Mold mounting equipment

A technology for installing equipment and molds, applied in the field of mold supporting equipment, can solve the problems of mold disassembly and replacement efficiency reduction, easy bending, and affecting the production of auto parts, so as to avoid the reduction of disassembly and replacement efficiency and prevent production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

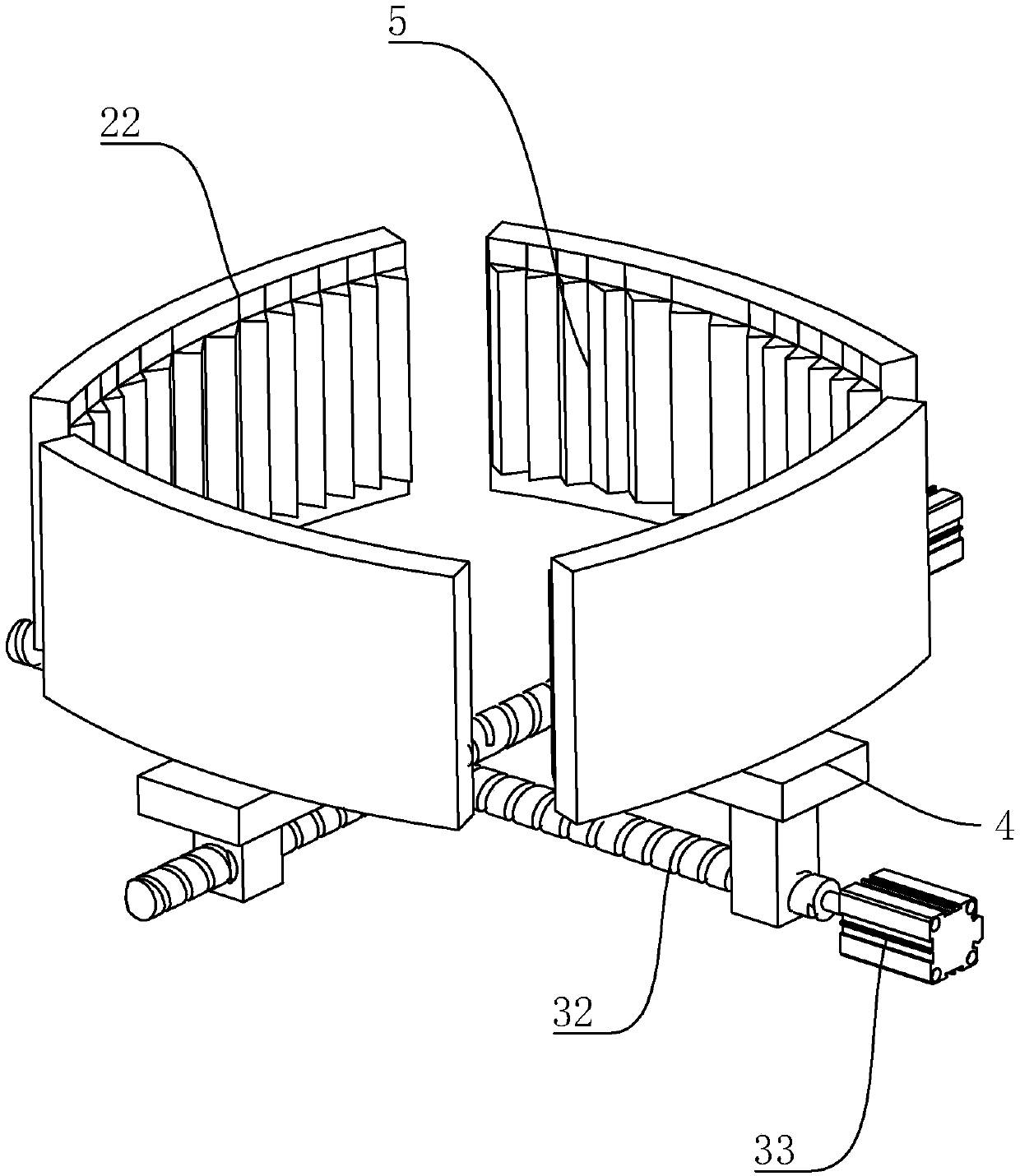

[0031] Embodiment 2, a kind of mold installation equipment, differs from Embodiment 1 in that, as image 3 As shown, the driving member 3 includes a driving screw 32 arranged in the base 1. The driving screw 32 is provided with two sections of threaded sections with opposite thread directions. The driving screw 32 is provided with two, and the two driving screw 32 Arranged in a staggered manner, while the driving screw 32 penetrates the two sliding blocks 4 located on the same straight line, and is threadedly connected with the sliding blocks 4 .

[0032] Such as image 3 As shown, the sliding blocks 4 are respectively located in two opposite threaded segments on the driving screw 32, and slide in the length of the threaded segments. The driving member 3 also includes a servo motor 33 arranged in the base 1, and the servo motor 33 The output shaft and the driving screw 32 are integrated. A rubber pad 5 is provided on the side of the movable plate 22 corresponding to the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com