Prefabricated component production line

A prefabricated component and production line technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of many workers' work procedures, large production line area, and waste of investment costs, so as to improve the production capacity per unit area and reduce the cost of production. The effect of factory area and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

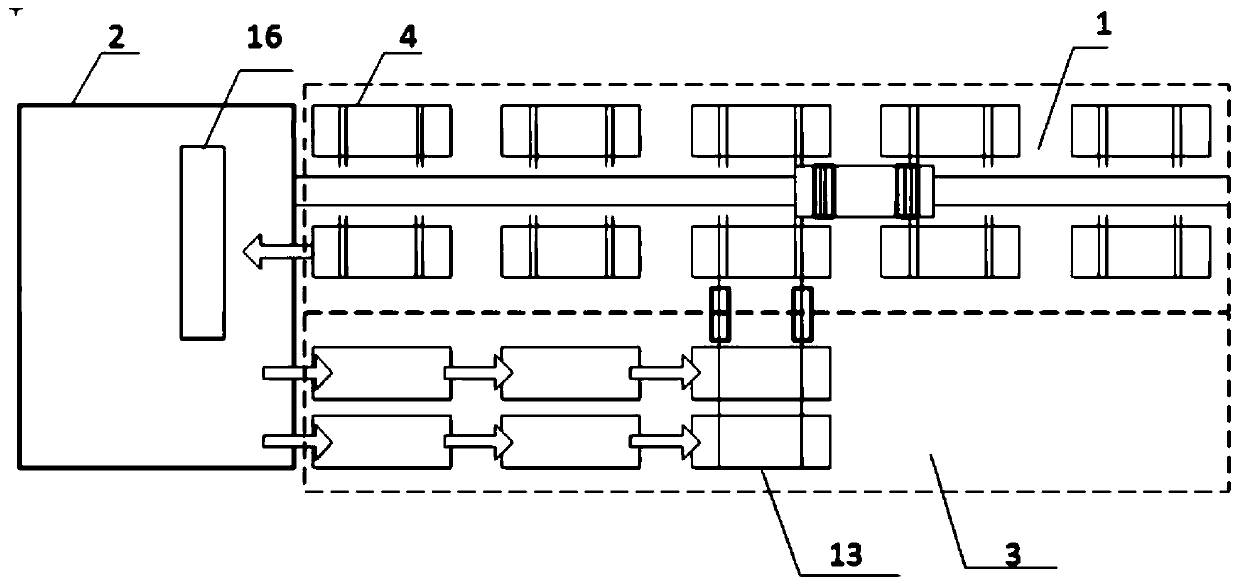

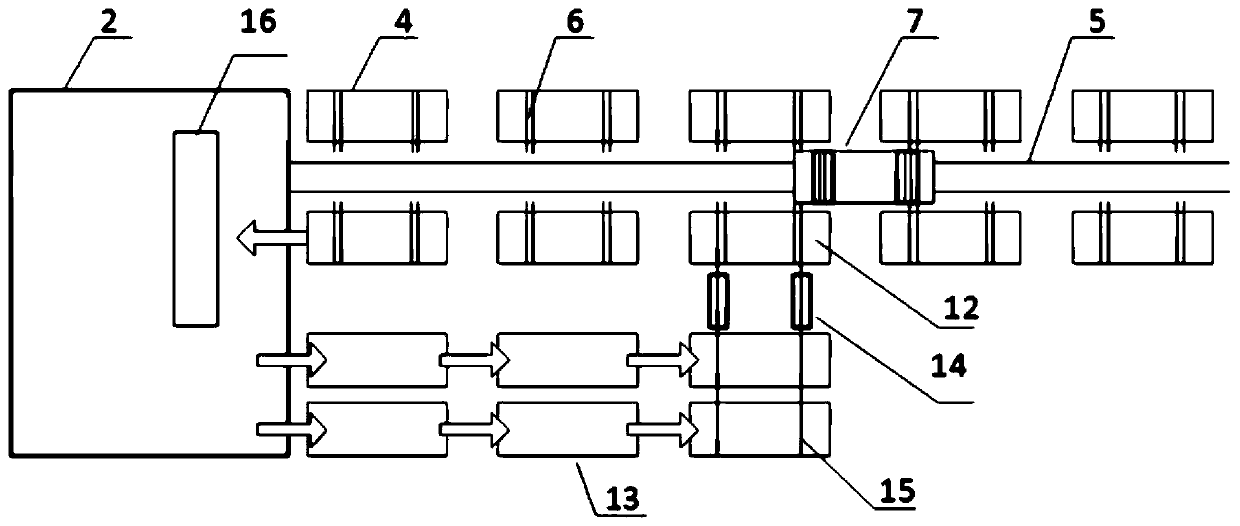

[0047] See attached figure 1 to attach image 3 As shown, the prefabricated component production line in this embodiment includes a first area 1, a second area 3 and a curing kiln 2, the first area 1 and the second area 3 are arranged side by side, and the curing kiln 2 is adjacent to the ends of the two; the second An area 1 includes a plurality of fixed stations 4 arranged in rows, a table form placed above the fixed stations 4, a horizontal track 5 parallel to the fixed stations 4, and each fixed station 4 is provided with a The vertical track 6, the master car 7, the master car 7 transports the table mold to the curing kiln 2 through the horizontal track 5 and the vertical track 6; the second area 3 includes a plurality of flow stations 13, connecting a plurality of flow The horizontal conveying line of the station 13, the table molds that have completed the curing process in the curing kiln 2 circulate in each mobile station 13 along the transverse conveying line. In th...

Embodiment 2

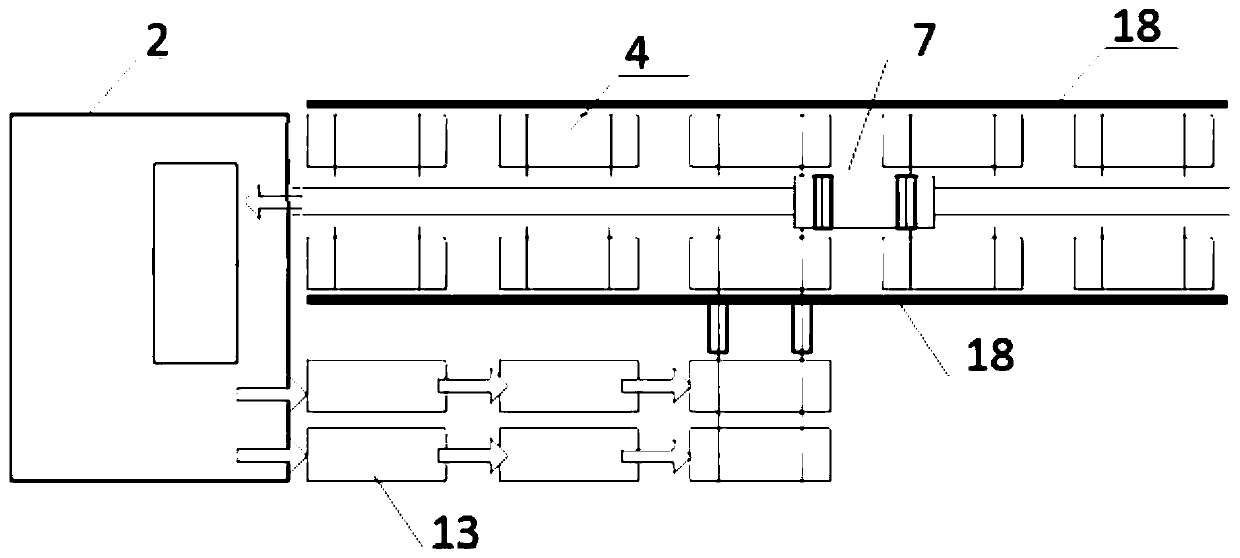

[0058] See attached Figure 7 As shown, the production line in this embodiment is roughly the same as in Embodiment 1, the difference is that a plurality of fixed stations 4 are arranged in parallel rows, and a horizontal track is arranged between every two rows of fixed stations 4 5, each horizontal track 5 is provided with a mother car 7. When producing prefabricated components with a simple structure, due to the short time-consuming procedures such as setting side forms and placing pre-embedded reserved parts, the idle rate of mobile stations 13 in the second area 3 is relatively high; at the same time, in low temperature weather such as winter The initial setting time of fixed station 4 in the first area 1 is relatively long, and it is also easy to cause the idle rate of mobile station 13 in the second area 3 to increase. Therefore, arranging multiple rows of fixed stations 4 can increase the production capacity of the first region 1, thereby improving the degree of coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com