Reserved rebar opening integrated template for pouring spreader opening

A reserved steel bar, one-piece technology, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. Low level of technical requirements, smooth and smooth effect, simple disassembly and assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

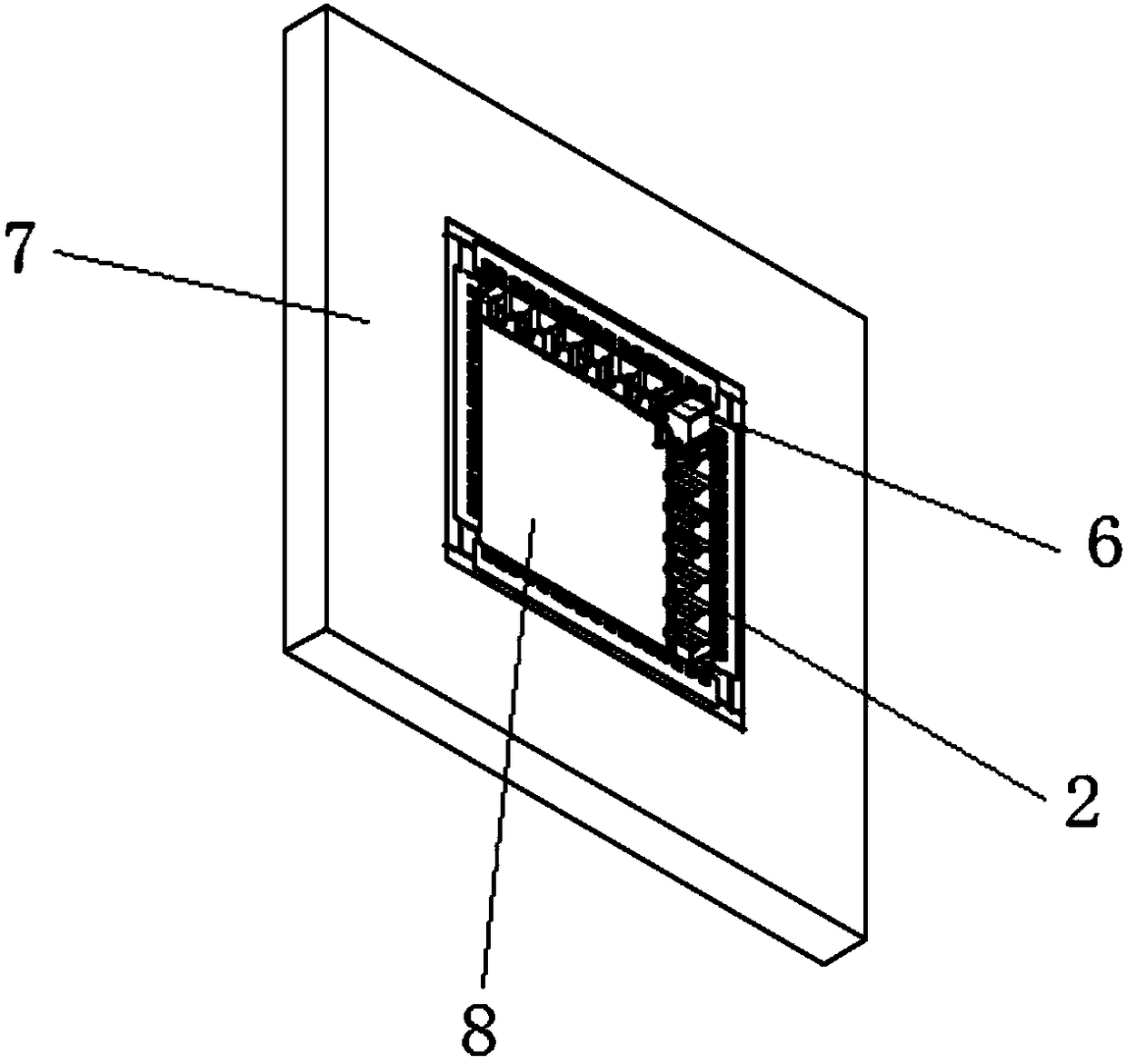

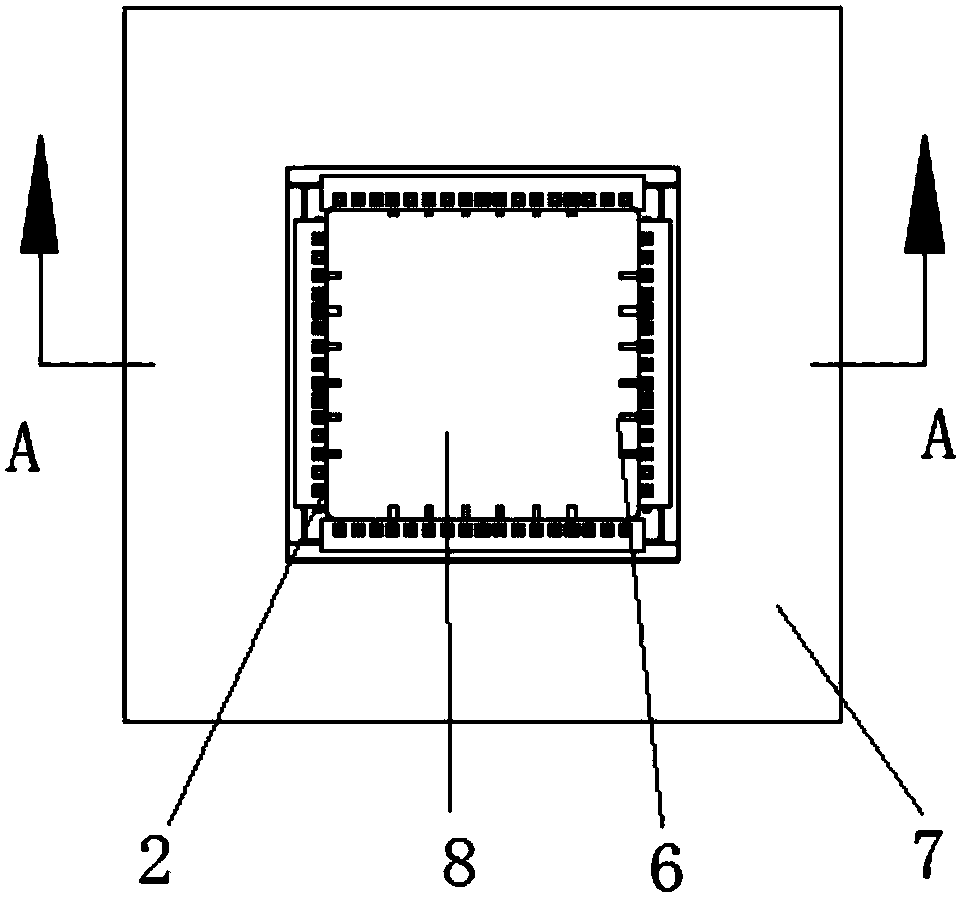

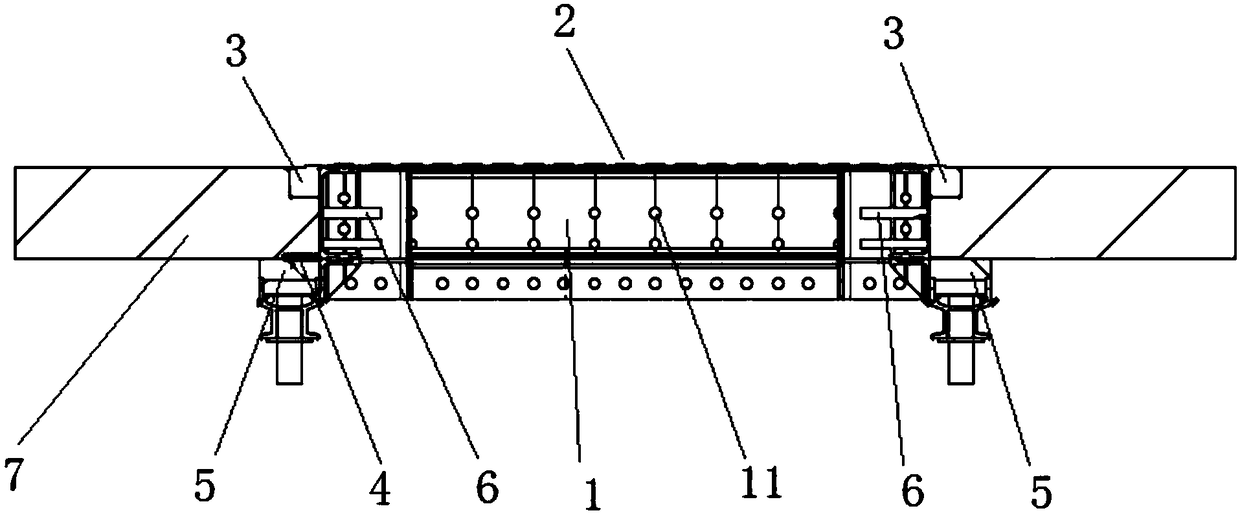

[0021] The specific implementation of the present invention is as follows: Figure 1-5 As shown, a pre-reinforced steel port integrated template for pouring of the cloth machine mouth includes a template 1, a template frame 2 that is spliced around a circle of a multi-segment template 1 and adapted to the orifice of the cloth machine mouth 8. The section formwork 1 is provided with a plurality of through holes 11 that are adapted to the steel bars 6, and the top of the formwork frame 2 is provided with an opening die 3 arranged around its outer side, and the bottom surface of the opening die 3 is set lower than the upper surface of the floor 7. , The bottom of the formwork frame 2 is provided with a support frame 5 that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com