Coating slurry and coating process for lithium battery diaphragm

A lithium battery diaphragm and coating technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of the diaphragm's high temperature resistance, poor compatibility, and ceramic particle materials falling off and falling off powder, so as to improve the discharge rate. Protective effect, increase the surface polarity, and improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the titanium dioxide dispersion liquid in the present invention is: disperse nano-titanium dioxide in deionized water under normal temperature, prepare suspension liquid; Place suspension liquid in magnetic stirrer and stir for 10min, make nano-titanium dioxide disperse evenly; Add 0.5% sodium lauryl sulfate and stir for 30 minutes to obtain a dispersion; then add acetic acid to a magnetic stirrer to adjust the pH of the dispersion to 5.0 to obtain a titanium dioxide dispersion.

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

Embodiment 1

[0038] Embodiment 1 is a coating slurry and a coating process for a lithium battery diaphragm disclosed by the present invention. The coating slurry includes the following components in parts by weight:

[0039] components parts by weight components parts by weight Copolymer emulsion 45 Chlorinated Polypropylene 4 Titanium Dioxide Dispersion 33 Hydroxyethyl cellulose 2.5 Sodium lignosulfonate 4.5

[0040] The copolymerization emulsion is a copolymerization emulsion of tetrahydrofuran acrylate and butyl methacrylate;

[0041] The mass fraction ratio of tetrahydrofuran acrylate to butyl methacrylate is 1:1;

[0042] The coating thickness of one side of the coating slurry is 5um;

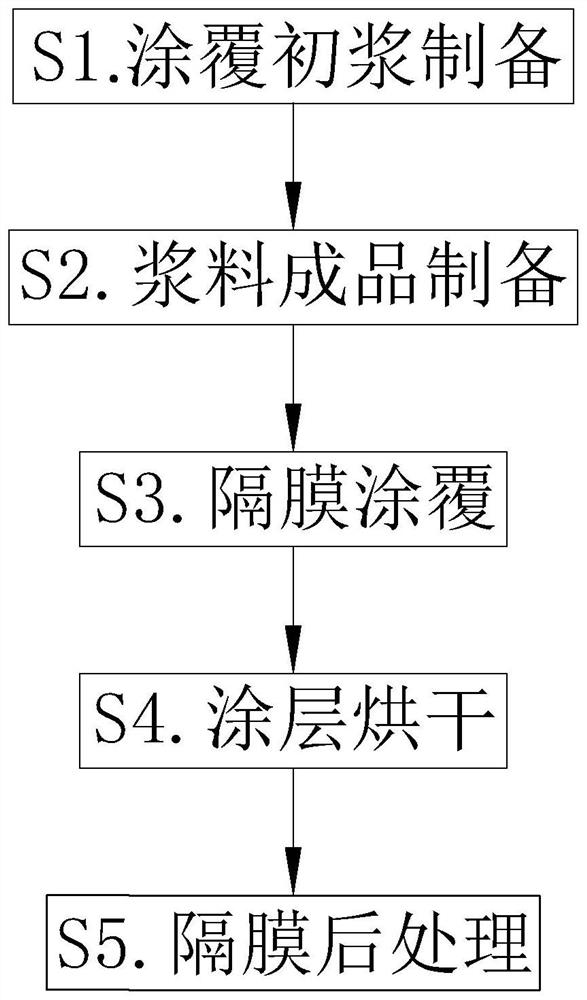

[0043] The coating process specifically includes the following steps:

[0044] S1. Coating initial slurry preparation: Add copolymer emulsion, titanium dioxide dispersion and chlorinated polypropylene to a magnetic stirrer and stir for 10 minutes, then ...

Embodiment 2

[0049] Embodiment 2 is a coating slurry and coating process for a lithium battery diaphragm disclosed by the present invention. The coating slurry includes the following components by weight:

[0050] components parts by weight components parts by weight Copolymer emulsion 35 Chlorinated Polypropylene 3 Titanium Dioxide Dispersion 25 Hydroxyethyl cellulose 1 Sodium lignosulfonate 3

[0051] The copolymerization emulsion is a copolymerization emulsion of tetrahydrofuran acrylate and butyl methacrylate;

[0052] The mass fraction ratio of tetrahydrofuran acrylate to butyl methacrylate is 1:1;

[0053] The coating thickness of one side of the coating slurry is 5um;

[0054] The coating process steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com