Continuous casting method for high-manganese and high-aluminum type austenite low-magnetic steel

A high-aluminum, austenitic technology, applied in the field of continuous casting of high-manganese, high-aluminum, austenitic low-magnetic steel, can solve the problems of many surface defects, low comprehensive yield, and long process route, etc., and achieve The effect of good quality, avoiding production accidents, and low tissue density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment focuses on the description of the continuous casting process, and other processes are operated according to conventional methods.

[0033] 1. The continuous casting method of the high manganese high aluminum type austenitic low magnetic steel provided in this embodiment, the production process route is as follows:

[0034] Hot metal pretreatment—K-OBM-S top-bottom combined blowing converter smelting—LF ladle refining—VD vacuum treatment—continuous casting—slab hot cutting—pile cooling

[0035] 2. Billet specification: 200mm×1260mm×2100±50mm

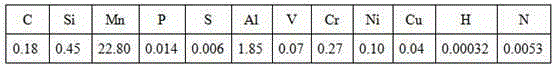

[0036] 3. See Table 1 for the composition of molten steel in continuous casting

[0037] Table 1 Composition of continuous casting molten steel

[0038]

[0039] 4. The sedation time after upper wishbone is 10 minutes; blow argon gas into the tundish for 5 minutes before the ladle is poured.

[0040] The embodiment of the continuous casting method of this high manganese high aluminum type austenitic low magn...

Embodiment 2

[0054] This embodiment focuses on the description of the continuous casting process, and other processes are operated according to conventional methods.

[0055] 1. The continuous casting method of the high manganese high aluminum type austenitic low magnetic steel provided in this embodiment, the production process route is as follows:

[0056] Hot metal pretreatment—K-OBM-S top-bottom combined blowing converter smelting—LF ladle refining—VD vacuum treatment—continuous casting—slab hot cutting—pile cooling

[0057] 2. Billet specification: 200mm×1260mm×2650±50mm

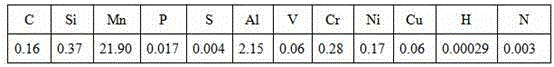

[0058] 3. See Table 2 for the composition of molten steel in continuous casting

[0059] Table 2 Composition of molten steel for continuous casting

[0060]

[0061] 4. The sedation time after upper wishbone is 10 minutes; blow argon gas into the tundish for 5 minutes before the ladle is poured.

[0062] The embodiment of the continuous casting method of this high manganese high aluminum type austenitic low ...

Embodiment 3

[0076] This embodiment focuses on the description of the continuous casting process, and other processes are operated according to conventional methods.

[0077] 1. The continuous casting method of the high manganese high aluminum type austenitic low magnetic steel provided in this embodiment, the production process route is as follows:

[0078] Hot metal pretreatment—K-OBM-S top-bottom combined blowing converter smelting—LF ladle refining—VD vacuum treatment—continuous casting—slab hot cutting—pile cooling

[0079] 2. Billet specification: 200mm×1260mm×2700±50mm

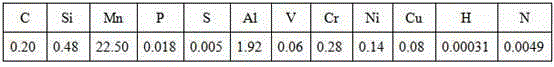

[0080] 3. The composition of molten steel for continuous casting is shown in Table 3

[0081] Table 3 Composition of molten steel for continuous casting

[0082]

[0083] 4. The sedation time after upper wishbone is 10 minutes; blow argon gas into the tundish for 5 minutes before the ladle is poured.

[0084] The embodiment of the continuous casting method of this high manganese high aluminum type austenitic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com