Low-concentration gas wet pressurization equipment and method of coal mine

A low-concentration gas and pressurization equipment technology, which is applied in the direction of mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems that it cannot be pressurized, and it is difficult to meet the requirements of ensuring the inlet pressure of the generator set, so as to achieve safety Complete measures, low cost, to ensure the effect of import pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

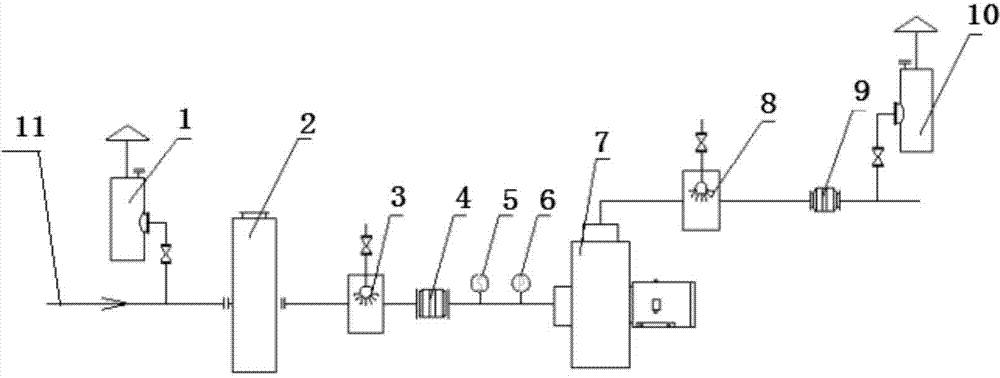

[0035] A low-concentration gas wet pressurization method of the present invention comprises the following steps:

[0036] 1. The gas with a concentration of 15% is transported from the gas drainage station along the main gas pipeline, flows in from the air inlet of the first wet pressure relief and explosion relief device, flows out from the gas outlet, and is transported to the water through the main pipeline. The air inlet of the sealed flame arrester flows out from the air outlet of the water sealed flame arrester;

[0037] 2. The low-concentration gas flowing out of the gas outlet of the water-sealed flame arrester is transported to the first spraying device through the main pipeline, and the low-concentration gas is dedusted and fire-stopped by the fine water mist sprayed from the first spraying device;

[0038] 3. After passing through the first spraying device, the gas is transported to the steam-water separator through the main pipeline, and the free water in the low-c...

Embodiment 2

[0043] A low-concentration gas wet pressurization method of the present invention comprises the following steps:

[0044]1. The gas with a concentration of 21% is transported from the gas drainage station along the main gas pipeline, flows in from the air inlet of the first wet pressure relief and explosion relief device, flows out from the gas outlet, and is transported to the water through the main pipeline. The air inlet of the sealed flame arrester flows out from the air outlet of the water sealed flame arrester;

[0045] 2. The low-concentration gas flowing out of the gas outlet of the water-sealed flame arrester is transported to the first spraying device through the main pipeline, and the low-concentration gas is dedusted and fire-stopped by the fine water mist sprayed from the first spraying device;

[0046] 3. After passing through the first spraying device, the gas is transported to the steam-water separator through the main pipeline, and the free water in the low-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com