Heat-resistant full-biodegradable straw and preparation method thereof

A technology of all-biological straws, applied in the field of heat-resistant full-biodegradable straws and its preparation, can solve problems such as non-conformity with use standards, poor heat resistance, and inability to use hot drinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of the above-mentioned heat-resistant fully biodegradable straw, comprising the following steps:

[0034] 1) Put the inorganic filler, biomass filler, lubricant and compatibilizer into the high-temperature mixing equipment, and stir at 1000rpm-3000rpm for 15-20min at 130-150°C;

[0035] 2) Add fully biodegradable resin, chain extender, and nucleating agent to the mixture prepared in step 1), mix well, put it into a mixer at 120-220°C for 10-15 minutes;

[0036] 3) putting the blend obtained after banburying in step 2) into a twin-screw extruder, extruding and granulating at 130-220° C. to obtain a heat-resistant fully biodegradable straw material;

[0037] 4) extruding the obtained heat-resistant fully biodegradable straw material into a tube shape with a straw extruder;

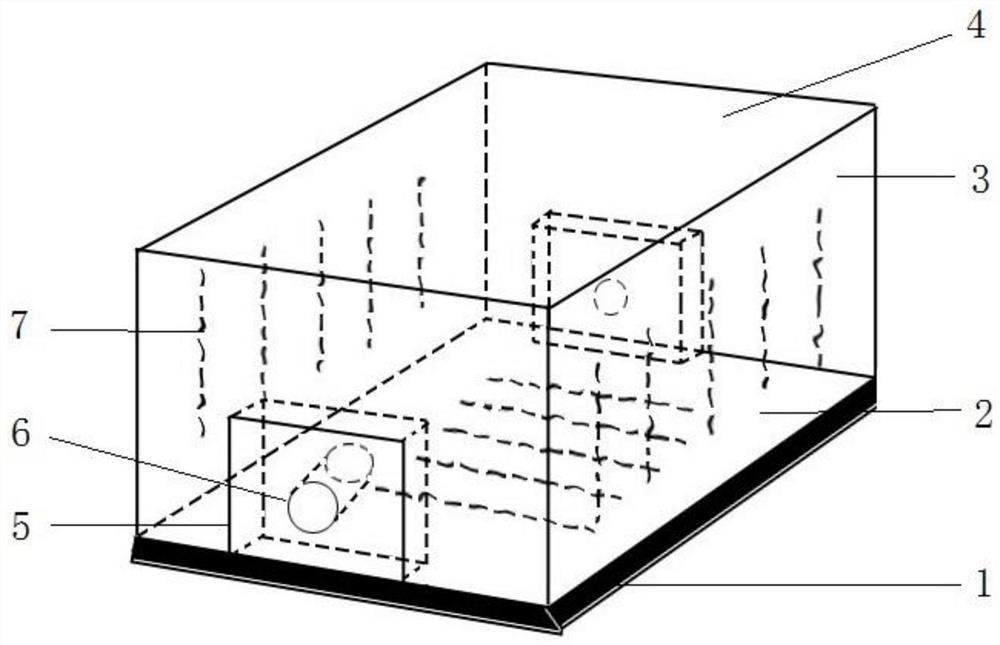

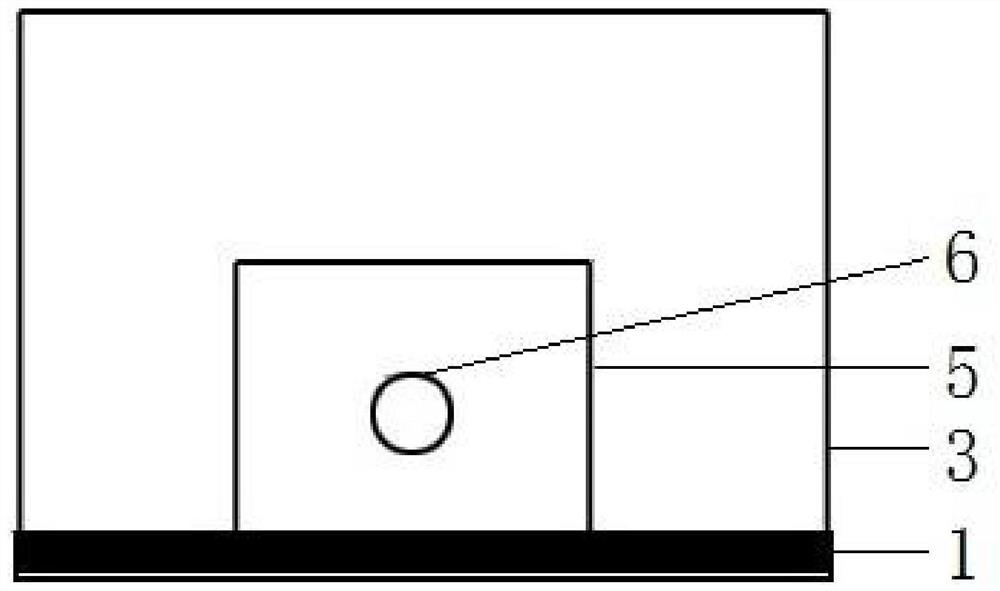

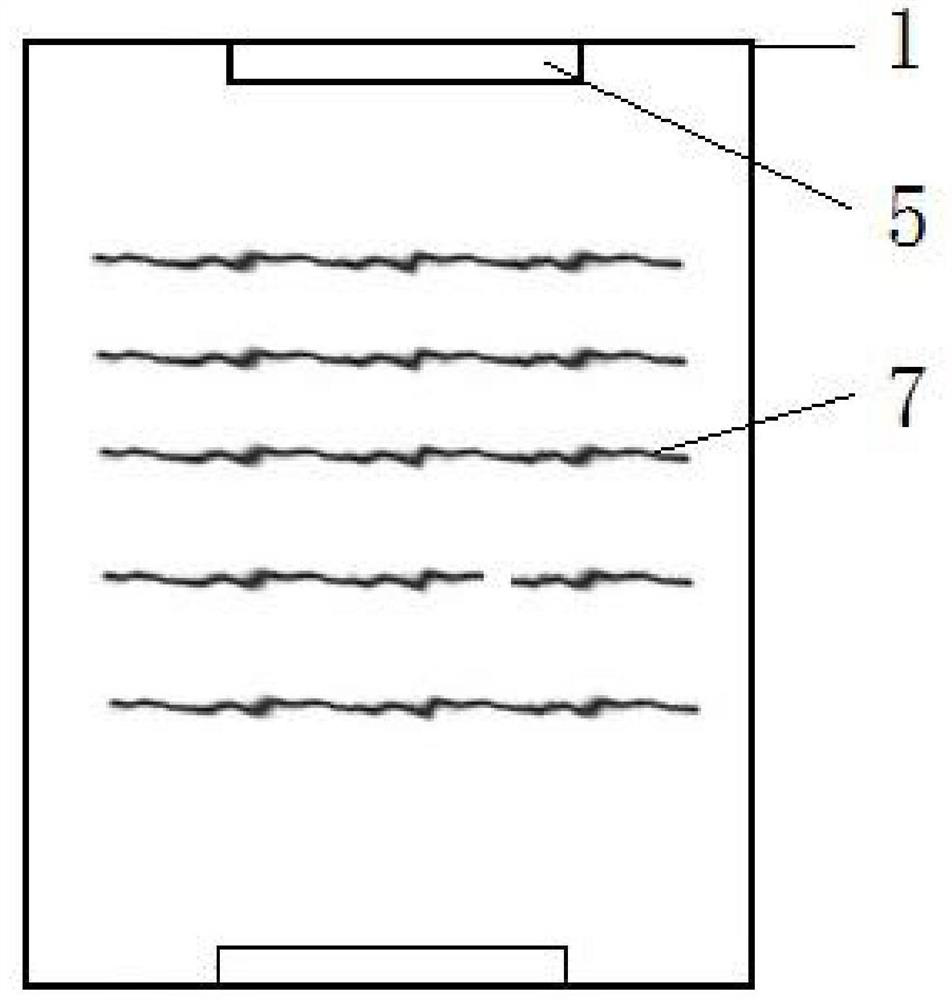

[0038] 5) Put the pipe obtained in step 4) into the post-processing equipment, the heating temperature inside the post-processing equipment ...

Embodiment 1

[0042] This embodiment provides a heat-resistant fully biodegradable straw, including the following components in parts by mass: 100 parts of polylactic acid, 3 parts of sodium silicate, 2 parts of diisocyanate, 30 parts of calcium carbonate, 1 part of aluminate, 1 part of calcium stearate, 25 parts of starch.

[0043] This embodiment also provides the preparation method of the above-mentioned heat-resistant fully biodegradable straw, including the following steps:

[0044] 1) Put calcium carbonate, starch, calcium stearate and aluminate into high-temperature mixing equipment, and stir at 2000rpm for 15min at 135°C;

[0045] 2) Add polylactic acid, diisocyanate, and sodium silicate to the mixture prepared in step 1), mix well, and put it into an internal mixer at 135°C for 10 minutes;

[0046] 3) Put the blend obtained after step 2) into a twin-screw extruder, extrude and granulate at 180°C to obtain a heat-resistant fully biodegradable straw material;

[0047] 4) Extrude th...

Embodiment 2

[0058] This embodiment provides a heat-resistant fully biodegradable straw, which includes the following components in parts by mass: 70 parts of polylactic acid, 30 parts of polybutylene succinate, 4 parts of ethylene bisstearamide, p-phenylene 3 parts of diisocyanate, 30 parts of talc, 1.5 parts of aluminate, 1 part of stearic acid, 20 parts of starch.

[0059] This embodiment also provides a preparation method for the above-mentioned heat-resistant fully biodegradable straw, including the following steps:

[0060] 1) Put talcum powder, starch, stearic acid and aluminate into high-temperature mixing equipment, and stir at 1500 rpm for 15 minutes at 140°C;

[0061] 2) Add polylactic acid, polybutylene succinate, p-phenylene diisocyanate, and ethylene bisstearamide to the mixture prepared in step 1), mix well, and put it into a 135°C internal mixer for banburying for 15 minutes;

[0062] 3) Put the blend obtained after step 2) into a twin-screw extruder, extrude and granulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com