Adhesive tape

An adhesive tape and adhesive technology, applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc., can solve the problems of decreased adhesion and water resistance, difficulty in air removal, etc., to achieve water resistance Excellent, secure adhesion, easy position adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

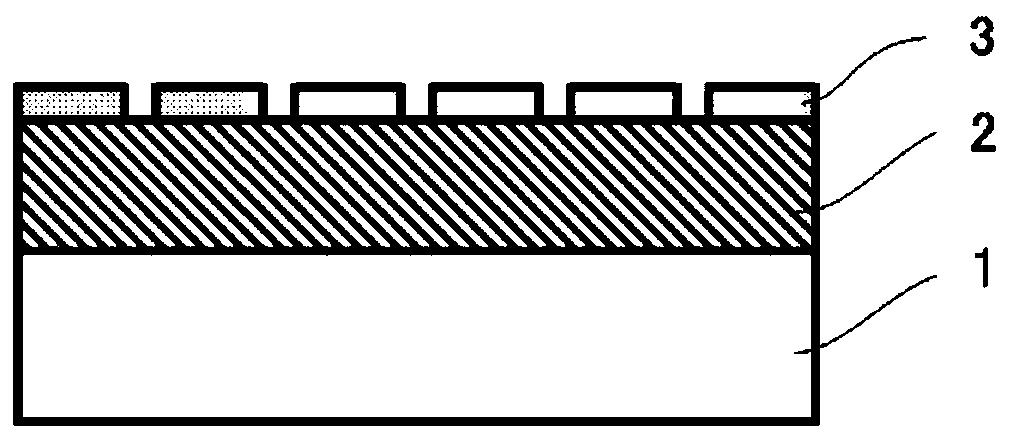

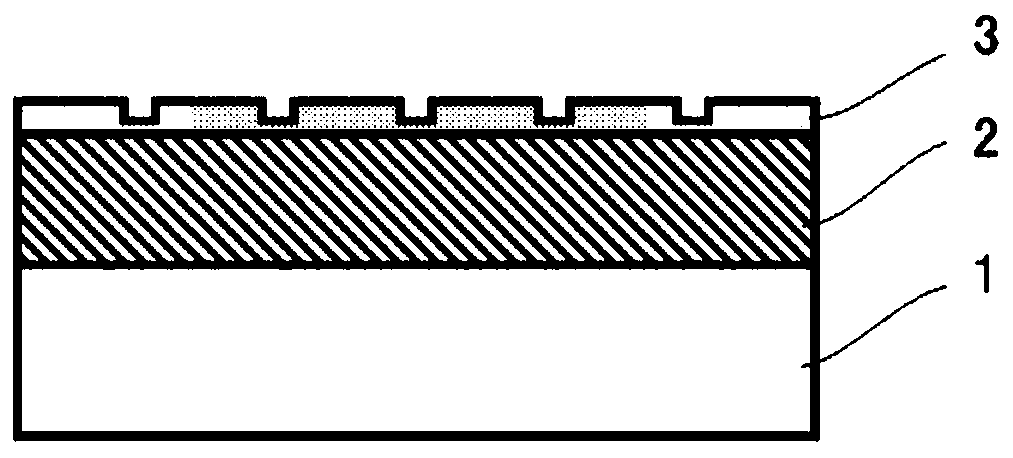

[0096] The previously prepared acrylic adhesive A (for the first adhesive layer) was uniformly applied on the release-treated PET film, cured, and dried to form a first adhesive layer with a thickness of 30 μm. Next, the first pressure-sensitive adhesive layer is transferred onto a polyolefin-based foamed resin substrate (1.8 to 2 times the expansion ratio).

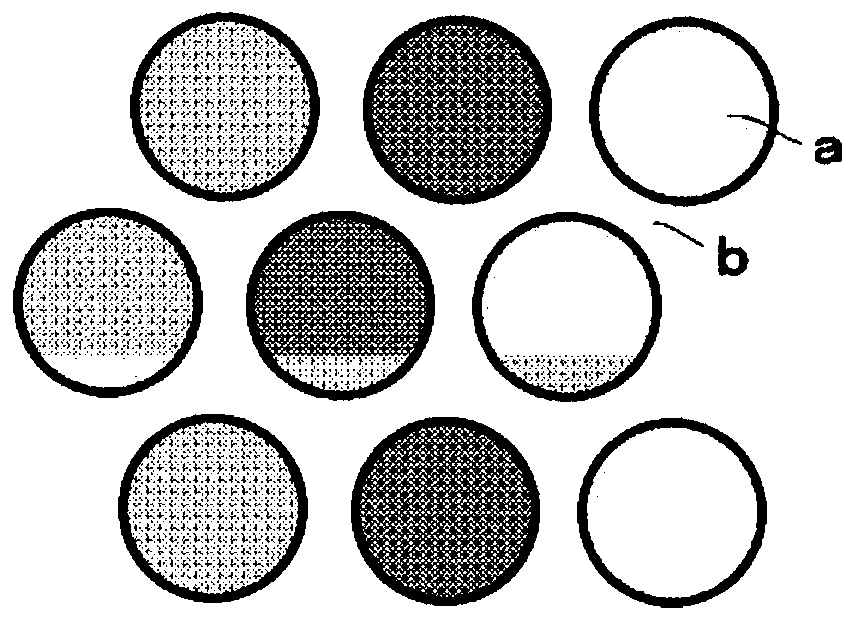

[0097] In addition, the acrylic adhesive A (for the second adhesive area) prepared previously was gravure printed on the PET film subjected to mold release treatment as follows: image 3 As shown, the circular island-shaped adhesive part a was applied in a pattern in which half-shifted rows were regularly arranged, cured, and dried to form a second adhesive region with a thickness of 3 μm. image 3 The diameter of the shown circular island-shaped adhesive part a is set to 1.0 mm, and the width of the non-adhesive part b is set to 0.25 mm. Then, the second adhesive region was transferred onto the first adhesive layer, an...

Embodiment 2

[0099] Change the uneven shape of the surface of the 2nd adhesive area to the following Figure 4 As shown, except the pattern in which the square island-shaped adhesive part a was regularly arranged at equal intervals, it carried out similarly to Example 1, and produced the adhesive tape. Figure 4 The length of one side of the shown square island-shaped adhesive part a was 1.2 mm, and the width of the non-adhesive part b was 0.33 mm.

Embodiment 3

[0101] Change the uneven shape of the surface of the 2nd adhesive area to the following Figure 5 The pressure-sensitive adhesive tape was manufactured in the same manner as in Example 1, except that the pattern in which the vertical stripe-shaped adhesive parts a were regularly arranged at regular intervals was carried out as shown. Figure 5 The width of the vertically stripe-shaped adhesive portion a of the adhesive layer 2 shown is 1.0 mm, and the width of the non-adhesive portion is 0.25 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com