Polyamide-imide prepared by adopting microchannel reactor and preparation method of polyamide-imide

A technology of microchannel reactor and polyamide-imide, which is applied in the field of material chemical industry, can solve problems such as incomplete reaction, poor safety performance, and insufficient mixing, so as to facilitate scale-up production, stable product performance, and increase economic cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation method of isocyanate excess 5% polyamide imide polymer solution, including the following steps:

[0046] (1) Pretreatment of substrate: 0.5 g of MDi51.96 g, TmA38.04 g, NMP210g, catalyst stearate, in a 500 ml beaker, and the solution was heated to 85 ° C under magnetic stirring conditions and maintained for 5 min. Stand in the substrate clear and restore the room temperature;

[0047] (2) Negative pressure divided CO 2 : The substrate produces a small amount of carbon dioxide gas during the pretreatment stage, and the substrate solution of the above step is poured into a 500 mL single-mouth bottle, and the pump is pulled up to dissolve the carbon dioxide excretion of dissolved in the solution;

[0048] (3) Parameter setting: adjust the constant temperature device, set the temperature of 165 ° C; adjust the constant current pump flow rate of 15 ml / min; pump the solvent NMP into the microreactor, by adjusting the back pressure valve knob to the pressure loss is ...

Embodiment 2

[0054] The preparation method of a polyamide imide polymer solution of a carboxylic acid is, including the following steps:

[0055] Comparative Example 1, the difference is that the substrate pretreatment: MDI49.80G, TmA40.20g, NMP210g, catalyst stearate 0.5 g, sequentially added 500 ml of beaker, and the solution under magnetic stirring conditions Heat until 85 ° C and kept 5 min, and the substrate was clear and transparent and restored at room temperature. The remaining steps are the same.

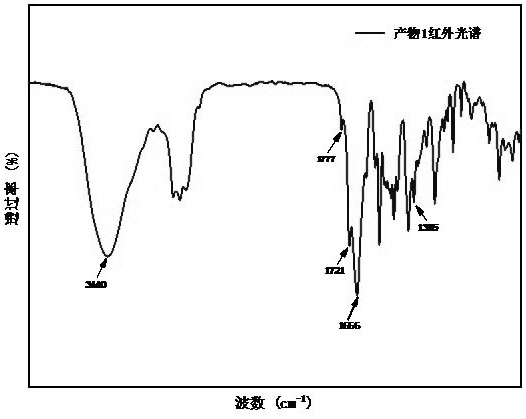

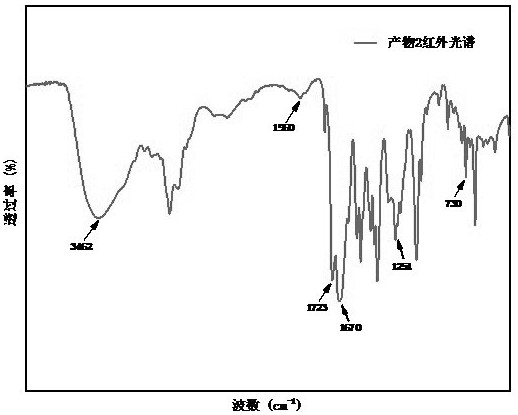

[0056] Infrared light analysis is performed on the product of this Example 2, and the results are respectively image 3 Indicated. image 3 Medium, at 3462cm -1 The peak appearing is the telescopic vibration absorption peak of amide bond N-H. At 1670cm -1 It is a telescopic vibration absorption peak in the amide in the amide, and its greater direction to the wave number is due to the increase in the PMDA content, resulting in increased imine rings to affect the peak position. 1779CM -1 1725cm...

Embodiment 3

[0058] Preparation of the isocyanate excess 5% PMDA involved in the reaction of the polyamide imide polymer solution, including the following steps:

[0059] Different from the first embodiment, the substrate pretreatment: MDI51.40g, TmA30.88 g, PMDA7.72G, NMP210G, catalyst stearate 0.5 g, sequentially added 500 ml of beaker, in magnetic stirring conditions The solution was heated to 85 ° C and maintained for 5 min, and the contained substance was clear and returned after returning. The remaining steps are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com