Patents

Literature

30results about How to "Ensure adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

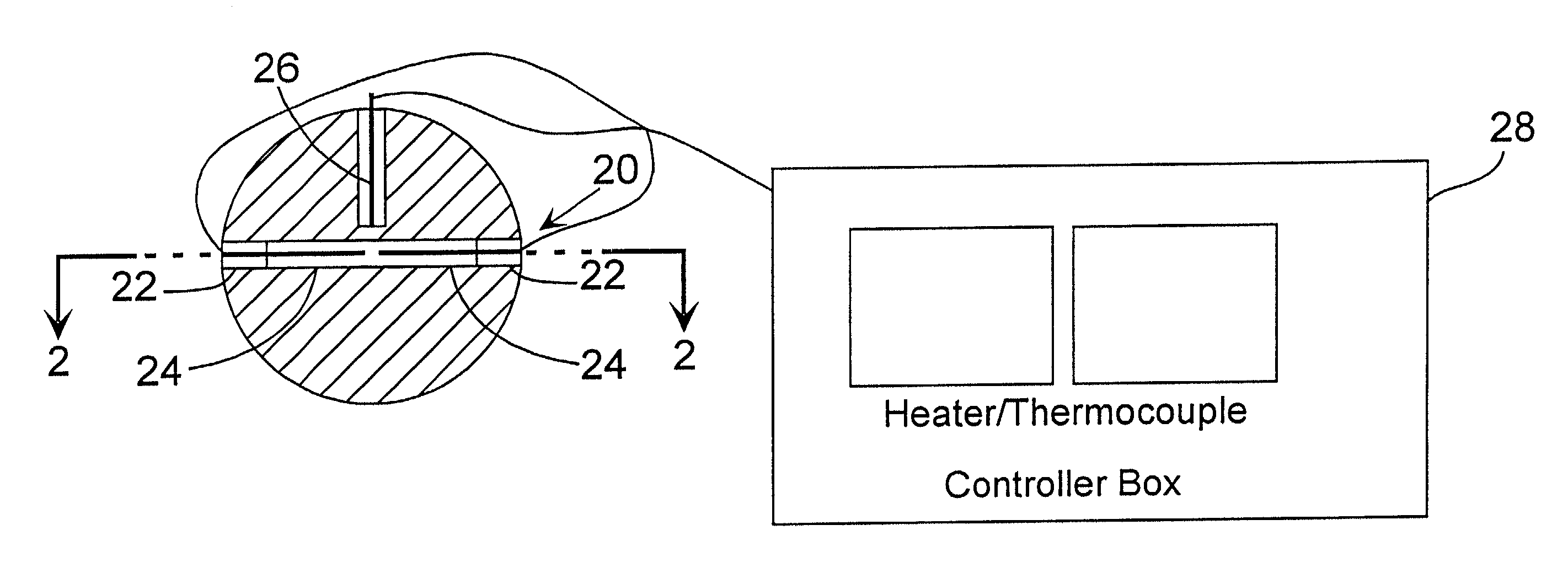

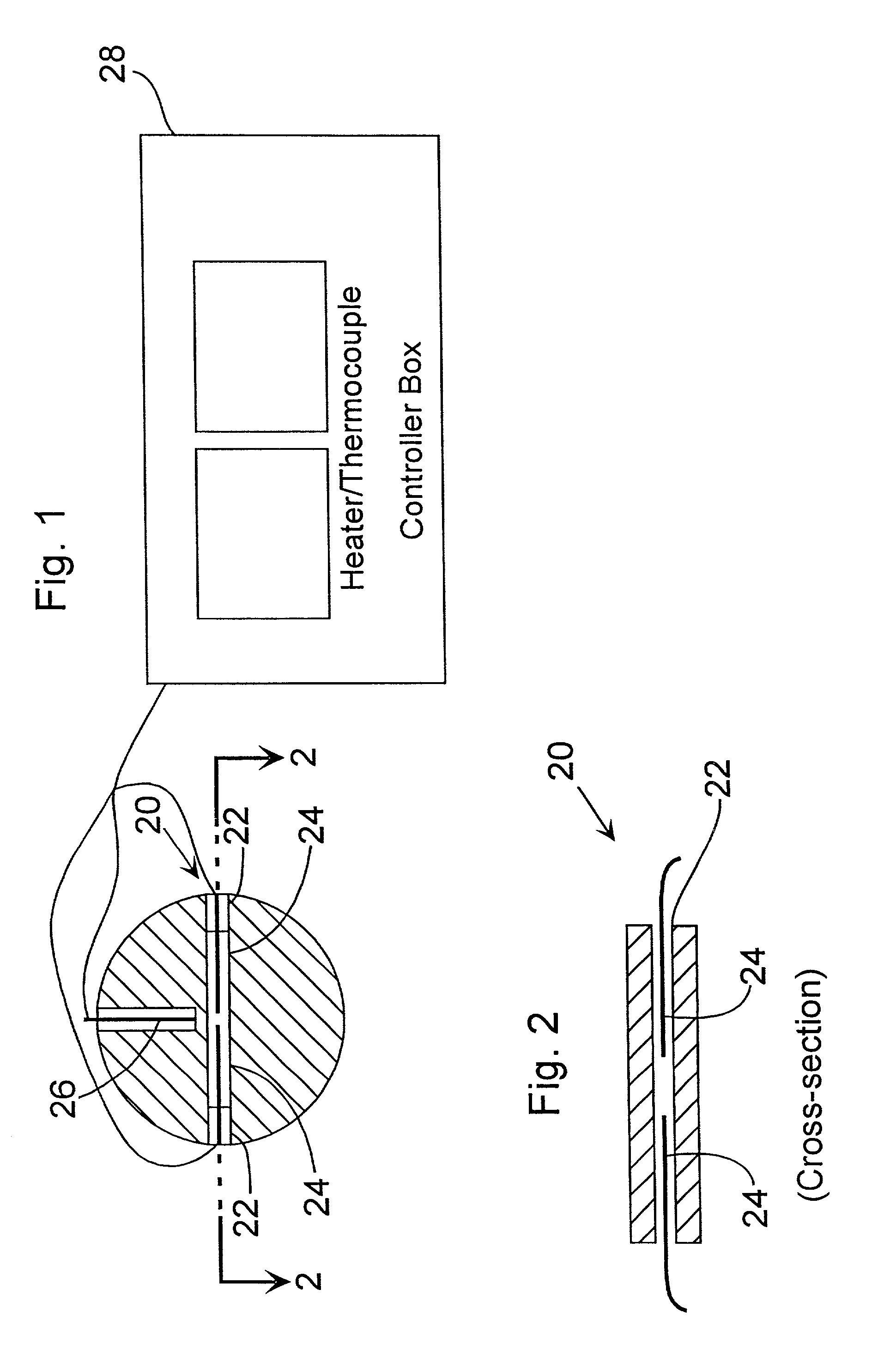

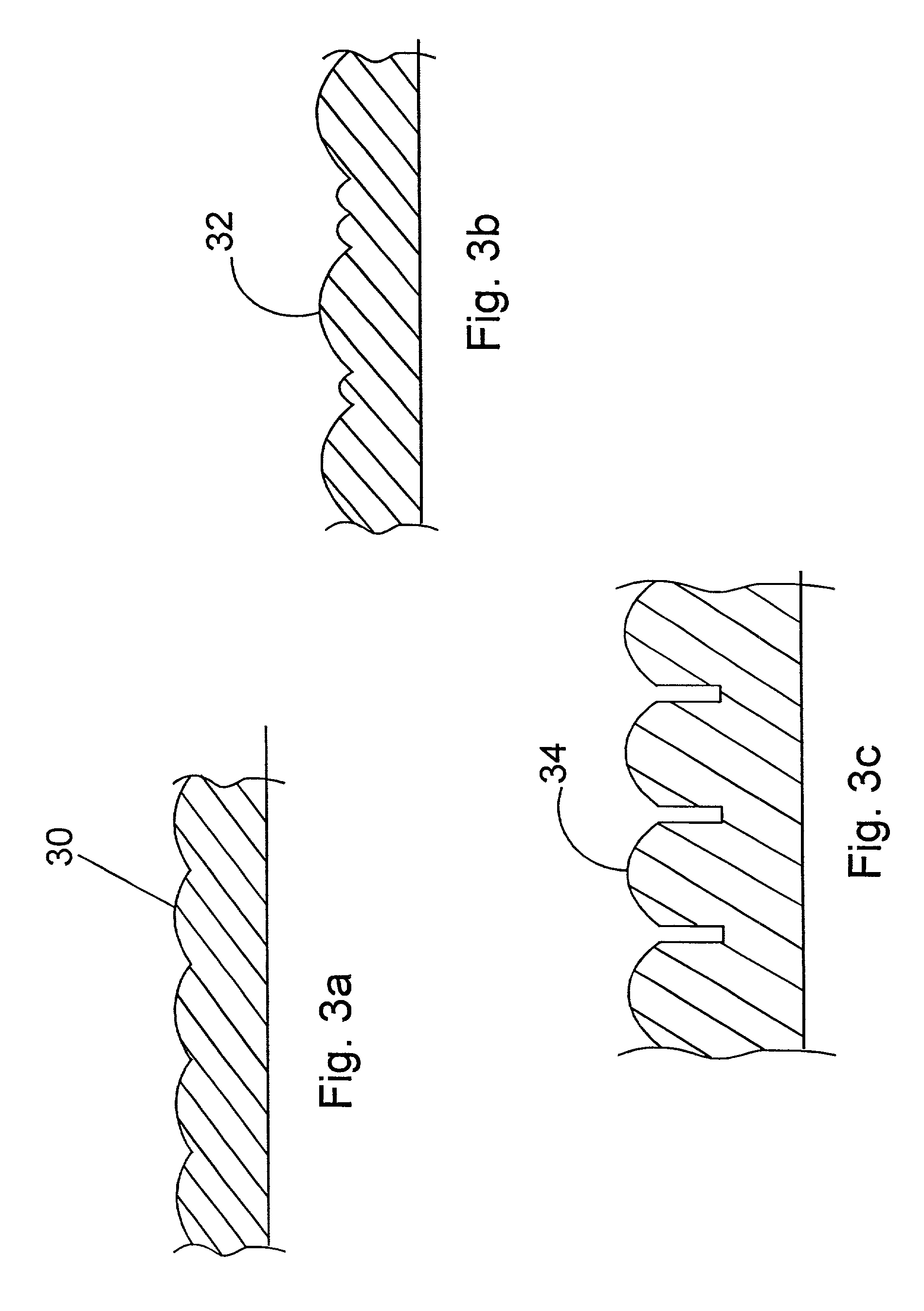

Reactor with heated and textured electrodes and surfaces

InactiveUS7439188B2Ensure adhesionInterfere with processElectric discharge tubesDecorative surface effectsEngineeringSemiconductor

A reactor for processing semiconductor wafers with electrodes and other surfaces that can be one of heated, textured and / or pre-coated in order to facilitate adherence of materials deposited thereon, and eliminate the disadvantages resulting from the spaulding, flaking and / or delaminating of such materials which can interfere with semiconductor wafer processing.

Owner:OEM GRP LLC

Adhesive composite coating for diamond and diamond-containing materials and method for producing said coating

InactiveUS7022403B1Strengthen faulty surfaceImprove adhesionPolycrystalline material growthDiffusion/dopingCouplingTungsten

The inventive coating for diamond and diamond-containing materials represents a coupling of an internal layer, made of tungsten carbide, with an external tungsten layer, both layers being fluorine alloyed. The inventive coating makes it possible to ensure a good adhesion of diamonds and diamond-containing materials to a backing. Methods for applying said coatings are also disclosed.

Owner:ISLE HARDIDE LTD

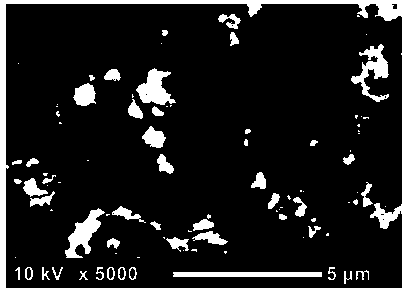

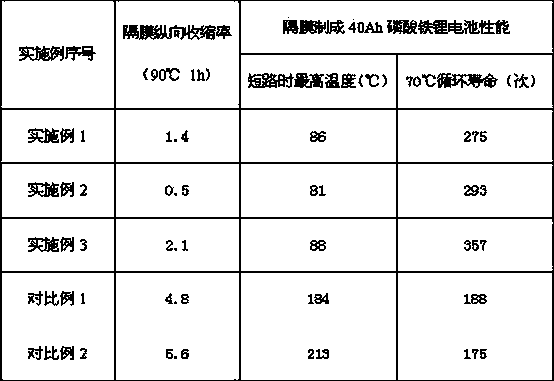

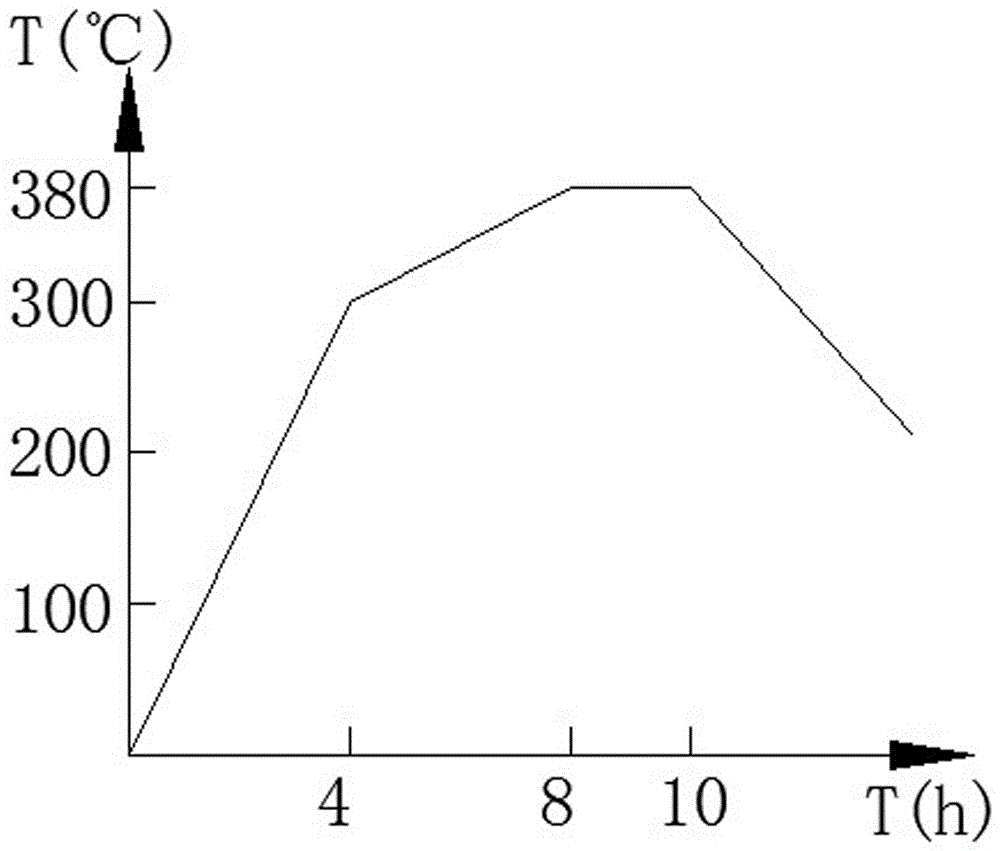

Preparation method for ceramic coating separator

ActiveCN104183805AOvercoming the drawbacks of effective decentralizationEnsure decentralizationCell component detailsCeramic coatingLithium-ion battery

The invention relates to a preparation method for a ceramic coating separator material used to lithium ion batteries. The preparation method comprises steps of preparation of a ceramic slurry, separator pretreatment, precise coating, drying and the like. The prepared product has the characteristics that the ceramic coating is compact, uniformly and firm in adhesion and the separator is small in thermal shrinkage, and the prepared product has obvious effect on improving safety performance of the lithium ion battery and prolonging battery service life.

Owner:ZHANGJIAGANG NENGCI MATERIAL SCI & TECHCO LTD

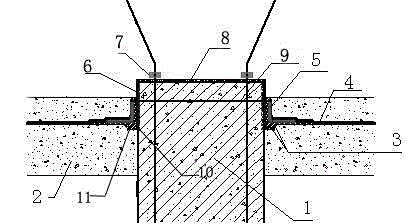

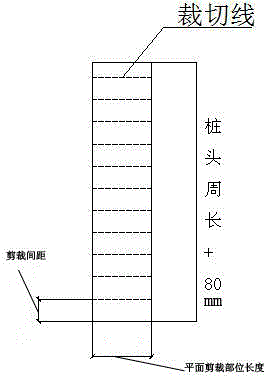

Waterproof construction method of basement foundation cast-in-place pile head

ActiveCN104975617AEnsure the overall effectAdhesive playProtective foundationEpoxyArchitectural engineering

The invention discloses a waterproof construction method of a basement foundation cast-in-place pile head. The waterproof construction method particularly comprises the steps of base plane cleaning, pile head root grooving, vertical face capillary crystalline type waterproof coating and waterproof mortar smearing, base layer treating agent smearing, sealant smearing, reinforcing layer coiling, reinforcing layer shearing position sealing, large face waterproof construction, sealing of the combining portion of a large face and the pile head, pile head waterproof closing and fixing and high-permeability epoxy resin waterproof coating smearing. High-permeability epoxy resin waterproof coating, sealants, capillary crystalline type waterproof coating and waterproof mortar are smeared, waterproof rolls are laid, and rigid waterproofing and flexible waterproofing are achieved. Waterproofness of a foundation platform and waterproofneses of a bearing platform and the pile head are combined into one, and leakage points are prevented from happening to the pile head to guarantee project quality. The construction process is easy and convenient to operate, construction speed is high, no water moving layer exists, energy saving and consumption reducing are achieved, and the waterproofing term is prolonged.

Owner:郑贤方

Molding resin composition

ActiveUS20090023841A1Improve adhesionGood gasoline resistanceSpecial tyresEmulsion paintsPolyesterPolyol

A molding resin composition which includes (a) an aromatic polyester, (b) a tackifier, (c) a polyol compound having two or more hydroxy groups per molecule and (d) a polyolefin, wherein the polyolefin (d) is present in an amount of 5 to 40 parts by weight per 100 parts by weight of the aromatic polyester (a) and the polyolefin (d) combined, has an excellent adhesion to polyolefins, metals and PVC, and also has an excellent gasoline resistance.

Owner:SIKA HAMATITE CO LTD

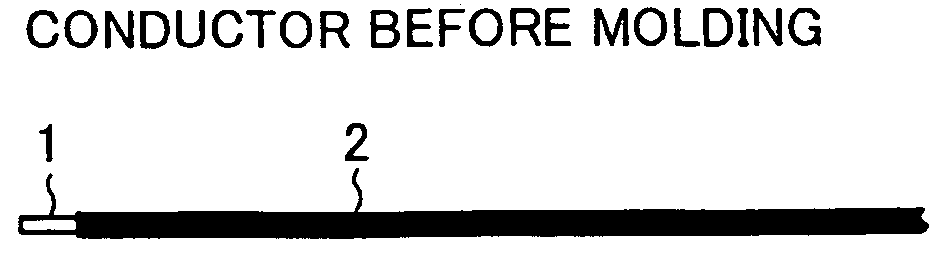

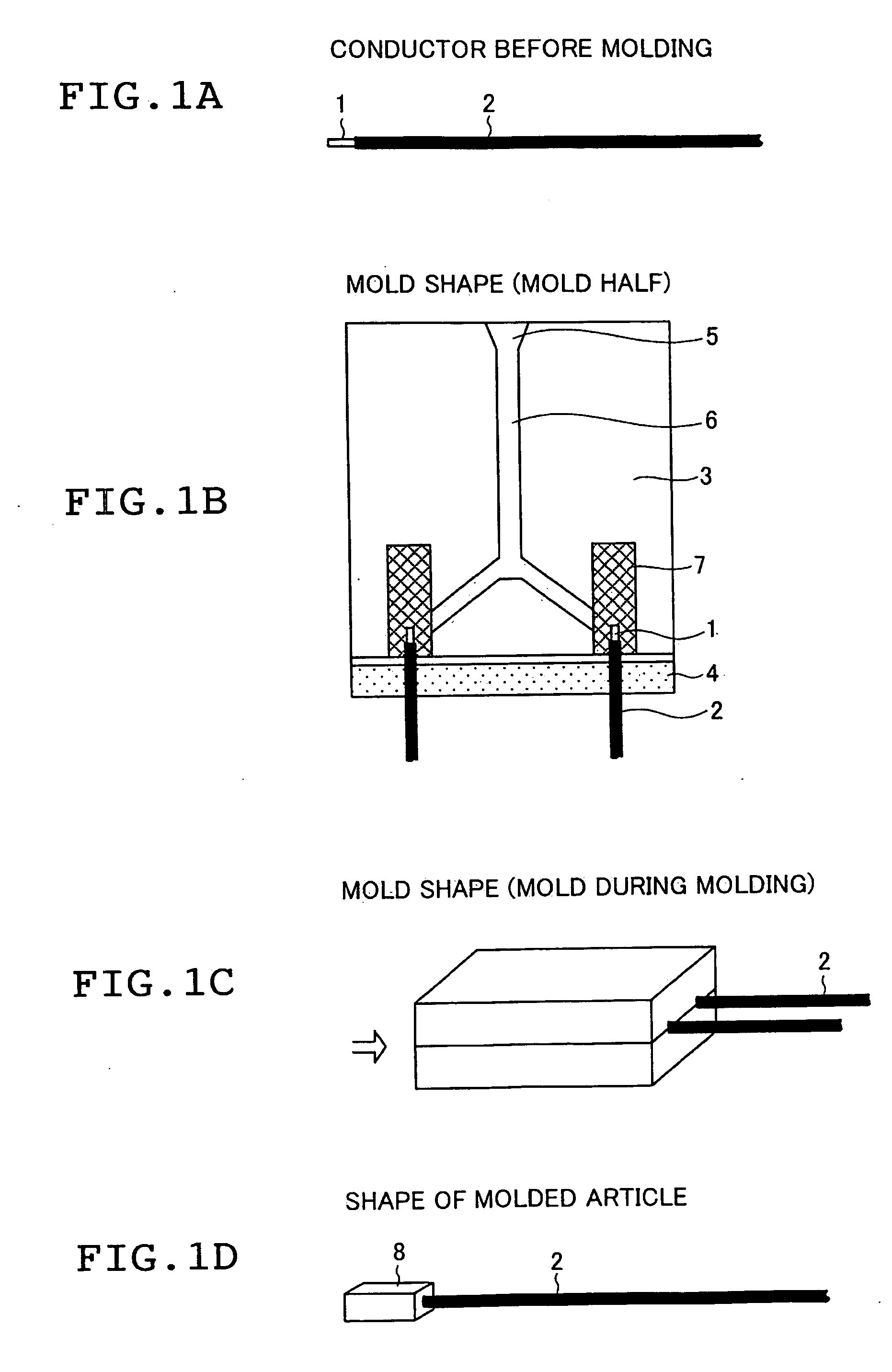

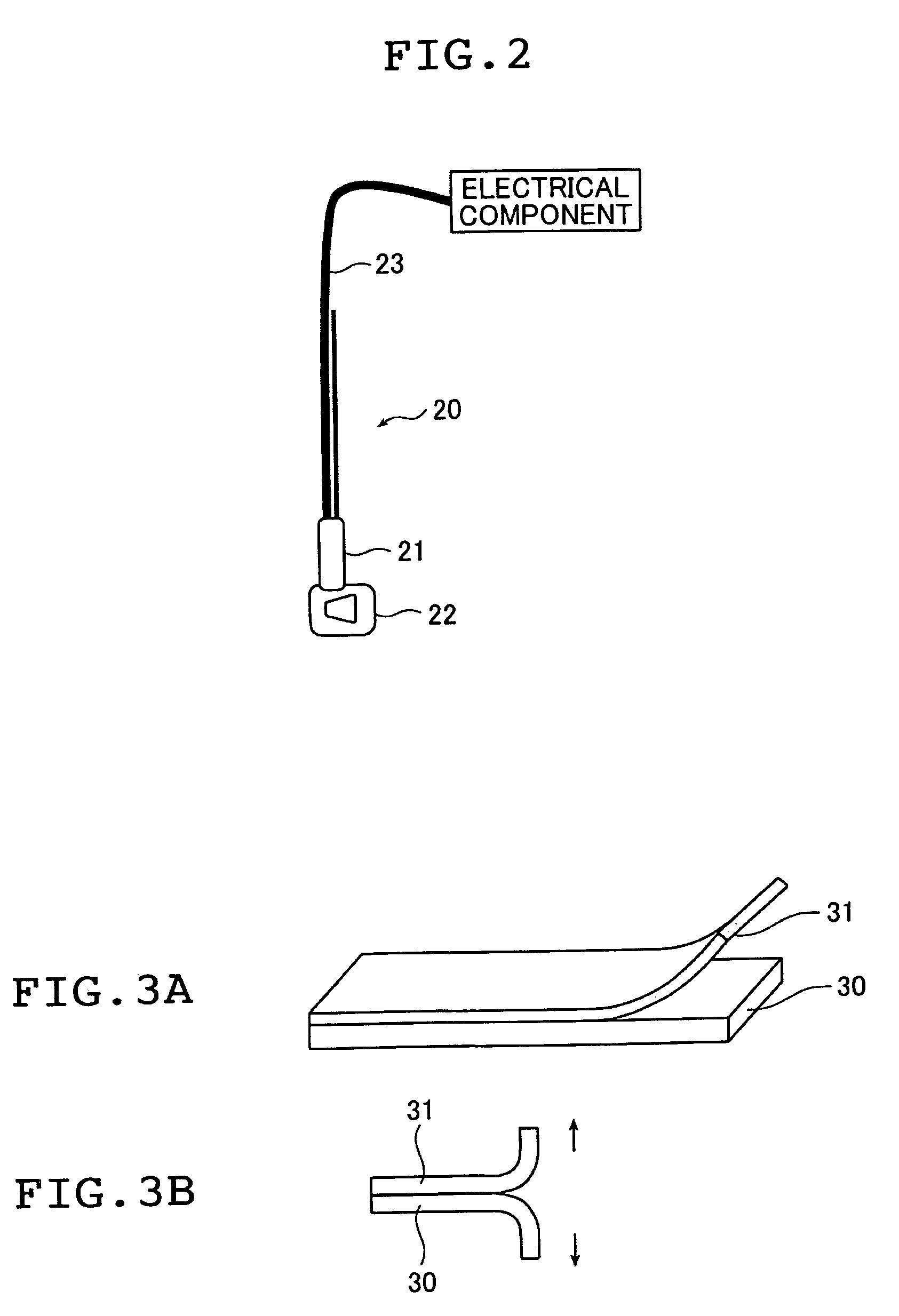

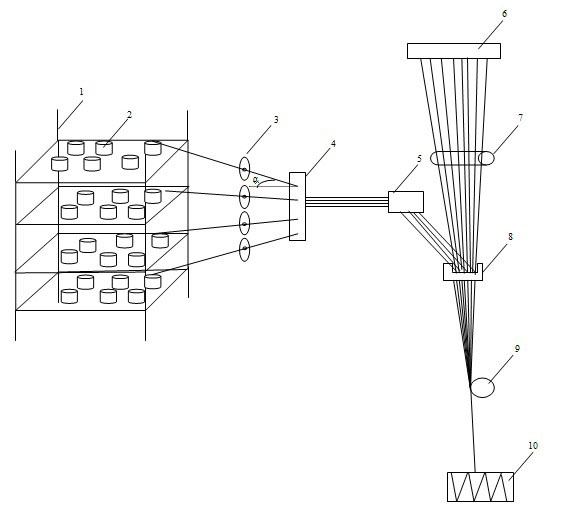

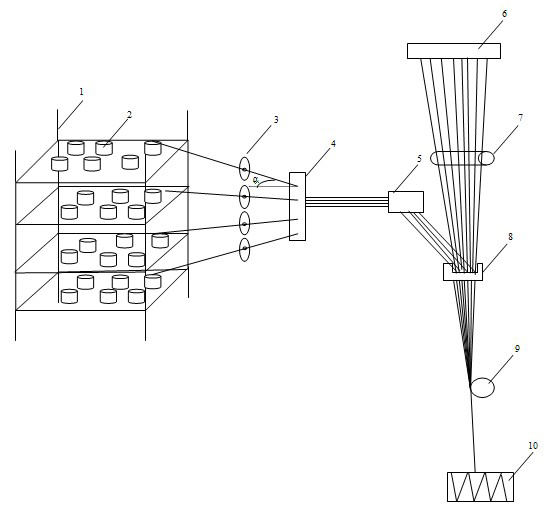

Method and equipment for manufacturing composite fiber containing continuous glass fiber

The invention relates to a method for manufacturing a composite fiber containing a continuous glass fiber. The composite fiber is formed by mutually mixing offline terylene and an online continuous glass fiber; the glass fiber is drawn on line, and the terylene is finished yarn; a plurality of bundles of terylene with different yarn feed angles are drawn to be converged into sheet shapes after being subjected to tension adjustment; and the converged terylene yarn bundles are separated and then compounded with the glass fiber processed with an impregnating compound. The invention has the advantages of simplified process equipment and improved production smoothness; and meanwhile, the introduction of chemical fiber yarn-feed tension adjustment ensures that better practicability and better effect on the baked yarn clew moulding effect are achieved.

Owner:JUSHI GRP CO

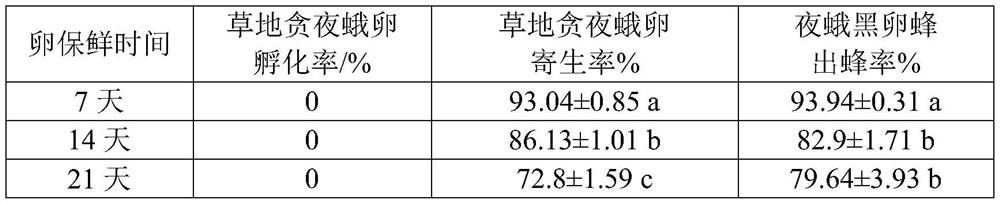

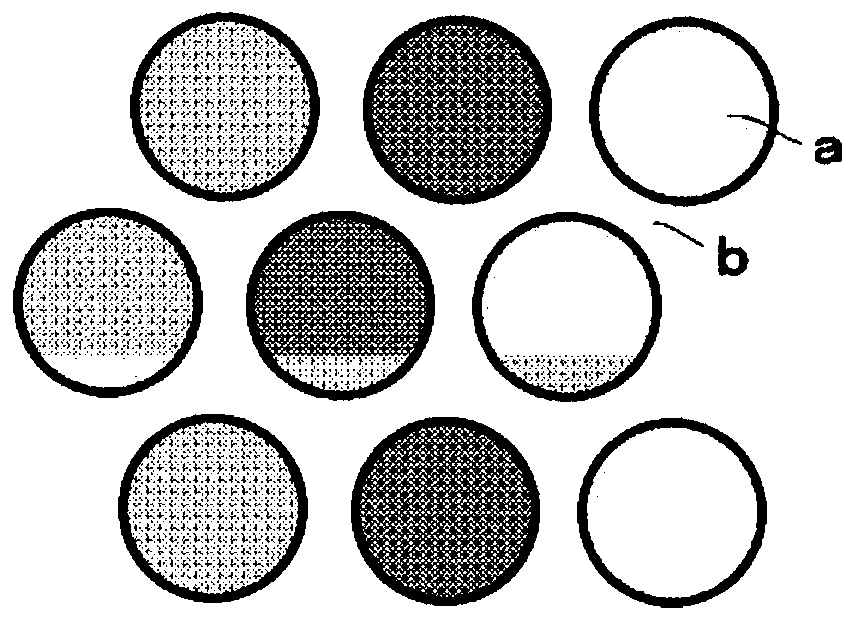

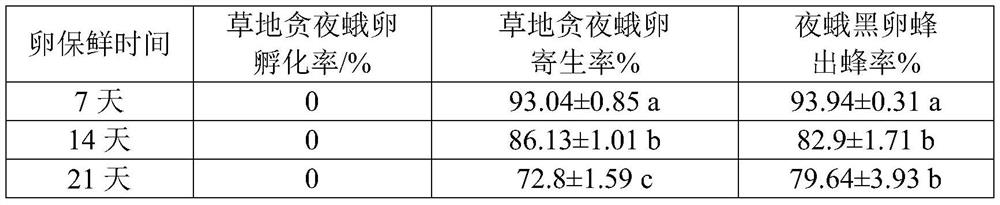

Method for propagating telenomus remus by using fresh-keeping spodoptera frugiperda egg masses

The invention discloses a method for propagating telenomus remus by using fresh-keeping spodoptera frugiperda egg masses. Kraft paper is mainly used as a bearing medium for the spodoptera frugiperda egg masses, the egg masses are stored under the limiting conditions such as airtightness, light shielding and constant low temperature, hatching of the spodoptera frugiperda eggs is inhibited, meanwhile, the method ensures that the telenomus remus can parasitize on the egg masses within a long time, the purpose of intensively propagating a large number of telenomus remus populations is achieved, and the method conveniently releases parasitic wasps in the field at the right time so as to achieve the biological control effect of preventing and controlling the spodoptera frugiperda. The method issimple in operation process, safe and reliable, and provides a large number of parasitic wasp sources are provided for conveniently and rapidly utilizing the spodoptera frugiperda eggs to massively propagate the telenomus remus and applying the biological prevention and control technology for preventing and controlling the spodoptera frugiperda eggs.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

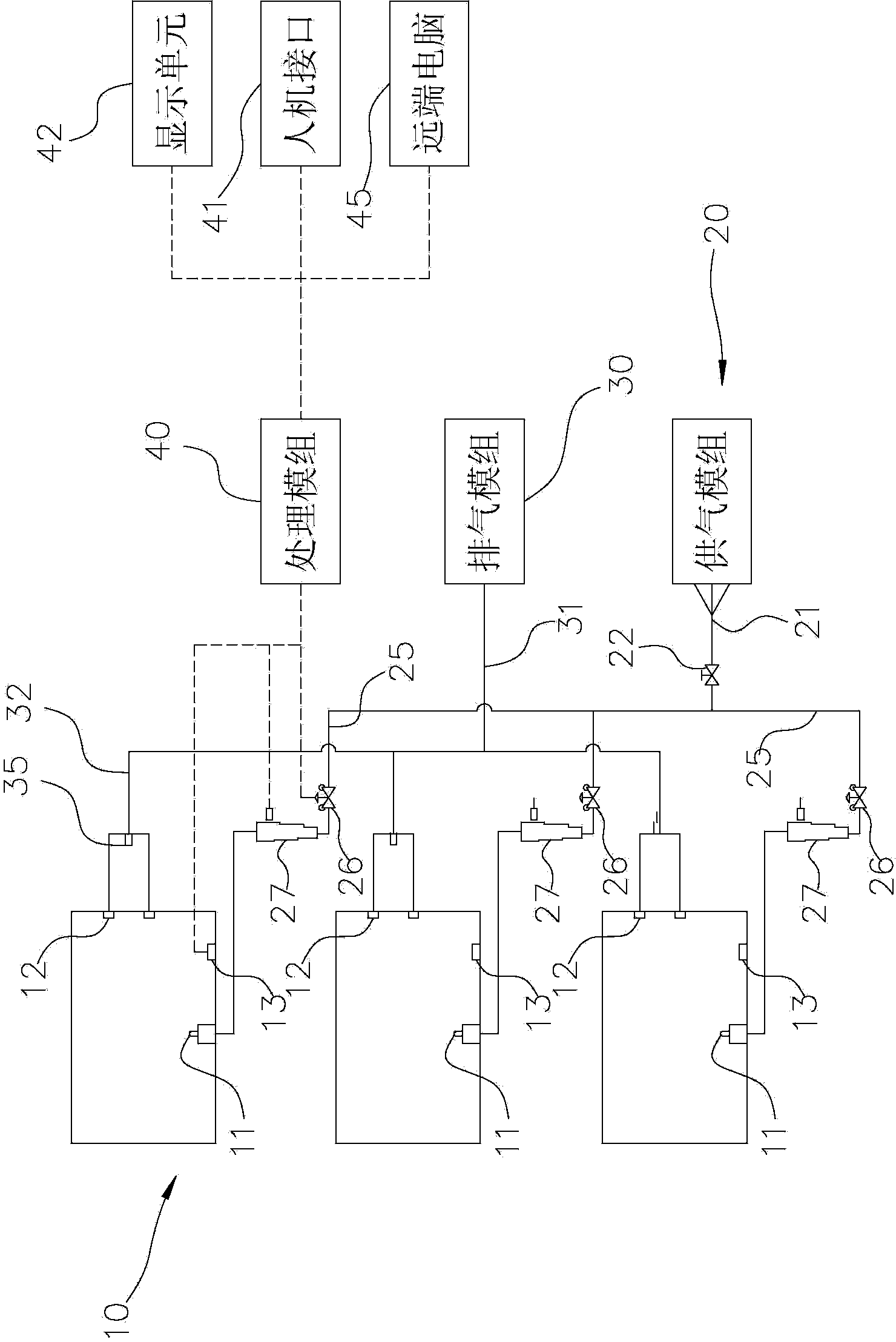

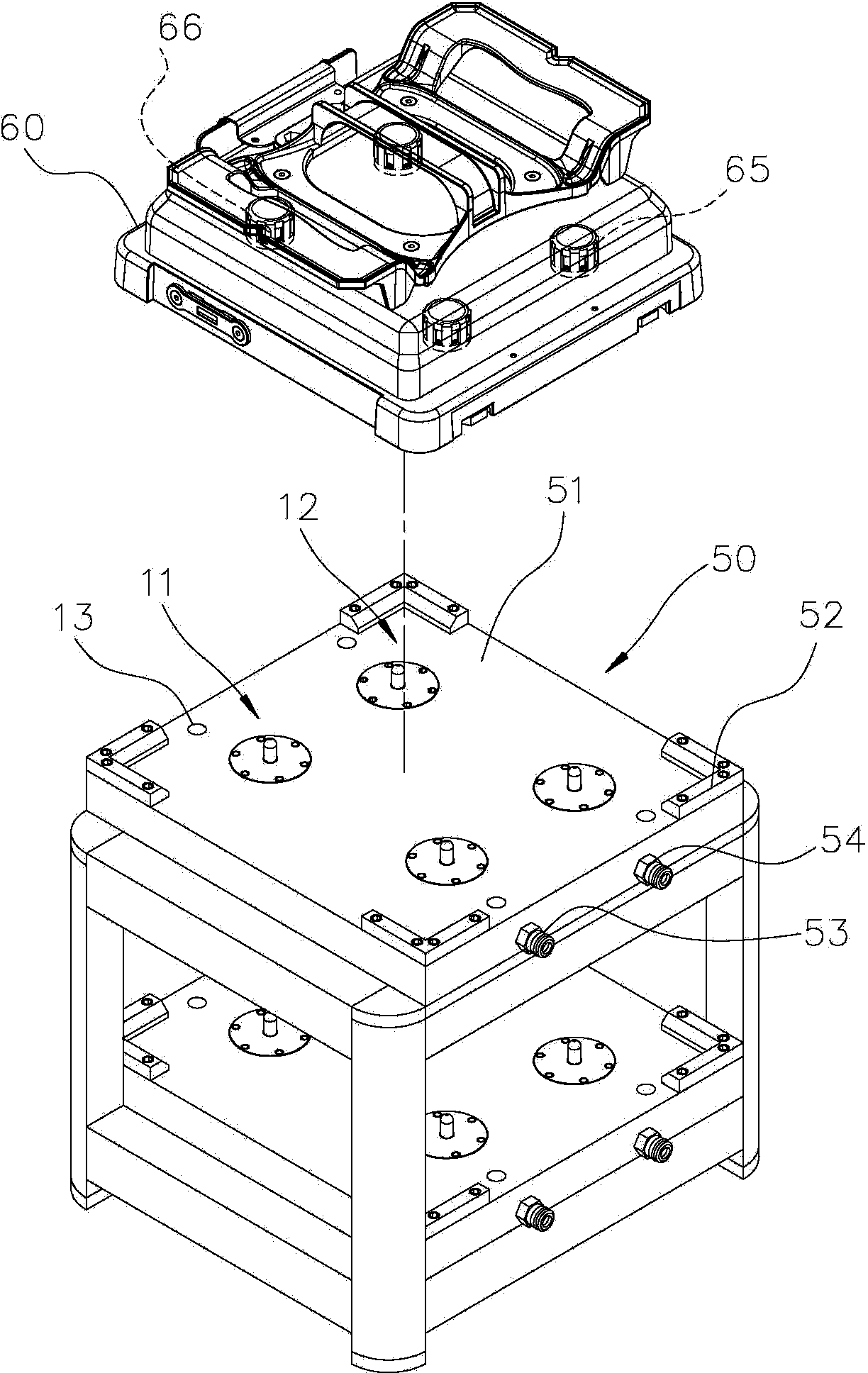

Inflation purification system of wafer/photomask sealed carrier

InactiveCN104241164AImprove process yieldImprove internal cleanlinessSemiconductor/solid-state device manufacturingConveyor partsEngineeringExhaust valve

The invention discloses an inflation purification system of a wafer / photomask sealed carrier, and particularly relates to an inflation purification system, with controllable gas inflow rate and high cleanliness effect, of the wafer / photomask sealed carrier. The system comprises at least one inflation module, a gas supply module, an exhaust module and a processing module, wherein at least one gas inflow valve connected with the gas supply module and at least one exhaust valve connected with the exhaust module are arranged on the inflation module, a flow regulating valve and a pressure flow meter are respectively arranged on the portion, between the gas supply module and the gas inflow valve, of a gas inflow loop, and the flow regulating valve is connected to the processing module. Thus, when the carrier is placed on the inflation module for inflation, the gas supply condition of the gas inflation module can be detected, known and displayed through the processing module, the flow and the pressure of the inflation module are regulated according to the actual condition so that inflation of the carrier can be fast completed, the inflow and outflow stability of clean gas in the carrier is kept, and the internal cleanliness of the carrier is effectively improved.

Owner:GUDENG PRECISION IND CO LTD

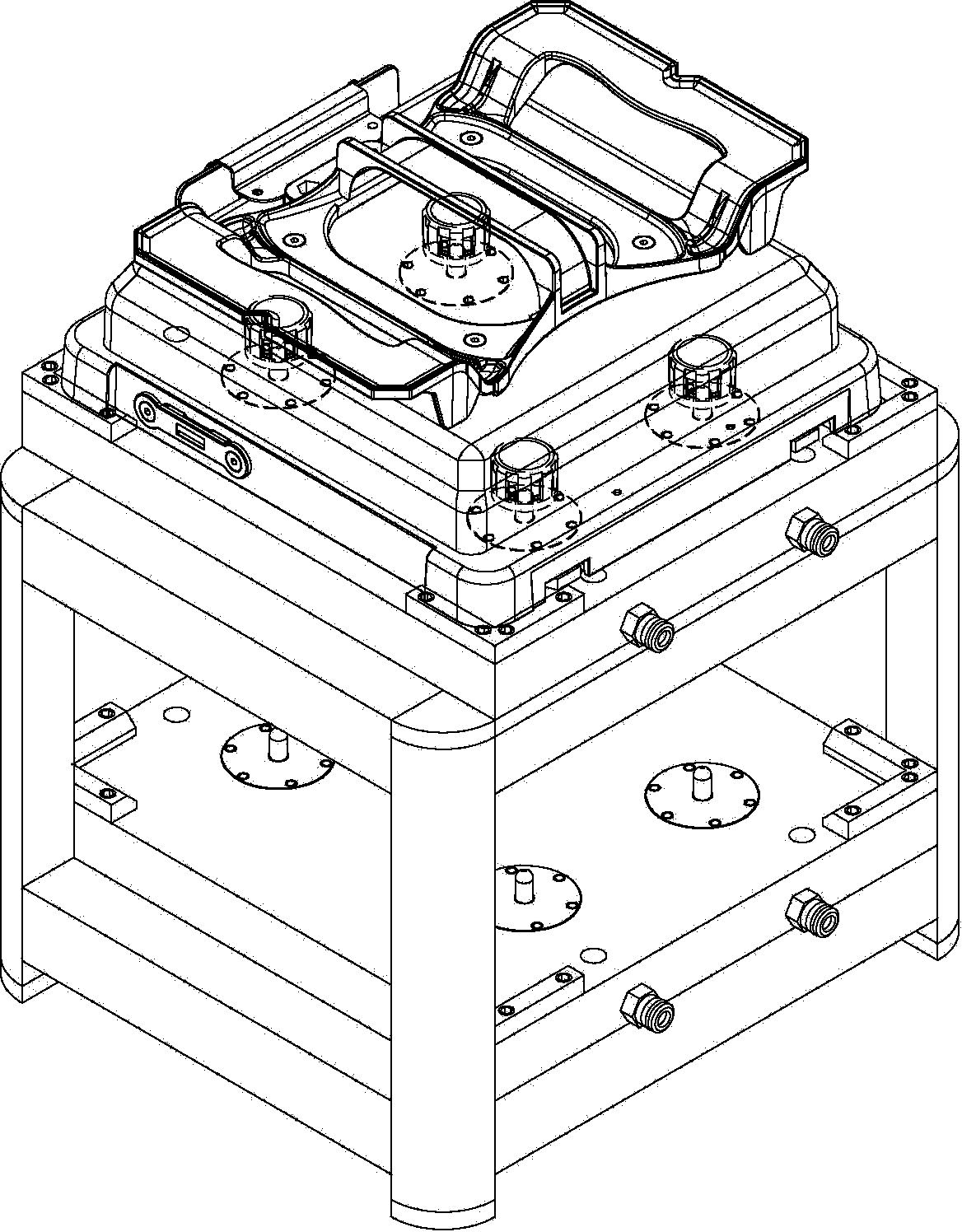

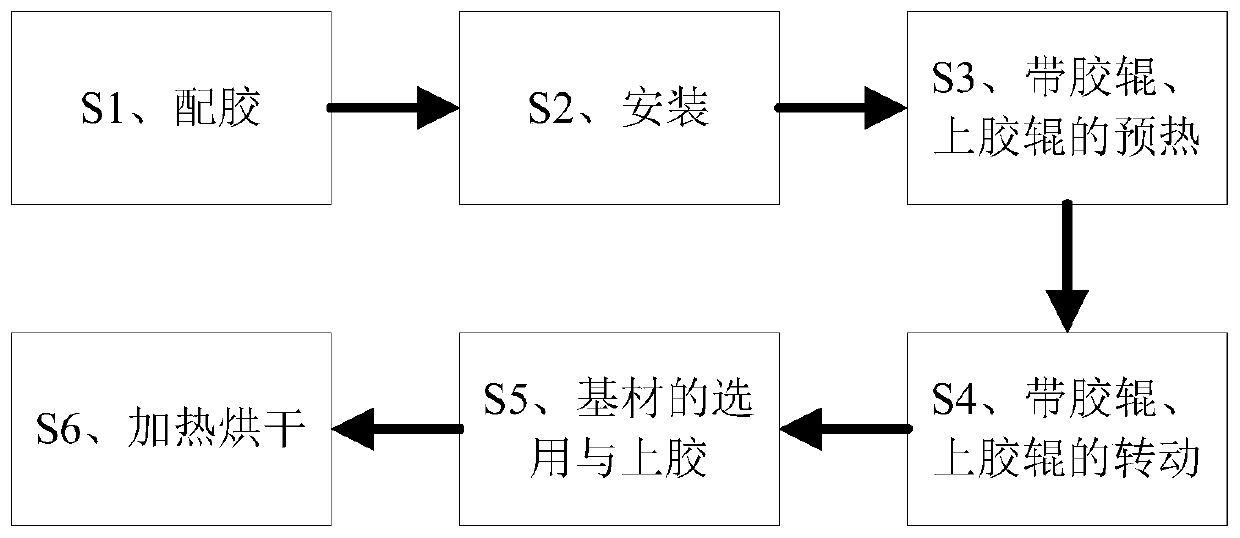

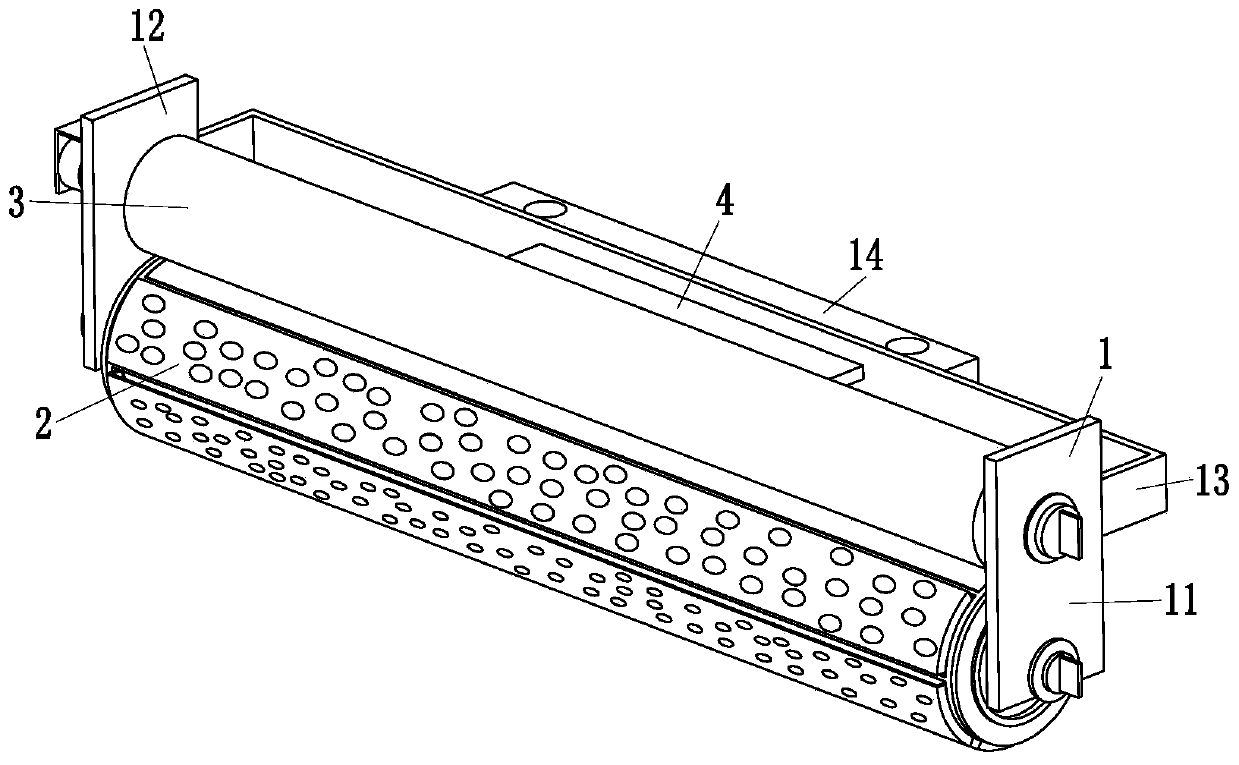

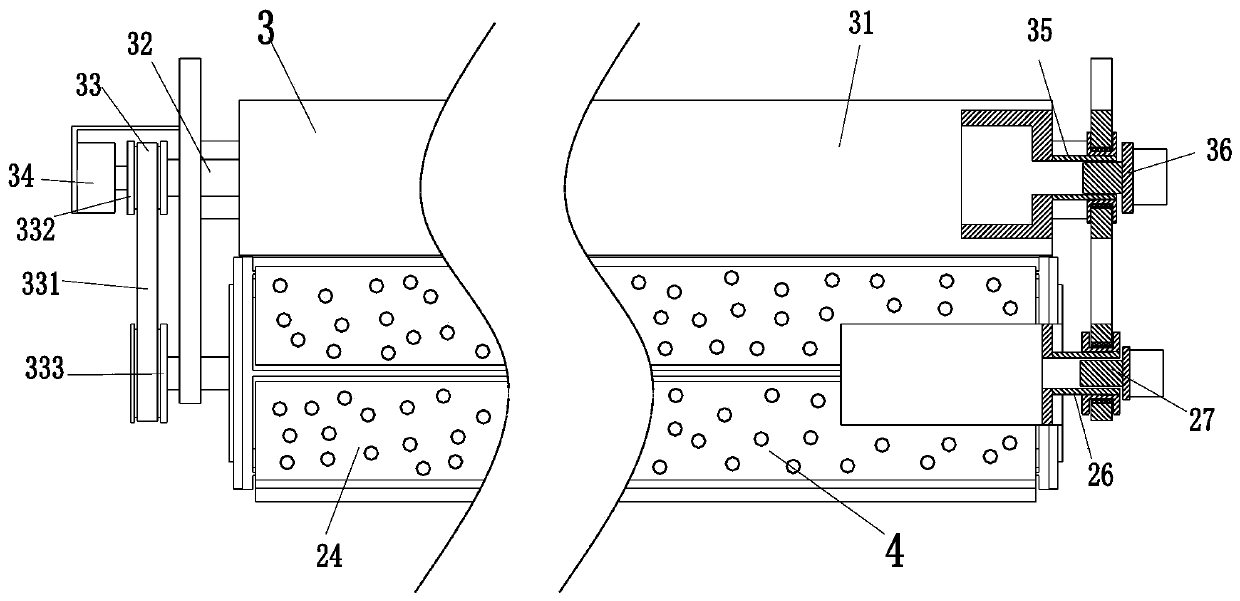

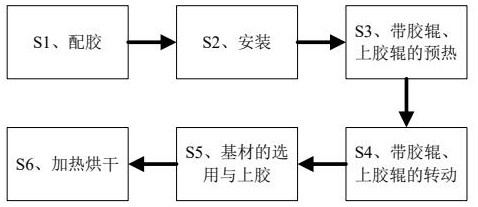

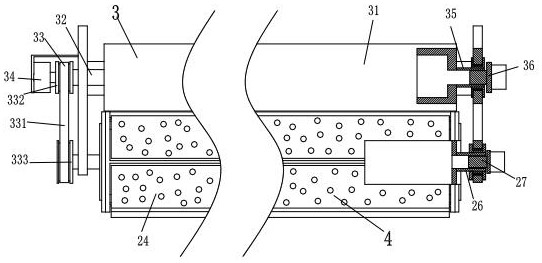

Gluing process for manufacturing copper-clad plate

ActiveCN110205872AAvoid Cured SituationsAvoid failure to adhere to gluePaper/cardboardPulp material addition processesFixed frameEngineering

The invention provides a gluing process for manufacturing a copper-clad plate. According to the gluing process, the work can be completed through the cooperation of a fixing frame, a rubber roller, agluing roller and a dispersing device. The gluing process can solve the problems that during gluing, the gluing amount of a base material is smaller, therefore a rotary transmission roller only needsto drive a small amount of glue liquid to the surface of the transmission roller, but resin glue liquid is in a fluid shape, so that the glue liquid is difficultly attached to the surface of the transmission roller, which may cause the situation that the distribution of the glue liquid is not uniform due to the fact that the resin glue liquid is not attached to the surface of the partial transmission roller, so that the partial base material is not subjected to gluing treatment, the resin glue liquid is in a fluid shape after being heated, since the temperature of the surface of the transmission roller is lower, the phenomenon may occur that the partial resin glue liquid is cured when the surface of the transmission roller is in contact with the resin glue liquid, thereby affecting the gluing efficiency of the base material.

Owner:安能电子有限公司

Electrostatic powder spraying method for valve casting

InactiveCN105457858AImprove adhesionStrong adhesionPretreated surfacesCoatingsEnvironmental resistanceSpray coating

The invention discloses an electrostatic powder spraying method for valve casting. Valve casting is processed by surface treatment, electrostatic spraying and workpiece curing, the surface, subjected to spraying treatment, of the valve casting is greatly improved in degree of finish, so that sealing reliability of a sealing surface, matched with an encapsulated gate plate, of a valve body is improved, and friction force, in a starting process, of the gate valve is further reduced, and therefore, operation torque is reduced; compared with a conventional spray coating, the valve casting is environmentally-friendly, is great in thickness of a spraying layer, is strong in adhesive force, is not liable to drop, and is relatively improved in abrasion resistance and water erosion resistance.

Owner:QINGDAO HEDELONG MACHINERY

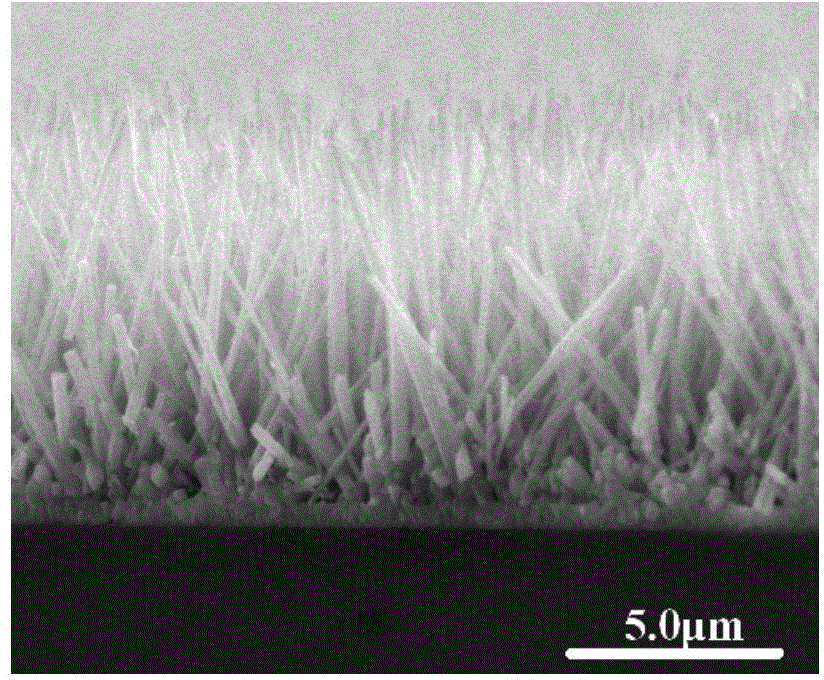

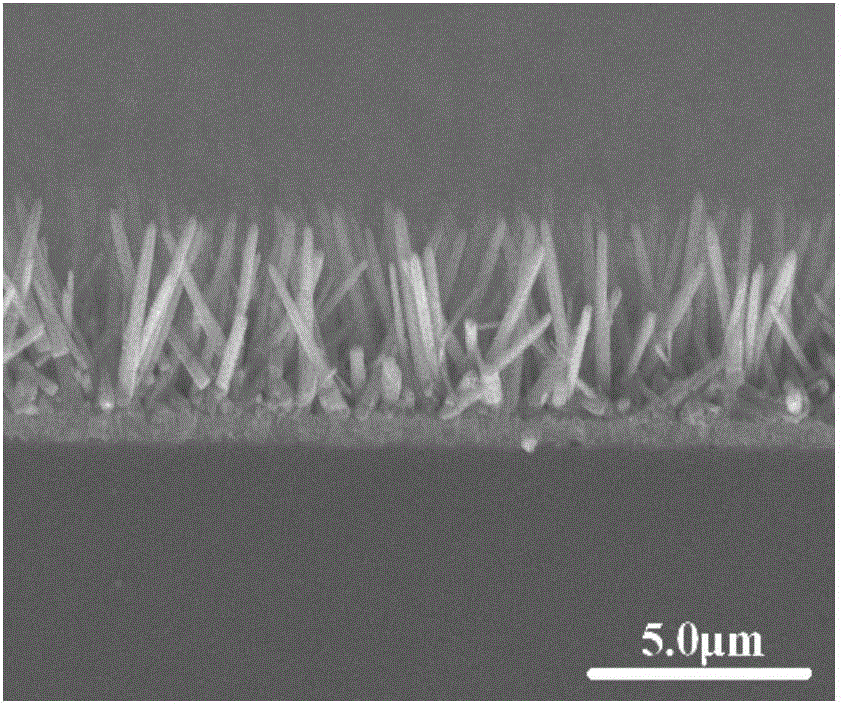

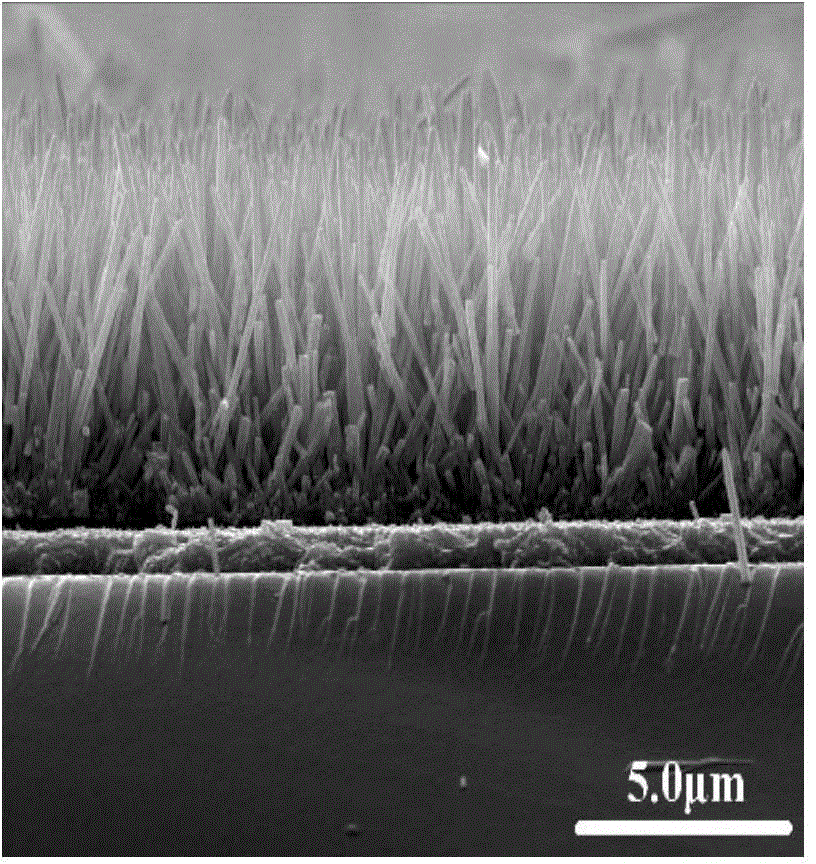

Preparation method of ZnO-CuInS2 heterogeneous core-shell structure nanorod array

InactiveCN104638064AStable structureReduce wasteFinal product manufacturePhotovoltaic energy generationHexamethylenetetramineThiourea

The invention relates to a preparation method of a ZnO-CuInS2 heterogeneous core-shell structure nanorod array. The preparation method comprises the following steps: immersing a cleaned FTO glass substrate in a zinc acetate ethanol solution to prepare a base covered with a ZnO seed layer, and putting in a reaction kettle; transferring a mixed solution, obtained by dissolving zinc nitrate, hexamethylenetetramine and polyethyleneimine in water, in the reaction kettle so that the base covered with the ZnO seed layer is immersed, heating, preserving heat, and taking out for annealing treatment to obtain the base grown with a ZnO nanorod array; extracting the base grown with the ZnO nanorod array in a cationic precursor solution (obtained by mixing a copper chloride complexing solution and an indium chloride complexing solution) and an anionic precursor solution (water solution of thiourea with NaOH solution adjusted pH) in sequence, thus obtaining the ZnO-CuInS2 heterogeneous core-shell structure nanorod array. The method is low in cost and simple in technology, and the obtained nanorod array is stable in structure, good in quality and high in photoelectric conversion efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

Production method for anticorrosive nodular cast iron pipe

The invention discloses a production method for an anticorrosive nodular cast iron pipe and relates to the technical field of metal corrosion resistance. The production method comprises the steps that firstly, the surface of a nodular cast iron pipe base body is subjected to sand blasting treatment; secondly, the surface of the nodular cast iron pipe base body is blown clean through compressed air; and thirdly, the nodular cast iron pipe base body is heated to 50-55 DEG C; a component A and a component B of a polyurethane anticorrosive coating are mixed evenly according to the proportion of one to one, an airless sprayer is used for evenly spraying the coating onto the surface of the nodular cast iron pipe base body, and construction is carried out in a one-layer multipass spraying mode. Compared with the prior art, the coating is sprayed onto the nodular cast iron pipe base body uniformly and is high in adhesive force; the nodular cast iron pipe produced through the method is high in corrosion resistance; a corrosion resistant coating layer of the nodular cast iron pipe is not prone to stripping, and operation is easy and convenient.

Owner:LIUZHOU BAITIAN MACHINERY

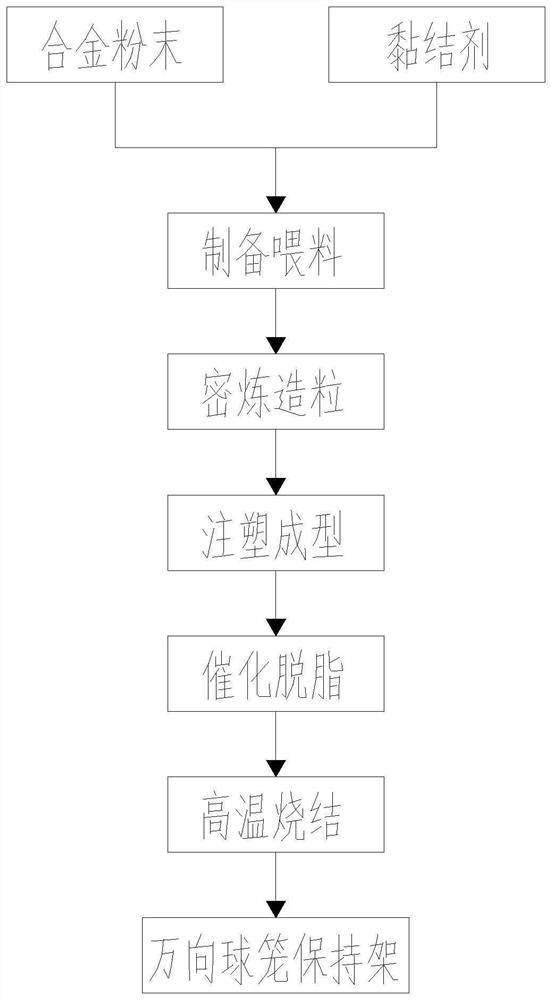

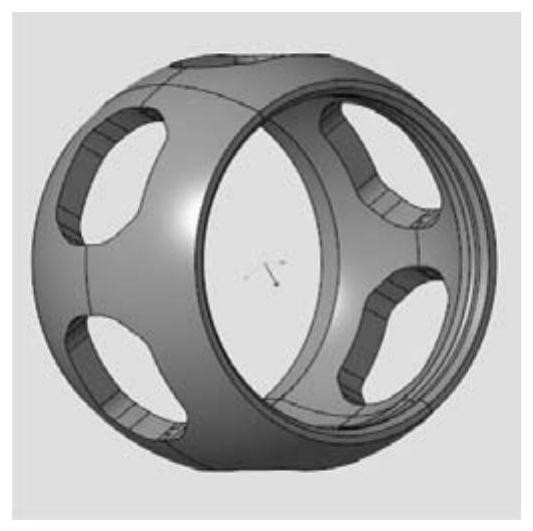

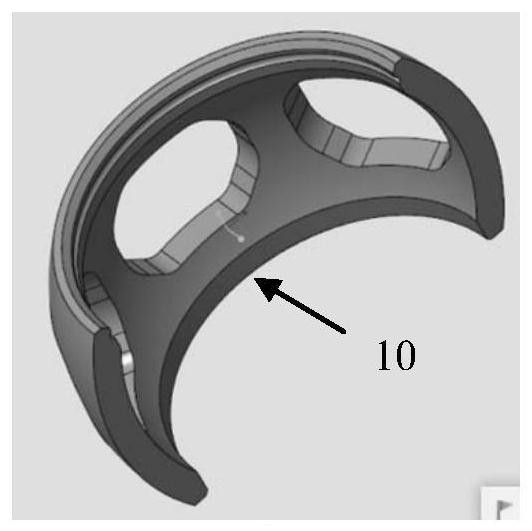

Manufacturing method of universal ball cage holder

PendingCN114453580AReduce the proportionEasy to buyTransportation and packagingMetal-working apparatusPolyoxymethyleneAdhesive

The manufacturing method of the universal ball cage holder comprises the following steps that A, alloy powder and an adhesive containing polyformaldehyde are mixed in proportion, and feed is obtained; b, the feed is subjected to banburying and granulation to be made into columnar particles with the diameter phi being 3 * 5 mm; c, preparing the columnar particles into a green body through an injection molding process; d, polyformaldehyde in the green body is removed through a catalytic degreasing technology, and then the universal ball cage holder is obtained through high-temperature sintering; wherein the alloy powder comprises ASTM 86 series low-alloy steel powder, ASTM 51 series low-alloy steel powder and 20CrMnTi alloy steel powder, the mass ratio of the alloy powder to the adhesive is (87.7-91.2)%: (8.8-12.3)%, the mass ratio of polyformaldehyde in the adhesive is 80-95%, the green body comprises a forming body, the size of the forming body is proportionally enlarged according to the size of the universal ball cage holder, and the size of the forming body is larger than that of the universal ball cage holder. According to the manufacturing method, metal material waste approaches to zero, the working procedures are simple, the number of steps is small, the production efficiency is high, the yield is high, stress residues do not exist, cost is low, and the manufacturing method is suitable for mass production of universal ball cage retainers.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

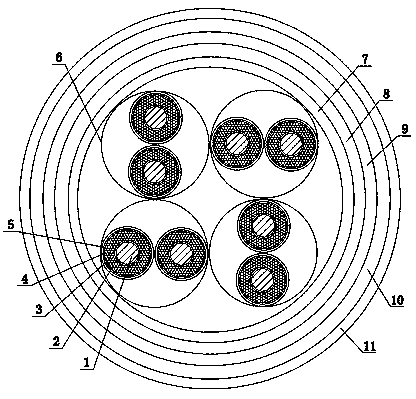

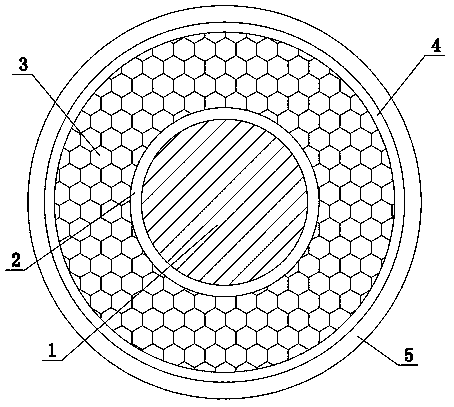

Communication cable with low dielectric constant insulation structure

PendingCN109243686AIncreasing the thicknessThe dielectric constant of the insulating layer and the working capacitance decreaseQuad constructionsInsulated cablesTemperature resistanceLow-k dielectric

The invention discloses a communication cable with a low dielectric constant insulation structure, which comprises a cable core, wherein, the cable core is composed of four pairs of wire pairs; each pair of wire pairs is formed by twisting two insulated core wires mutually; A cable core shielding layer is coated on the cable core, and each pair of wire groups is coated with a pair of wire shielding layers; The insulating core wire comprises a core wire conductor, wherein the core wire conductor is sequentially coated with an inner layer of silica gel, a foam layer, an outer layer of silica geland a thin film layer of the core wire from the inside to the outside; The thickness of the silica gel inner layer and the silica gel outer layer is 3 [mu] m-5. [mu]m, and that thickness of the corewire film lay is 4[mu]m-6[mu]m. The silica gel inner layer and the silica gel outer layer are coated with room temperature silicone rubber. The core wire film layer and the cable core film layer are high-temperature polyester film layers. The communication cable not only has excellent electrical performance, but also has chemical resistance, water resistance and high temperature resistance.

Owner:JIANGSU DONGQIANG

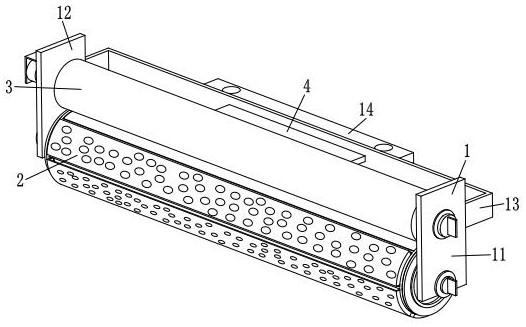

Printer, copier and multifunctional integrated machine fixing mechanism and processing technology of heating roller thereof

InactiveCN106773578AGuaranteed smoothnessGuaranteed roughElectrographic process apparatusState of artEngineering

The invention relates to a printer, copier and multifunctional integrated machine fixing mechanism and a processing technology of a heating roller thereof. According to the printer, copier and multifunctional integrated machine fixing mechanism and the processing technology of the heating roller thereof, a resin sleeve film is used and replaces an existing coating, so that the smoothness and the roughness of the heating roller surface can be effectively ensured; the easy abrasion caused by the grinding process in the prior art can be avoided, so that the service life of the product can be prolonged; meanwhile, the surface of the resin sleeve film is smooth and free from a gap, so that the release property is ideal, and as a result, the carbon powder attaching is completely avoided, and the powder adhering is prevented; the fluororesin sleeve film is high in heat conductivity and abrasion resistance, so that the energy is saved, and the service life of the heating roller is prolonged.

Owner:叶大江

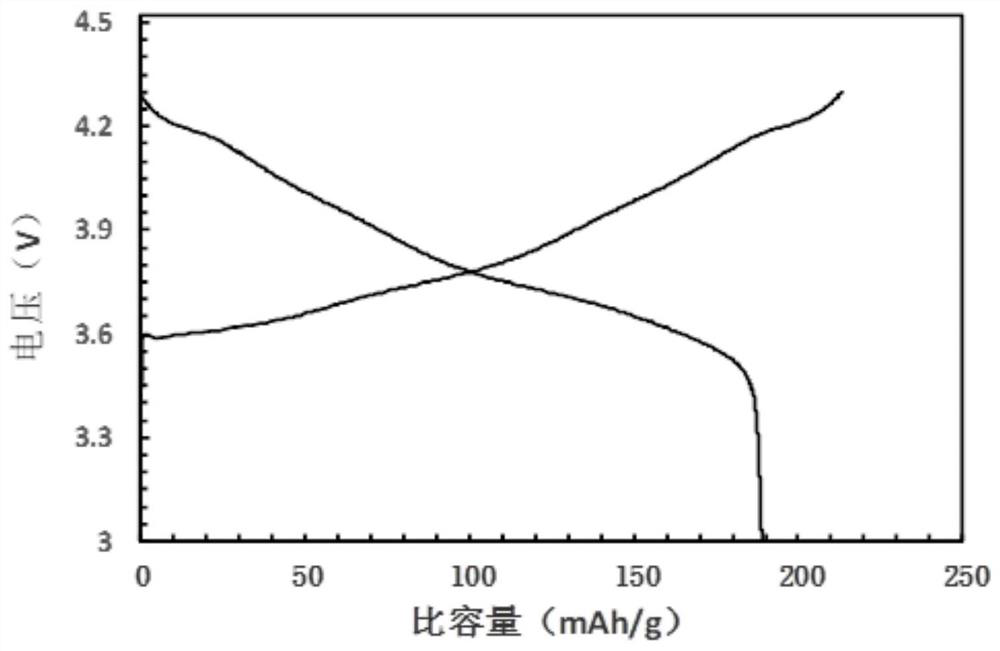

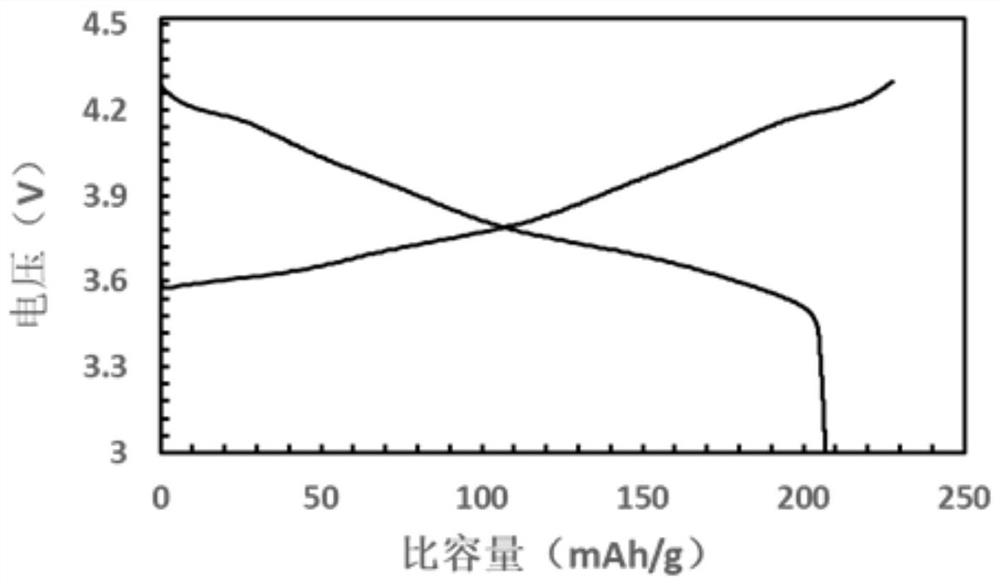

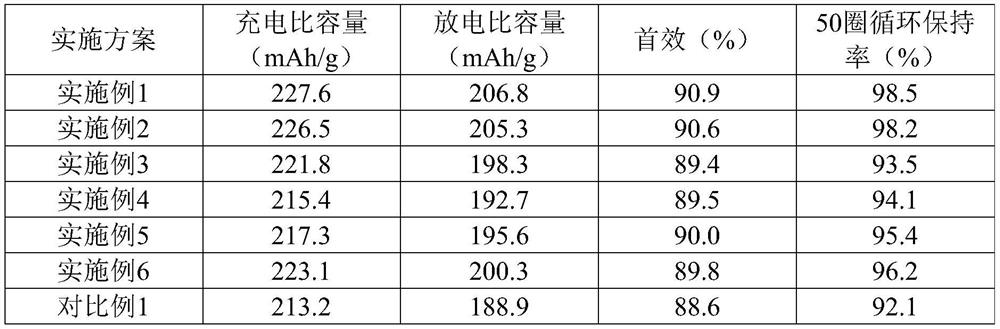

Positive electrode material as well as preparation method and application thereof

ActiveCN113328077AImprove conductivityImprove cycle stabilityPolycrystalline material growthSecondary cellsPhysical chemistrySingle crystal

The invention discloses a positive electrode material and a preparation method and application thereof. The positive electrode material comprises a single-crystal positive electrode material inner core and a CoxB layer located on the surface of the single-crystal positive electrode material inner core. According to the invention, the surface of the single-crystal positive electrode material is coated with the CoxB layer, so the oxygen activity of the surface / interface is reduced, side reactions are reduced, and the conductivity and the cycle performance of the material are improved. The introduction of the CoxB layer has a particularly remarkable improvement effect on the quaternary positive electrode material, and the conductivity and the cycling stability can be greatly improved under the original conditions of high capacity and low gas production, so the electrochemical performance of the positive electrode material is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

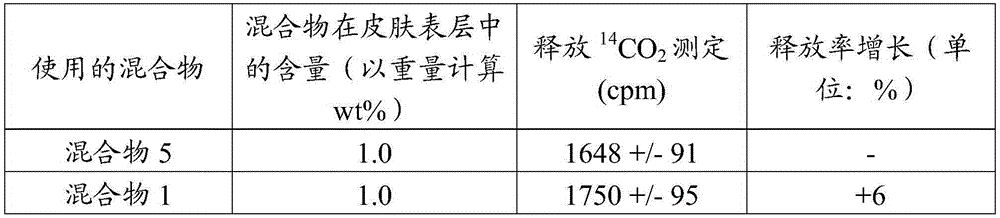

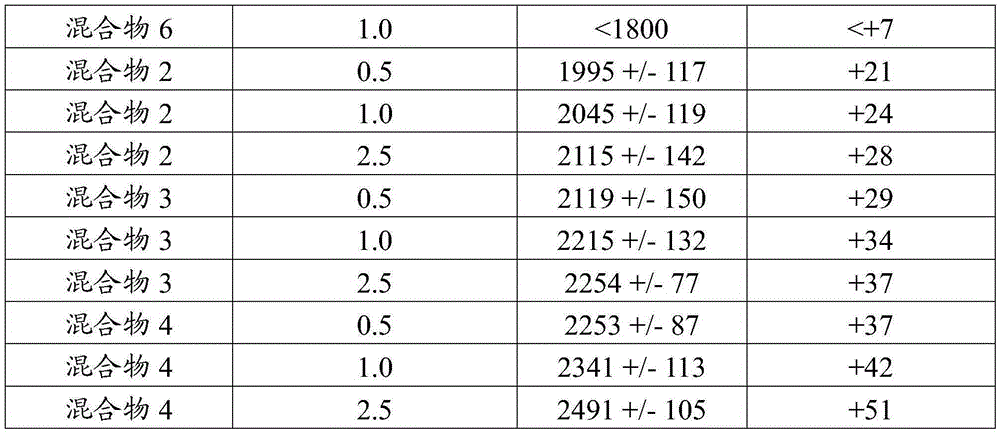

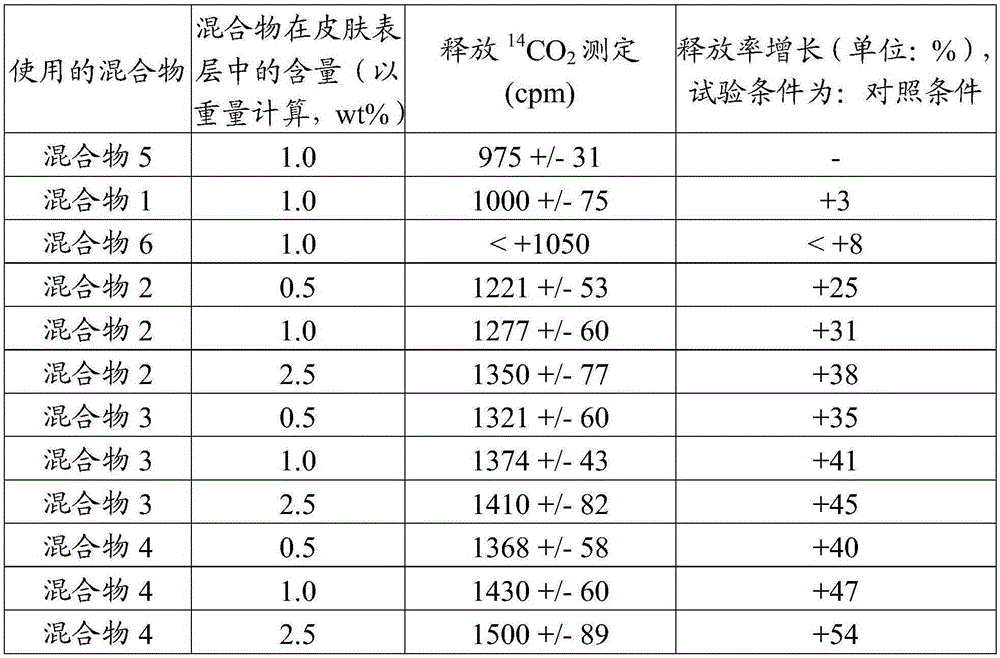

Cosmetic plant polysaccharide composition

InactiveCN105287298AGood cosmetic active effectEnhance metabolic functionCosmetic preparationsToilet preparationsPolysaccharideHerb

The invention provides a cosmetic plant polysaccharide composition. The cosmetic plant polysaccharide composition is characterized by comprising a component (A), a component (B) and a component (C), wherein the component (A) is gotu kola cell or gotu kola cell homogenate, the component (B) is snow lotus herb extract and the component (C) is water, plant glycerin or a mixture of water and plant glycerin. According to the invention, the gotu kola cell or gotu kola cell homogenate and the snow lotus herb extract are cooperatively used as effective components and a physiologically acceptable substrate used for cosmetics is added so as to prepare the cosmetic plant polysaccharide composition; and the prepared cosmetic plant polysaccharide composition has god beautifying active effect, can improve metabolism of the skin and enables the skin to be bright, glossy and beautiful.

Owner:INFINITUS (CHINA) CO LTD

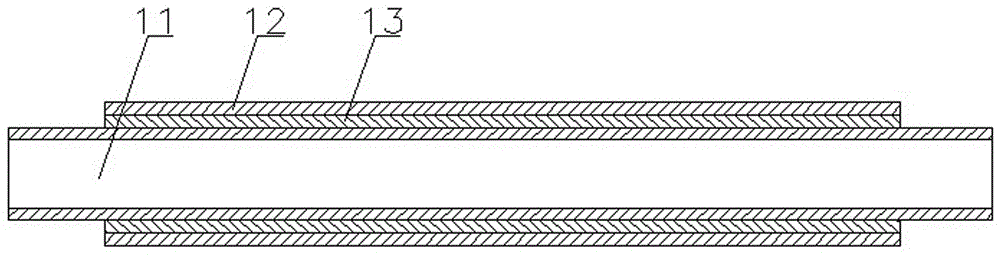

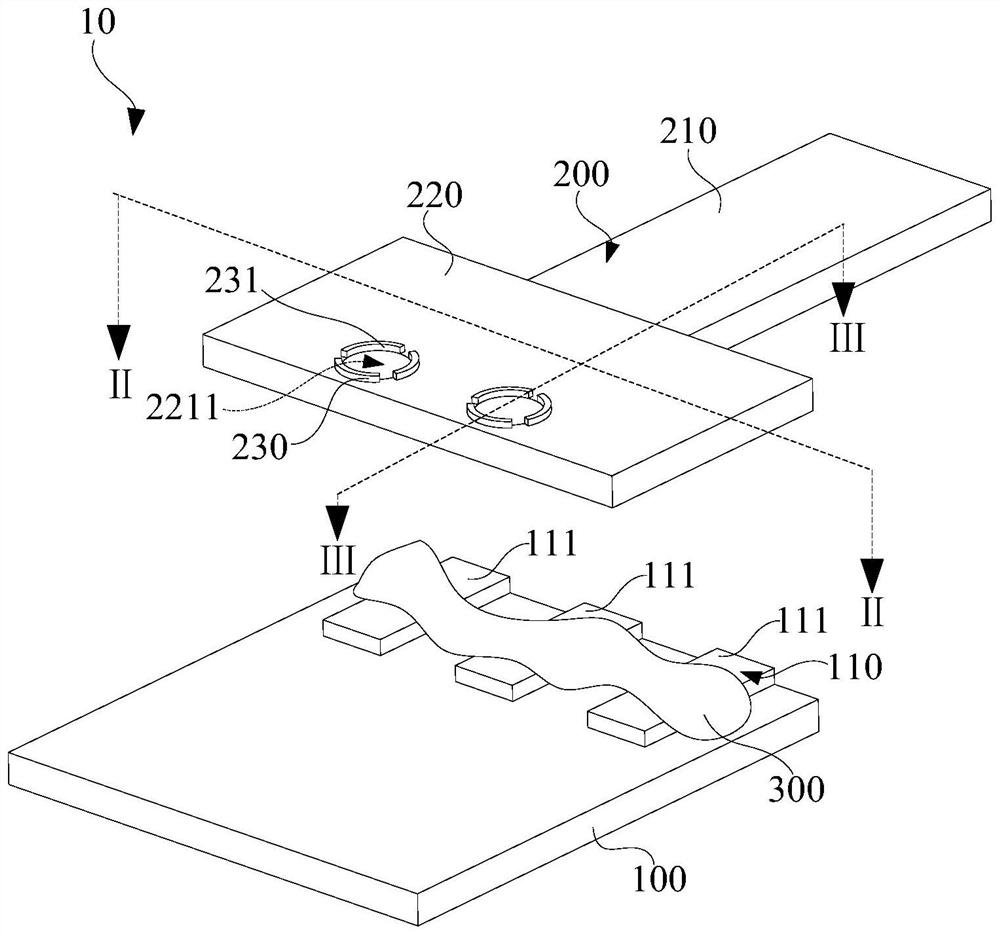

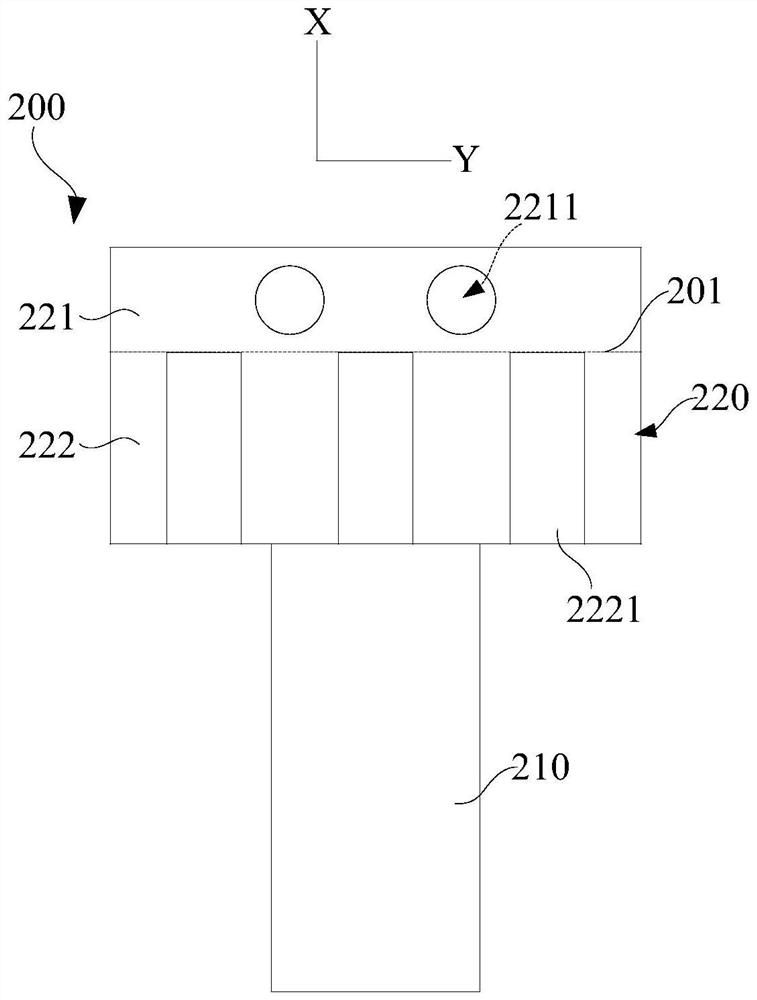

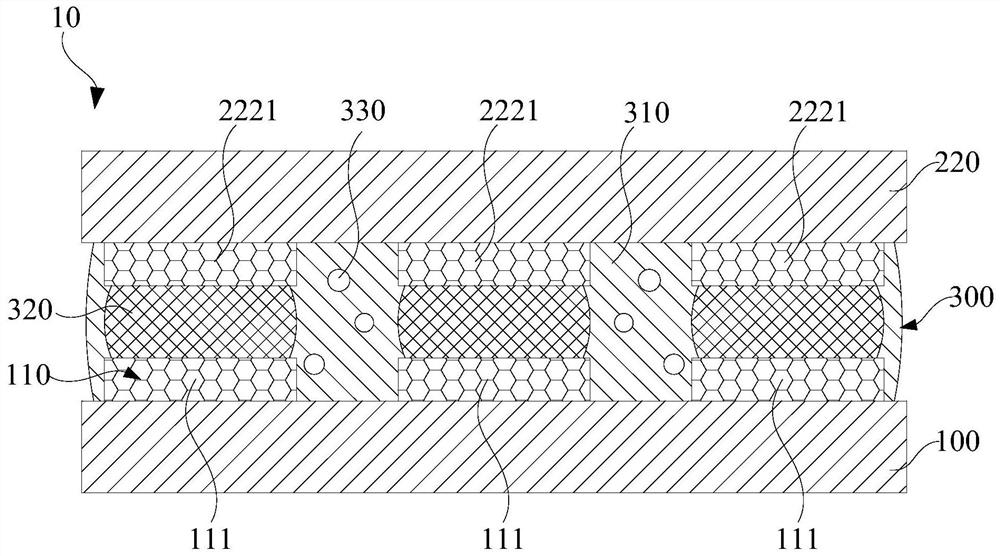

Flexible circuit board, laminating method and circuit board assembly

ActiveCN111668621AEnsure adhesionEnsure connectivityFixed connectionsFlexible circuitsElectrical connection

The invention relates to a flexible circuit board, a laminating method and a circuit board assembly. The flexible circuit board comprises a main body part and a binding part, wherein the binding partcomprises a first area and a second area, the second area is arranged between the first area and the main body part, the binding part forms a boundary line at the connection position of the first areaand the second area, the binding part is provided with an exhaust hole penetrating through the first area, the binding part is provided with a plurality of wiring contacts arranged at intervals on the same side of the second area, and the wiring contacts extend to the boundary line. When a conductive adhesive is pressed, gas in the conductive adhesive can be exhausted from the exhaust hole alongthe gap (the gap between two adjacent wiring contacts) between the electrodes, and the gas in the conductive adhesive is easier to discharge, so that residual bubbles in the conductive adhesive are greatly reduced, and the binding adhesive force and the electrical connection performance of the flexible circuit board on a to-be-laminated panel are ensured.

Owner:INTERFACE TECH CHENGDU CO LTD +2

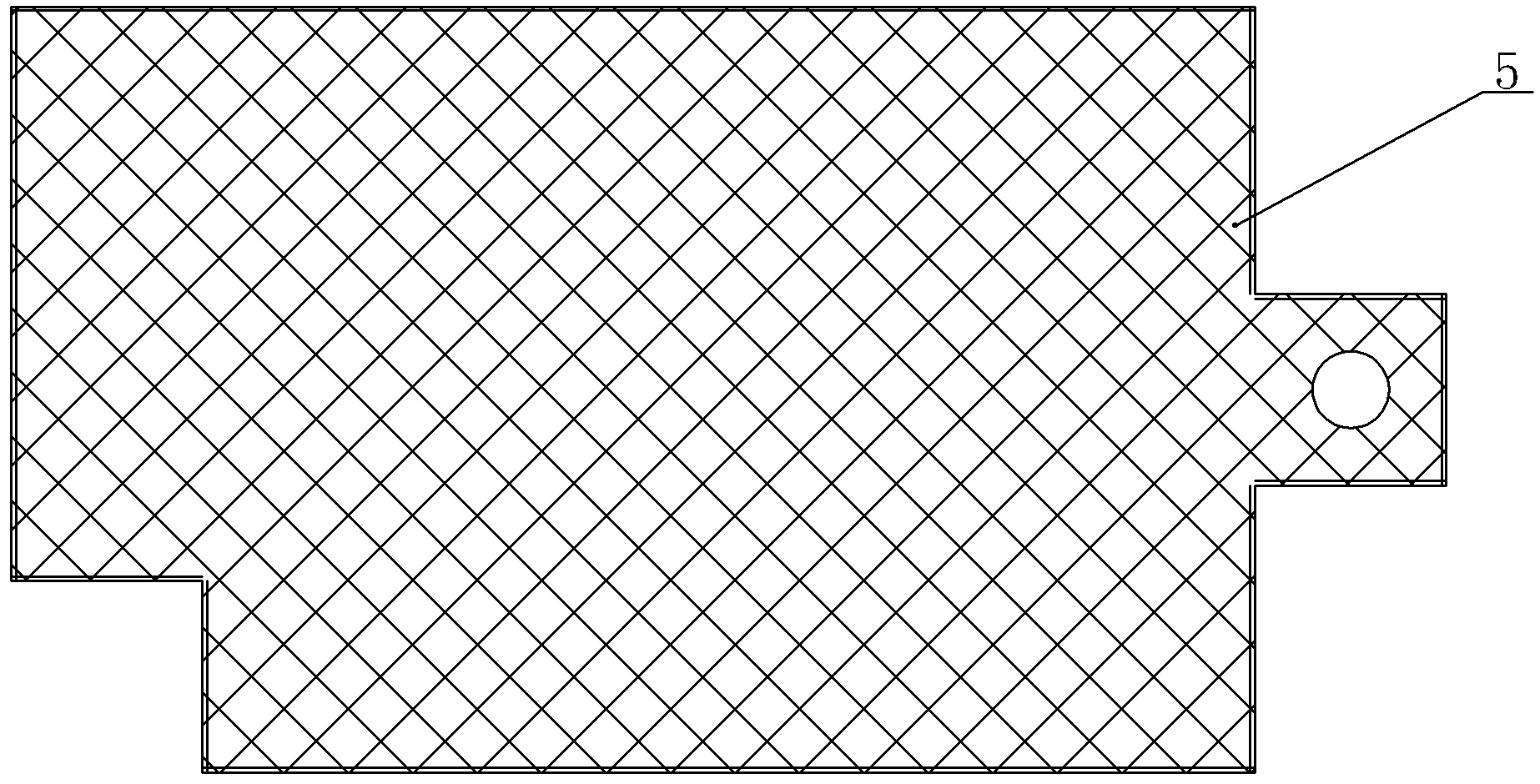

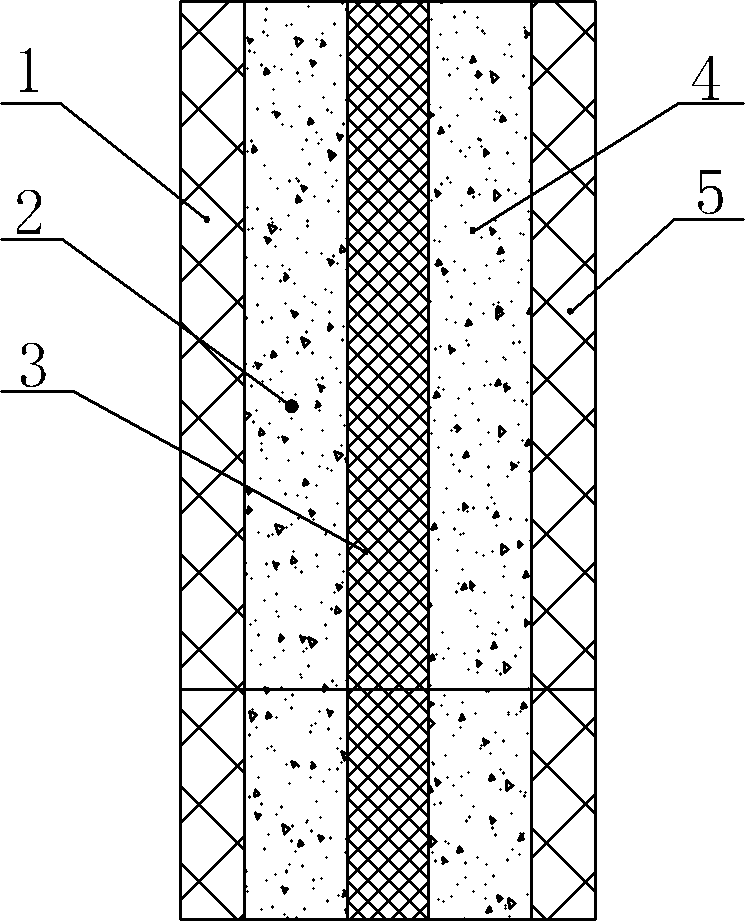

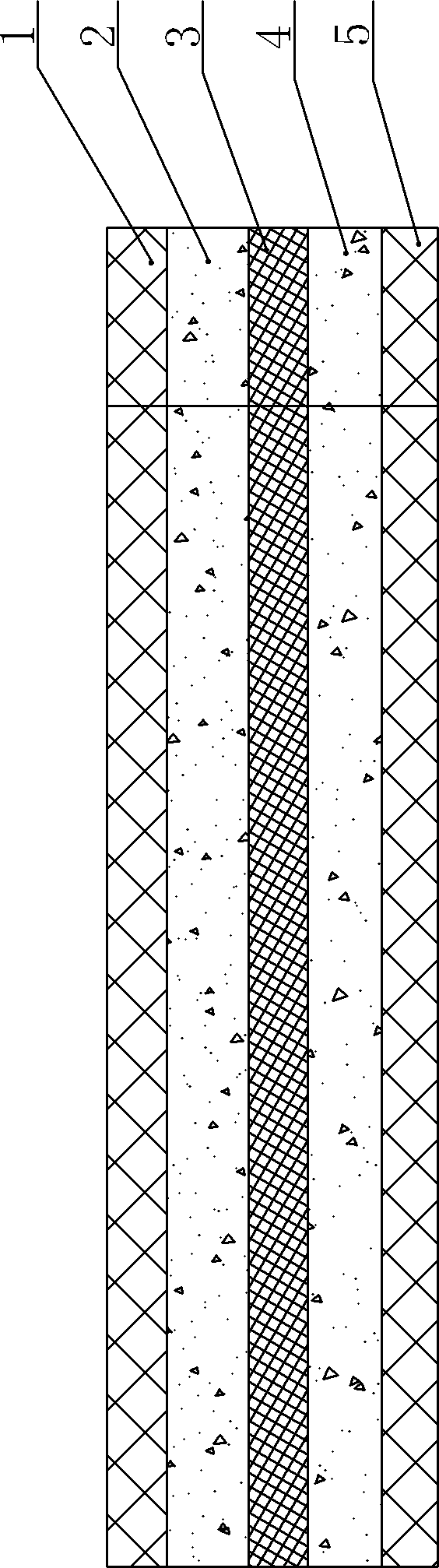

Microbiological fuel cell composite material anode and its manufacturing method

The invention provides a microbiological fuel cell composite material anode and a manufacturing method thereof, and relates to a fuel cell composite material anode and a manufacturing method thereof, so that the problems of low electricity generation capacity and low removal rate of organic pollutant in water body or deposit can be solved. The anode is a compressing piece, the anode comprises a first wire mesh layer, a first non-metal sheet layer, a second wire mesh layer, a second non-metal sheet layer and a third wire mesh layer, the second non-metal sheet layer is positioned between the first wire mesh layer and the second wire mesh layer, the second non-metal sheet layer is arranged between the second wire mesh layer and the third wire mesh layer. The main steps for manufacturing the microbiological fuel cell composite material anode comprise: 1) irregularly etching the wire mesh, 2) performing a nitrocementation to liquid phase plasma, 3) compacting the material, 4) performing a carburization to liquid phase plasma, and 5) treating the composite material. The invention is used for power generation of the microbiological fuel cell and the organic pollutant in water body deposit removal.

Owner:哈尔滨佳泰达微生物燃料电池科技有限公司

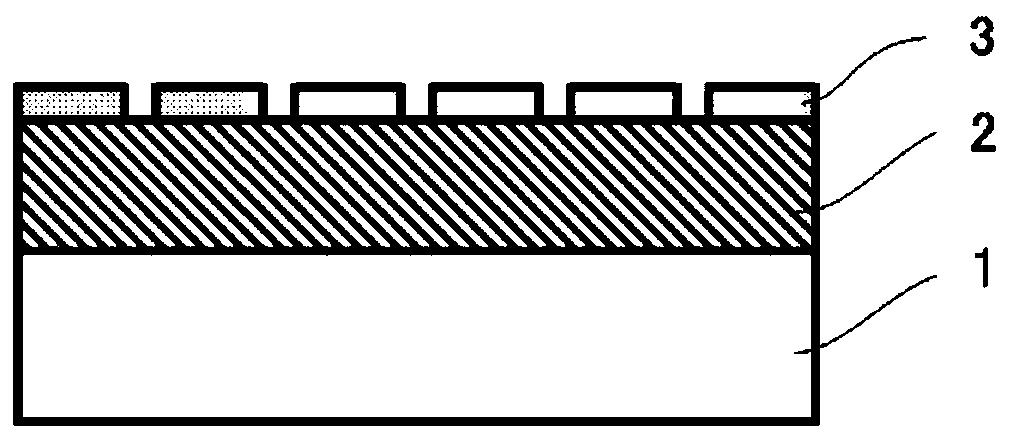

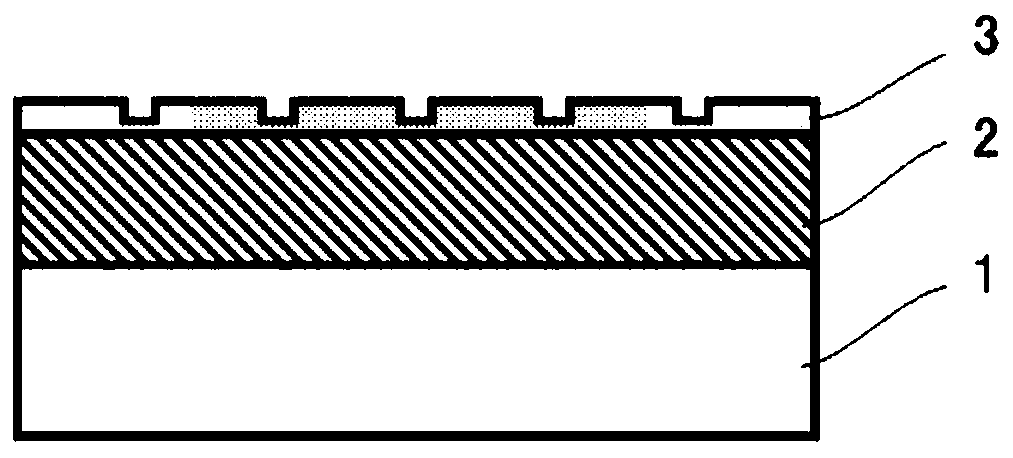

Adhesive tape

ActiveCN110621752AGood removal effectImprove waterproof performancePressure sensitive film/foil adhesivesPressure sensitiveChemistry

Disclosed is a pressure-sensitive adhesive tape which comprises a base 1 and one or two pressure-sensitive adhesive layers disposed on one or both surfaces thereof, characterized in that either the pressure-sensitive adhesive layer in the case where the base 1 has a pressure-sensitive adhesive layer on only one surface or at least one of the two pressure-sensitive adhesive layers in the case wherethe base 1 has two pressure-sensitive adhesive layers on both surfaces comprises a first pressure-sensitive adhesive layer 2, which is in contact with the base 1, and second pressure-sensitive adhesive regions 3, which are in contact with the first pressure-sensitive adhesive layer 2 and are located on the surface side in the pressure-sensitive adhesive tape and that the first pressure-sensitiveadhesive layer 2 has a higher storage modulus G' than the second pressure-sensitive adhesive regions 3. This pressure-sensitive adhesive tape facilitates positional adjustment and air removal during application and has an excellent waterproof performance after the application.

Owner:TERAOKA SEISAKUSHO

A method for preserving the egg mass of Spodoptera frugiperda for multiplying Spodoptera spp.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

A gluing process for the manufacture of copper clad laminates

ActiveCN110205872BAvoid Cured SituationsAvoid failure to adhere to gluePaper/cardboardPulp material addition processesPolymer scienceResin adhesive

The invention provides a gluing process for the manufacture of copper-clad laminates. The operation is completed by the cooperation of a fixed frame, a rubber roller, a gluing roller and a dispersion device. The amount of glue is small, so the rotating drive roller only needs to bring a small amount of glue to the surface of the drive roller, but because the resin glue is fluid, it is difficult for the glue to adhere to the surface of the drive roller, which may cause partial transmission The surface of the roller fails to adhere to the resin glue, and the glue is not evenly distributed, so that part of the substrate cannot be glued. The resin glue is fluid after being heated. Due to the low surface temperature of the drive roller, when the drive roller When the surface is in contact with the resin glue solution, part of the resin solution may be cured, which affects the gluing efficiency of the substrate and other issues.

Owner:安能电子有限公司

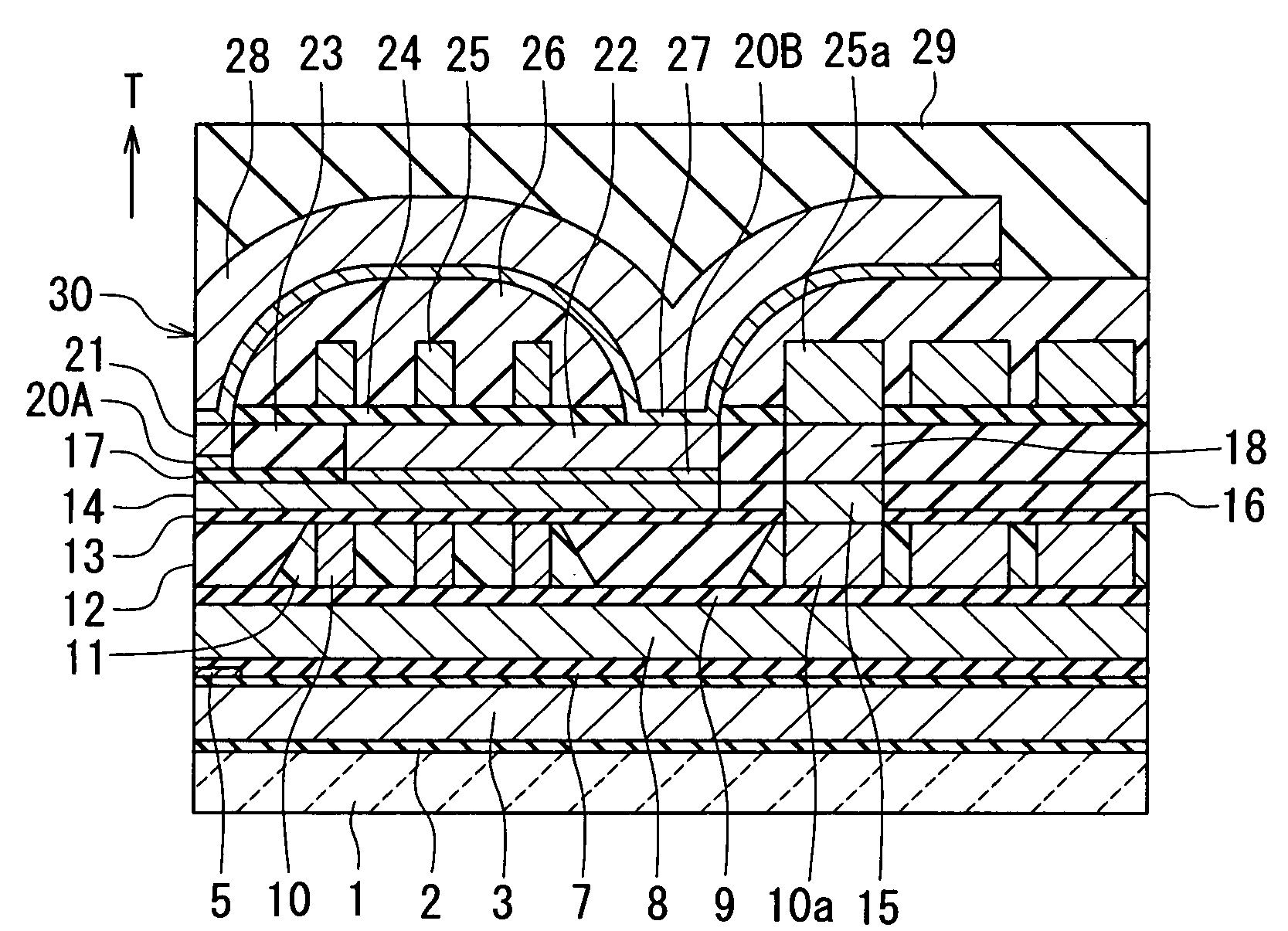

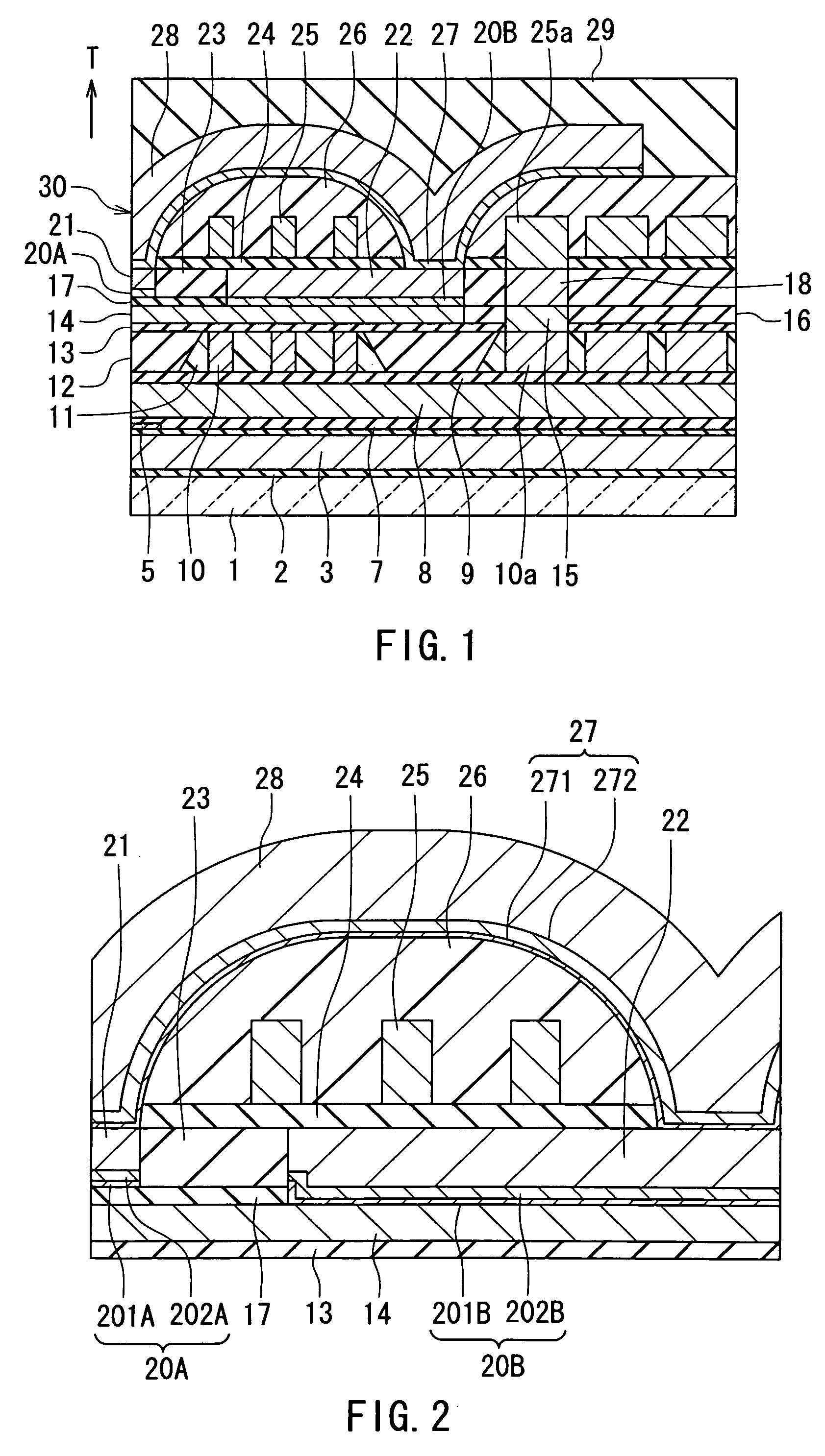

Magnetic structure including two ferromagnetically coupled magnetic layers and method of manufacturing same

ActiveUS20090268349A1Ensure adhesionGuaranteed adhesionRecord information storageManufacture of flux-sensitive headsOxygen atomMagnetic layer

A magnetic structure includes a first magnetic layer, a nonmagnetic insulating layer, a nonmagnetic adhesion layer disposed on the top surfaces of the first magnetic layer and the nonmagnetic insulating layer, and a second magnetic layer disposed on the nonmagnetic adhesion layer. The nonmagnetic insulating layer contains an oxygen atom. The nonmagnetic adhesion layer is composed of one element or a plurality of elements selected from the group consisting of Al, Si and nonmagnetic transition metal elements except Ru, and the bond enthalpy of a diatomic molecule composed of an atom of the one element or each of the plurality of elements and an oxygen atom is 400 kJ / mol or higher. The nonmagnetic adhesion layer has a thickness within a range of 0.3 to 0.8 nm. The first magnetic layer and the second magnetic layer are ferromagnetically coupled to each other.

Owner:TDK CORPARATION

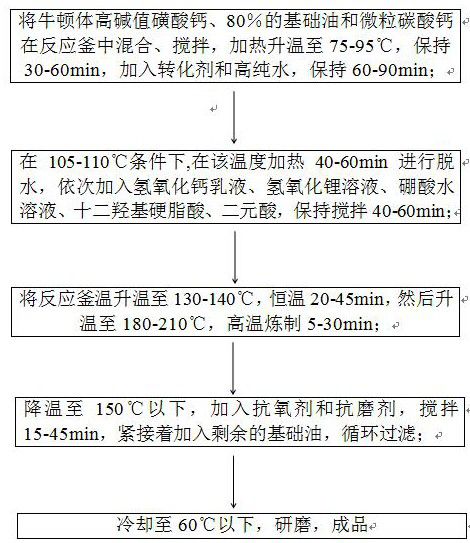

Heavy-load high-temperature water-resistant roll bearing lubricating grease and preparation method thereof

PendingCN114752429AEnsure high drop pointEnsure high temperature wear resistanceLubricant compositionLithium hydroxideAntioxidant

The invention discloses heavy-load high-temperature water-resistant roller bearing lubricating grease and a preparation method thereof. The heavy-load high-temperature water-resistant roll bearing lubricating grease is prepared from base oil, Newtonian high-base-number calcium sulfonate, particle calcium carbonate, boric acid, a transforming agent, high-purity water, calcium hydroxide, lithium hydroxide, binary acid, 12-hydroxystearic acid, an antioxidant and an anti-wear agent. The composite thickening agent is used for improving the composite calcium sulfonate-based mechanical stability, especially reducing the consistency change value of the composite calcium sulfonate-based lubricating grease in the storage process, so that the colloidal stability of the composite calcium sulfonate-based lubricating grease is improved. Meanwhile, the high-temperature oxidation resistance, the extreme pressure anti-wear performance and the anti-rust performance of the composite calcium sulfonate-based lubricating grease are improved.

Owner:山东联博新材料科技有限公司

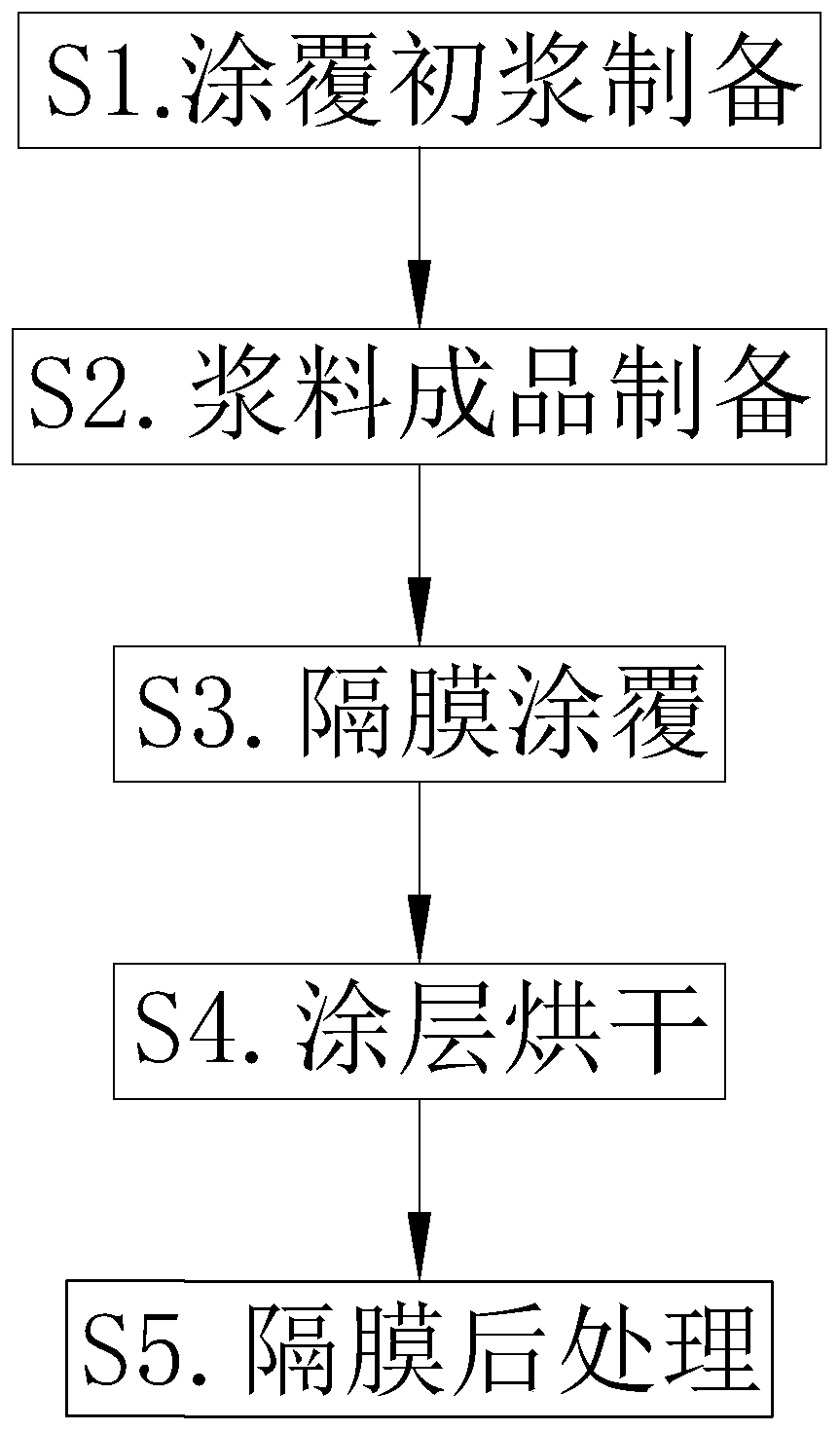

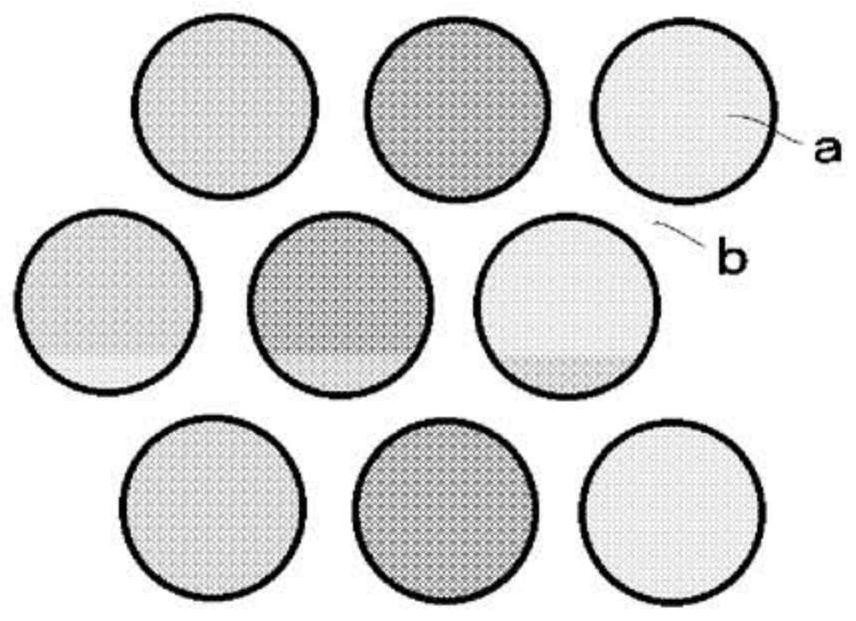

Coating slurry for lithium battery diaphragm and coating process

ActiveCN111048720AGood compatibilityImprove adhesionSecondary cellsCell component detailsAdhesiveSlurry

The invention relates to a coating slurry for a lithium battery diaphragm and a coating process. The coating slurry is prepared from the following components, by weight, 35 to 55 parts of copolymerization emulsion, 25 to 40 parts of a titanium dioxide dispersion liquid, 3 to 6 parts of a dispersing agent, 3 to 5 parts of chlorinated polypropylene and 1 to 4 parts of an adhesive, wherein the copolymerization emulsion is the copolymerization emulsion of tetrahydrofuran acrylate and butyl methacrylate. The coating process comprises the following steps: S1, adding the copolymerization emulsion, the titanium dioxide dispersion liquid and the chlorinated polypropylene into a magnetic stirrer, stirring for 8 to 10min, then adding the dispersing agent, continuing to stir for 45 to 55min, and finally adding the adhesive, and stirring for 25 to 35min so as to prepare a coating primary slurry; S2, carrying out ball milling treatment on the coating primary slurry to prepare a slurry finished product; S3, placing a diaphragm on a coating machine, and coating the surface of the diaphragm with the slurry finished product at a normal temperature; S4, placing the diaphragm in an environment of 42-45 DEG C for vacuum drying treatment to obtain a coating modified microporous membrane; and S5, winding the coating modified microporous membrane to obtain a finished product. Good adhesiveness is achieved between the coating slurry and the diaphragm.

Owner:深圳市新非泽科技有限公司

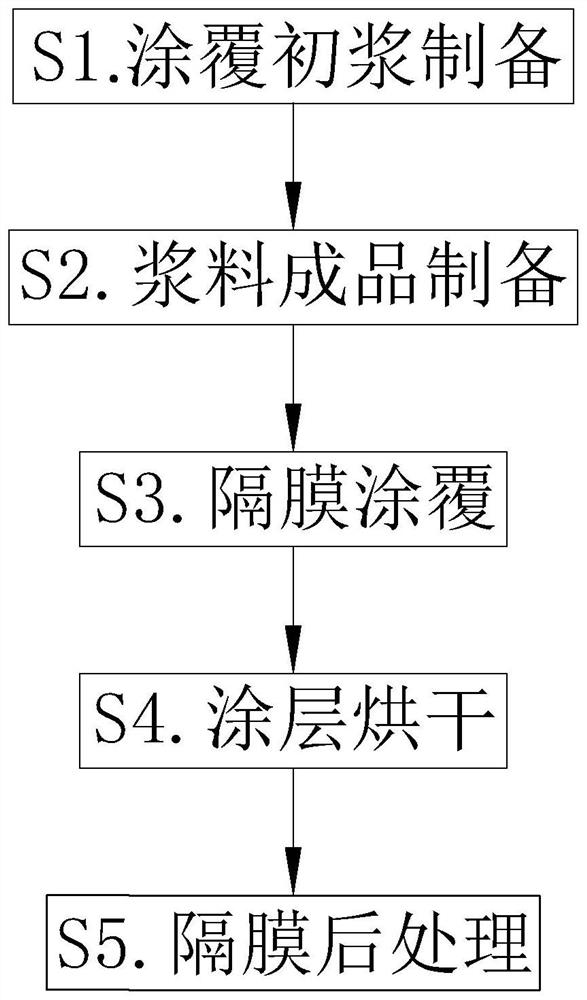

Coating slurry and coating process for lithium battery diaphragm

ActiveCN111048720BGood compatibilityImprove adhesionSecondary cellsCell component detailsAdhesivePolypropylene

The invention relates to a coating slurry for a lithium battery diaphragm and a coating process. The coating slurry comprises the following components in parts by weight: 35-55 parts of a copolymer emulsion, 25-40 parts of a titanium dioxide dispersion, and 3-6 parts of a dispersant 3-5 parts of chlorinated polypropylene and 1-4 parts of adhesive; the copolymer emulsion is a copolymer emulsion of tetrahydrofuran acrylate and butyl methacrylate; the coating process includes the following steps: S1. dispersing the copolymer emulsion and titanium dioxide Add liquid and chlorinated polypropylene to a magnetic stirrer and stir for 8-10min, then add a dispersant and continue stirring for 45-55min, and finally add an adhesive and stir for 25-35min to obtain a primary slurry for coating; S2. Perform ball milling treatment to obtain the finished slurry; S3. Place the diaphragm on a coating machine, and coat the finished slurry on the surface of the diaphragm at room temperature; S4. Place the diaphragm in an environment of 42-45°C for vacuum drying processing to obtain a coating-modified microporous membrane; S5. winding the coating-modified microporous membrane to obtain a finished product. The coating slurry in the present invention has good adhesion to the separator.

Owner:深圳市新非泽科技有限公司

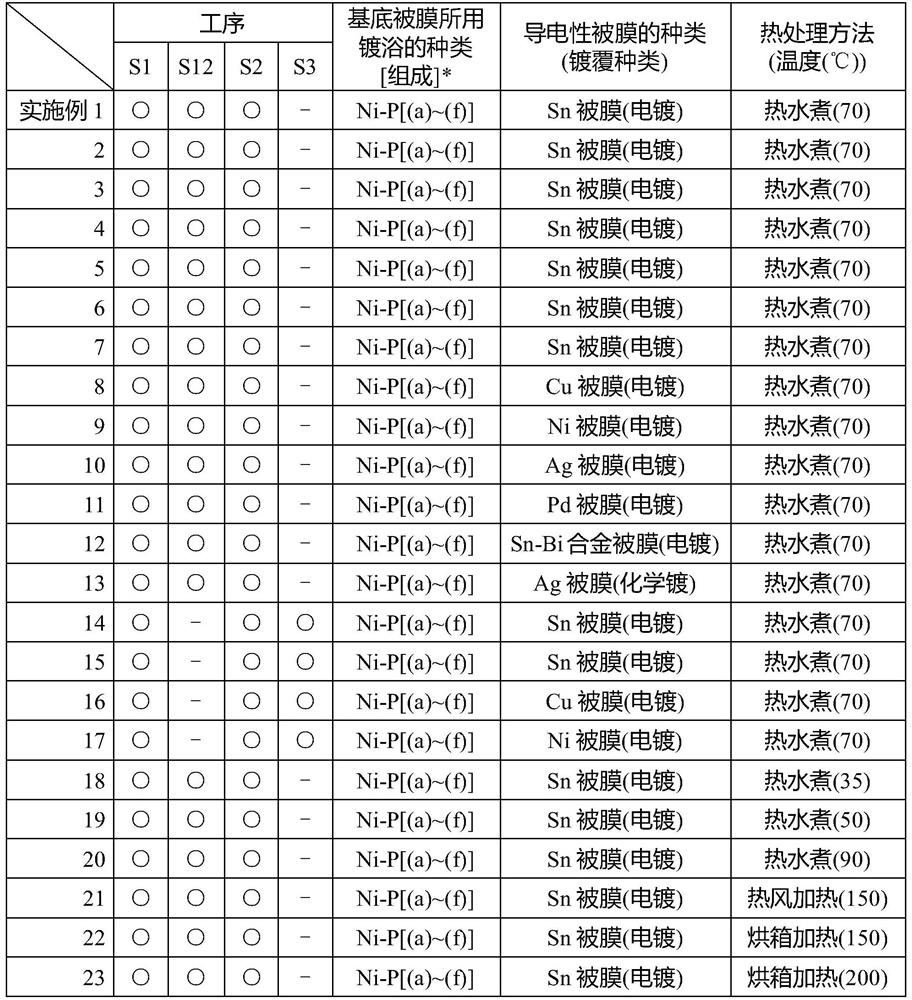

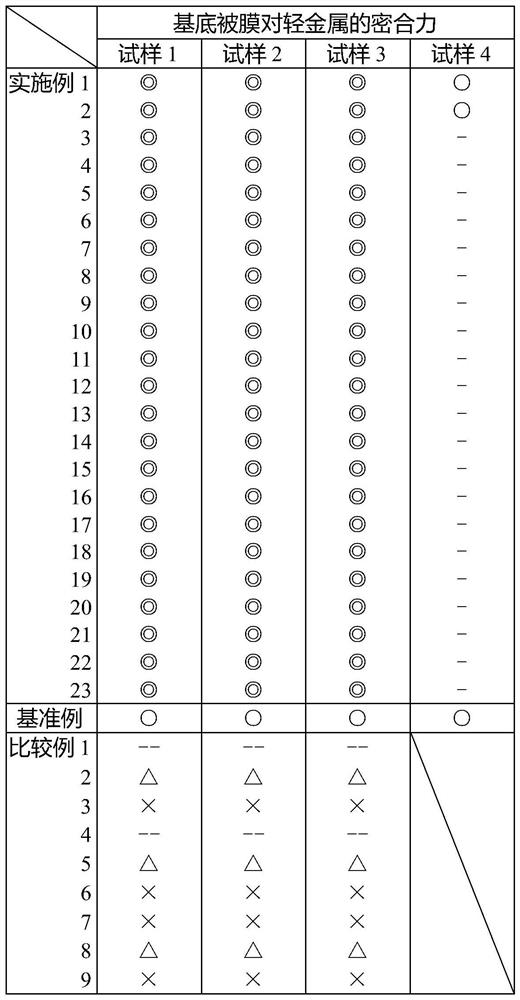

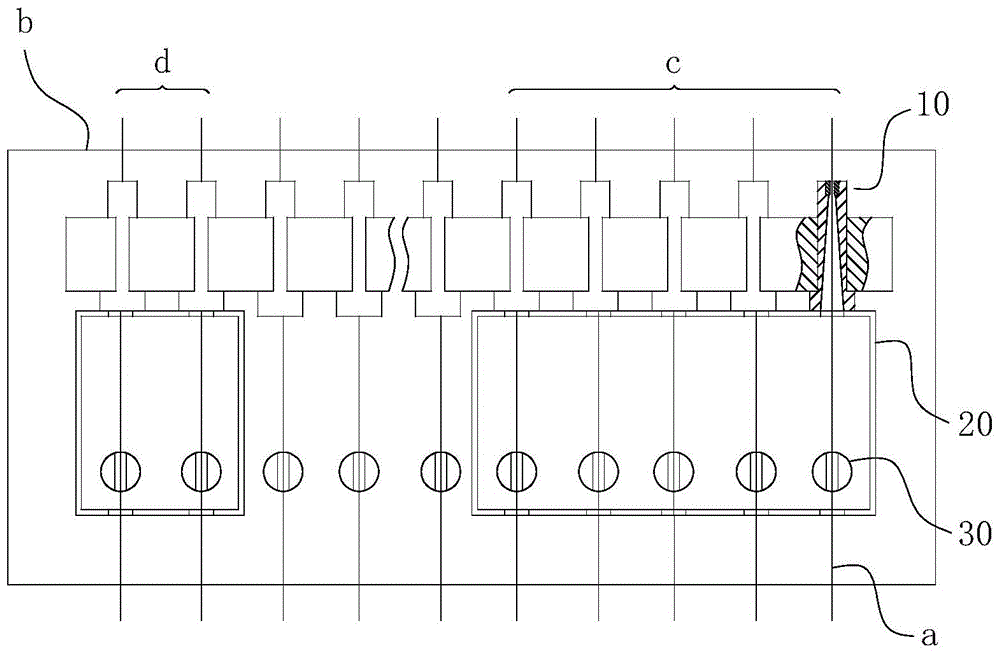

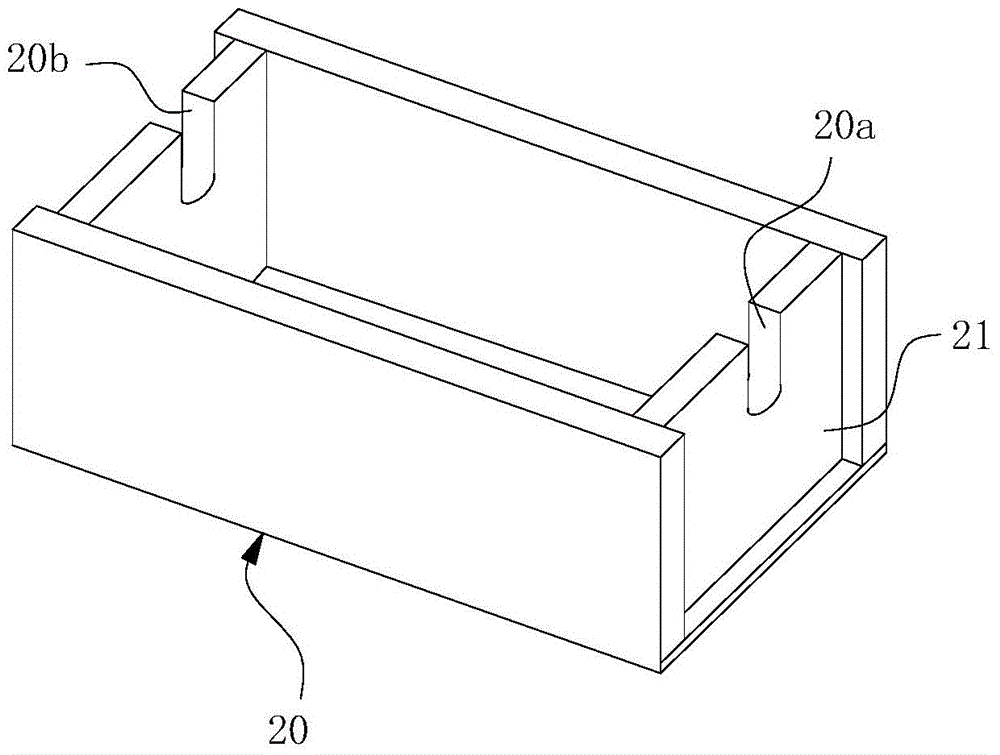

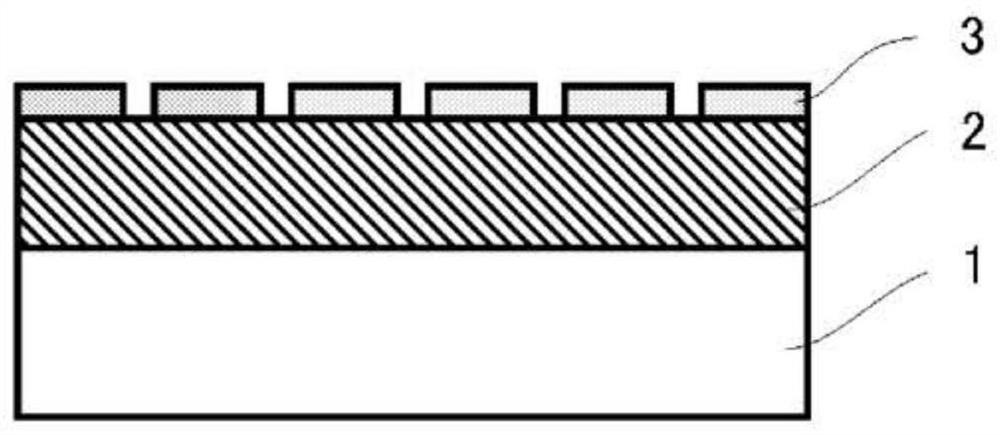

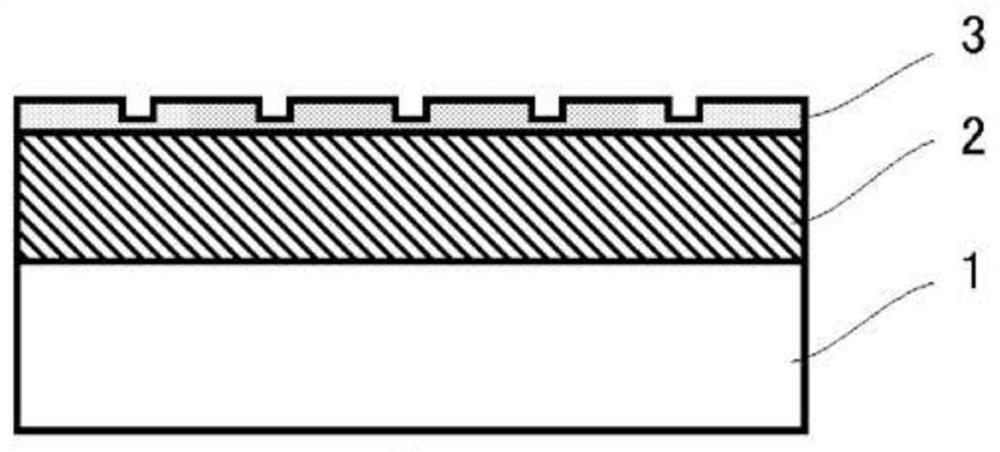

Heat treatment type conductive film forming method on passivation light metal

ActiveCN109891004BExcellent adhesionFit closelyLiquid/solution decomposition chemical coatingSuperimposed coating processNickel saltTitanium

The present invention provides a method for forming a heat-treated conductive film on a passivation-forming light metal, which is to form a conductive film such as silver, copper, tin, etc. on a passivation-forming light metal selected from aluminum, magnesium, and titanium through a base film. A coating method, the base coating is a nickel-phosphorus coating, the base coating is formed by using a nickel-phosphorus electroplating bath containing a prescribed soluble nickel salt, a phosphorus-containing compound, a complexing agent, a surfactant, a buffer, and a brightener, And heat-treating the base coating, or the base coating and the conductive coating under conditions including a low temperature range of 30°C or higher, can strengthen the adhesion of the base coating to the passivation light metal compared to a method without heat treatment. A conductive film is formed on the passivation-forming light metal more firmly.

Owner:ISHIHARA CHEM

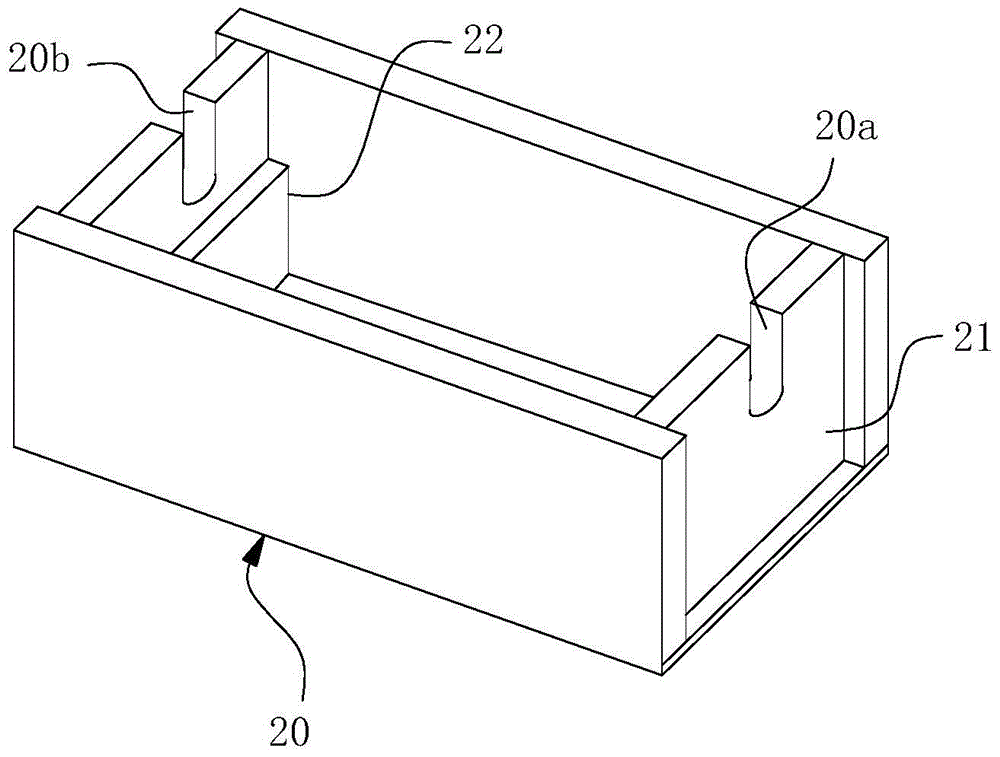

Copper wire painting equipment for horizontal high-speed enamelling machine

ActiveCN104240858BTo achieve the coating effect on the surface of copper wireEliminate the phenomenon of poor paintingInsulating conductors/cablesCopper wireEngineering

The invention belongs to the field of painting devices of enamelled wires, and particularly relates to a copper wire painting device for a horizontal high-speed enamelling machine. The copper wire painting device is provided with painting molds and a paint supplying device. The painting molds are used for carrying out multi-channel painting on each row wire, and the paint supplying device supplies paint liquid to the painting molds. The painting molds are horizontally arranged in parallel in the axial direction of mold holes in the molds, and containing boxes for containing paint liquid are arranged on wire inlets of the painting molds at the first painting working procedure and the last painting working procedure, each containing box is provided with a wire inlet end and a wire outlet end, copper wires to be painted pass through the wire inlet end and the wire outlet end of each containing box, the arrangement positions of the wire inlet end and the wire outlet end of each containing box are lower than the maximum containing height position of the paint liquid in the corresponding containing box, and the wire inlet end and the wire outlet end of each containing box are coaxial with the wire inlet of the corresponding painting mold. Due to the fact that the containing boxes are used as preparation painting units of the copper wires, painting stability of the enamelled wires at the painting technological position is effectively ensured, and the good film painting and coating effects of the enamelled wires are ensured.

Owner:TONGLING JINGDA REA SPECIAL ENAMELED WIRE

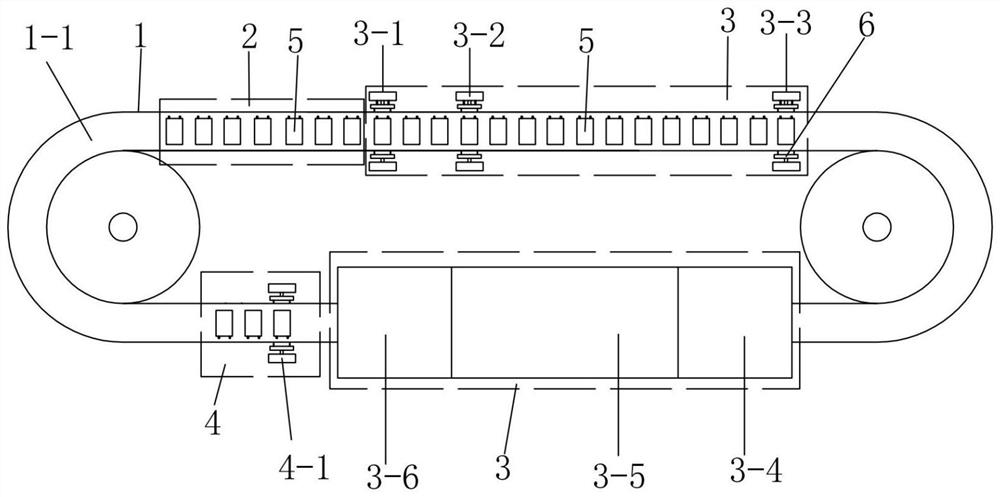

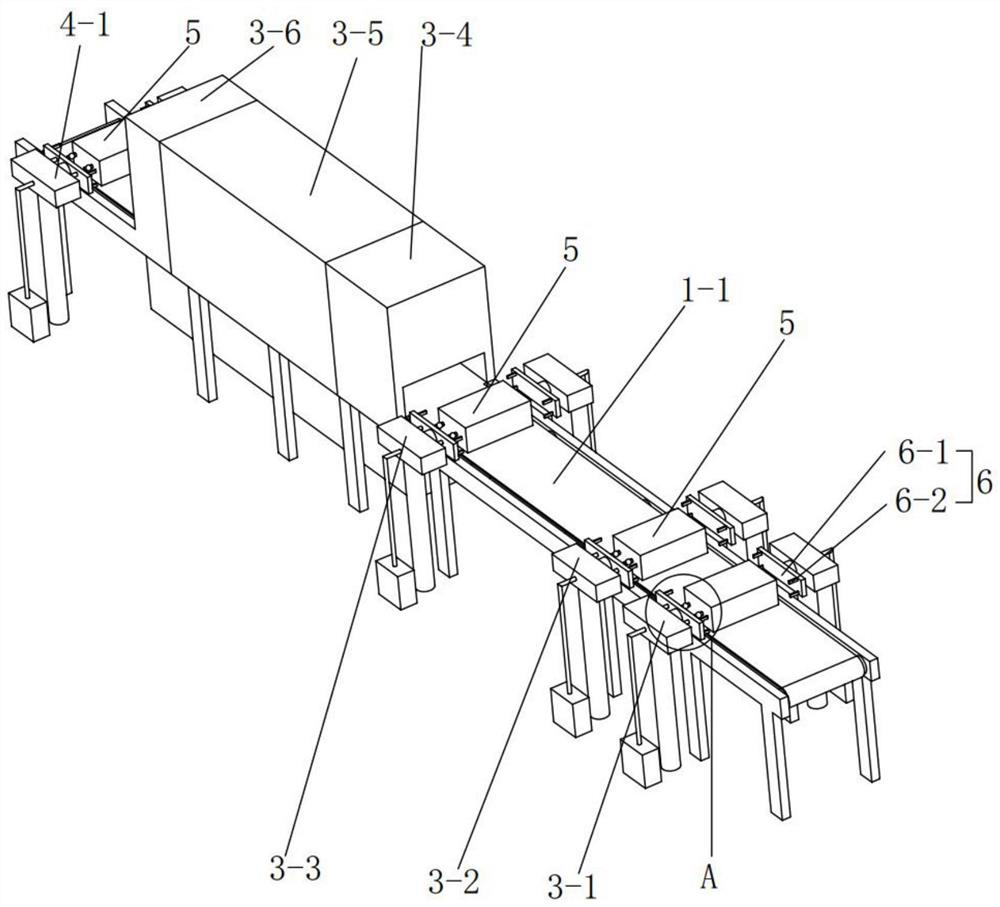

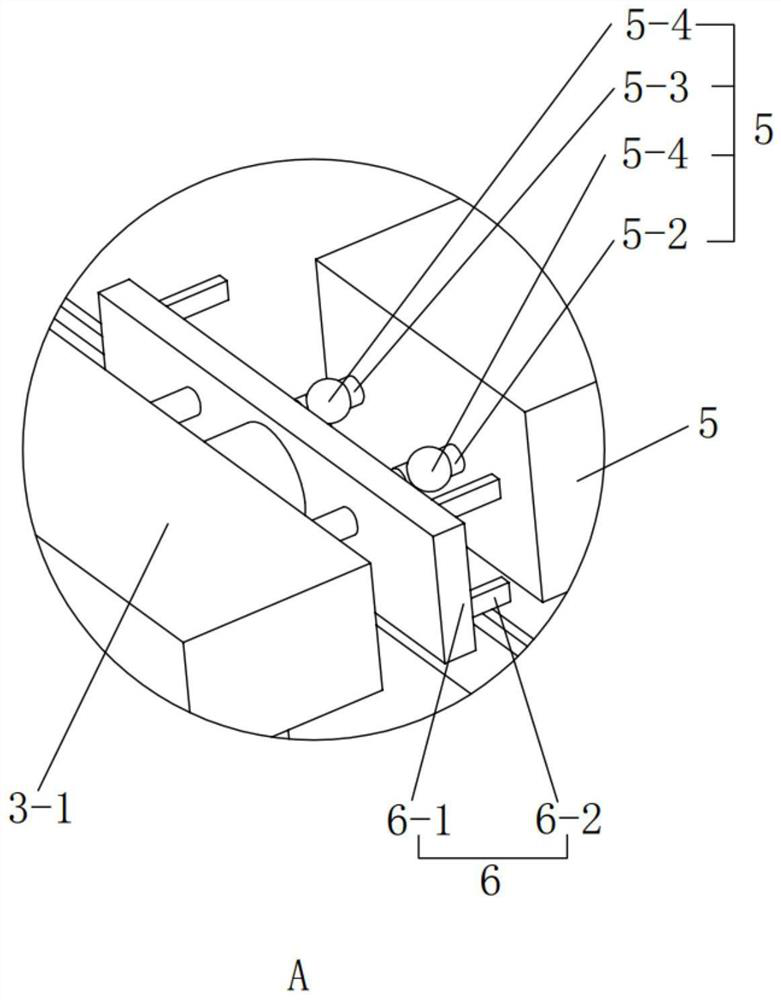

Fuel cell gas diffusion layer batch hydrophobic treatment method and production line thereof

ActiveCN114824307AGood water-air balance performanceAchieve water-repellent effectCell electrodesProduction lineFuel cells

The invention discloses a fuel cell gas diffusion layer batch hydrophobic treatment method and a production line thereof, and the hydrophobic treatment method comprises the following steps: vacuumizing, filling an atomized water repellent solution, vacuumizing again, drying at a low temperature, roasting at a high temperature, cooling and filling air. According to the mode, continuous hydrophobicity of batch gas diffusion layers is achieved, the working efficiency is improved, high hydrophobicity uniformity is achieved, and potential safety hazards in the hydrophobicity calcination process can be reduced so as to save the cost; in the production line, the annular conveying track is utilized, and the metal sealing box can be repeatedly utilized under the condition that the metal sealing box does not need to be carried and transferred, so that hydrophobic treatment of large-batch diffusion layers is realized; and a hydrophobic treatment process is realized by combining a vacuumizing mechanism I, a hydrophobic solution atomizing mechanism, a vacuumizing mechanism II, a low-temperature heating oven, a high-temperature roasting furnace, a cooling chamber and other mechanisms.

Owner:上海碳际实业集团有限公司

adhesive tape

ActiveCN110621752BGood removal effectImprove waterproof performancePressure sensitive film/foil adhesivesPolymer sciencePolymer chemistry

An adhesive tape is disclosed, which is characterized in that it is an adhesive tape having an adhesive layer on one side or both sides of a substrate 1, an adhesive layer in the case of having an adhesive layer on one side of the substrate 1, or an adhesive layer on one side of the substrate 1. When the base material 1 has adhesive layers on both surfaces, at least one of the two adhesive layers has the first adhesive layer 2 in contact with the base material 1 and the first adhesive layer 2 Next, in the second adhesive region 3 located on the surface side of the adhesive tape, the storage elastic modulus G' of the first adhesive layer 2 is higher than the storage elastic modulus G' of the second adhesive region 3 . This pressure-sensitive adhesive tape is easy to perform position adjustment and air removal at the time of sticking, and is excellent in waterproofness after sticking.

Owner:TERAOKA SEISAKUSHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com