Waterproof construction method of basement foundation cast-in-place pile head

A technology of cast-in-situ piles and basements, which is applied in the direction of foundation structure engineering, protective devices, buildings, etc., can solve the problems of low coating strength, structural safety impact, poor connection of pile heads, etc., and achieve strong bonding strength and compressive strength, The construction process is easy to operate and the effect of prolonging the waterproof life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

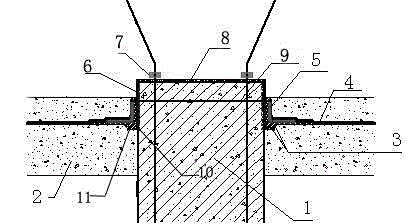

[0030] Example 1: A basement foundation pouring pile head waterproof construction method, it comprises the following steps:

[0031] S1. Lay foundation cap bottom layer cushion 2 around pile head 1;

[0032] S2. Clean the base surface of the pile head 1, punch a groove 11 with a depth of 10mm and a width of 20mm on the cushion layer 2 around the pile head 1, and paint the penetrating crystalline waterproof coating on the side of the pile head 1, and then apply the infiltration crystallization Water-proof mortar is applied to the coating of type waterproof coating to form waterproof coating-water-proof mortar layer 6; the water-cement ratio of waterproof mortar is 1:2.5, the thickness of permeable crystalline waterproof coating is 1mm, and the thickness of waterproof mortar is 3mm;

[0033] S3. After the waterproof mortar is finally set and dried, brush the base treatment agent on the root of pile head 1, and the coating amount of the base treatment agent is 0.2Kg / m...

Embodiment 2

[0036] Example 2: A basement foundation pouring pile head waterproof construction method, it comprises the following steps:

[0037] S1. Lay foundation cap bottom layer cushion 2 around pile head 1;

[0038]S2. Clean the base surface of the pile head 1, punch out a groove 11 with a depth of 15mm and a width of 23mm on the cushion 2 around the pile head 1, and paint the penetrating crystalline waterproof coating on the side of the pile head 1, and then apply the infiltration crystal Brush waterproof mortar on the coating of type waterproof coating to form waterproof coating-waterproof mortar layer 6; the water-cement ratio of waterproof mortar is 1:2.5, the thickness of permeable crystal waterproof coating coating is 2mm, and the thickness of waterproof mortar is 4mm;

[0039] S3. After the waterproof mortar is finally set and dried, brush the base treatment agent on the root of pile head 1, and the coating amount of the base treatment agent is 0.3Kg / m 2 After the grass-r...

Embodiment 3

[0042] Example 3: A basement foundation pouring pile head waterproof construction method, it comprises the following steps:

[0043] S1. Lay foundation cap bottom layer cushion 2 around pile head 1;

[0044] S2. Clean the base surface of the pile head 1, punch a groove 11 with a depth of 20 mm and a width of 30 mm on the cushion layer 2 around the pile head 1, and paint the penetrating crystalline waterproof coating on the side of the pile head 1, and then apply the infiltration crystal Water-proof mortar is applied to the coating of type waterproof coating to form waterproof coating-water-proof mortar layer 6; the water-cement ratio of waterproof mortar is 1:2.5, the thickness of permeable crystalline waterproof coating is 4mm, and the thickness of waterproof mortar is 5mm;

[0045] S3. After the waterproof mortar is finally set and dried, brush the base treatment agent on the root of pile head 1, and the coating amount of the base treatment agent is 0.4Kg / m 2 Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com