Aluminum alloy heat dissipation device with automatic sealing mechanisms

An automatic sealing and heat dissipation device technology, which is applied to heat exchanger sealing devices, valve devices, engine components, etc., can solve the problems of limited heat dissipation of heat dissipation devices, shortened service life of mechanical equipment, and increased maintenance costs of enterprises, so as to avoid Production efficiency is affected, the overall structure is simple and reliable, and the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that all directional indications (such as top surface, bottom surface, left, right, front, back...) in the embodiments of the present invention are only used to explain the relationship between the components in a certain posture (as shown in the accompanying drawings). If the relative positional relationship of the specific posture changes, the directional indication will also change accordingly.

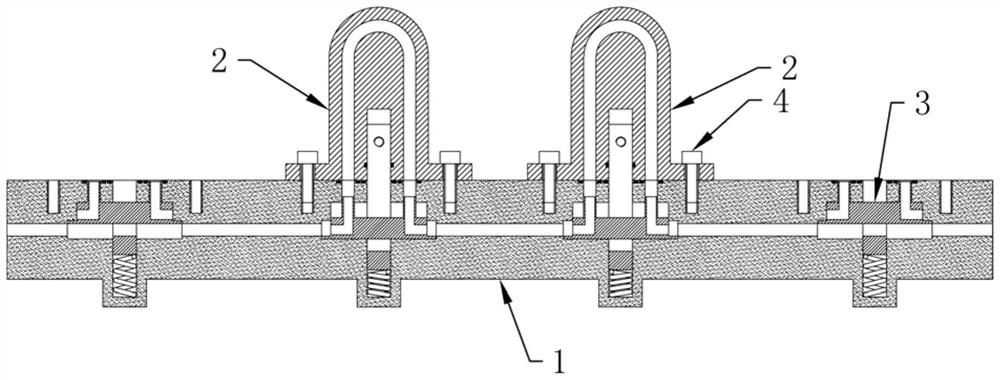

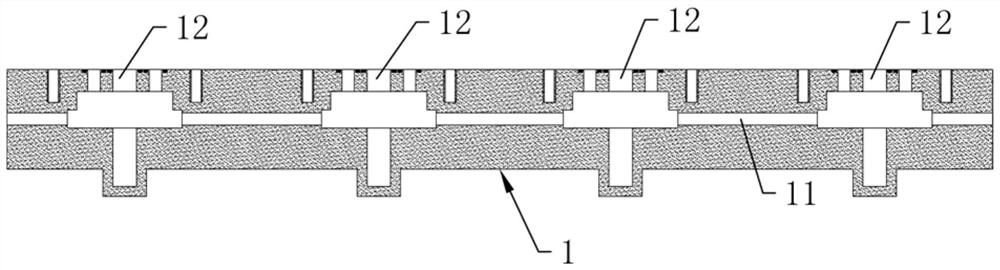

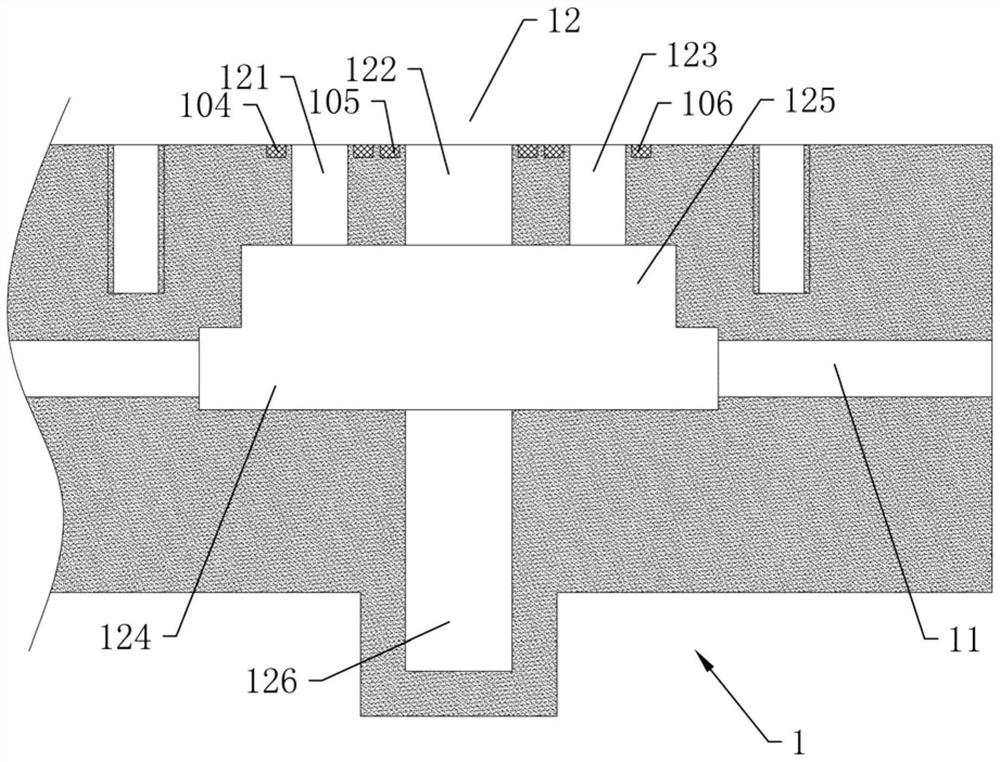

[0022] Such as figure 1 As shown, an aluminum alloy heat sink with an automatic sealing mechanism according to the present invention includes a heat dissipation base 1, a plurality of heat sinks 2, a plurality of automatic sealing mechanisms 3, and a plurality of screws 4, wherein, as Figure 1 to Figure 4As shown, the heat dissipation base 1 is made of aluminum alloy, the first water guide hole 11 is opened in the heat dissipation base 1, and the two openings of the first water guide hole 11 penetrate to the outer surface of the heat dissipation base 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com