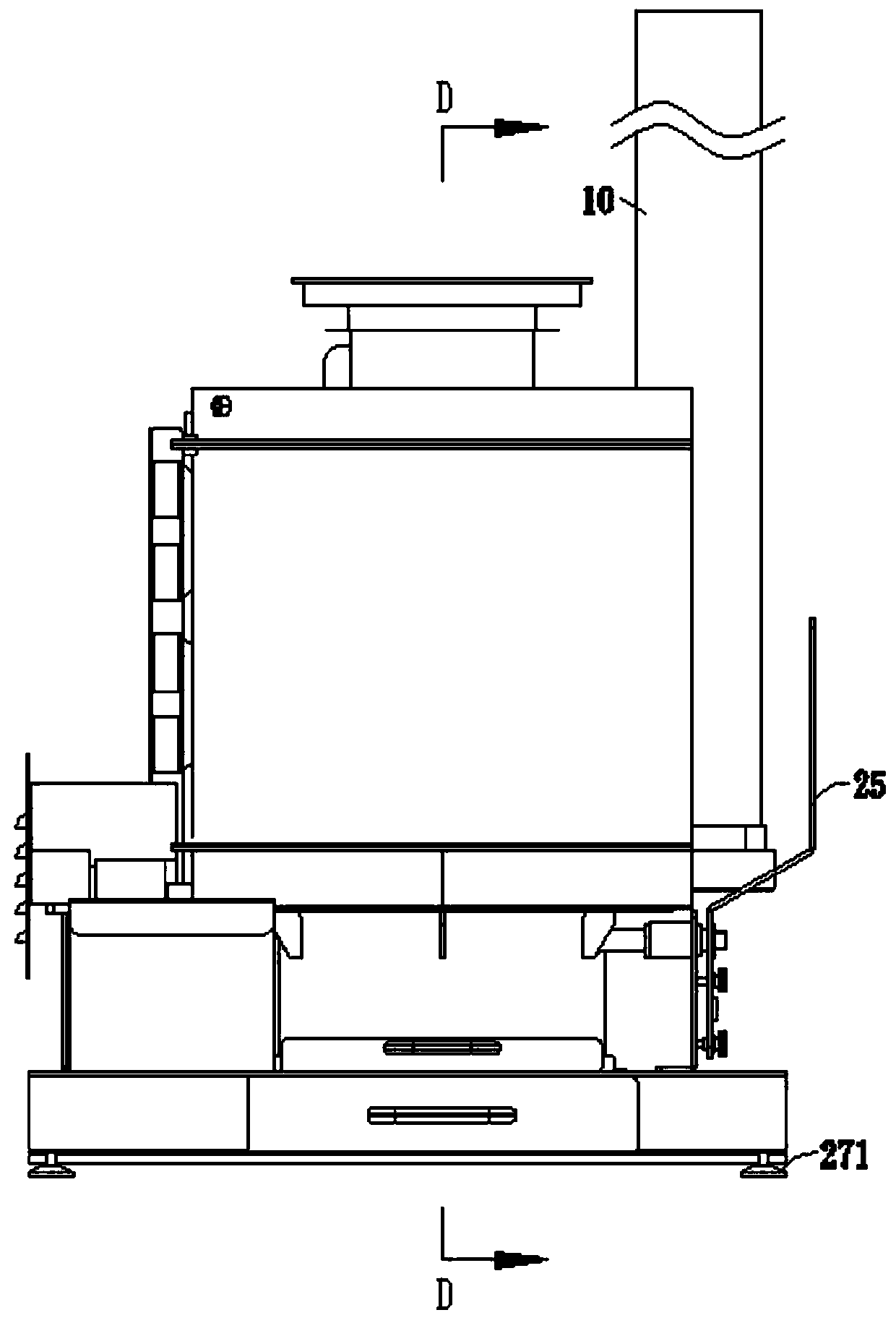

[0049] Such as Figure 1-7 said, of which figure 1 and figure 2 Part of the upper distribution duct 5 and the lower distribution duct 6 are hidden,

[0050] A heating device using solid fuel, including a combustion system, the combustion system includes a furnace 1 and a furnace mouth 2; it also includes an air distribution system, the air distribution system supplies air to the furnace 1 through the top and bottom of the furnace 1, and the air volume can be independent adjust. The air distribution system includes a first wind source 41 and a second wind source 42, the first wind source 41 and the second wind source 42 are fixed on a fan bracket 43, the first wind source 41 sends air to the top of the furnace 1, and the second wind source 42 to send air to the bottom of the furnace 1; the first air source 41 is communicated with the upper air duct 5, and the second air source 42 is communicated with the lower air duct 6; the upper air duct 5 and the lower air duct 6 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com