Crimping tooling for outside rearview mirror lens

A technology for exterior rearview mirrors and lenses, which is applied in the field of crimping tooling for exterior rearview mirror lenses, which can solve the problems of high labor intensity for operators, large gaps between lenses and frames, and reduced production efficiency, so as to improve product quality and quality stability , Stress is uniform, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments.

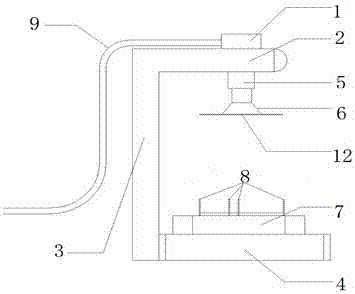

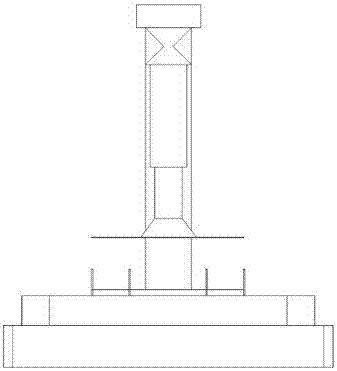

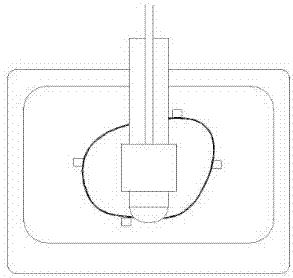

[0021] Such as Figure 1-3 As shown, the external rearview mirror lens crimping tooling includes a workbench, a cylinder 1, a crimping mechanism and a strong sponge body 7. The workbench is composed of a horizontally arranged cantilever beam 2, a base platform 4 and a vertically arranged connecting beam 3, the lower end of the connecting beam 3 is fixed on the base platform 4, and one end of the cantilever beam 2 is fixedly connected with the upper end of the connecting beam 3, The cantilever beam 2 and the base platform 4 are located on the same side of the connecting beam 3 . The cylinder 1 is fixedly installed on the cantilever beam 2 and is used to drive the pressing mechanism. The press-fit mechanism includes a lower pressure rod 5 and a suction cup 6, the suction surface of the suction cup 6 faces downward for absorbing the lens 12, and the other side is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com