Core-embedded mold facilitating ejection-out of forging

A technology of inserting cores and molds, which is applied in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., which can solve the problems of reduced enterprise efficiency, deformation and damage of forgings, and time-consuming cleaning of molds. , to achieve the effect of avoiding production interruption and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

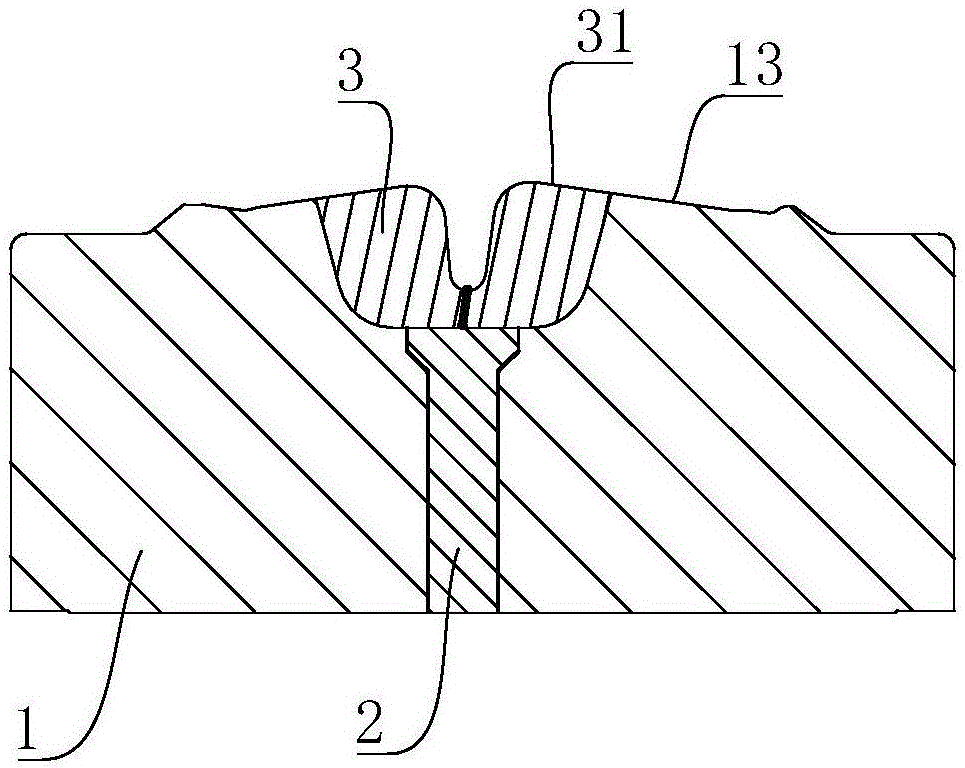

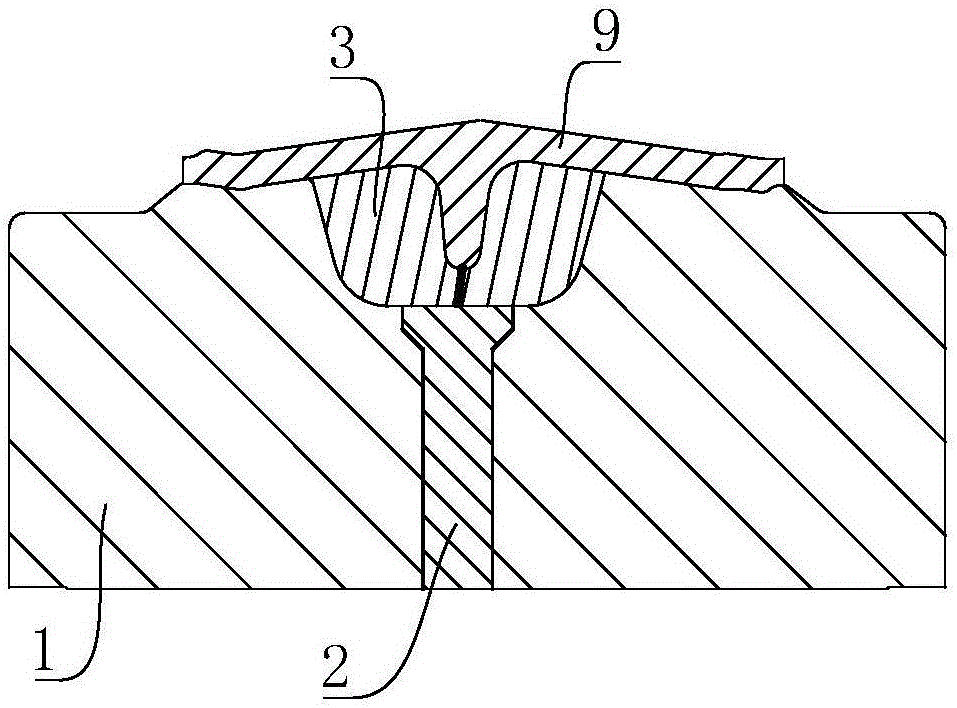

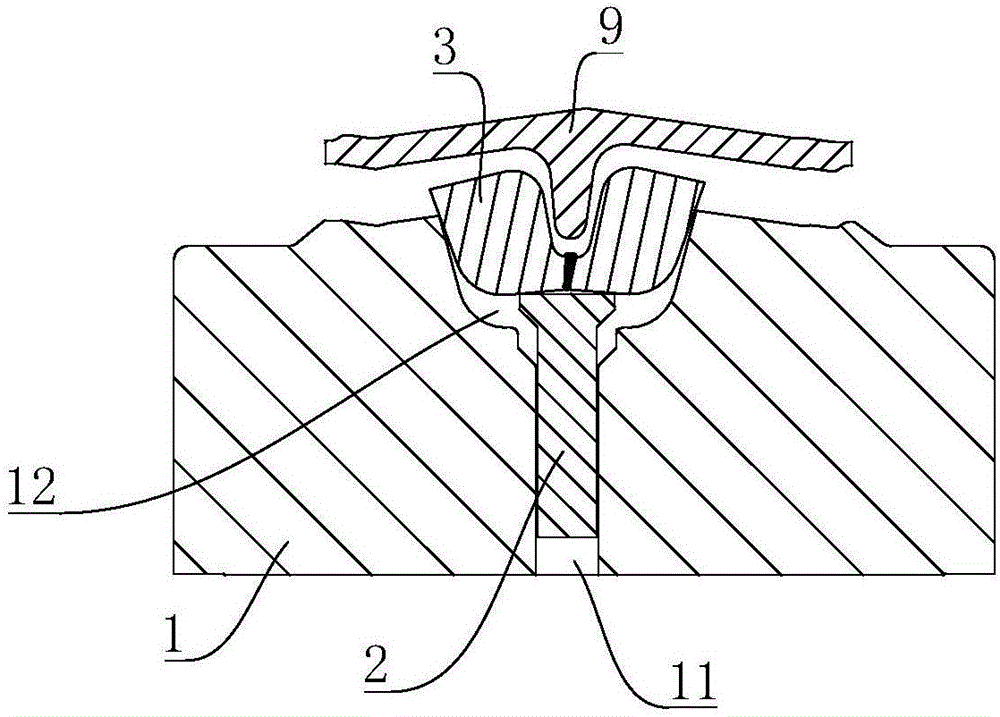

[0020] A core-inserted mold for facilitating the ejection of forgings, including a mold body 1, a first cavity surface 13 is provided on the surface of the mold body 1, a movable ejector rod 2 for ejecting forgings is arranged in the mold body 1, and the mold body 1 A mosaic cavity 12 is also provided, and a mosaic core 3 is embedded in the mosaic cavity 12. The surface of the mosaic core 3 exposed from the mosaic cavity 12 is provided with a second cavity surface 31, and the second cavity surface 31 is in contact with the first cavity surface. The cavity surface 13 is combined into a preset cavity, the mosaic cavity 12 is movably matched with the insert core 3, and the insert core 3 is located on the ejection path of the ejector rod 2, and the insert core 3 is ejected close to the ejector rod 2 The size of one end is smaller than that of the opposite end; the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com