Method and equipment for manufacturing composite fiber containing continuous glass fiber

A glass fiber and composite fiber technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve the problems of low glass fiber content, high cost, and large quality fluctuations, and achieve strong bonding performance and good film-forming performance , the effect of uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

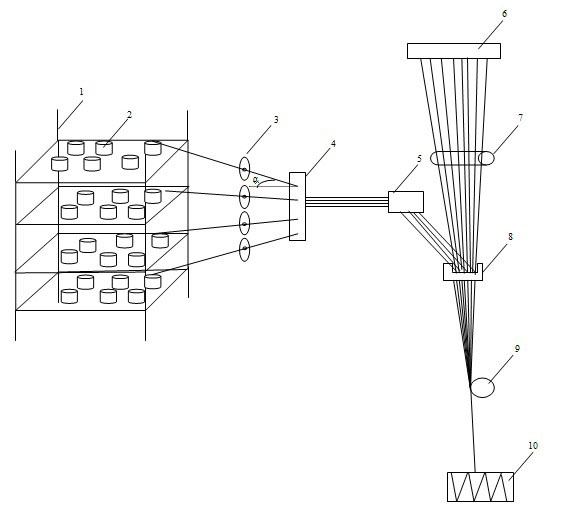

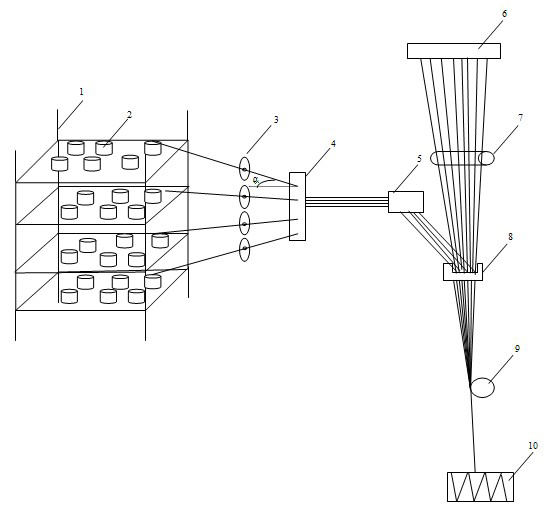

[0026] refer to figure 1 , a composite fiber manufacturing method containing continuous glass fiber, the composite fiber is formed by mixing offline polyester and online continuous glass fiber, the glass fiber is drawn online, the polyester is a finished yarn, and multiple bundles of different yarn feed angles The polyester is pulled and the tension is adjusted and then converged into a sheet, and the converged polyester tow is separated and compounded with the glass fiber treated with the sizing agent.

[0027]The polyester draws at the same speed as the fiberglass.

[0028] The glass fiber is compounded with one or more kinds of polyester, and the mass ratio of the glass fiber to the polyester is 85:15-10:90.

[0029] The boiling water shrinkage of the polyester is within 3%, the yarn feeding angle is between 0° and 60°, and the adjusted tension is between 15 and 300CN.

[0030] In the manufacturing method of composite fibers containing continuous glass fibers according to...

example

[0035] 1. Using 7 polyester yarn balls with a linear density of 333dtex as the source of polyester, the shrinkage in boiling water was 1.4%. The yarn feeding angle of the chemical fiber is at most 20°, and the tension value of the chemical fiber after passing through the tensioner 3 is between 25 and 45CN. After obtaining the yarn clusters of composite fibers according to the method and equipment of the present invention, the final composite fiber product is obtained after drying at a high temperature of 122° C. for 18 hours. The linear density is 800 tex, the ratio of glass fiber to polyester is 70:30, and the water 0.05%.

[0036] The obtained composite fiber is woven into a unidirectional fabric by using a warp knitting machine, and the weft yarn is also polyester, and then the multi-layered unidirectional fabric is pressed on a hot press to form a unidirectional glass fiber-reinforced PET thermoplastic resin composite material, and its mechanical properties are shown in ...

Embodiment 2

[0043] refer to figure 1 , special equipment for the composite fiber manufacturing method containing continuous glass fibers, including a glass fiber drawing device that pulls the glass liquid into glass fibers, an oiling roller 7 coated with a sizing, a composite device 8, cluster wheel 9, wire drawing machine 10, and also includes a multi-layer creel 1 for placing polyester yarn clusters 2, behind which creel 1 is provided with a tensioner 3 for adjusting the tension of polyester yarn and a rectifier for converging polyester yarn 4. A separator 5 for dispersing polyester yarn bundles, said separator 5 is located above the compounder 8 .

[0044] The tensioner 3 is a liquid damping compensation tensioner, including a base, a wire inlet plate, a compensation component, an adjustment rod and a dial.

[0045] The separator 5 is a porous plate with a plurality of ceramic holes evenly distributed.

[0046] The compounder 8 is a phenolic resin plate with a notch.

[0047] The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com