Boiler with improved air supply manner

A boiler and air supply technology, which is applied in the boiler field, can solve problems such as insufficient combustion, reduced boiler heat transfer efficiency, and inadaptability to the use of semi-coke special boilers, and achieve the effect of expanding energy saving and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

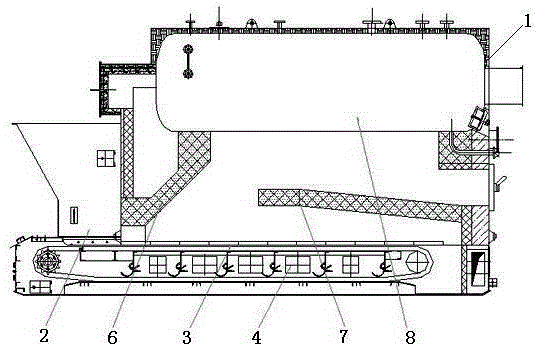

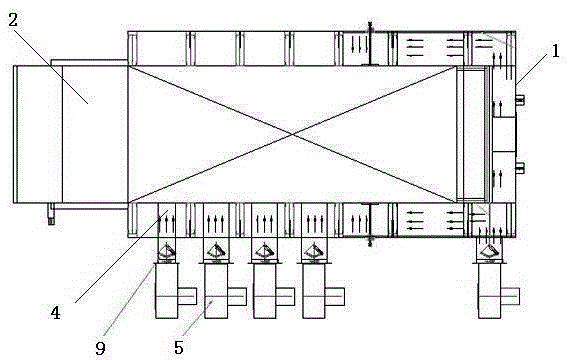

[0020] see figure 1 , 2 , The names of the parts are as follows: furnace body 1, feed port 2, fire grate 3, air chamber 4, fan 5, front arch 6, rear arch 7, furnace barrel 8, and damper 9.

[0021] see figure 1 , 2 , a semi-coke boiler for improving air supply, including a furnace body 1, a feed port 2 (or a hopper, such as semi-coke raw material) in front of the furnace body 1, and a grate 3 inside the furnace body 1 (the chain furnace is shown in the figure row, the structure is not limited to this), there are multiple air chambers 4 under the fire grate 3, and each air chamber 4 is equipped with a fan 5 for air supply, or each air chamber 4 in the first few air chambers 4 near the front of the furnace body 1 Equipped with a fan 5 for air supply, or every two air chambers 4 or three air chambers 4 are equipped with a fan 5 for air supply. The arrangement is not limited, as long as multiple air chambers 4 are equipped with multiple fans 5 . Or be equipped with a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com