Preparation method of LED light-emitting device, and LED light-emitting device

A light-emitting device, LED chip technology, applied in semiconductor devices, optics, instruments, etc., can solve the problems of thinning difficulties, low production efficiency, and high process requirements, and achieve low production costs, high production efficiency, and high tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

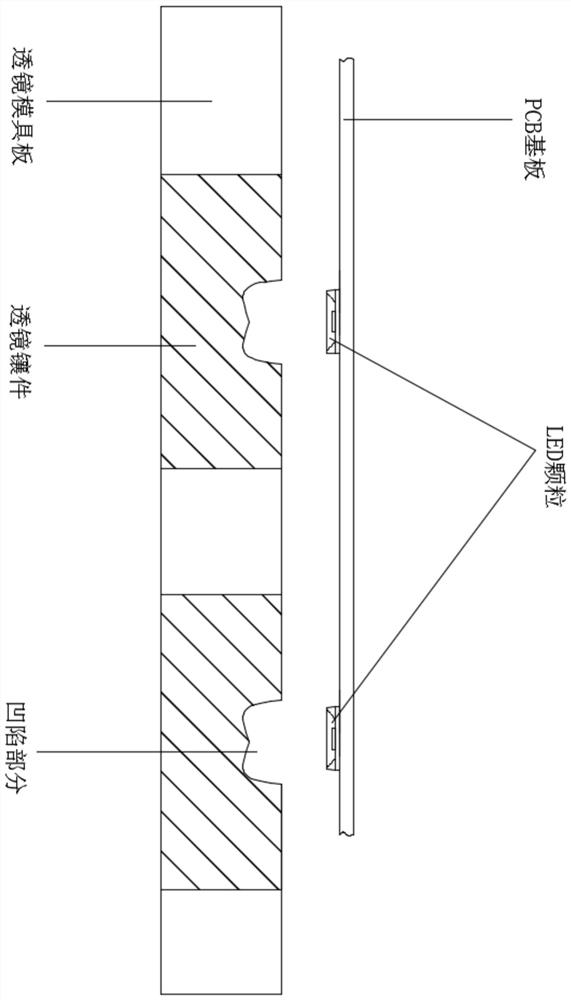

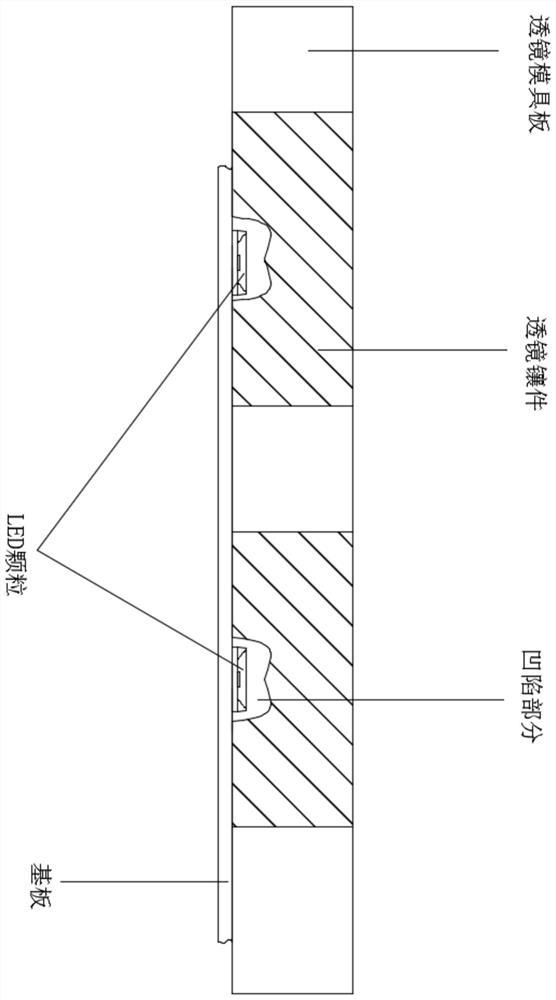

[0052] A kind of preparation method of LED light-emitting device, such as Figure 1-Figure 7 shown, including steps:

[0053] S1, attaching the LED particles to the substrate of the LED light-emitting device;

[0054] S2, filling the concave part of the lens insert on the lens mold plate with curing glue;

[0055] S3, inverting and pressing the substrate after step S1 onto the lens mold plate after step S2, the position of the LED particles corresponds to about the middle position of the concave part of the lens insert;

[0056] S4, curing the substrate and the lens mold plate pressed together after step S3, after the curing glue is cured, the curing glue, LED particles, and the substrate are fixed together, and after the mold is opened, an LED light-emitting device is obtained.

[0057] The lens formed after the curing glue is cured has only one optical surface. There are multiple concave parts of the lens insert, and the specific number and distribution of the concave par...

Embodiment 2

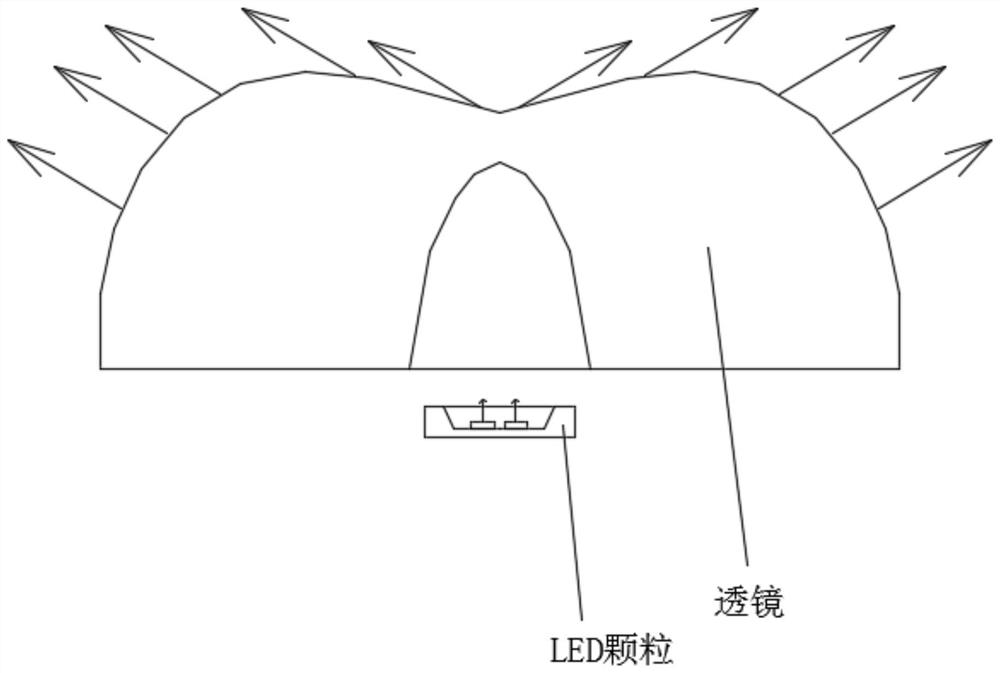

[0061] A kind of LED lighting device, such as Figure 4 with Figure 5 As shown, it includes: a substrate, LED particles, and a lens. The LED particles or LED chips are mounted on the substrate, and the lens is above the LED particles. It is characterized in that the LED particles are located at about the middle of the lens, and the lens There is only one optical surface, and the lens is directly molded by curing glue.

[0062] The shape of the lens is preferably: M shape, the curing glue is heat curing glue, and the substrate is a PCB substrate or an FPC substrate. When the substrate is an FPC substrate, a back plate is also provided under the FPC substrate. Curing glue fixes LED particles, FPC substrate and backplane together. There are multiple LED particles or LED chips, which are evenly distributed and mounted on the substrate in the form of rows and columns. LED particles include LED chips and brackets. LED chips include: blue LED chips, red LED chips, green LED chips,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com