Lithium ion battery floating liquid detection device and floating liquid detection method

A lithium-ion battery and detection device technology, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of battery CID inversion, liquid sealing, liquid seepage in cutting grooves, etc., and achieves simple and reasonable structure, simple and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

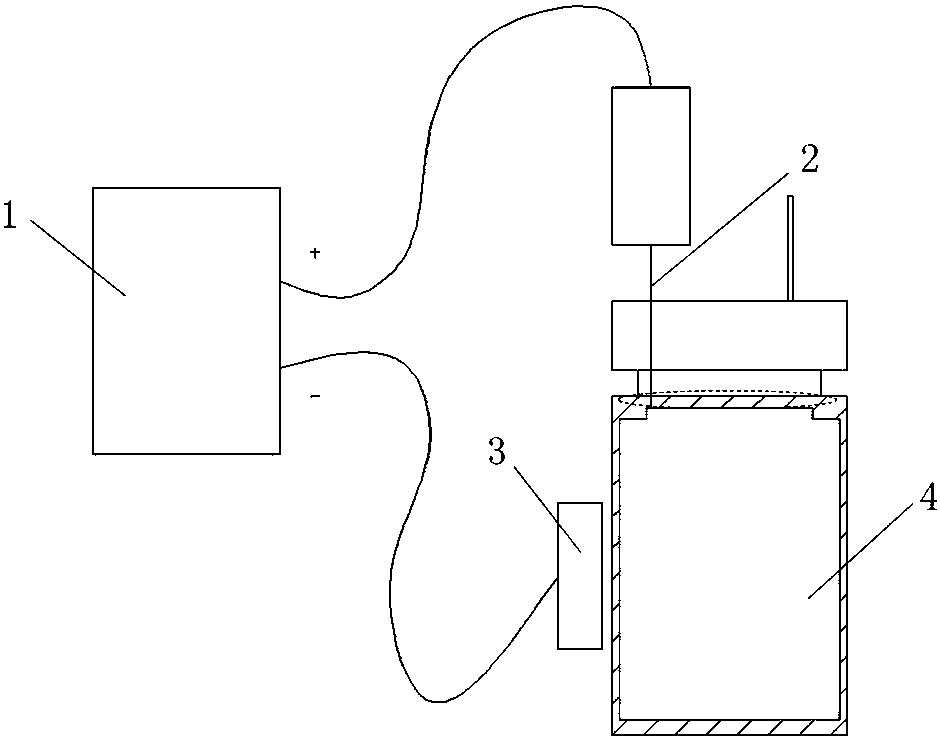

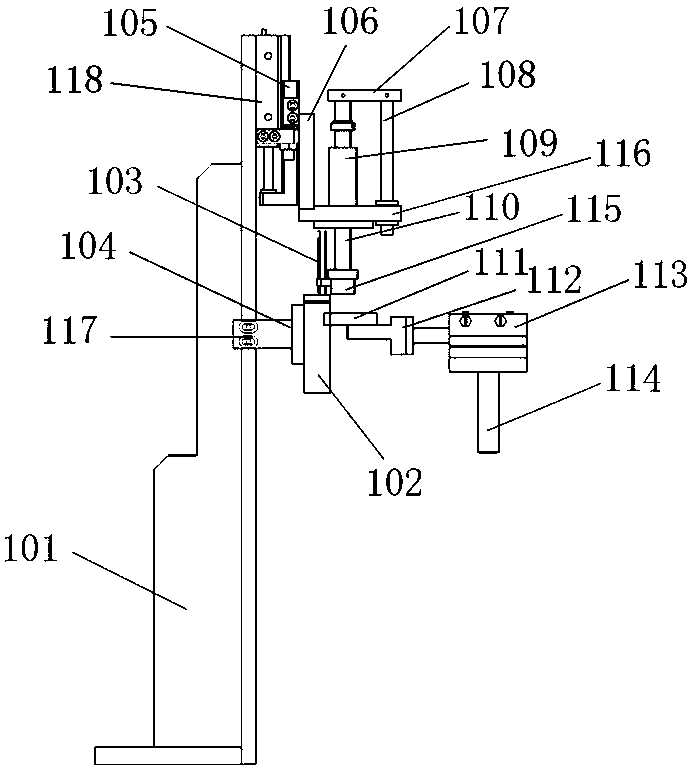

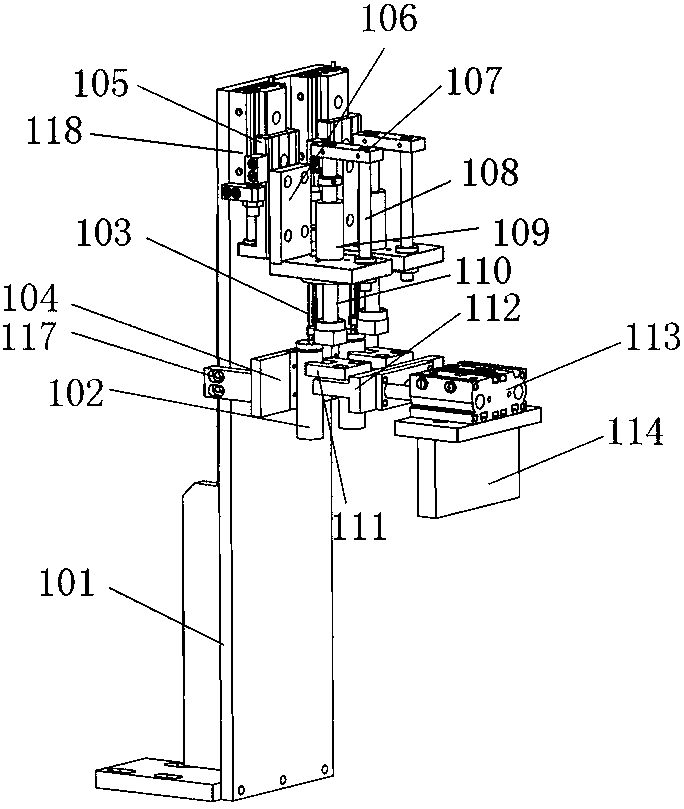

[0036] as attached figure 1 Shown is a schematic diagram of the working principle of the lithium-ion battery floating liquid detection device in the present invention. In the process of actual lithium-ion battery assembly, if floating liquid is generated, it will gather on the upper part of the positive insulating sheet of the battery, that is, the attached figure 1At the middle dotted line frame, in the present invention, the lithium-ion battery floating liquid detection mechanism is used to measure the resistance value between the top of the positive insulating sheet of the lithium-ion battery to be tested and the negative electrode casing, and judge whether the lithium-ion battery to be tested is a floating liquid according to the resistance value Battery. as attached figure 1 The floating liquid detection device in the present invention mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com