Method for assessing and guaranteeing a thermal hygiene effect

a technology of thermal hygiene and thermal hygiene, applied in the field of thermal hygiene effect assessment and guaranteeing, can solve the problems of laying lines in this way, leakage, and so on, and achieve the effect of automatically correcting irregularities in washing operation and prolonging run tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

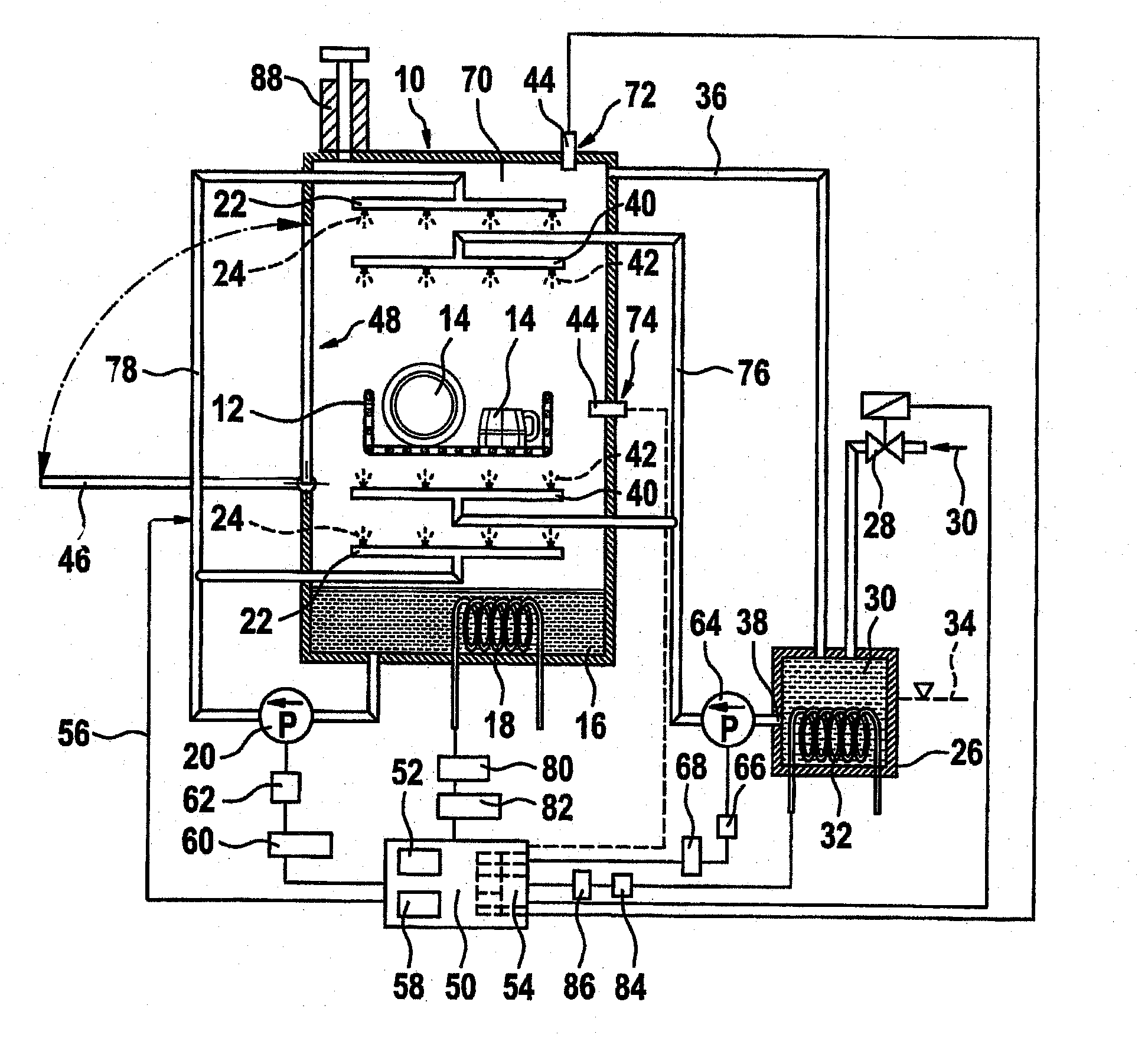

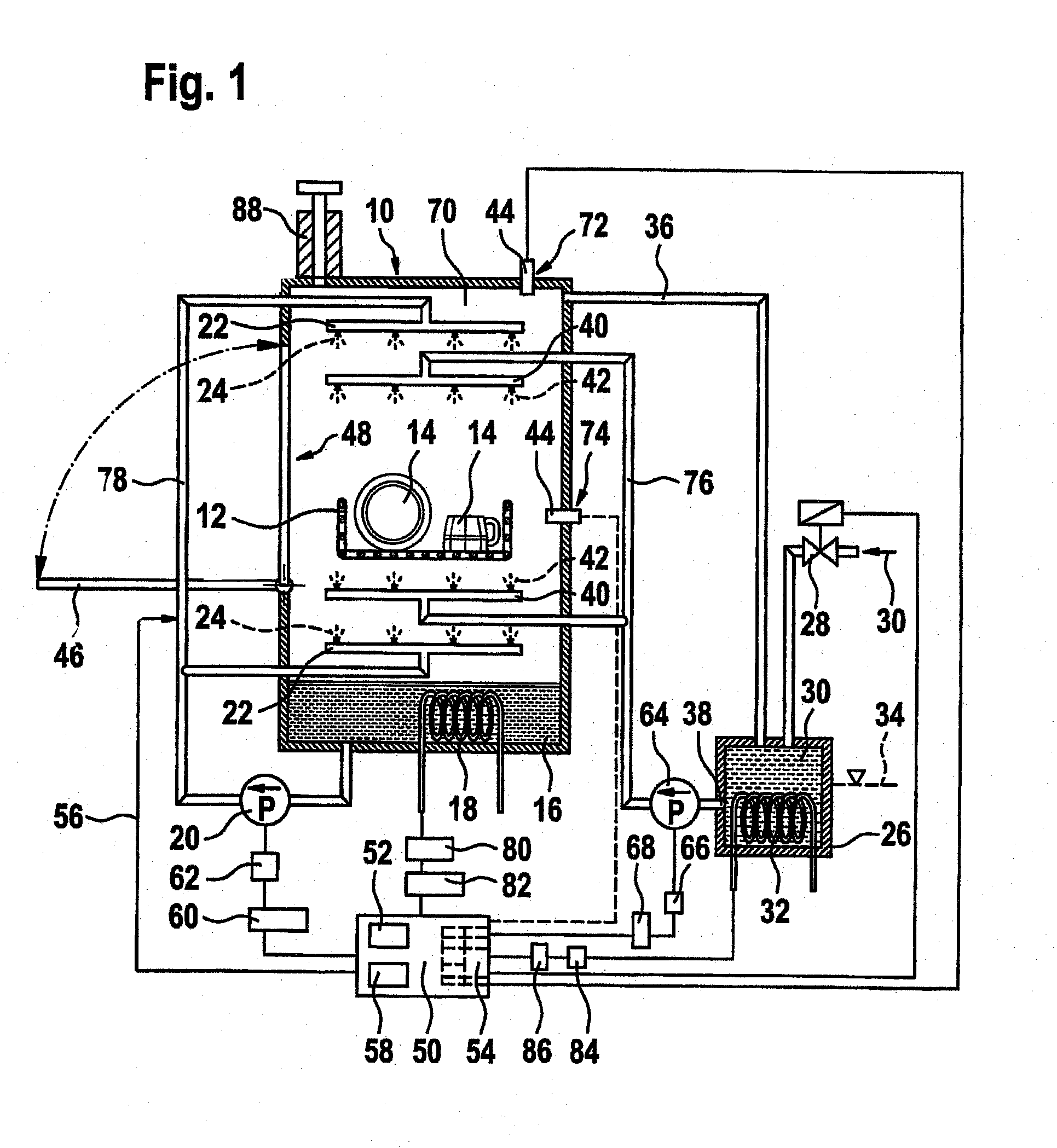

[0030]FIG. 1 shows a dishwasher which is a single-chamber dishwasher which can be loaded with items to be cleaned via an appliance door.

[0031]A single-chamber washer 10 comprises a washing chamber 70 which accommodates a rack 12. The rack 12 contains items 14 to be washed which may be plates, cups, cutlery, glasses, pots and pans etc. The lower region of the single-chamber washer 10 contains a tank 16 for holding the washing liquor to which cleaner has been added. The washing liquor, which is contained in the tank 16, is heated by means of a heating element 18. The washing liquor is transported from the tank 16 of the single-chamber washer 10 to a washing system 22 for washing liquor by means of a circulation pump 20. The washing system 22 for washing liquor is connected to the circulation pump 20 via a washing-liquor line 78. The washing system 22 for washing liquor, which washing system preferably comprises rotary arms having nozzles 24, is arranged both in the upper region of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com