A self-tar removing biomass fixed bed gasifier system

A fixed-bed gasifier, biomass technology, applied in the petroleum industry, the manufacture of combustible gas, etc., can solve the problems of circulating water pollution of the working environment, cost increase, deterioration, etc., to improve energy utilization, save investment costs, save The effect of cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

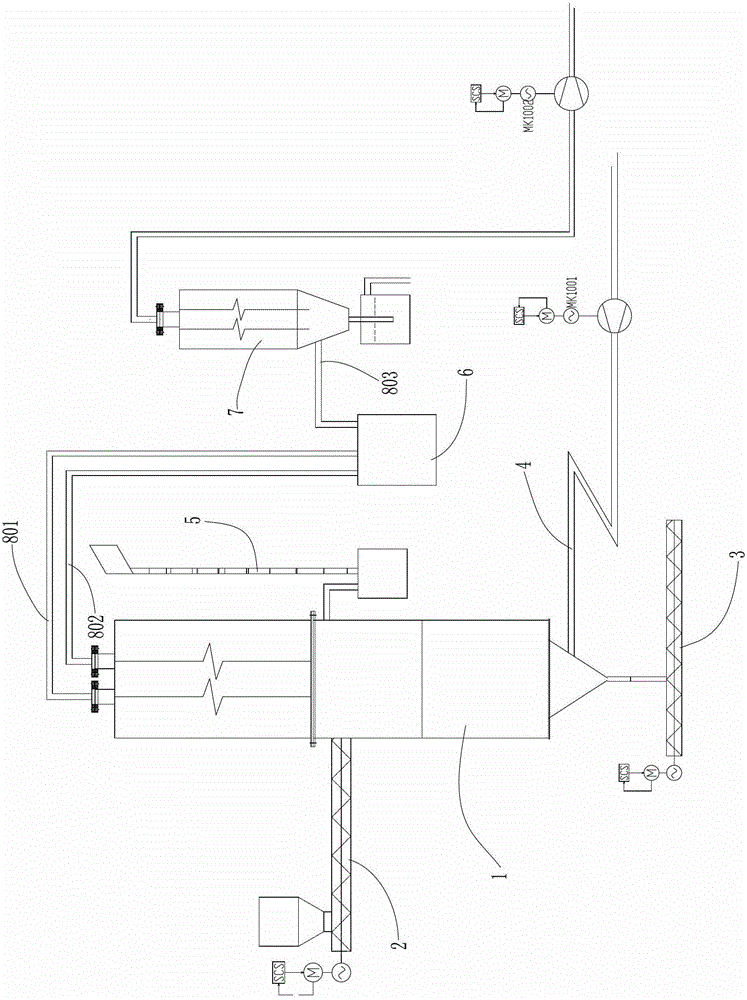

[0042] Such as figure 1 As shown, the self-tar removal type biomass fixed-bed gasifier system of this embodiment includes a self-removal tar type biomass fixed-bed gasification furnace 1, and a refrigerant cooling device (cooling tower, not shown in the figure), feed Device 2, tail ash conveying device 3, gasification medium supply device 4, furnace start and release device 5, water seal valve 6, second-stage tar removal device 7, gas pipelines 801, 802, 803.

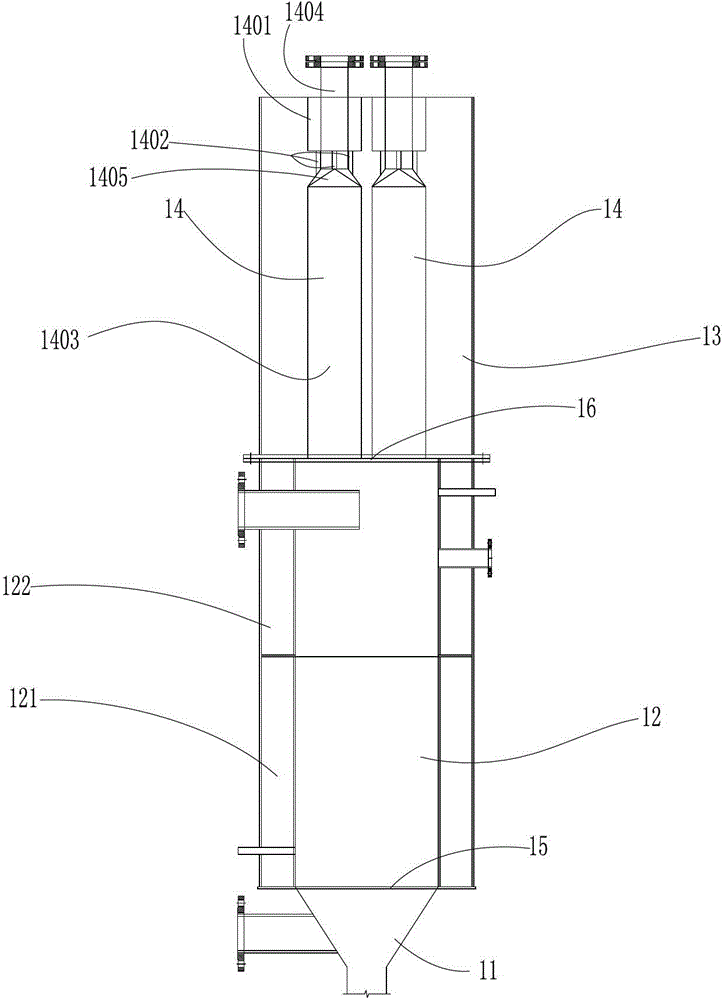

[0043] Among them, such as figure 2 The self-tar removal type biomass fixed-bed gasification furnace 1 shown includes a furnace body arranged vertically, a steam generator 121 , and a recirculation gas heating section 122 . From bottom to top, the furnace body consists of a cone-shaped tail ash section 11, a cylindrical reaction section 12, and a tar removal section 13. A water-cooled fire grate 15 is provided between the tail ash section 11 and the reaction section 12 . The top of the tar removal section 13 is prov...

Embodiment 2

[0054] The differences between this embodiment and Embodiment 1 are: (1) The number of tar removal device in the furnace is one; (2) The steam generator has two outlets, and there are also two gasification medium inlets, one It is connected to the water inlet of the water basin, the other outlet of the steam generator is connected to a gasification medium inlet, and the other gasification medium inlet is fed with air.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is that the number of tar removal devices in the furnace is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com