Injection mold mounting equipment

A technology for installing equipment and injection molds, applied in the field of mold supporting equipment, can solve problems such as easy bending, lower efficiency of mold disassembly and replacement, and impact on the production of auto parts, so as to prevent production efficiency and avoid disassembly and replacement efficiency Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

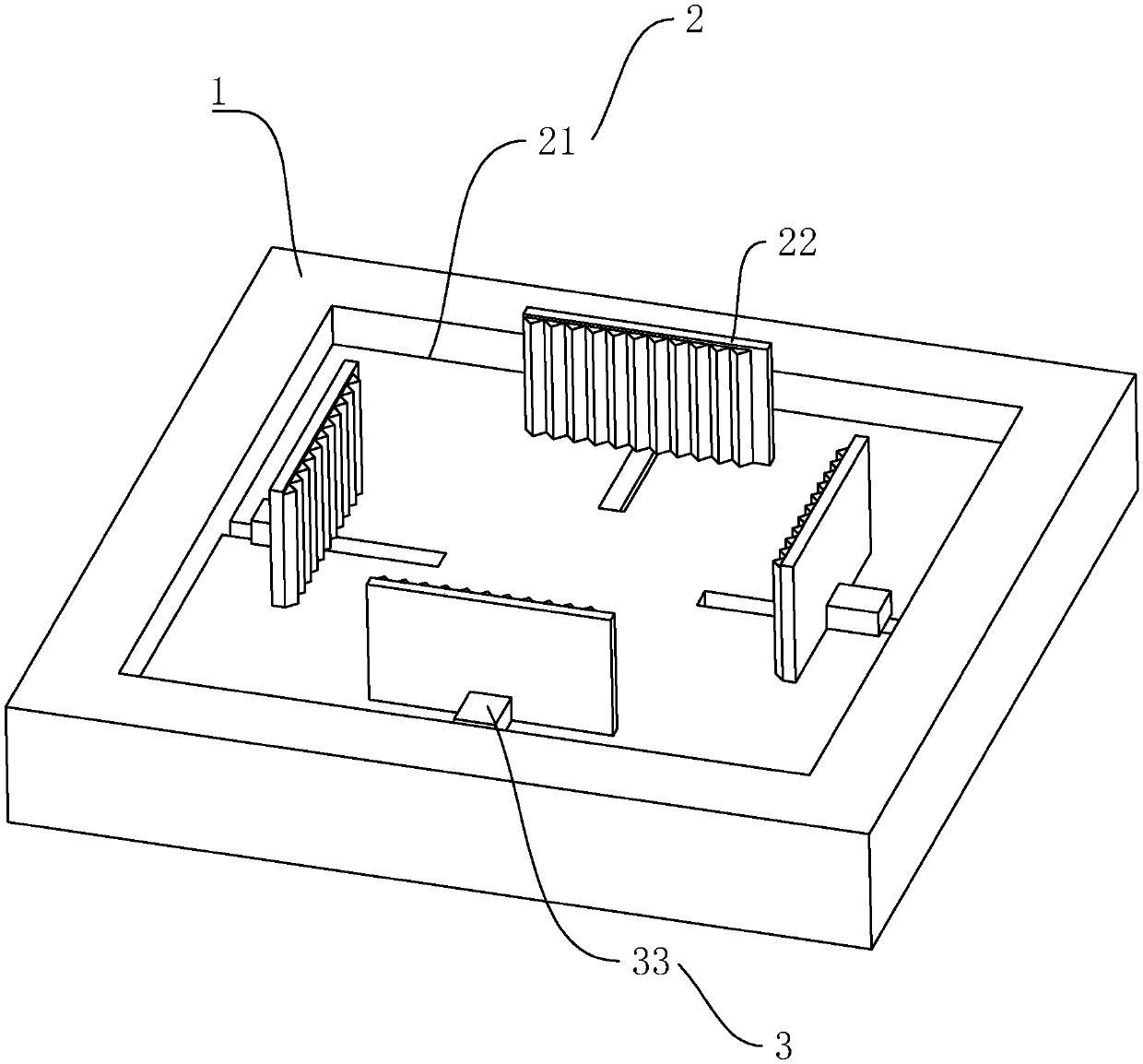

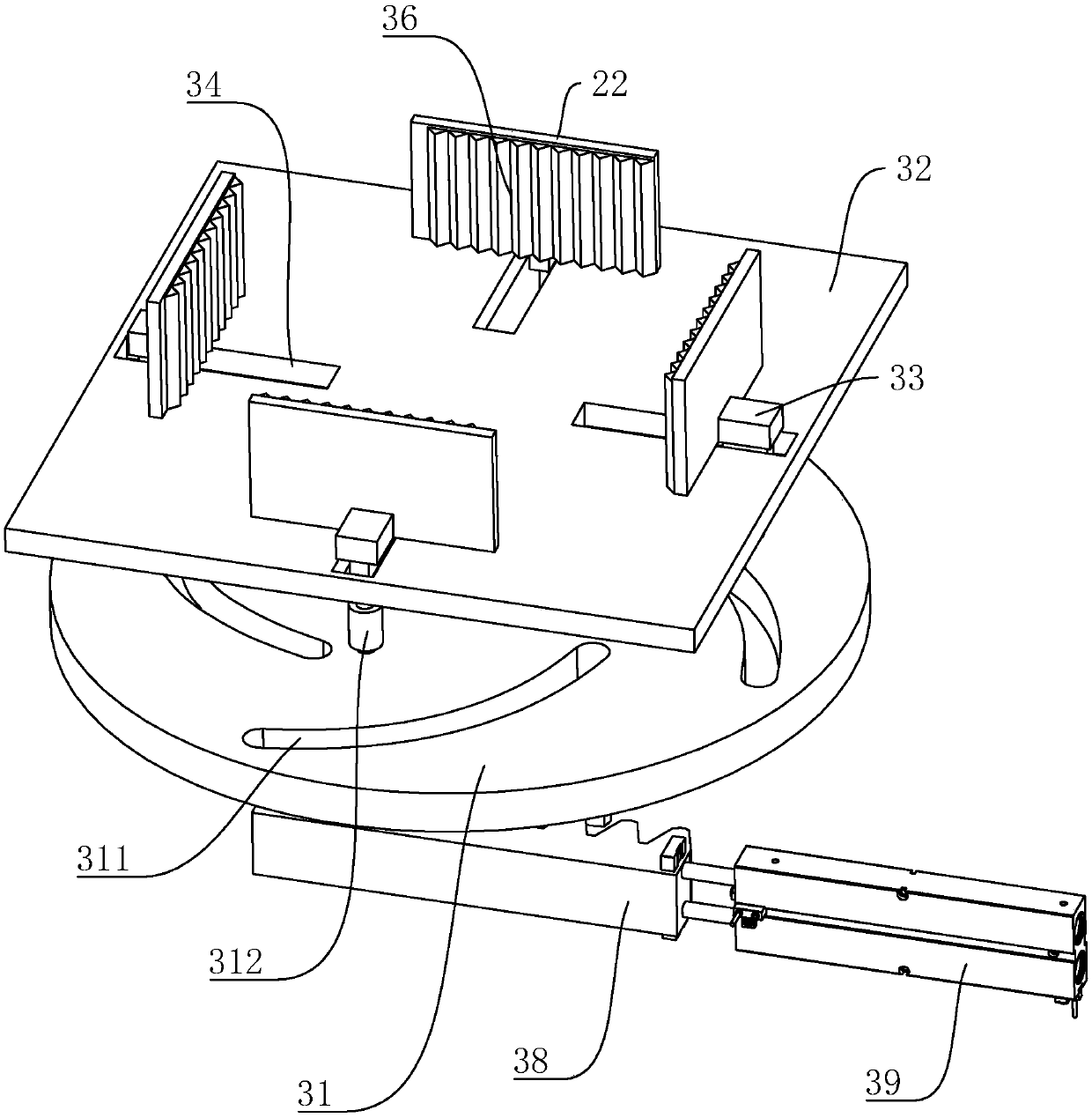

[0028] An injection mold installation device provided in this embodiment has a structure such as Figure 1-3 As shown, the base 1 is included, and the base 1 is fixed on the ground by several bolts. The base 1 is provided with a mounting part 2 for connecting and fixing the mold. The mounting part 2 includes a mounting groove 21 arranged on the base 1. The mounting groove 21 is integral It is square, and the mold is placed in the installation groove 21, and the clamping plate 22 for fixing the square mold is also arranged in the installation groove 21.

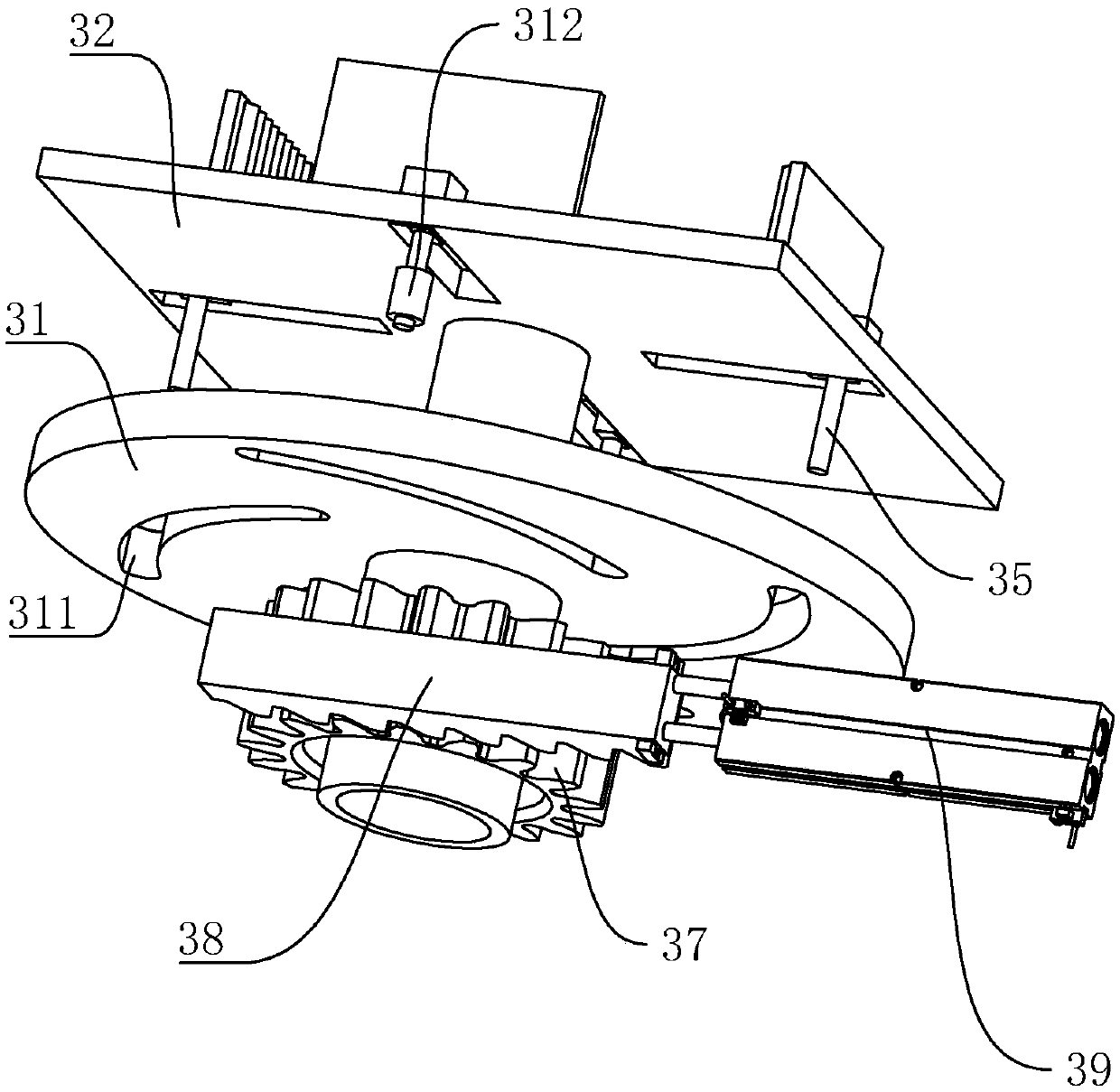

[0029] Such as Figure 1-3 As shown, the clamping plate 22 is arranged around the four sides of the installation groove 21 for clamping and fixing the mould, and the base 1 is also provided with a driving member 3 for driving the clamping plate 22 to slide towards or away from the mold synchronously. The driver 3 includes a driving disc 31 that is rotatably connected to the base 1 and an adjusting disc 32 fixed in the base 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com