Directional freeze steel ingot side wall double-layer hollow adiabatic apparatus

A double-layer hollow, directional solidification technology, applied in the field of metallurgical industry production technology, can solve the problems of large temperature gradient, unfavorable columnar crystal growth, and reduce the quality of steel ingots, achieve large air thermal resistance, reduce heat transfer, and improve ingot quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

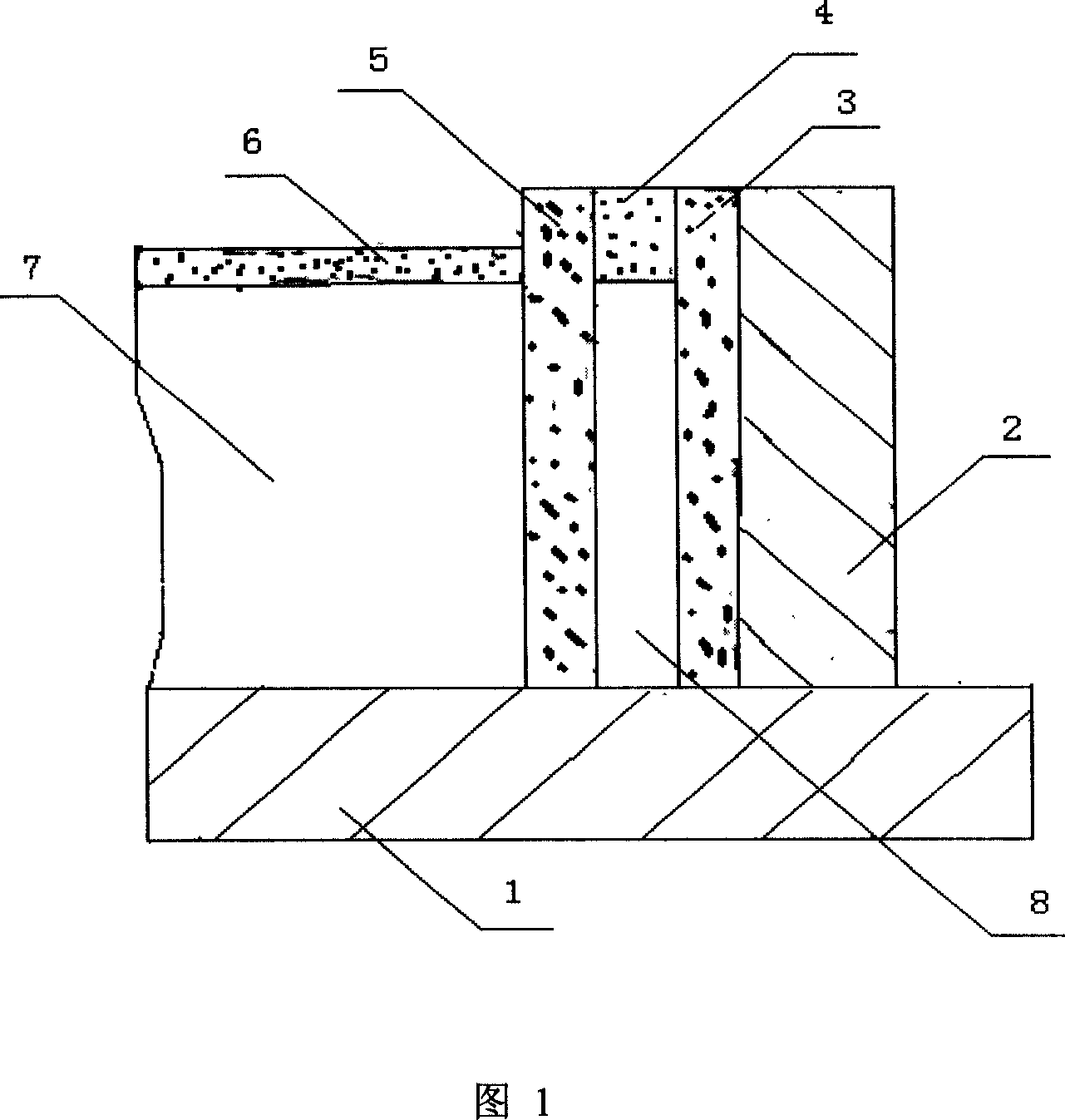

[0014] As shown in Figure 1, the device is provided with two layers of heat insulating material inside the mold filled with molten steel 7, an outer layer of heat insulating material 3 and an inner layer of heat insulating material 5, and an insulating gas layer 8 filled with air is arranged between the two layers of heat insulating material. The inner heat-insulating material 5 is in contact with the molten steel 7; heat-preserving and heating agents 6 and 4 are arranged on the upper part of the molten steel 7 and the insulating air layer 8; the water-cooling chassis 1 is arranged at the bottom of the device.

[0015] The water-cooled chassis 1 and the mold 2 are made of cast iron, wherein the water-cooled chassis 1 is equipped with connected water pipes, and water inlet and outlet devices are installed on both sides of the chassis to cool the molten steel and reduce the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com