Automatic control method of fire prevention, deflagration prevention and stable combustion in furnace based on single burner

An automatic control device and technology for fire prevention and fire prevention, which are applied in the field of explosion-proof, stable combustion automatic control solutions, and fire-prevention and fire-extinguishing nozzles. It can solve problems such as wrong adjustment directions, changes in boiler combustion states, and different adjustment levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] For the furnace type of the intermediate storage pulverizing system with a single primary fan, the automatic control method for fire prevention, deflagration prevention and stable combustion:

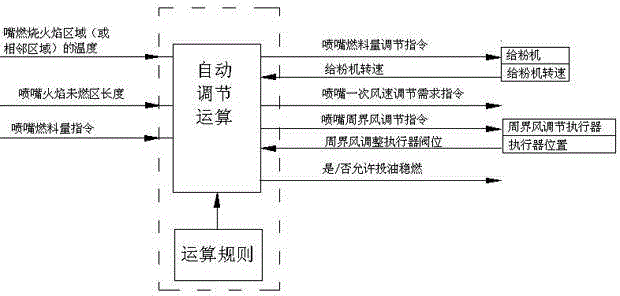

[0128] Such as figure 2 As shown, the length signal of the black dragon area (unburned area) of the burning flame of the burner, the temperature signal of the burning flame area (or adjacent area) of the burner, and the fuel quantity command signal of the burner from the boiler load regulation system are sent to a single Fire nozzle anti-fire, anti-deflagration, stable combustion automatic control unit, a single fire nozzle anti-fire, anti-deflagration, stable combustion automatic control unit performs automatic control calculations on these signals, and outputs fuel volume adjustment instructions to directly control the powder feeding machine. Speed, the speed of the powder feeder is fed back to the single burner anti-fire, anti-knock, and stable combustion automatic control un...

Embodiment 2

[0130] The automatic control method for fire prevention, deflagration prevention and stable combustion of the furnace type burner of the direct blowing pulverizing system:

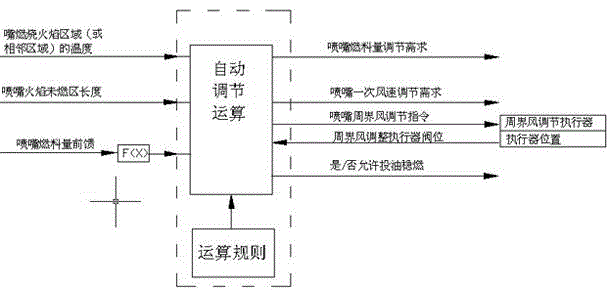

[0131] Such as image 3 Shown: the length signal of the black dragon area (unburned area) of the burning flame of the burner, the temperature signal of the burning flame area (or adjacent area) of the burner, the amount of fuel from the burner from the pulverizing system supplying fuel to the burner The feed-forward signal is input to the automatic control unit for fire prevention, deflagration and stable combustion of a single burner, and the automatic control unit for fire prevention, deflagration and stable combustion of a single burner performs automatic control calculation on these signals, and the output perimeter of the burner The air volume adjustment command directly controls the air actuator around the burner, and the position of the actuator is fed back to the automatic control unit for fire pre...

Embodiment 3

[0133] For the furnace type of the intermediate storage type pulverizing system, based on the single burner stable combustion, the automatic control method of fire prevention, deflagration and stable combustion of the burner layer, such as Figure 4 Shown:

[0134]The fire-proof, anti-deflagration and stable combustion automatic control unit of the burner layer receives the following signals: the temperature signal of the burner flame area (or adjacent area), the length of the black dragon area (unburned area) of the burning flame of each burner in the combustion layer , from the fire-proof, deflagration-proof, stable combustion automatic control unit of the whole furnace (or boiler load adjustment system), the floor distribution air volume command signal and the layer fuel command signal, from the fire-proof, deflagration-proof, stable combustion automatic control unit of the whole furnace (or layer flame temperature given operation function block) the given signal of layer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com