Top module installing and adjusting mechanism for illumination

A technology for installation, adjustment, and frame adjustment, which is applied to lighting devices, lighting auxiliary devices, and components of lighting devices. The effect of high repeatability of positioning and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

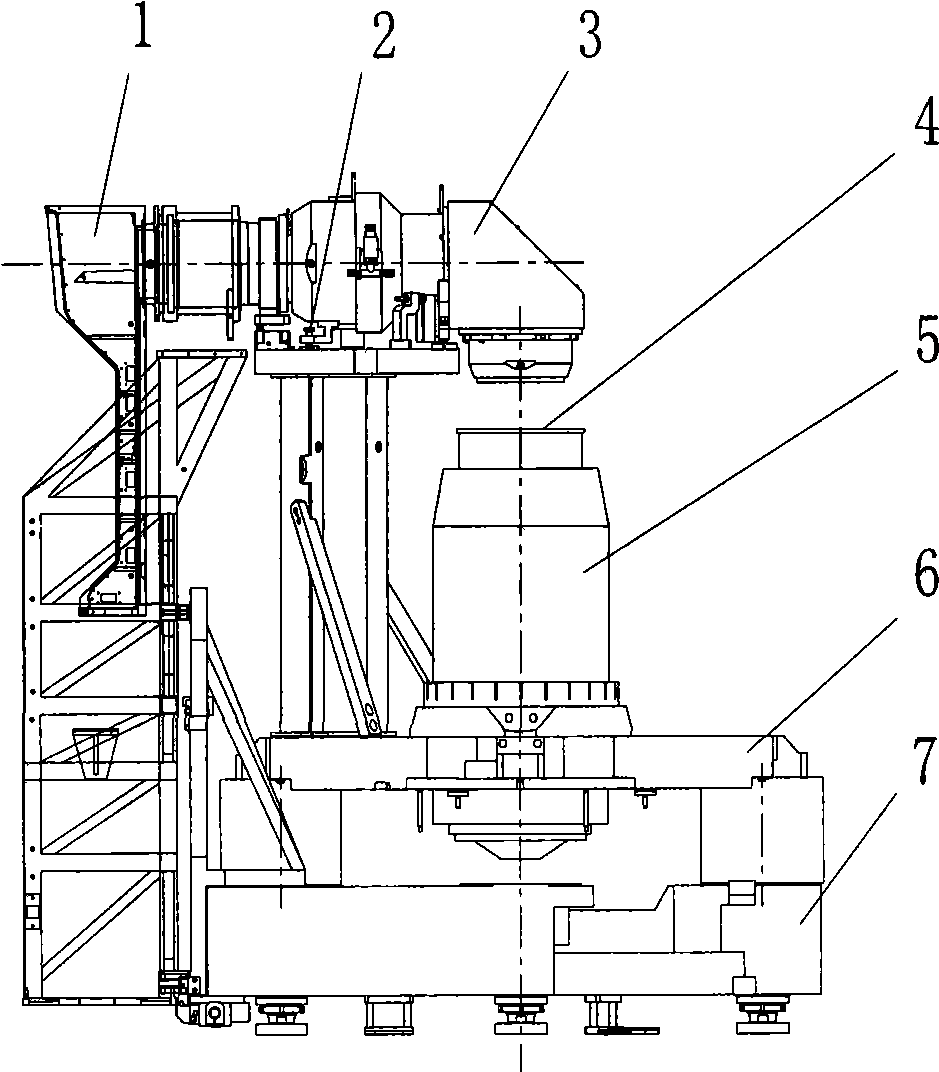

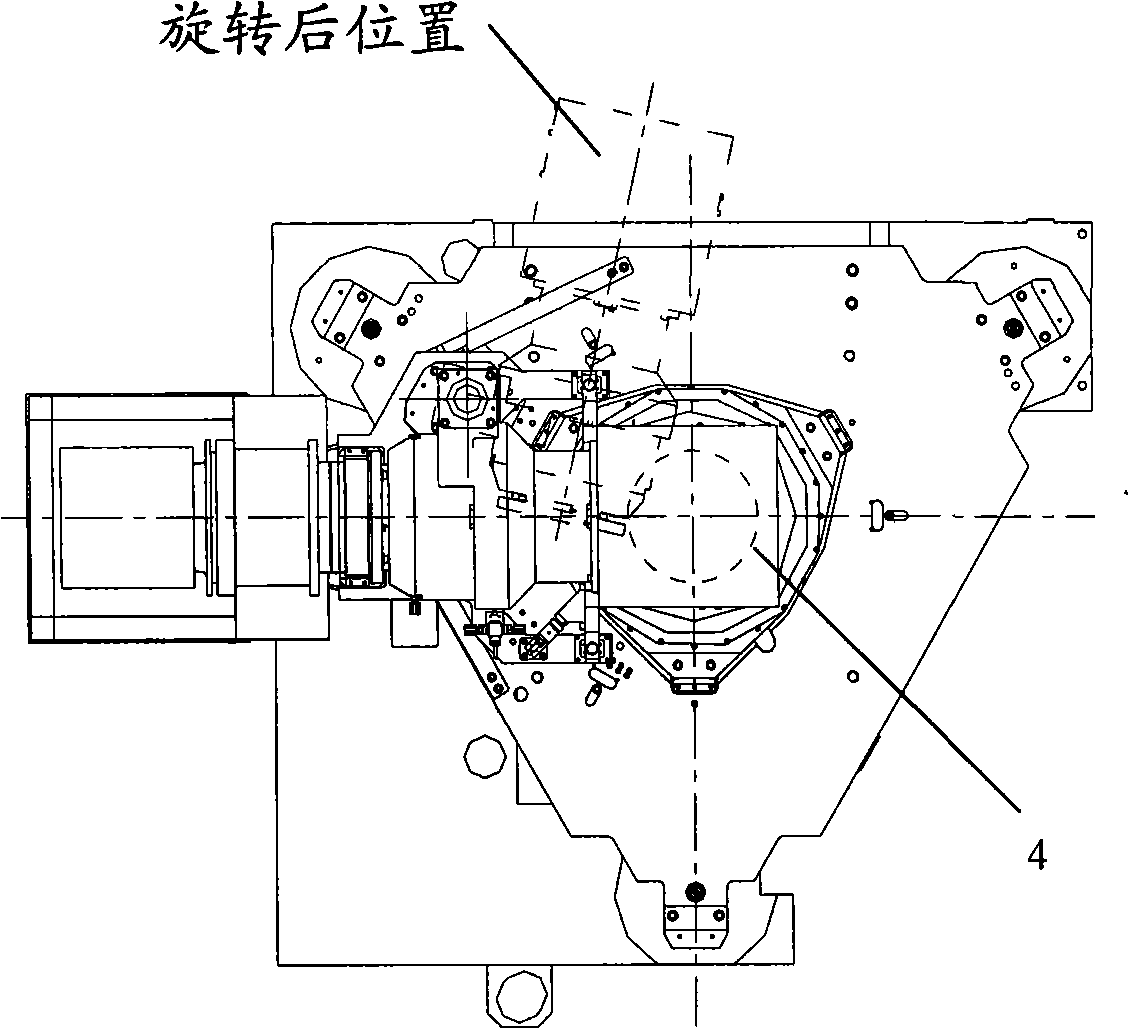

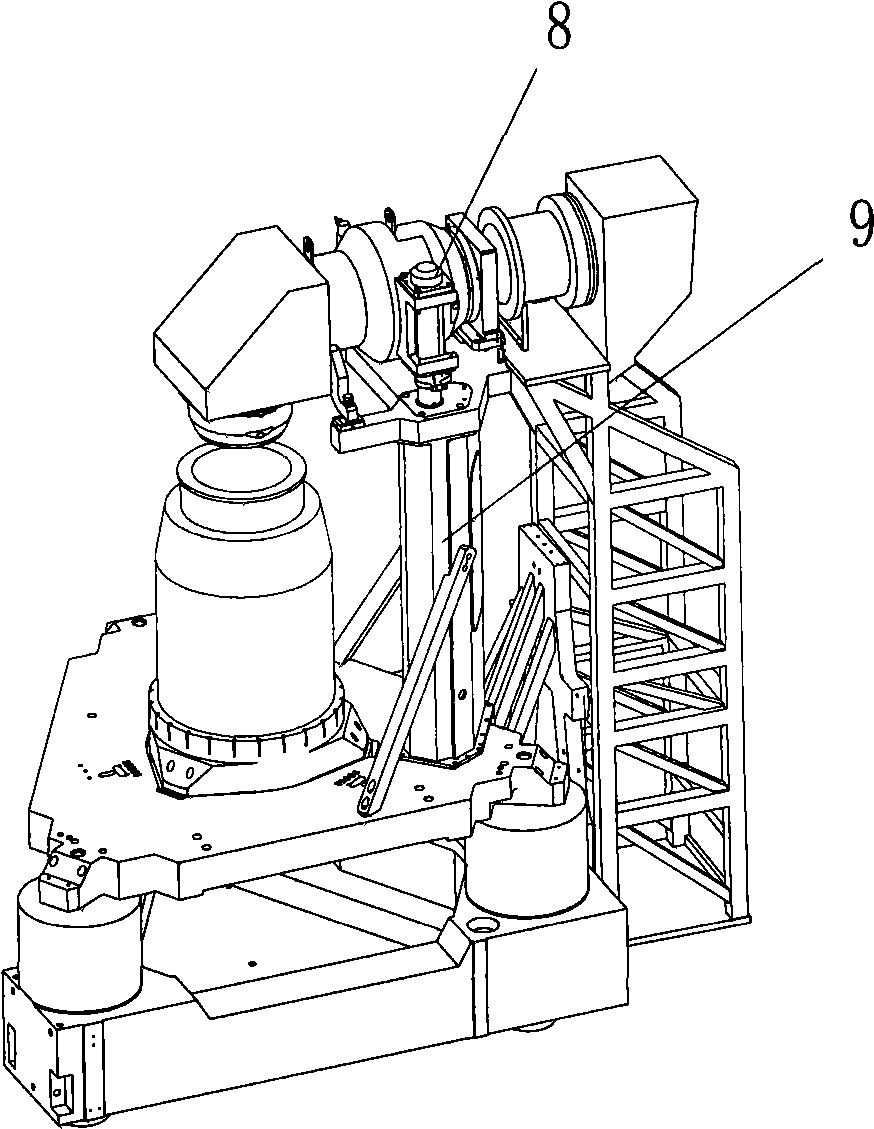

[0027] Below in conjunction with accompanying drawing, the present invention is described clearly and completely:

[0028] The installation and adjustment mechanism of the lighting top module in this embodiment, please refer to Figure 4-9 . Figure 4-9 Middle: 10—lighting bottom module, 11—lighting frame, 12—lighting top module, 13—installation seat plate, 14—(projection objective lens) lens, 15—projection objective lens, 16—moving guide rail, 17—moving cylinder, 18— Lifting cylinder, 19—first fastening screw, 20—unlocking cylinder, 21—lock hook, 22—torsion spring, 23—lock hook support plate, 24—adjustment frame, 25—second fastening screw, 26—lock Tightening screw, 27—locating seat, 28—locating pin, 29—adjusting gasket, 30—adjusting screw, 31—connecting seat plate, 32—hydraulic buffer, 33—slider.

[0029] see Figure 4 This lighting top module installation adjustment mechanism includes a mounting seat plate 13, an adjustment and positioning device is arranged between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com