Diffluence hopper for aluminum fused mass casting

A technology of aluminum melt and funnel, which is used in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of slag removal, easy cracking, and inability to preheat for a long time at high temperature to remove crystal water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

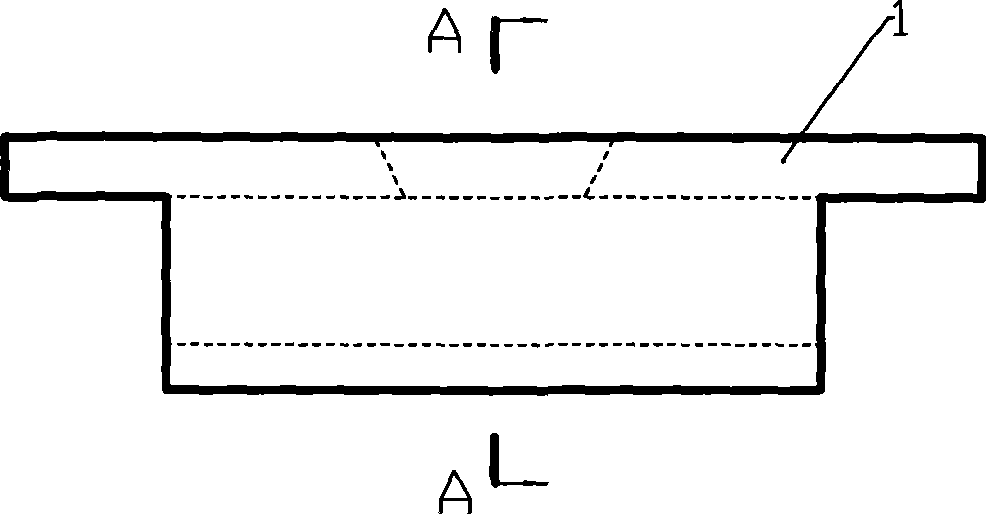

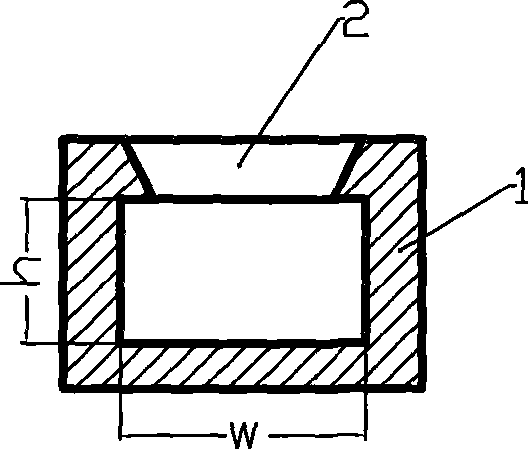

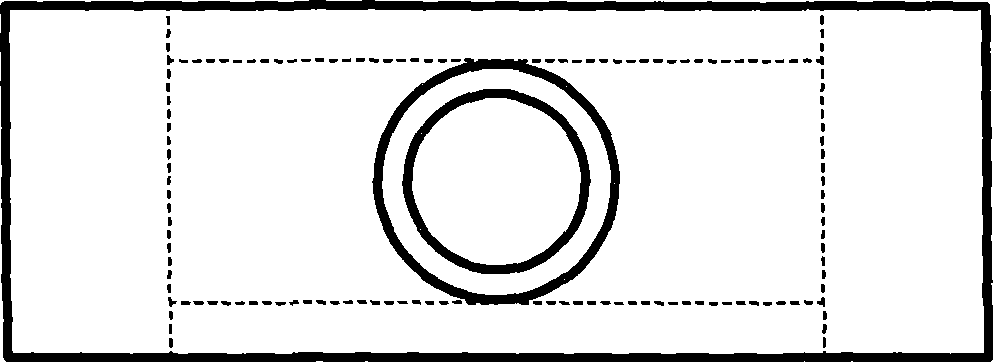

[0012] Such as Figure 1 to Figure 3 Shown is the diverting funnel 1 for aluminum melt casting of the present invention, which is made of insural 140 material, which can be purchased by Pyrotek. The diverting funnel made of this material is sticky aluminum, high temperature resistant And the strength is high, no slag and cracks will be generated during use, and the crystal water will pollute the molten aluminum, which ensures that the slag inclusion of the aluminum ingot will not be caused by the material of the funnel.

[0013] The width w of the shunt groove of the shunt funnel is 70-120 mm, and the height h is 50-120 mm. By appropriately increasing the width and height of the shunt, the flow area of the shunt and the depth of the aluminum liquid in the shunt are increased, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com