Activation catalyst for energy conservation, automobile economizer containing catalyst and installation method of automobile economizer

A technology of activation catalyst and installation method, applied in chemical instruments and methods, separation methods, charging systems, etc., can solve problems such as affecting the service life of the engine, unable to achieve the best combustion state, etc., and achieve the reduction of harmful gases, high power, The effect of increasing molecular activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

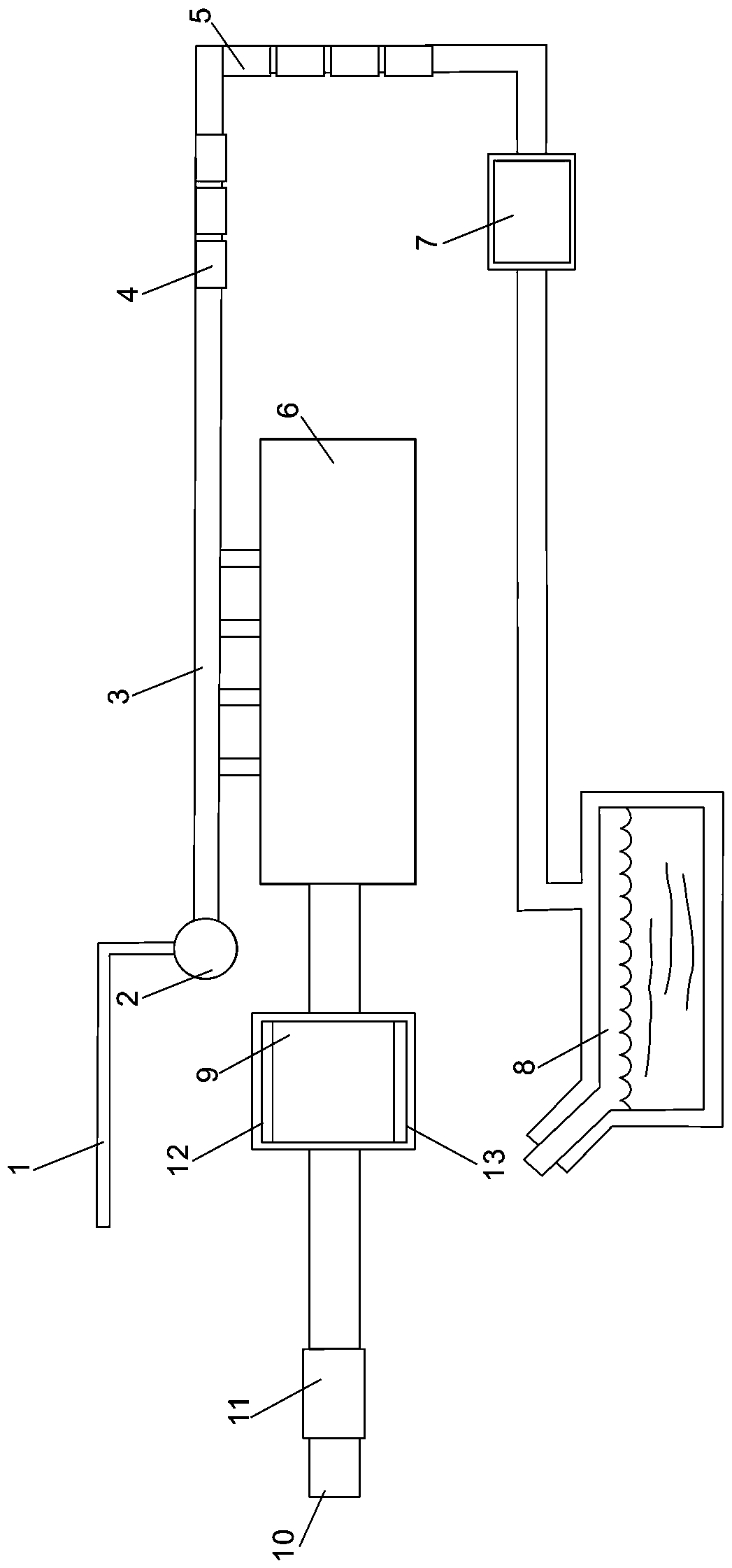

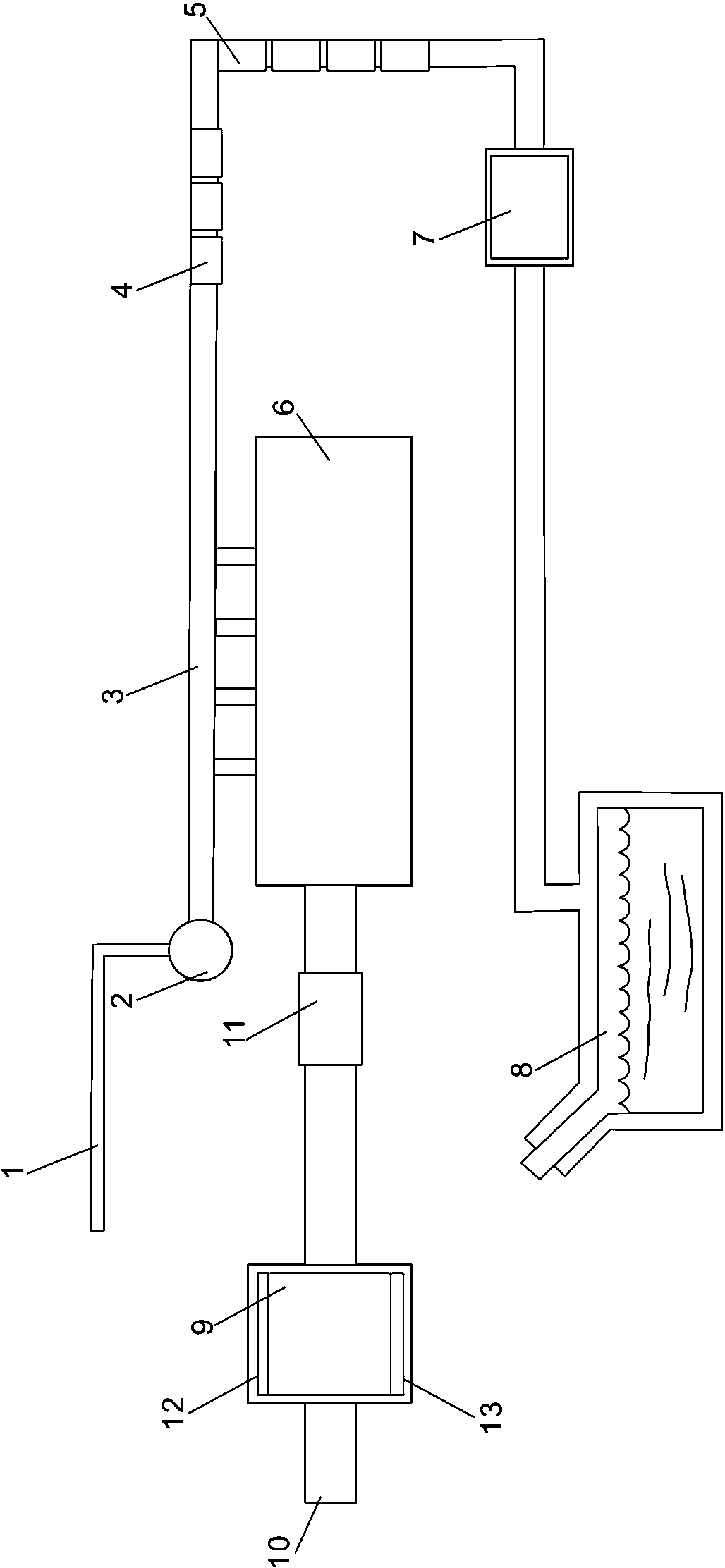

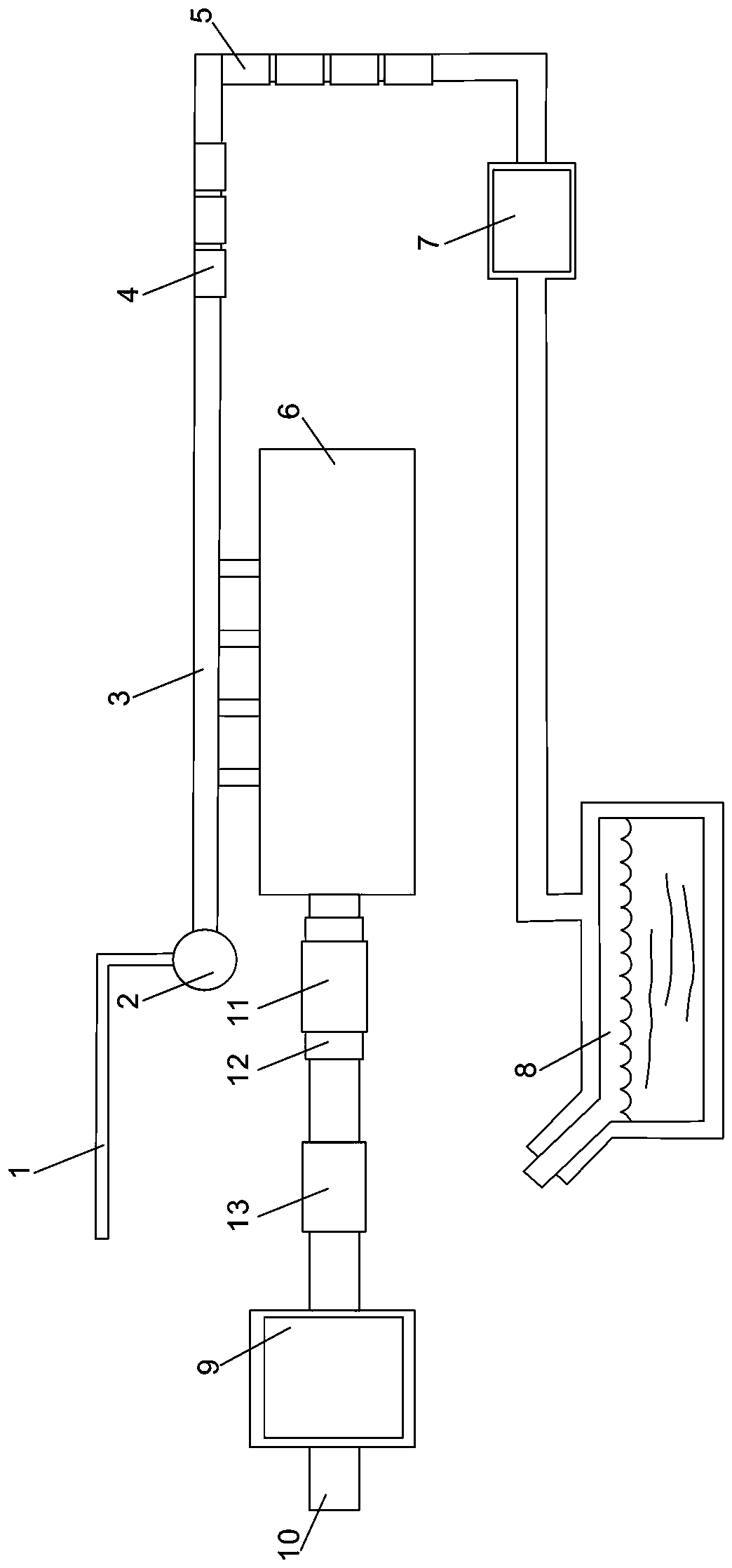

Image

Examples

Embodiment 1

[0027] The fuel-activated catalyst and the air-activated catalyst include nanocomposite anion far-infrared materials and carriers, and the nanocomposite anion far-infrared materials include the following components: Al 2 o 3 、K 2 O, SiO 2 , Fe 2 o3 , MgO, Na 2 O, CaO, TiO 2 , FeO, P 2 o 5 , Mn, La 2 o 3 , Yb 2 o 3 . The carrier is one or more of pressure-sensitive adhesive, cordierite ceramic material, limestone, rubber and plastic. In this embodiment, the carrier is pressure-sensitive adhesive.

[0028] The dosage of the nanocomposite anion far-infrared material accounts for 30-90wt% of the total dosage of the material and the carrier material. In this embodiment, the amount of the nanocomposite anion far-infrared material accounts for 70-90wt% of the total amount of the material and the carrier material.

[0029] The weight percentage of each component in the nanocomposite negative ion far-infrared material in the material is: Al 2 o 3 8-19wt%, K 2 O is 0.5...

Embodiment 2

[0033] The fuel-activated catalyst and the air-activated catalyst include nanocomposite anion far-infrared materials and carriers, and the nanocomposite anion far-infrared materials include the following components: Al 2 o 3 、K 2 O, SiO 2 , Fe 2 o 3 , MgO, Na 2 O, CaO, TiO 2 , FeO, P 2 o 5 , Mn, La 2 o 3 , Yb 2 o 3 . The carrier is one or more of pressure-sensitive adhesive, cordierite ceramic material, limestone, rubber and plastic. In this embodiment, pressure-sensitive adhesive and cordierite ceramic materials are selected as the carrier.

[0034] The dosage of the nanocomposite anion far-infrared material accounts for 30-90wt% of the total dosage of the material and the carrier material. In this embodiment, the consumption of the nanocomposite negative ion far-infrared material accounts for 70-90wt% of the total consumption of the material and the pressure-sensitive adhesive, and the consumption of the nanocomposite negative ion far-infrared material account...

Embodiment 3

[0039] The fuel-activated catalyst and the air-activated catalyst include nanocomposite anion far-infrared materials and carriers, and the nanocomposite anion far-infrared materials include the following components: Al 2 o 3 、K 2 O, SiO 2 , Fe 2 o 3 , MgO, Na 2 O, CaO, TiO 2 , FeO, P 2 o 5 , Mn, La 2 o 3 , Yb 2 o 3 . The carrier is one or more of pressure-sensitive adhesive, cordierite ceramic material, limestone, rubber and plastic. In this embodiment, pressure-sensitive adhesive and rubber are selected as the carrier.

[0040] The dosage of the nanocomposite anion far-infrared material accounts for 30-90wt% of the total dosage of the material and the carrier material. In this embodiment, the amount of the nanocomposite anion far-infrared material accounts for 70-90wt% of the total amount of the material and the pressure-sensitive adhesive, and the amount of the nanocomposite anion far-infrared material accounts for 30-40wt% of the total amount of the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com