Robot cleaner and operating method thereof

一种自动吸尘器、吸尘器的技术,应用在吸尘器、自动控制行进运动、非电动变量控制等方向,能够解决不能适当地完成清洁操作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, examples of which are shown.

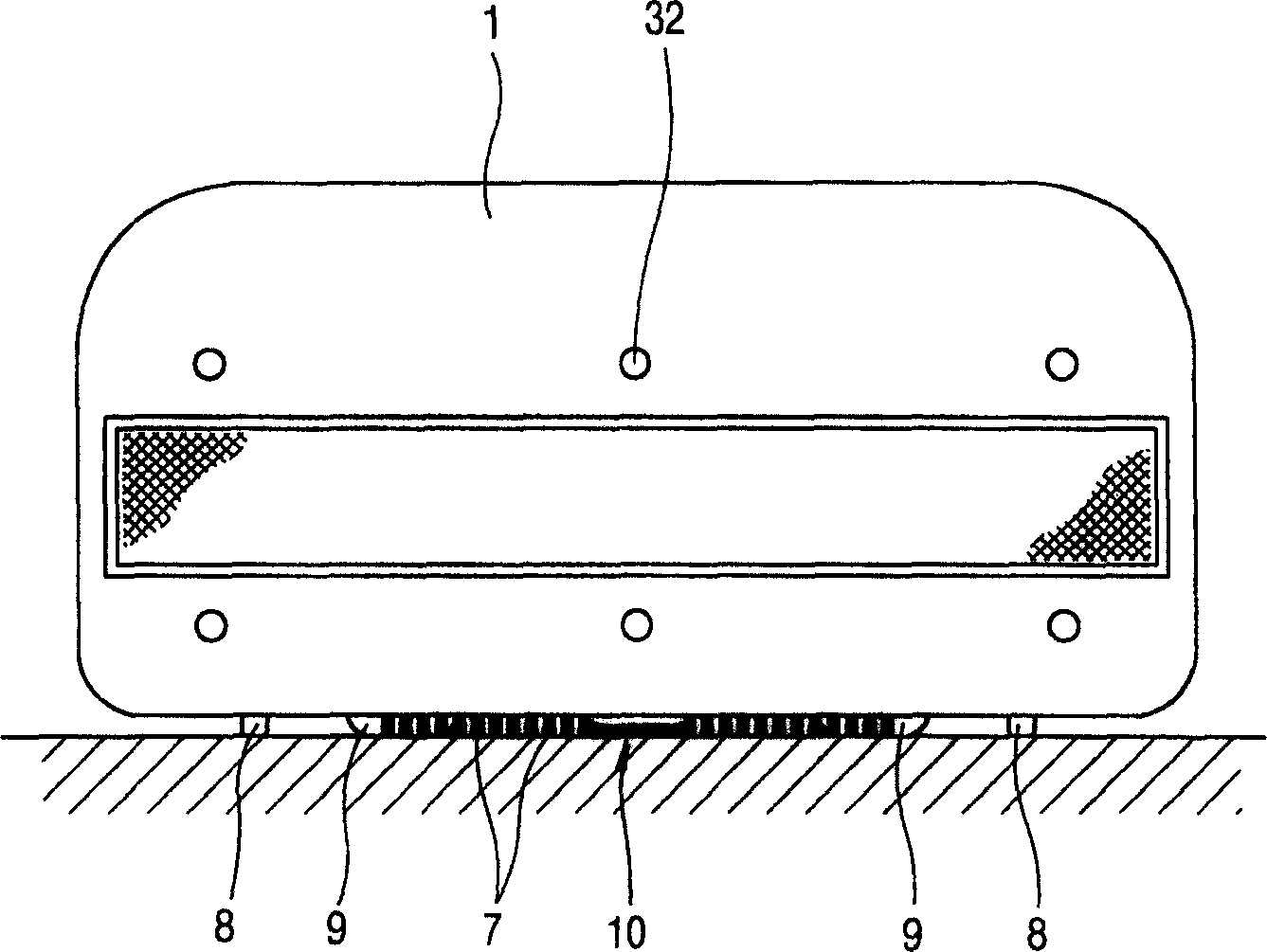

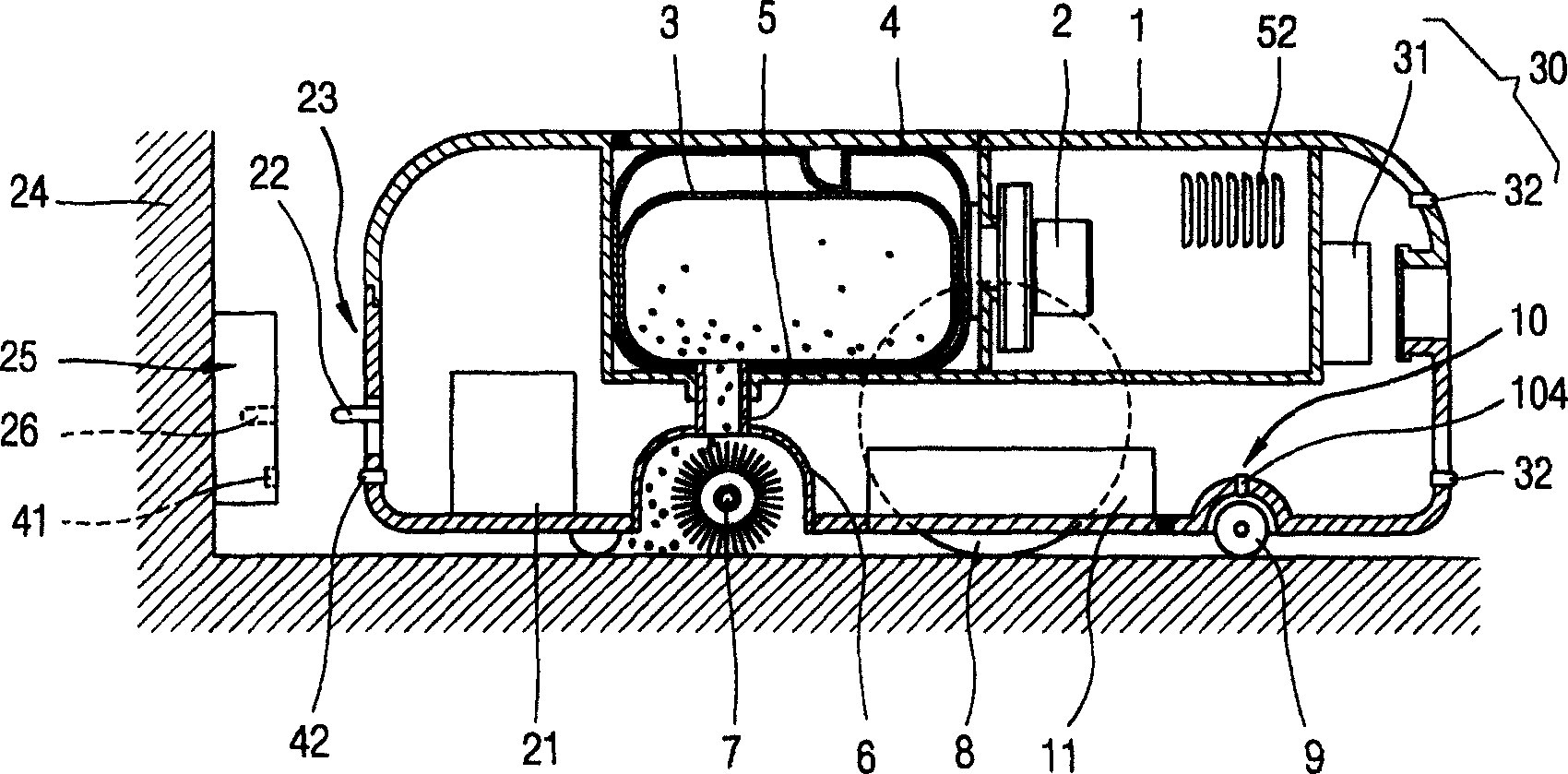

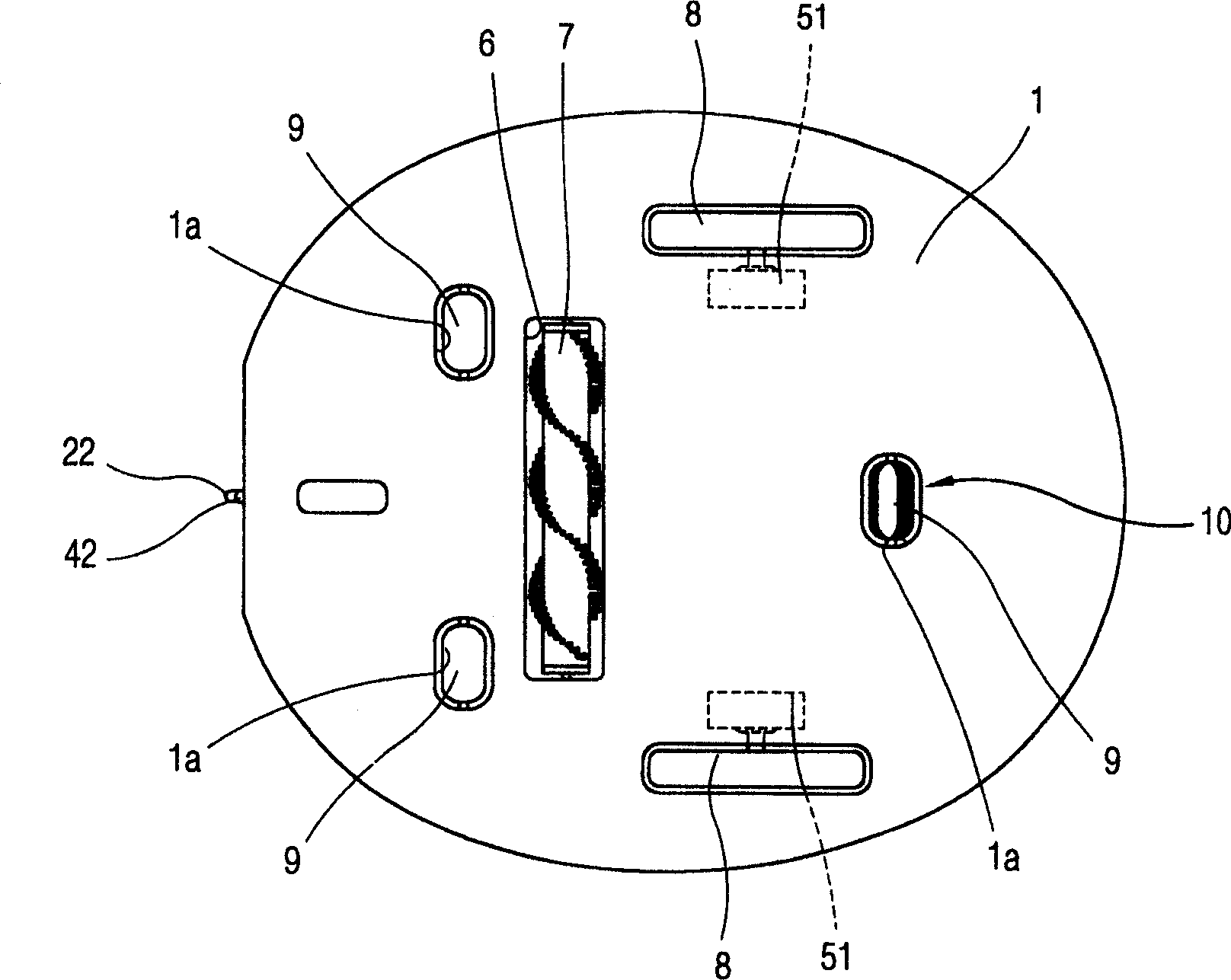

[0017] Such as Figure 1 to Figure 3 As shown, the vacuum cleaner according to the present invention includes: a fan motor 2, which is installed inside the vacuum cleaner body 1 to generate suction; a filter container 4, which has a filter 3 installed near the fan motor 2 and filters the The dirt sucked by the fan motor 2; a suction head 6, which is located at the bottom of the body and is connected with the filter container 4 through a connecting pipe 5, thereby sucking away the dirt on the floor; a brush 7, which is rotatably arranged In the suction head 6, it is used to brush the dirt stuck on the floor; an exhaust port 52 is formed on one side of the body 1, and the filtered air is discharged through the exhaust port 52; at least one navigation Sensor 30, which is installed on one side of the vacuum cleaner body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com