Printer, copier and multifunctional integrated machine fixing mechanism and processing technology of heating roller thereof

A technology for heating rollers and copiers, which is applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography. Problems such as the effect of copying, to avoid easy wear, improve service life, and avoid the effect of toner adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

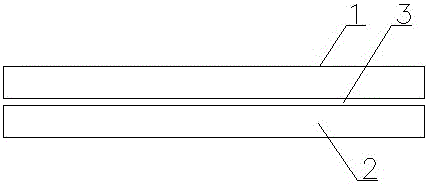

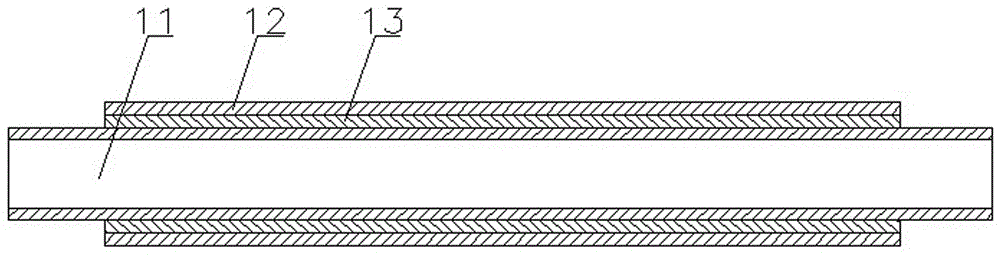

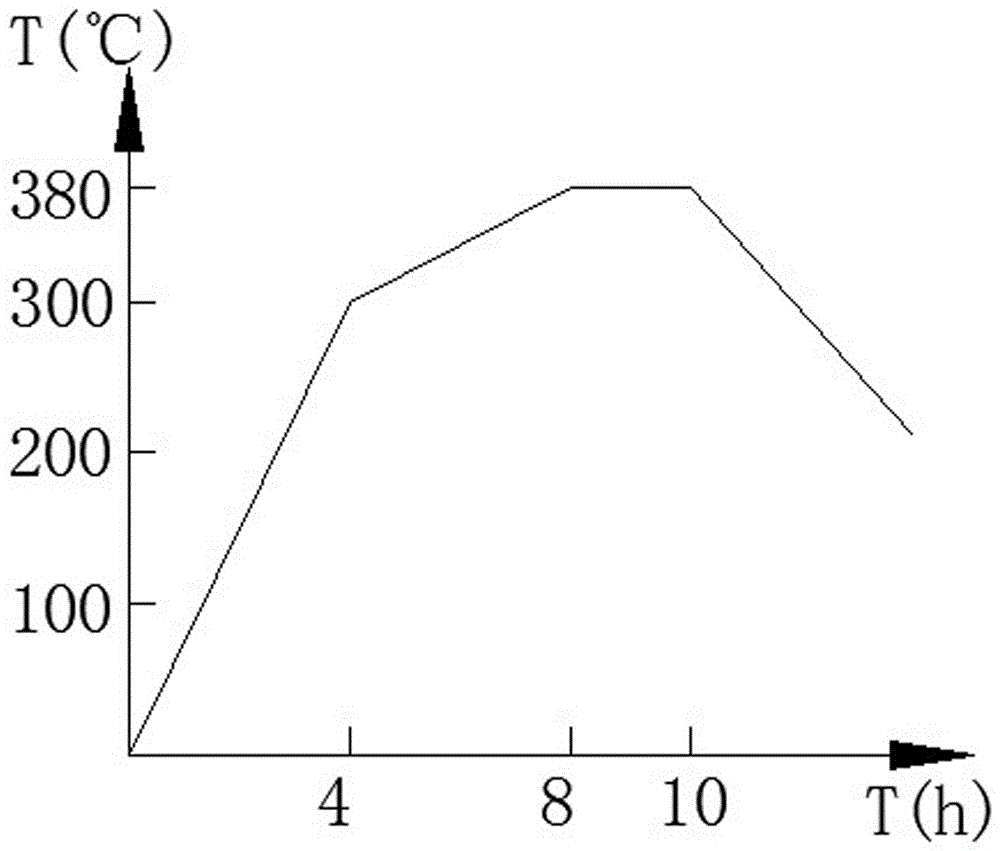

[0022] As shown in the figure, a fixing mechanism of a printer, a copier, and an all-in-one machine includes a heating roller 1 and a pressure roller 2, and the pressure roller 2 is arranged below the heating roller 1 in parallel. The paper gap 3, the heating roller 1 is connected with a heating source, the heating roller 1 is made of metal, resin or ceramic material, and the metal material includes commonly used copper, aluminum, iron and stainless steel, etc. The outer diameter of the heating roller 1 and the roller body 11 is preferably 29.5-30.5mm , the wall thickness of the roller body 11 is preferably 1 mm; the surface of the heating roller 1 is covered with a resin film cover 12, and the material of the resin film cover 12 is a fluororesin such as PFA or PTFE, and the resin film cover 12 completely covers the working surface of the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com