Square outer shell drying device used for electronic product production

A technology for electronic products and drying devices, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., which can solve the problems of poor drying effect and inability to evenly heat the shell surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

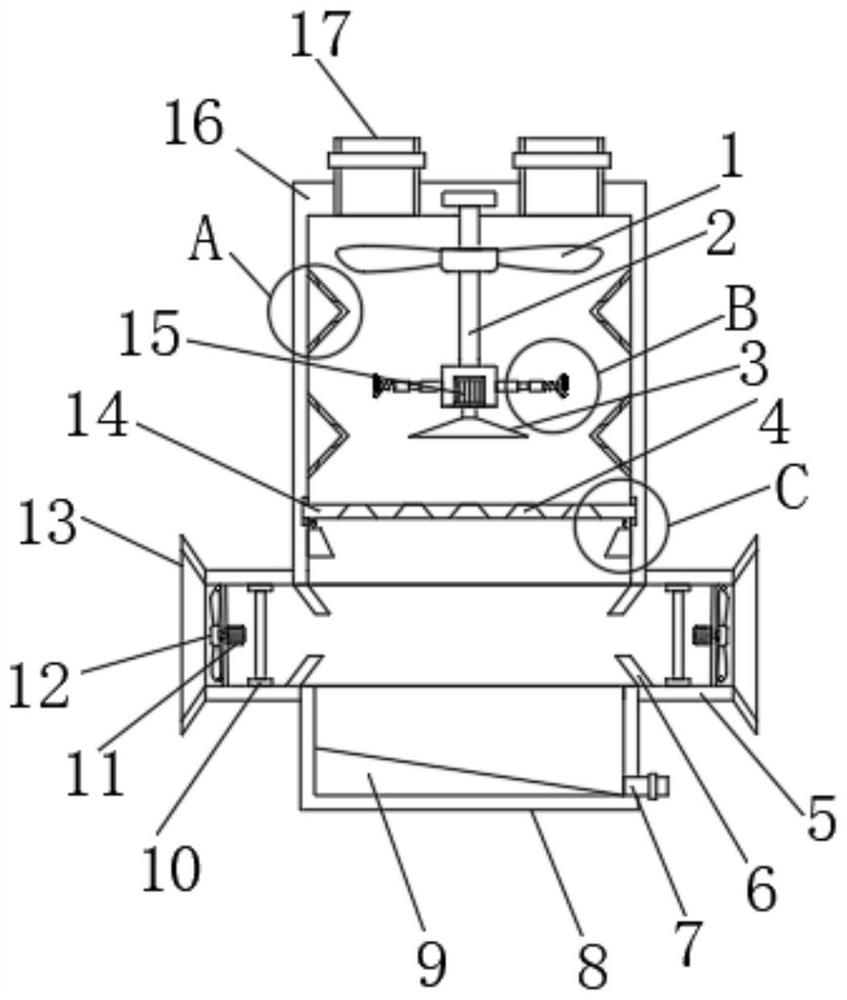

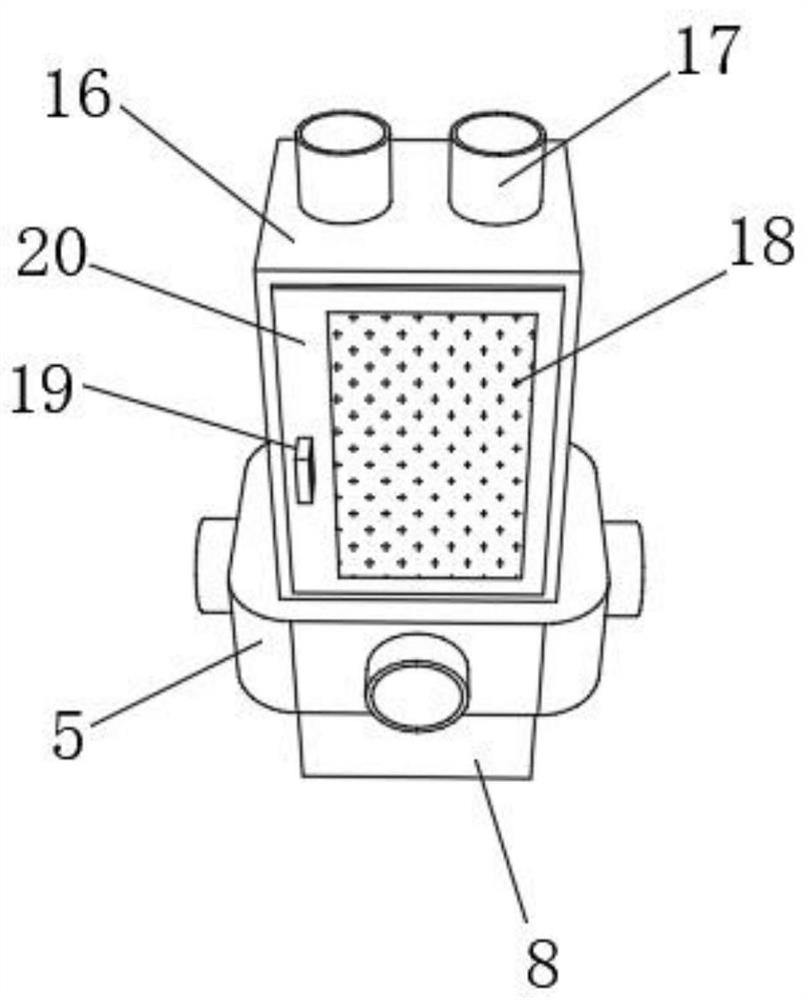

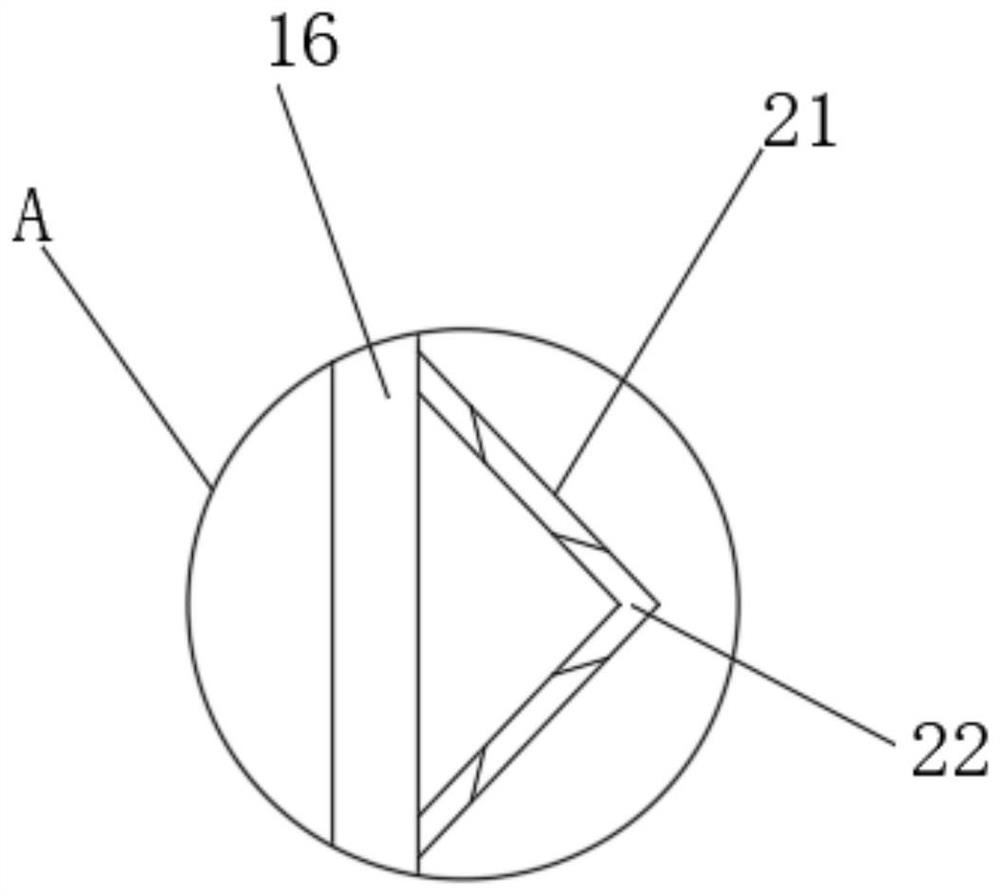

[0030] refer to Figure 1-4 , a square shell drying device for electronic product production, comprising an air inlet tray 5, the outer walls of the air inlet tray 5 are provided with air inlets, and the inner wall of the air inlet is provided with an air inlet mechanism, and the air inlet is close to the air inlet mechanism. The inner wall of the side is fixed with an electric heating film 10 by screws, and the top outer wall of the air inlet tray 5 is provided with an installation opening, and the inner wall of the installation opening is provided with a drying box 16, and the top inner wall of the drying box 16 is connected with a rotating rod 2 through a bearing. And the outer wall of the rotating rod 2 is sleeved with paddles 1, the bottom end of the rotating rod 2 is fixed with a fixed block by screws, and the bottom outer wall of the fixed block is provided with a fixing groove, the inner wall of the fixing groove is provided with a vacuum pump 15, and the vacuum pump 15...

Embodiment 2

[0040] refer to figure 1 and Figure 5 , a square shell drying device for electronic product production. Compared with Embodiment 1, this embodiment also includes that the inner walls of both sides of the drying box 16 are fixed with trapezoidal blocks 30 by screws, and the top outer wall of the trapezoidal block 30 is set There is a buffer spring 29, the top outer wall of the buffer spring 29 is provided with a support plate 14, the top outer wall of the support plate 14 is provided with an air outlet 4 with a trapezoidal structure in section, and the inner walls of both sides of the drying box 16 are provided with chutes 28 , and the supporting plate 14 forms a sliding fit with the inner wall of the chute 28 .

[0041] The supporting plate 14 can play a good supporting effect. During the supporting process, the buffer spring 29 can play a good buffering effect, which can effectively prevent the shell from falling and causing damage when it is fixed unstable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com