Heavy-load high-temperature water-resistant roll bearing lubricating grease and preparation method thereof

A roll bearing and lubricating grease technology, which is applied in the field of heavy-duty high-temperature water-resistant roll bearing lubricating grease and its preparation, can solve the problems of poor colloidal stability, easy hardening of the surface, and easy precipitation of base oil, etc., to increase shear stability , the effect of good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

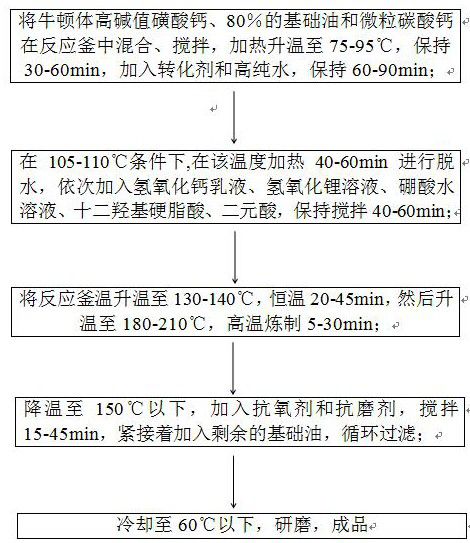

[0028] A method for preparing heavy-duty high-temperature water-resistant roll bearing grease, comprising the following steps:

[0029] S1: First determine the proportion of each component, then mix and stir Newtonian high basic number calcium sulfonate, 80% base oil and particulate calcium carbonate in the reaction kettle, heat up to 75-95°C, and keep for 30-60min , under the condition of constant stirring, add the transforming agent and high-purity water, keep it for 60-90min, then control the kettle temperature at 105-110℃, heat at this temperature for 40-60min for dehydration, add calcium hydroxide emulsion, hydrogen Lithium oxide solution, boric acid aqueous solution, dodecylhydroxystearic acid, dibasic acid, keep stirring for 40-60min;

[0030] S2: then the temperature of the reaction kettle is raised to 130-140°C, kept constant for 20-45min, then raised to 180-210°C, refined at high temperature for 5-30min, cooled to below 150°C, added antioxidant and anti-wear agent, s...

Embodiment 1

[0035]A heavy-duty high-temperature water-resistant roll bearing grease, the heavy-duty high-temperature water-resistant roll bearing grease is composed of base oil, Newtonian high base number calcium sulfonate, particulate calcium carbonate, boric acid, transforming agent, high-purity water, calcium hydroxide, Lithium hydroxide, dibasic acid, dodecahydroxystearic acid, antioxidant, antiwear agent, and the specific gravity of each component is as follows: 40 parts of base oil, 20 parts of Newtonian high base number calcium sulfonate, particulate calcium carbonate 0.001 part, 0.4 part of boric acid, 3 parts of conversion agent, 2 parts of high-purity water, 1 part of calcium hydroxide, 1 part of lithium hydroxide, 1 part of dibasic acid, 1 part of dodecahydroxystearic acid, 0.1 part of antioxidant, anti-wear dose 0.5 servings.

[0036] The base oil is a mixture of mPAO and diester, mPAO is SpectraSyn Elite 65, and the diester is dioctyl sebacate.

[0037] The Newtonian overbas...

Embodiment 2

[0048] A heavy-duty high-temperature water-resistant roll bearing grease, the heavy-duty high-temperature water-resistant roll bearing grease is composed of base oil, Newtonian high base number calcium sulfonate, particulate calcium carbonate, boric acid, transforming agent, high-purity water, calcium hydroxide, Lithium hydroxide, dibasic acid, dodecahydroxystearic acid, antioxidant, antiwear agent, and the specific gravity of each component is as follows: 50 parts of base oil, 35 parts of Newtonian high base number calcium sulfonate, particulate calcium carbonate 0.01 part, 1 part of boric acid, 5 parts of conversion agent, 10 parts of high-purity water, 6 parts of calcium hydroxide, 6 parts of lithium hydroxide, 8 parts of dibasic acid, 8 parts of dodecylhydroxystearic acid, 2 parts of antioxidant, antioxidant Grinding agent 1.5 parts.

[0049] Described base oil is the mixture of mPAO and diester, mPAO is SpectraSyn Elite 65, SpectraSynElite 150, SpectraSyn Elite 300, diest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com