Patents

Literature

96results about How to "Solve easy wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

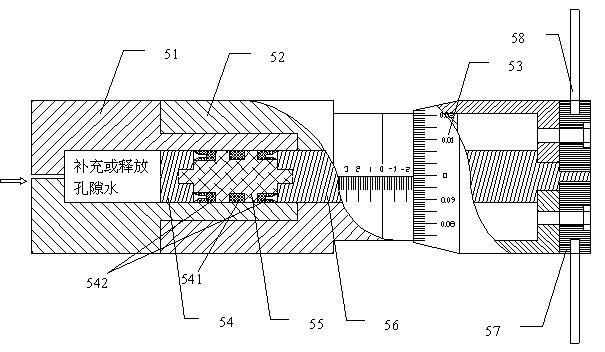

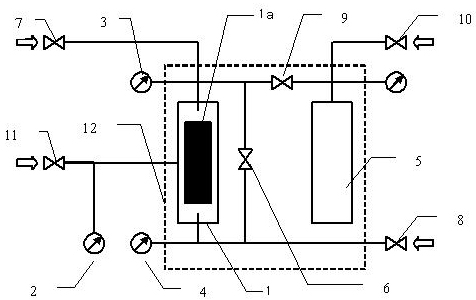

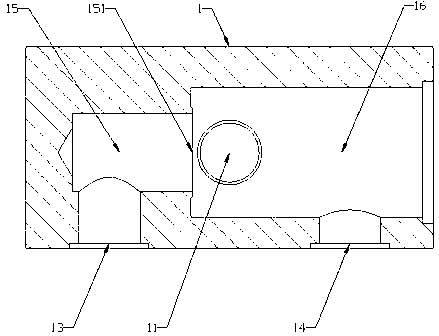

Method and device for measuring pore volume change of porous medium

InactiveCN101995373AResolve continuitySolve quicklyPermeability/surface area analysisVolume variationPorous medium

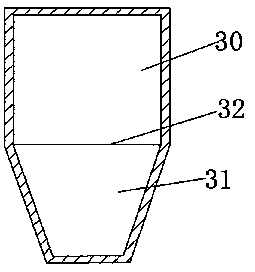

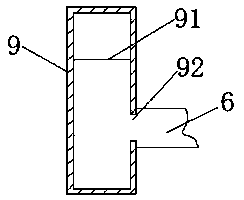

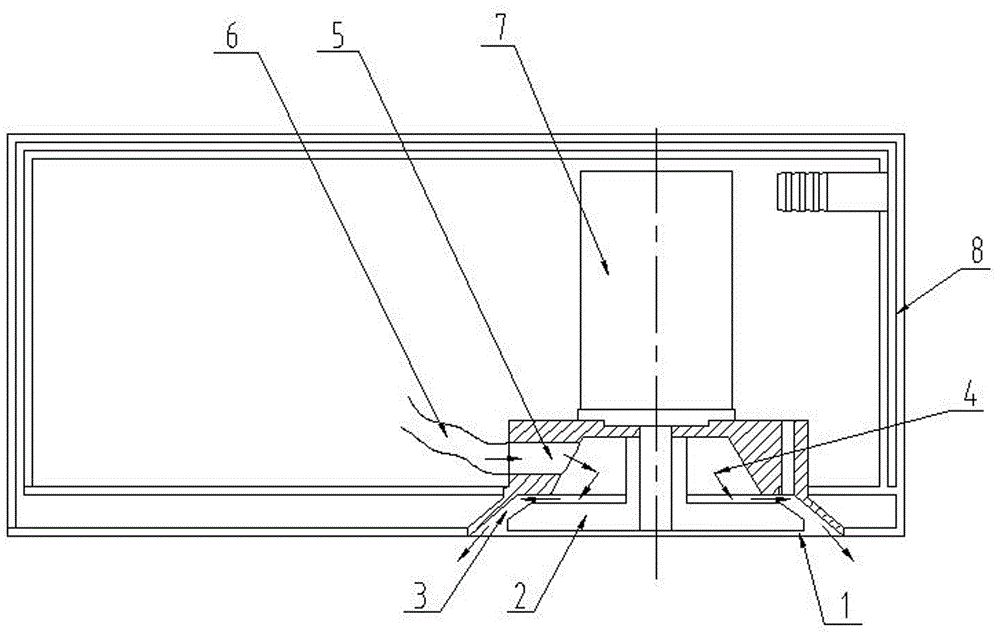

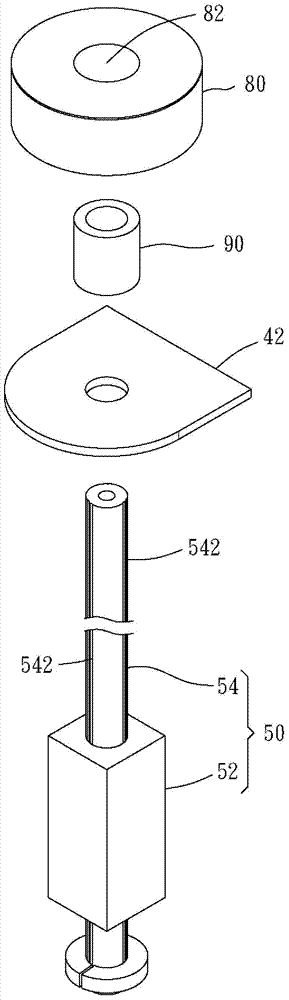

The invention discloses a method and a device for measuring the pore volume change of a porous medium. The method comprises the following steps of: A, putting a workpiece to be tested into a holder; B, closing an upstream control valve and a vent valve, and opening a communication valve, a downstream control valve and a pressure regulating control valve; C, after the device is positioned in the vacuum state and stable, closing the downstream control valve; D, performing confining pressure stepwise loading / unloading experiments; and E, opening the vent valve, setting a pressure regulating controller to be zero, and finishing the measurement of the pore volume change. The pressure regulating controller mainly comprises a front fixing sleeve, a rear fixing sleeve, a movable sleeve, a sliding head, a sliding block, a screw rod, a rotary head and a rotary rod, wherein the rear fixing sleeve is provided with a main scale; the movable sleeve is provided with a branch scale; and the main scale and the branch scale are used for reading the volume difference. The device is easy to operate, is convenient to read, is stable in performance and reliable in measurement, and is suitable for quick, continuous, accurate and intuitive measurement of wide-range pore volume change of porous media under the condition of complicated stress variation.

Owner:中国科学院武汉岩土力学所

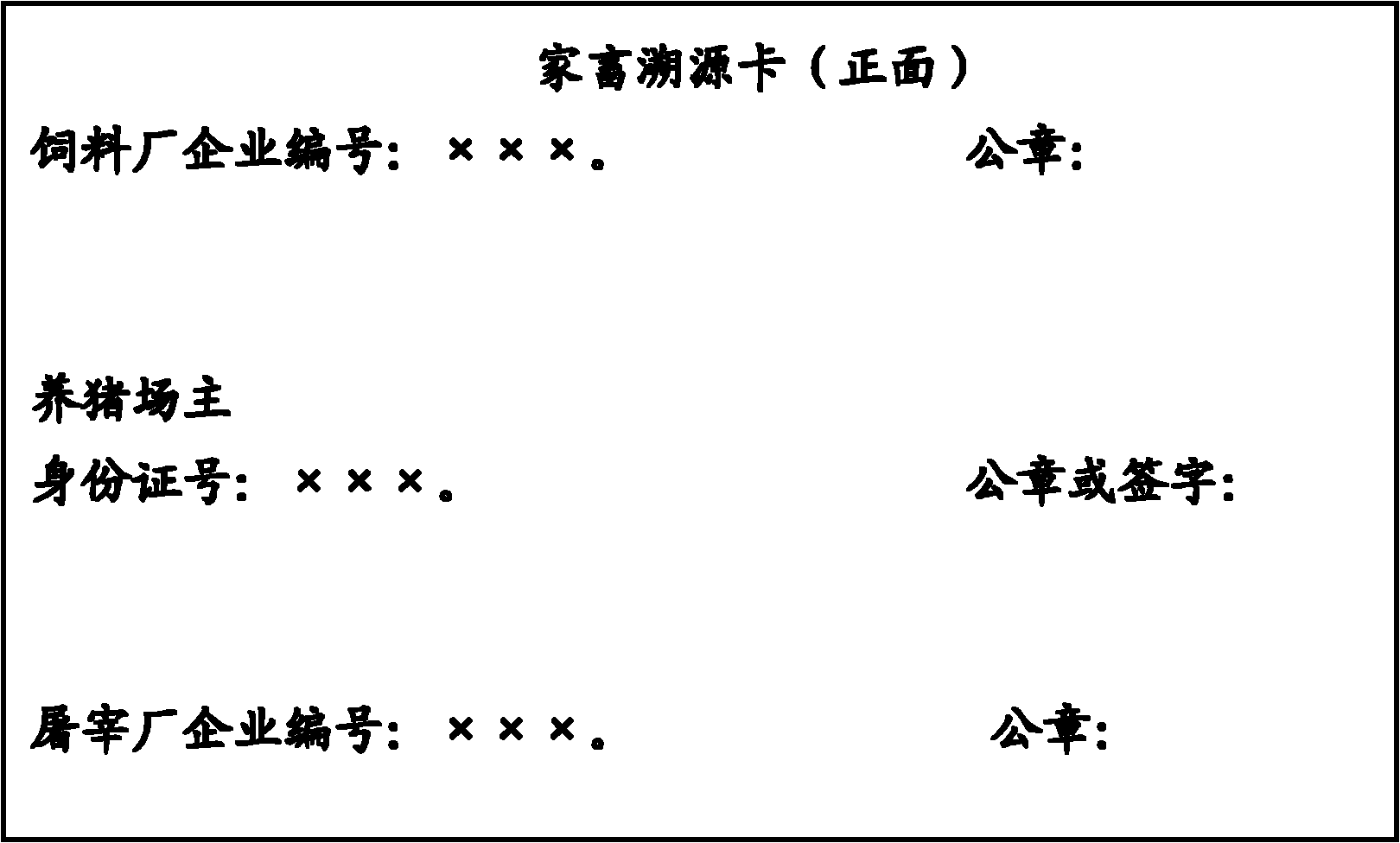

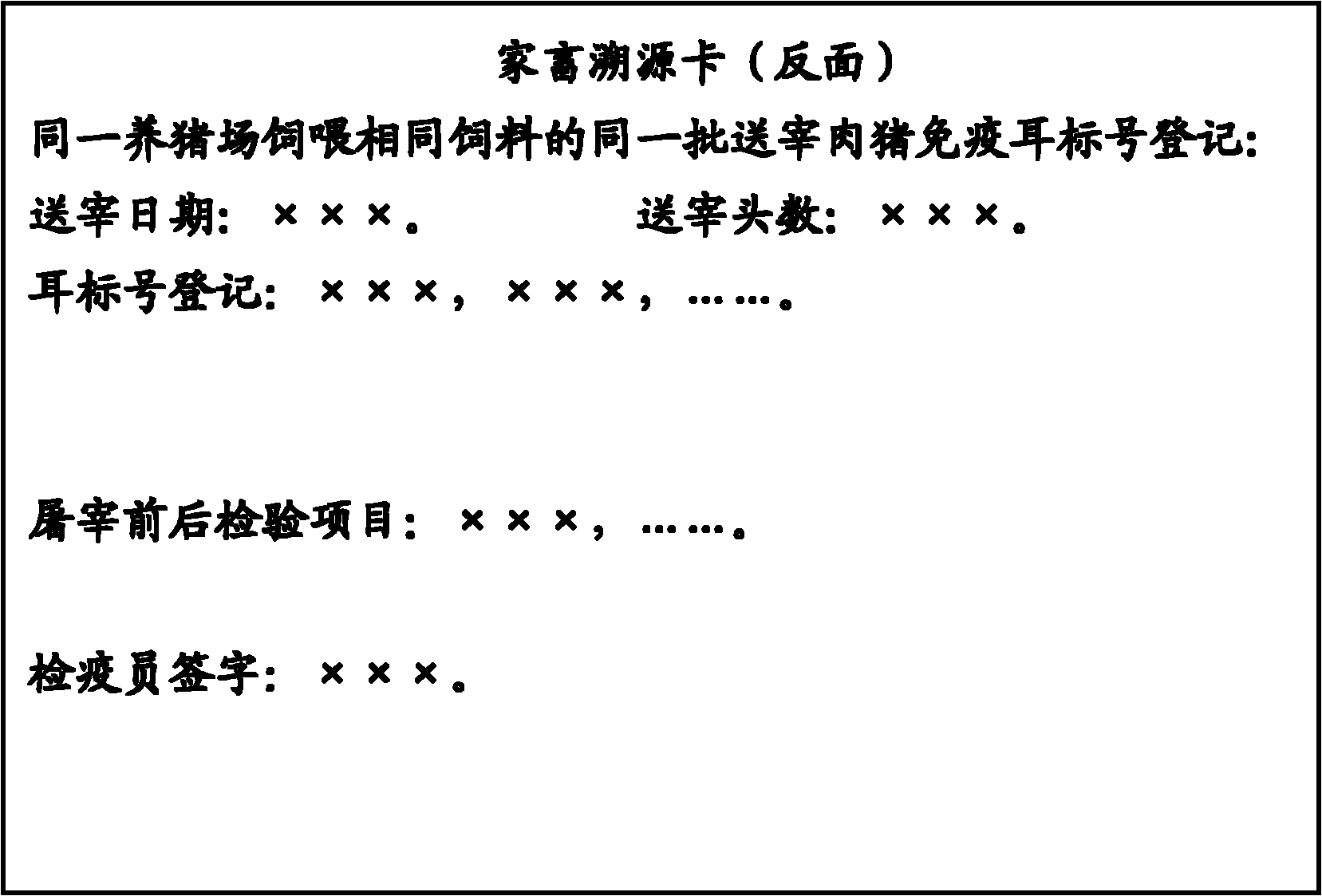

Method for tracing source of information of livestock products

InactiveCN102142116AAchieve standardizationAchieve scaleData processing applicationsEar tagFood safety

The invention relates to the field of food safety, in particular to a method for tracing a source of the information of livestock products. In links of feed plants, culture farms, slaughter houses and sales persons, the information of the livestock products is managed by source tracing cards and a source tracing system, wherein according to the quantity of carcasses or cut meat obtained after livestock is slaughtered and cut, the source tracing cards, together with the carcasses or the cut meat, enter a sales link, so that consumers can acquire the register information of the source tracing system according to the register information of the source tracing cards; the register information of the source tracing cards comprises the enterprise information of the feed plants, the enterprise information of the culture farms or the host information of raisers, the immune ear tag numbers of the livestock, slaughtering date, slaughtering number, the enterprise information of the slaughter houses, quarantine results of the livestock and the information of quarantine personnel; and the register information of the source tracing system comprises feed information provided by the feed plants, the feeding and management information of the livestock, immune program information and the slaughtering information of the livestock. Therefore, if problems appear in the livestock products, the reason can be traced from the source of feed quickly.

Owner:JILIN ACAD OF AGRI SCI

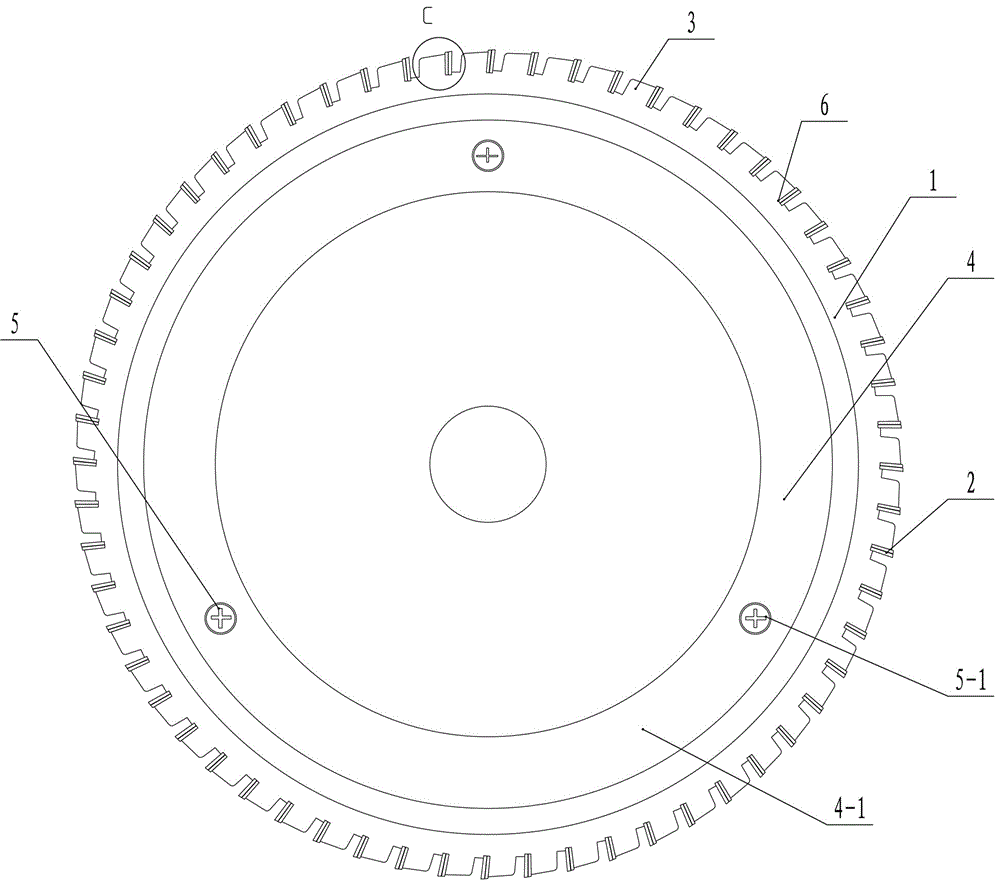

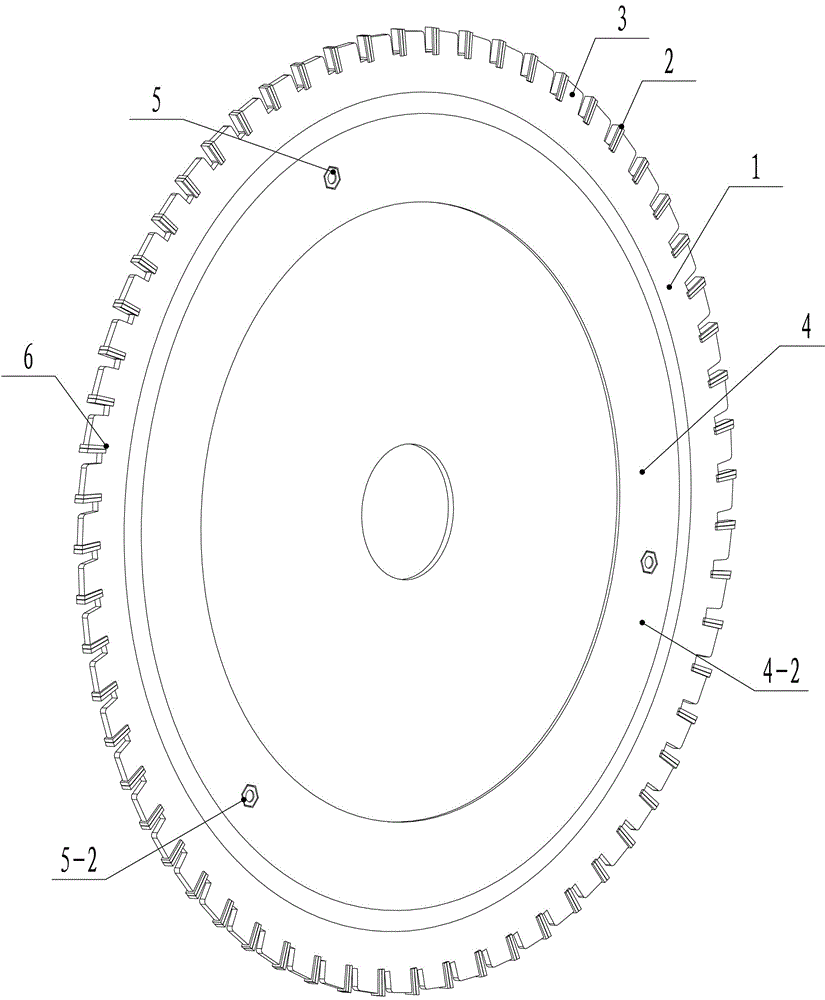

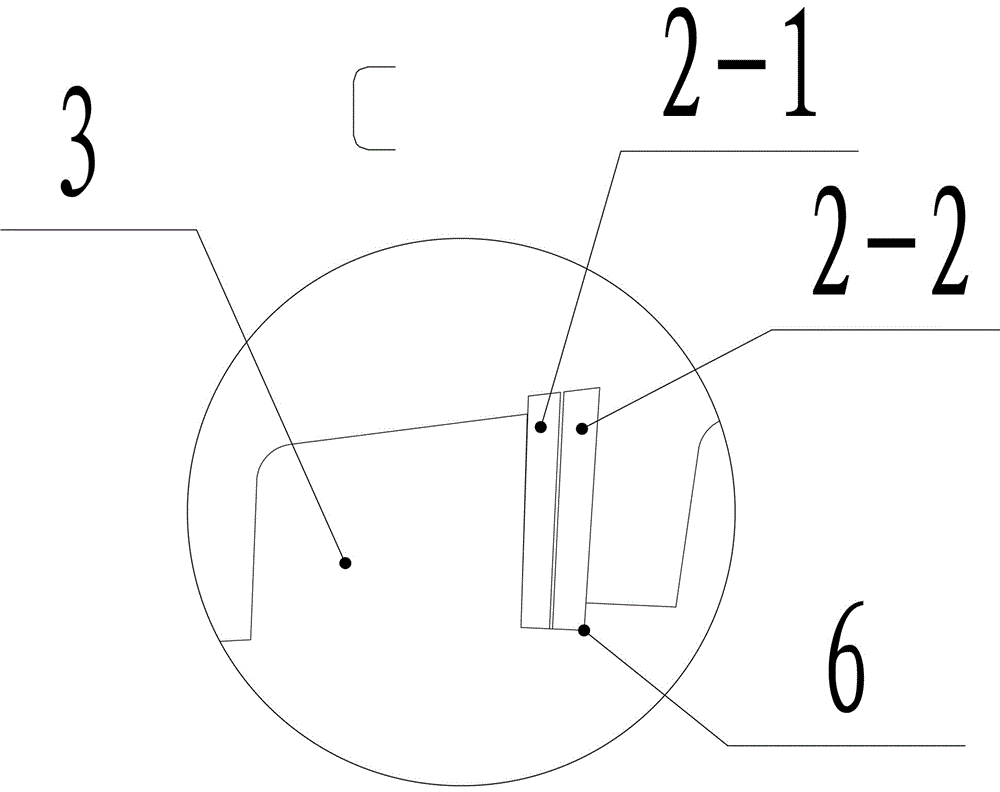

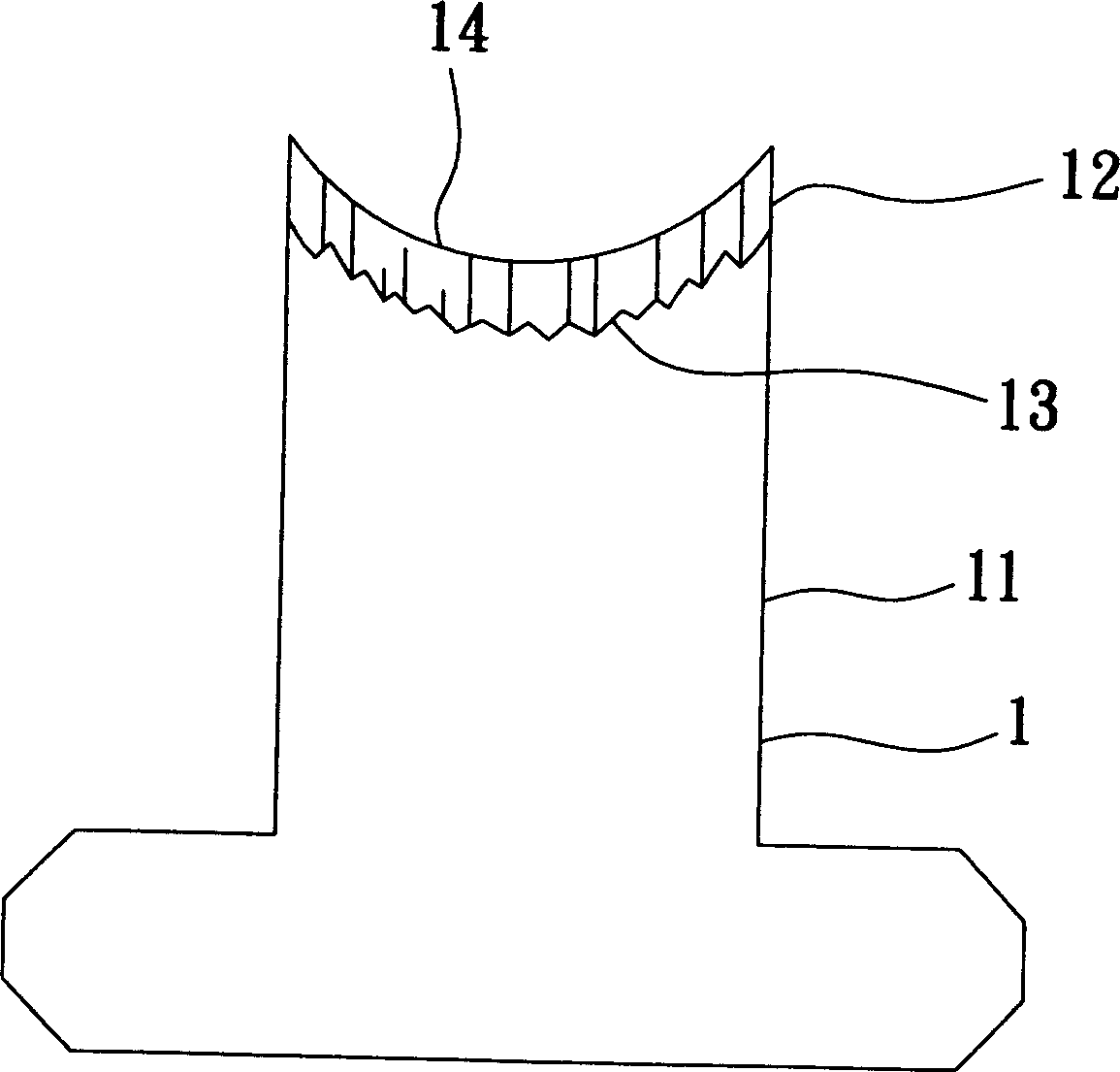

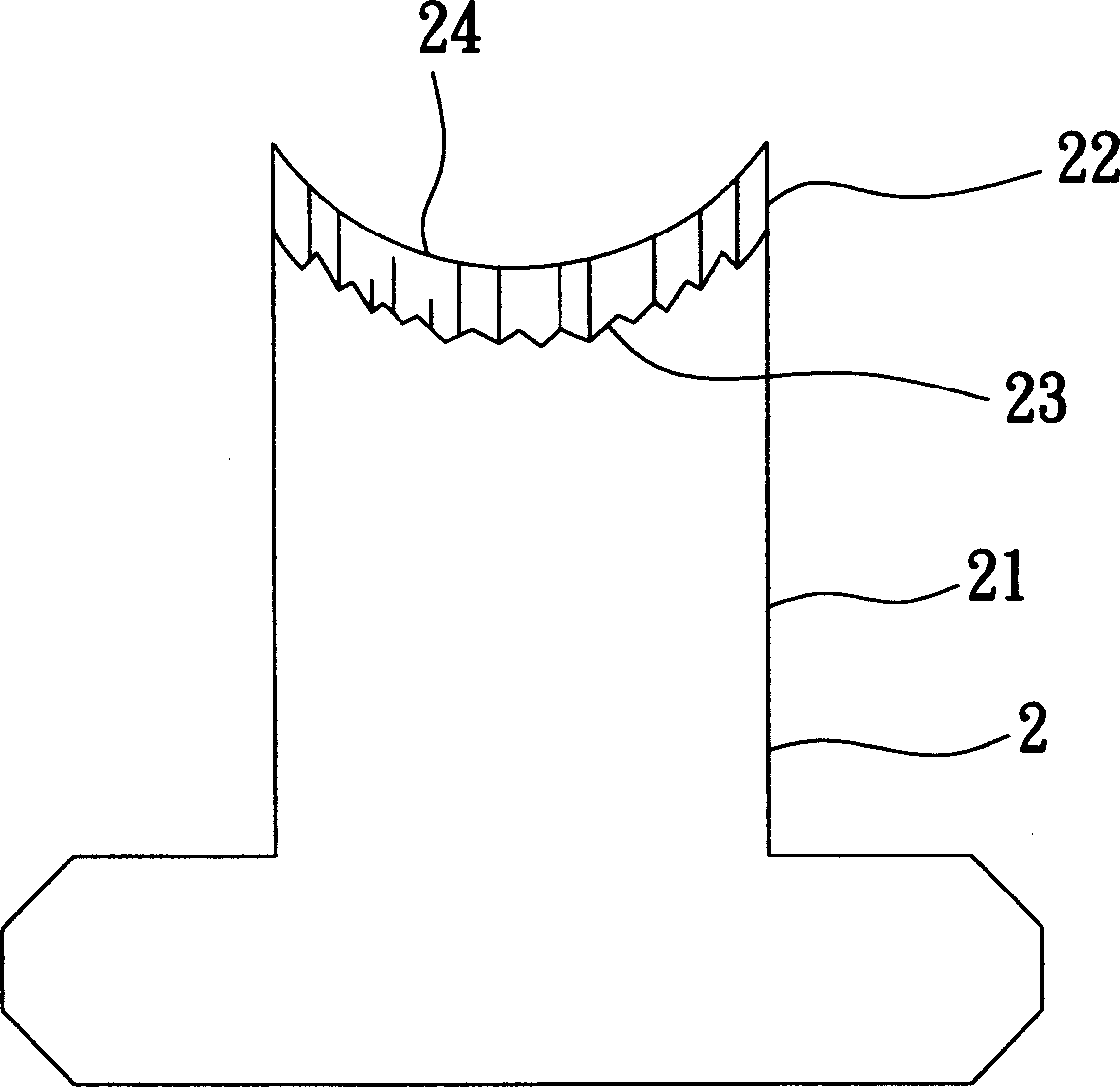

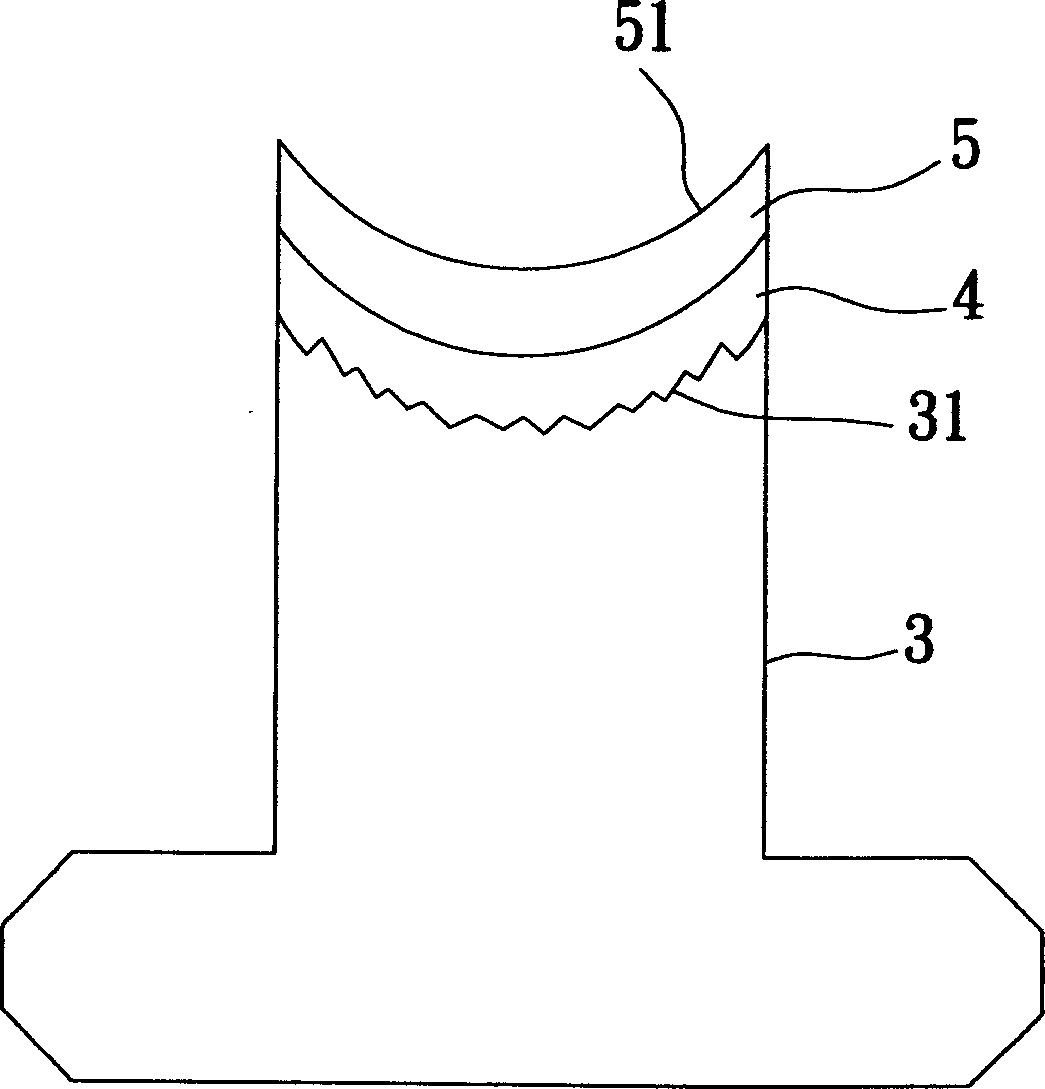

Saw web used for both cutting and grinding

ActiveCN106424940ARepair smoothImprove verticalityEdge grinding machinesMetal sawing toolsEngineeringGrinding wheel

The invention relates to a saw web used for both cutting and grinding. The saw web comprises a saw web body, double-layer cutter heads, tooth backs and a grinding wheel. Grooves are formed in the positions, on the same sides of the tooth backs, of the saw web body. The double-layer cutter heads are welded in the grooves. The grinding wheel comprises an upper grinding wheel body and a lower grinding wheel body. The upper grinding wheel body and the lower grinding wheel body are annular and arranged on the both sides of the saw web body correspondingly. The saw web body, the upper grinding wheel body and the lower grinding wheel body are provided with bolt through holes in fit with one another. The upper grinding wheel body and the lower grinding wheel body are fixed to the saw web body through bolts. By adoption of the saw web used for both cutting and grinding, a cut surface can be cut and ground at the same time, the efficiency is greatly improved, the flatness of the ground surface is improved, and the perpendicularity of the ground surface and a profile is improved; and meanwhile, by designing the embedded cutter heads, the impact resistance of saw web cutter teeth of the saw web to to-be-cut materials during cutting is greatly improved, and the cutter heads are not prone to falling off.

Owner:HEBEI JIMEIDA TOOLS CO LTD

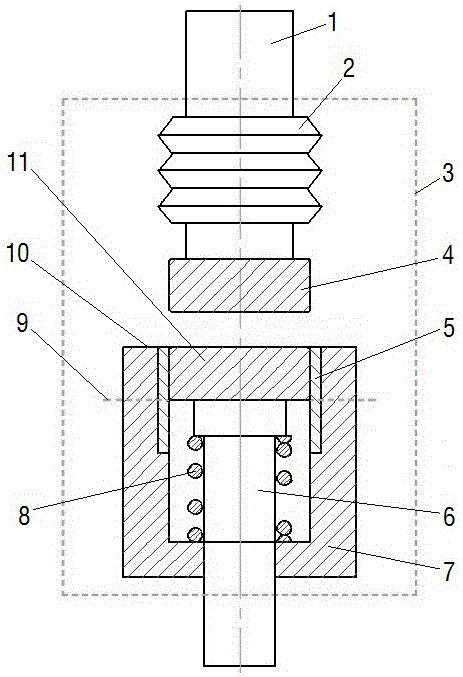

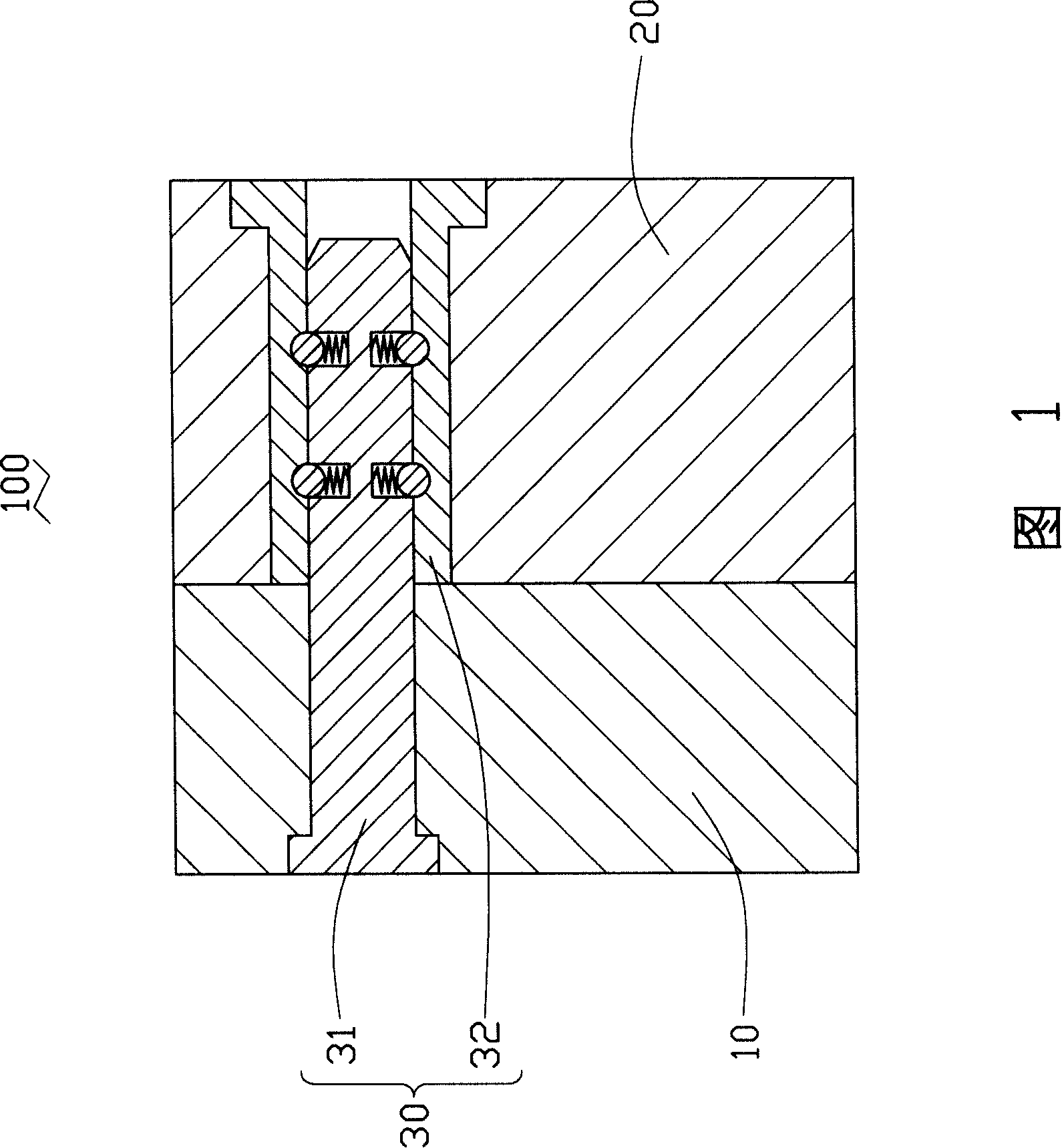

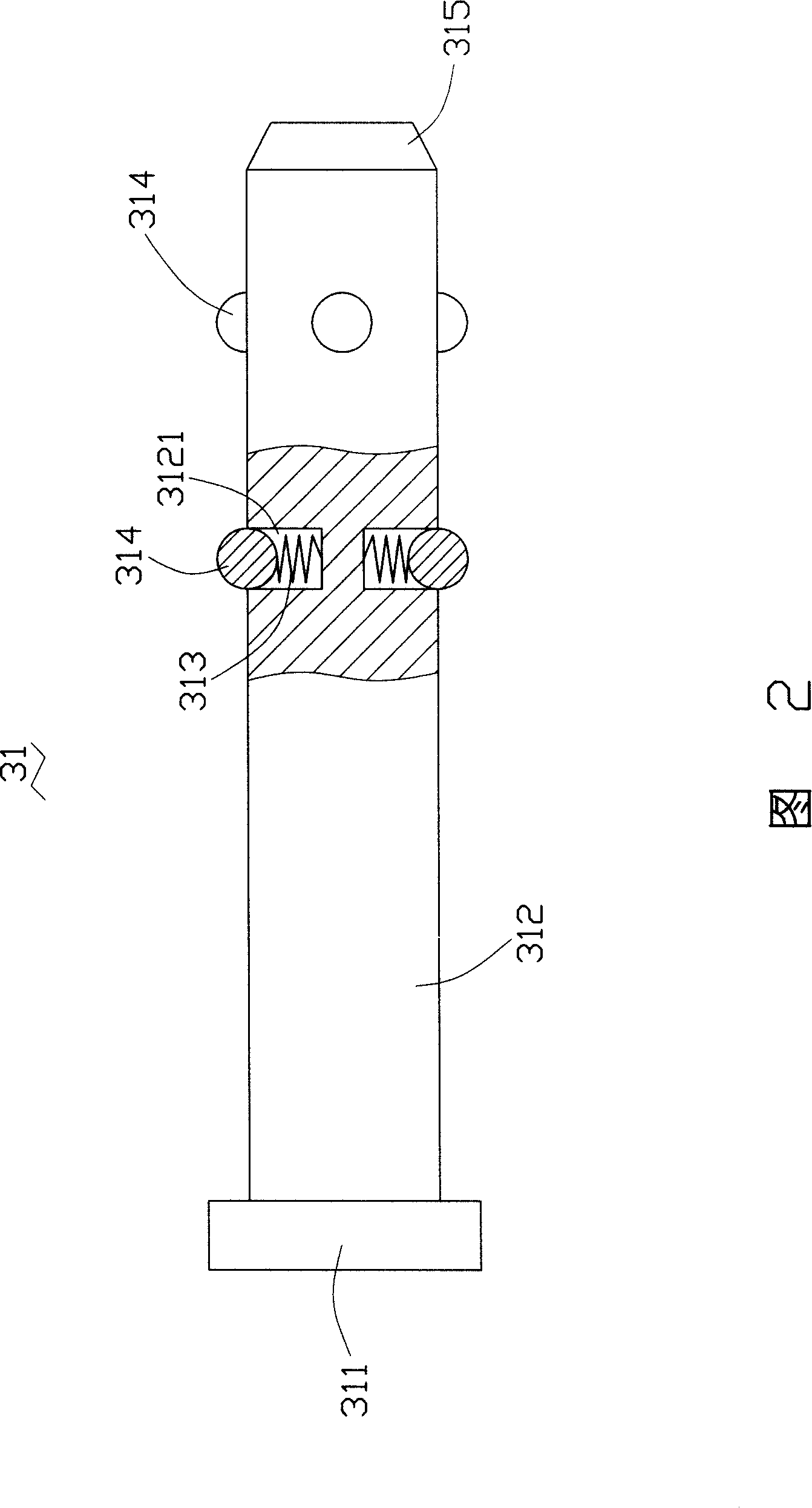

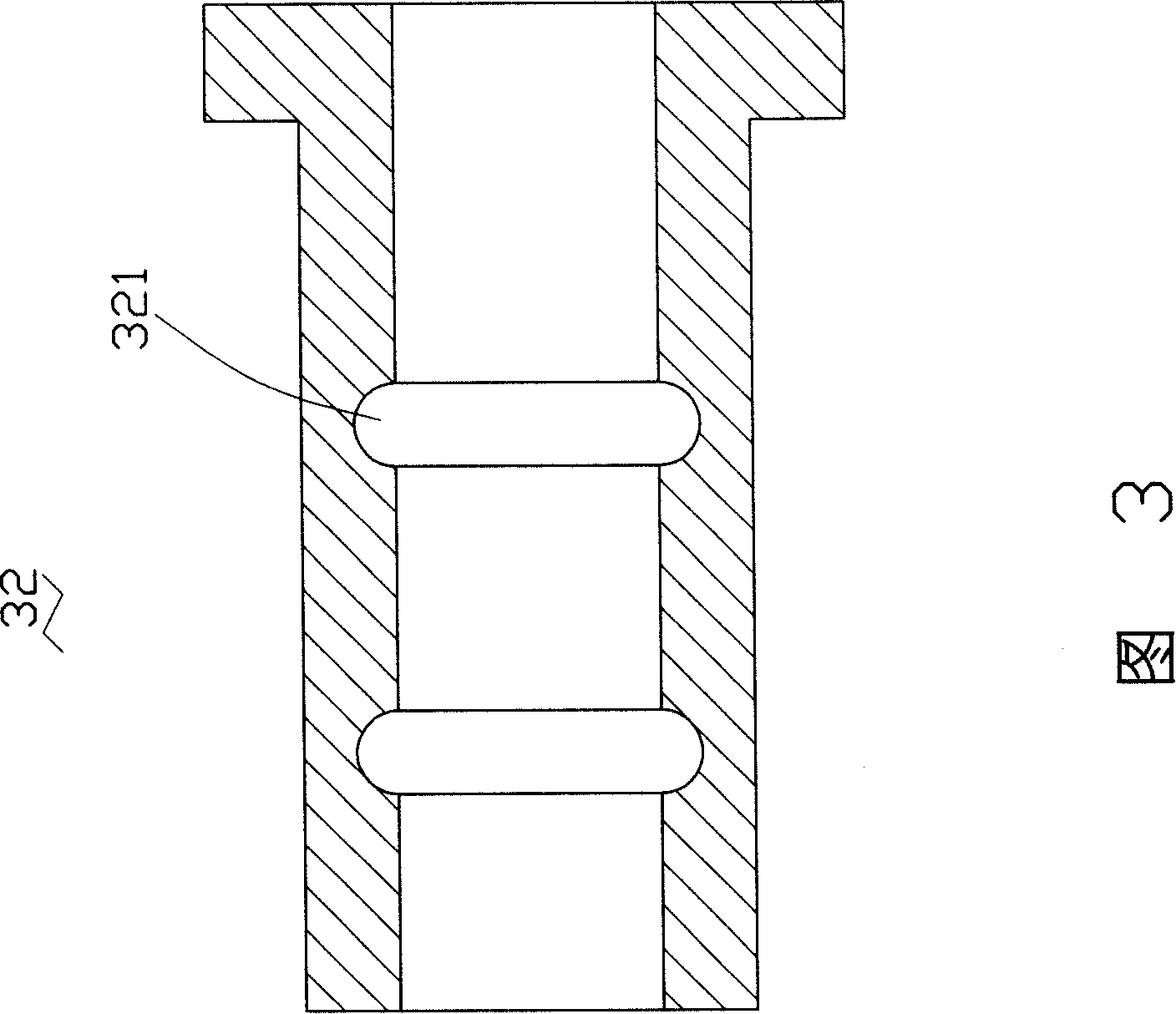

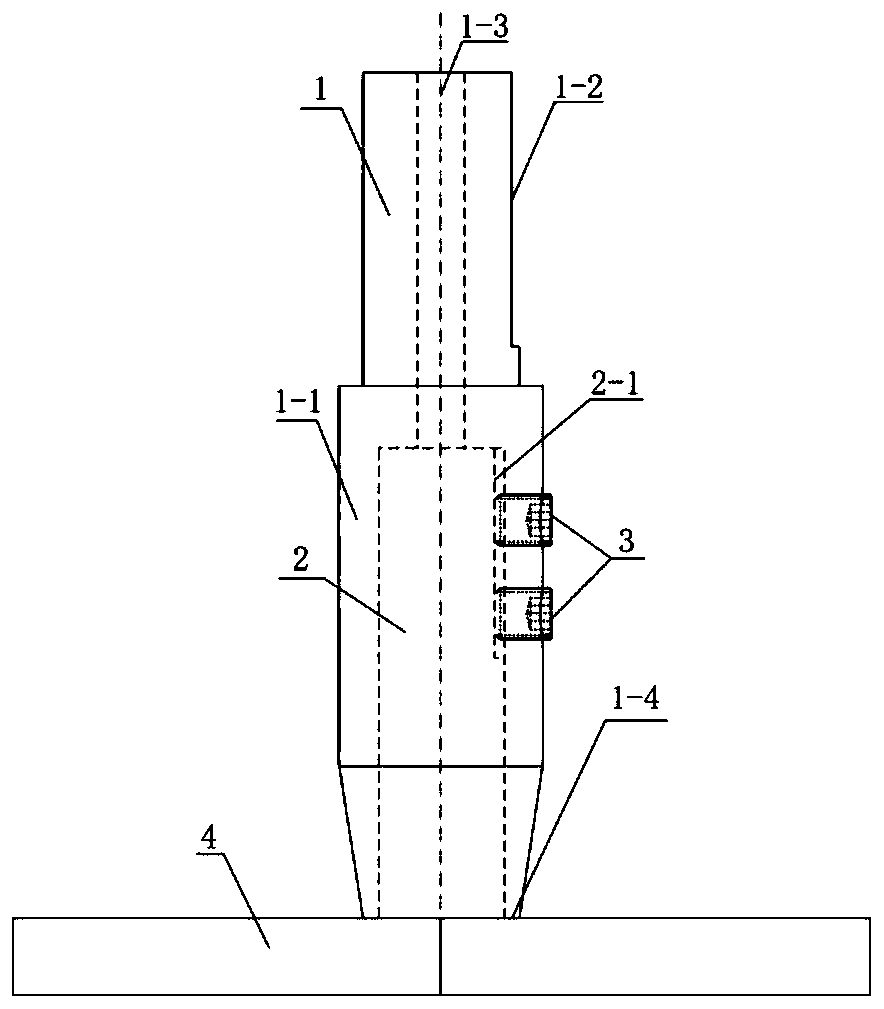

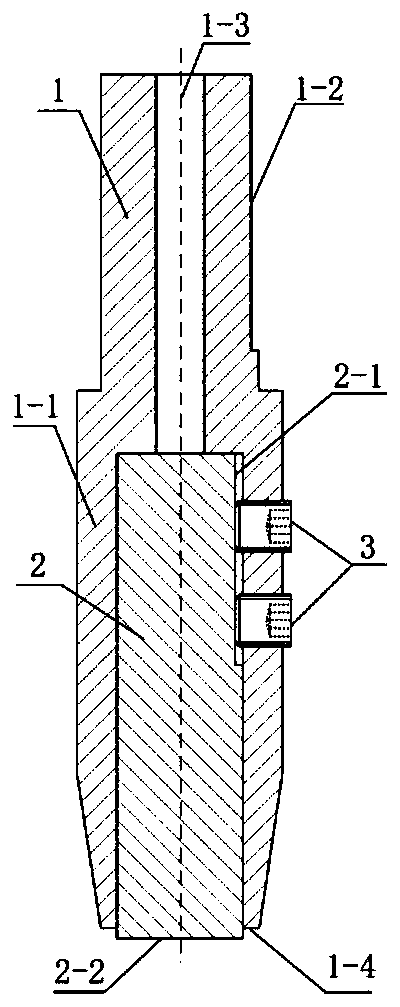

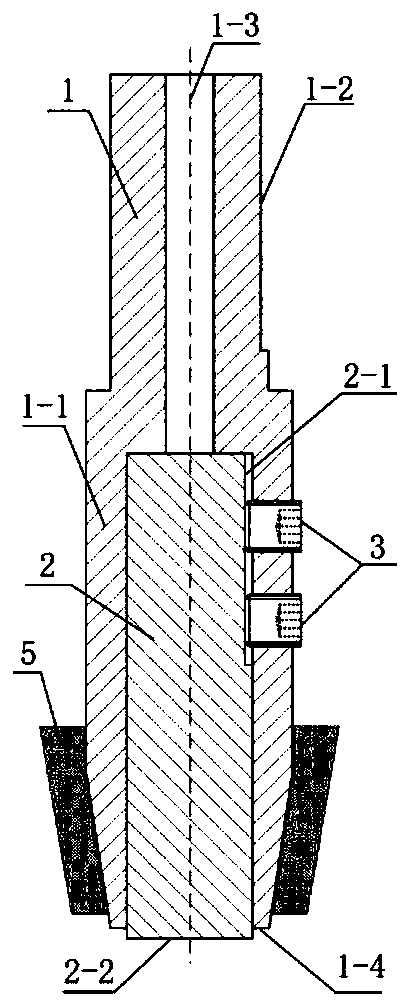

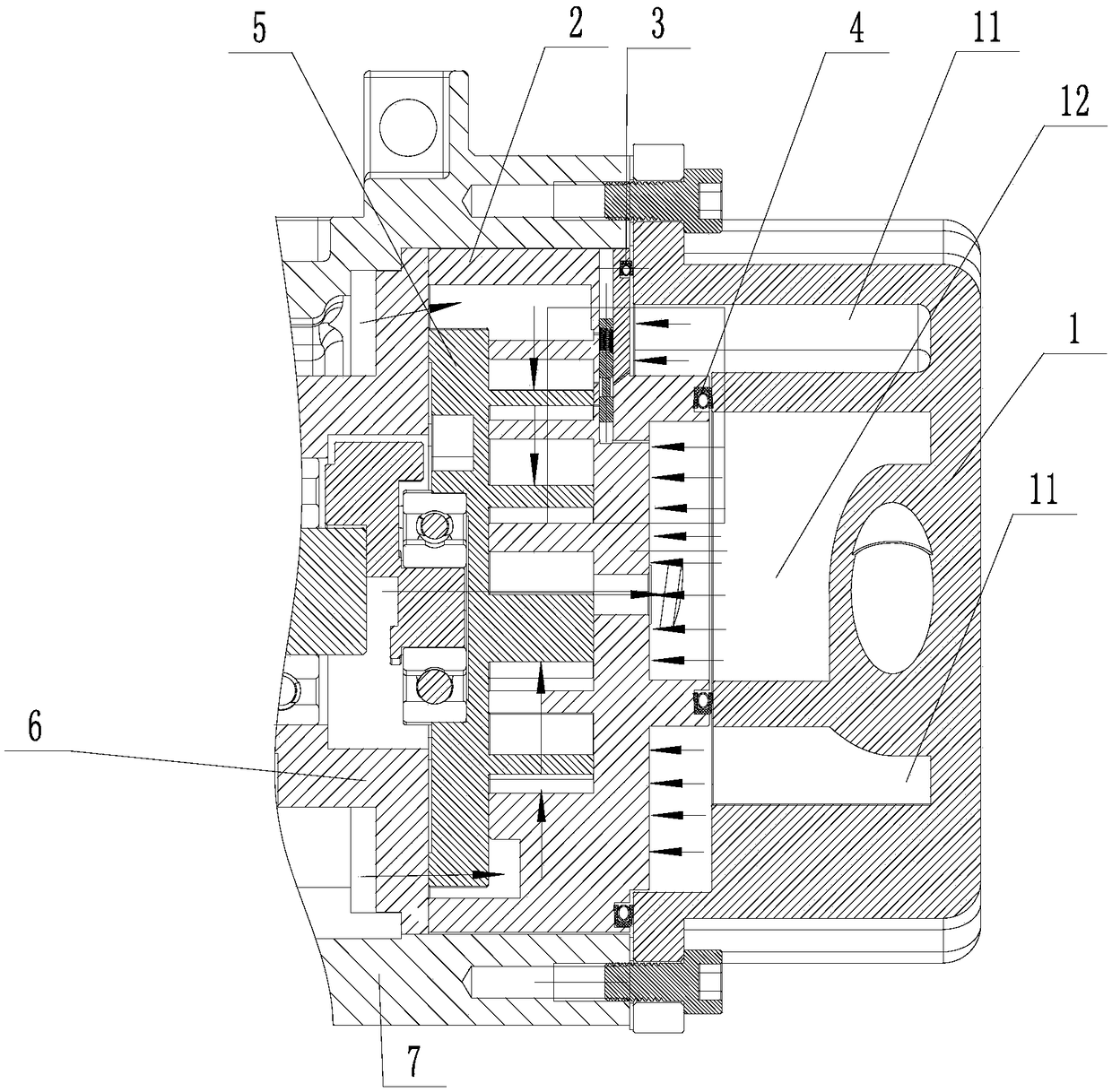

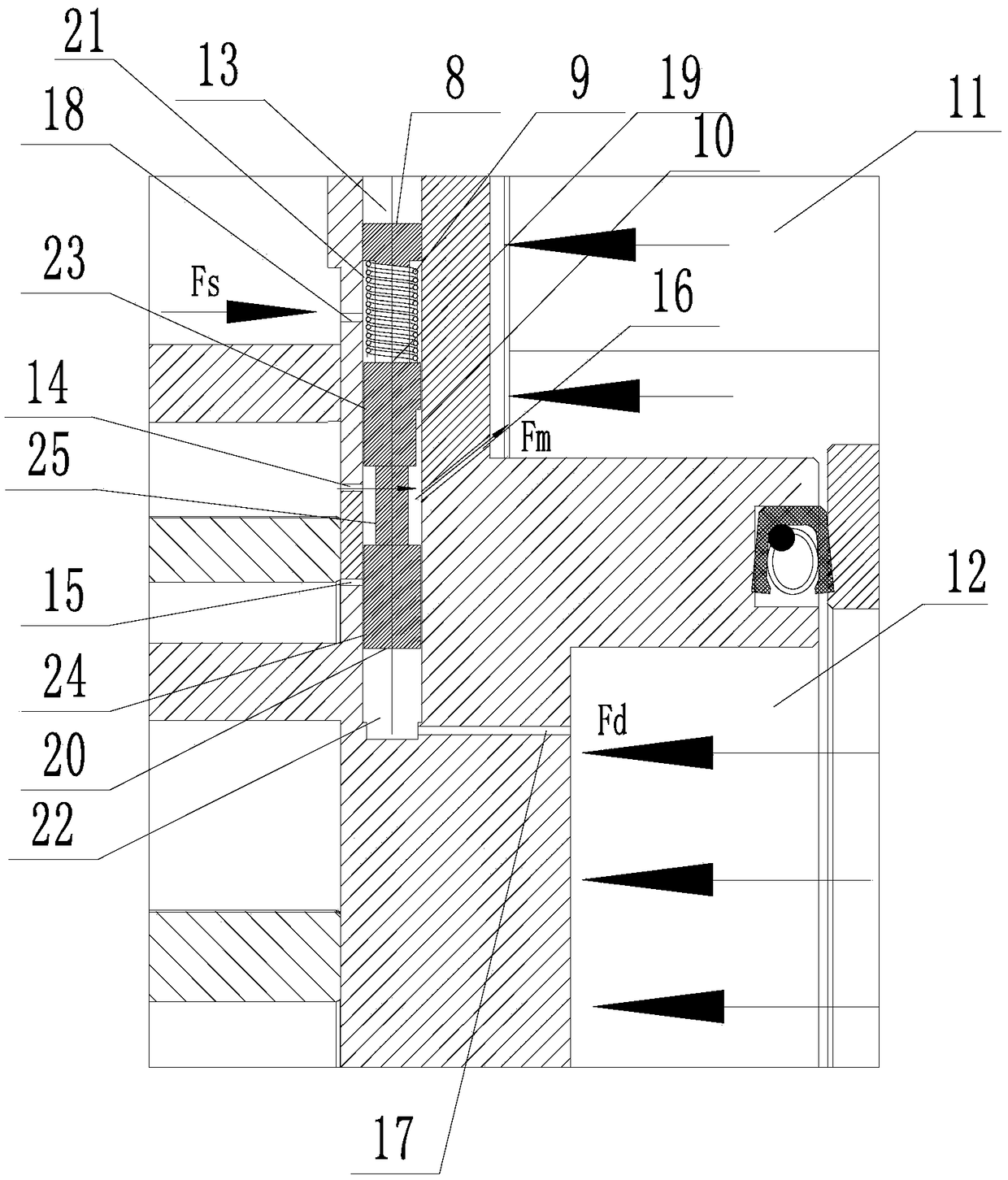

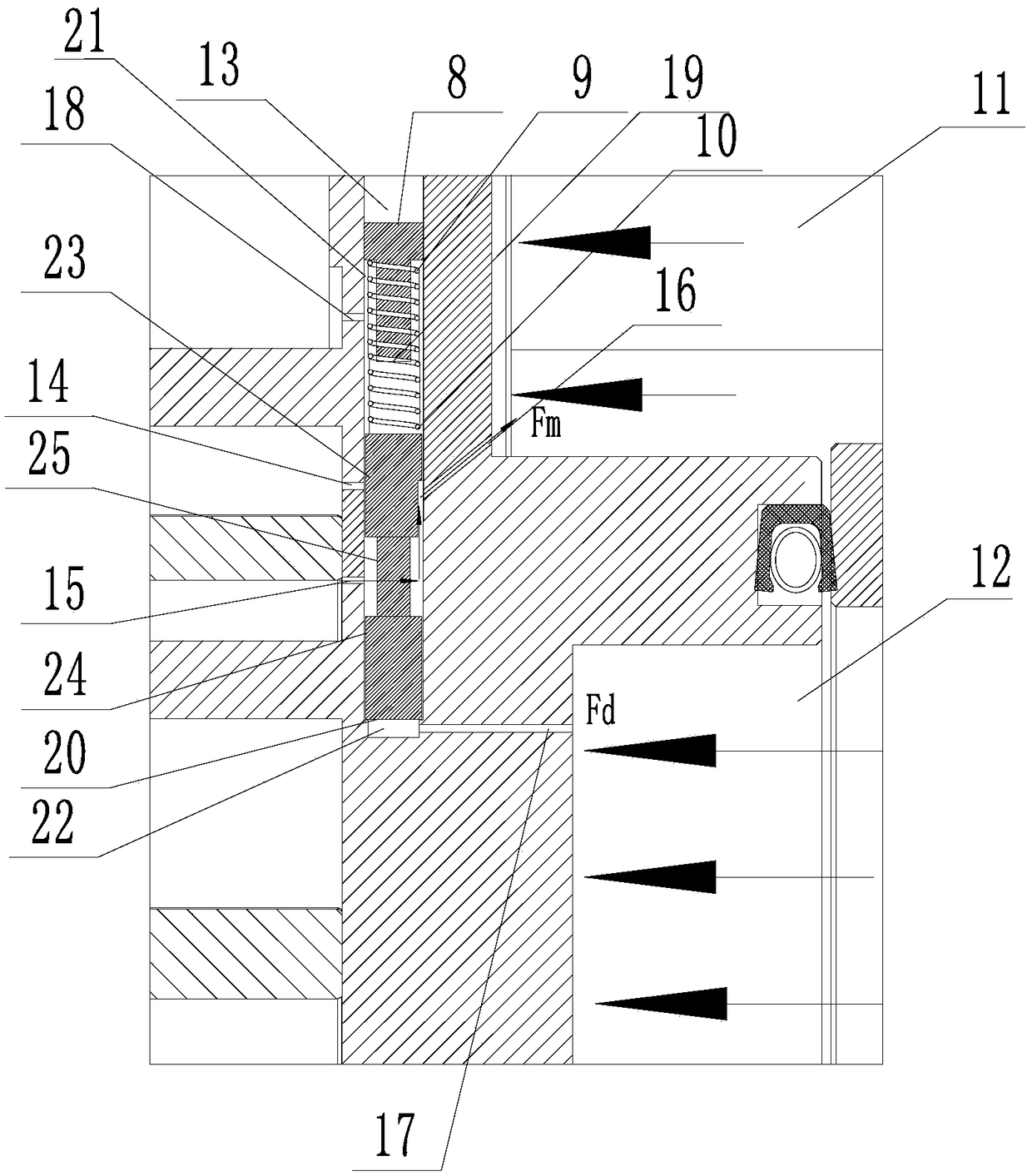

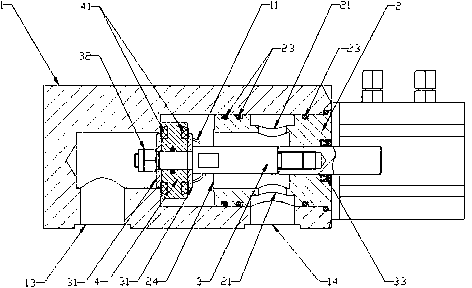

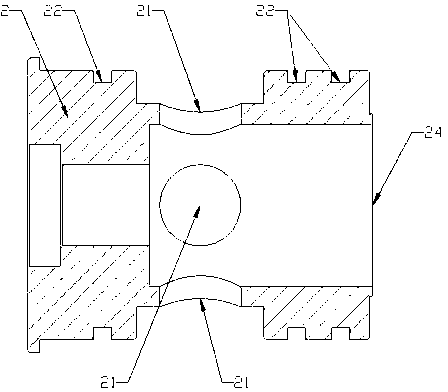

Bounce-free plug-in type vacuum arc-extinguishing chamber

InactiveCN105977094AEliminate bounceSolve easy wear and tearHigh-tension/heavy-dress switchesAir-break switchesElastic componentVacuum arc

The invention provides a bounce-free plug-in type vacuum arc-extinguishing chamber. The bounce-free plug-in type vacuum arc-extinguishing chamber comprises a static contact, the static contact is provided with a contact portion used for plugging conduction with the outer peripheral face of a moving contact, the static contact is internally provided with a buffer contact used for contact cooperation with the end surface of the moving contact through elastic components. The bounce-free plug-in type vacuum arc-extinguishing chamber has the following advantages: the static contact is internally provided with the buffer contact used for contact cooperation with the end surface of the moving contact through the elastic components, such that when the moving contact is in plugging fit with the static contact, the end surface of the moving contact is in contact with the buffer contact, when the moving contact moves, under the effect of the elastic components, the buffer contact moves along with the moving contact, the elastic components are compressed, in such a process, kinetic energy of the moving contact is absorbed by the buffer contact and the elastic components, bounce of the moving contact is eliminated through proper design of the buffer contact and the elastic components, and the problem of easy wear caused to the outer peripheral face of the moving contact in a bounce process is also solved.

Owner:XUJI GRP +2

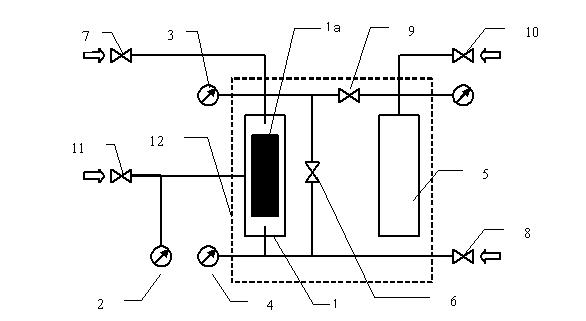

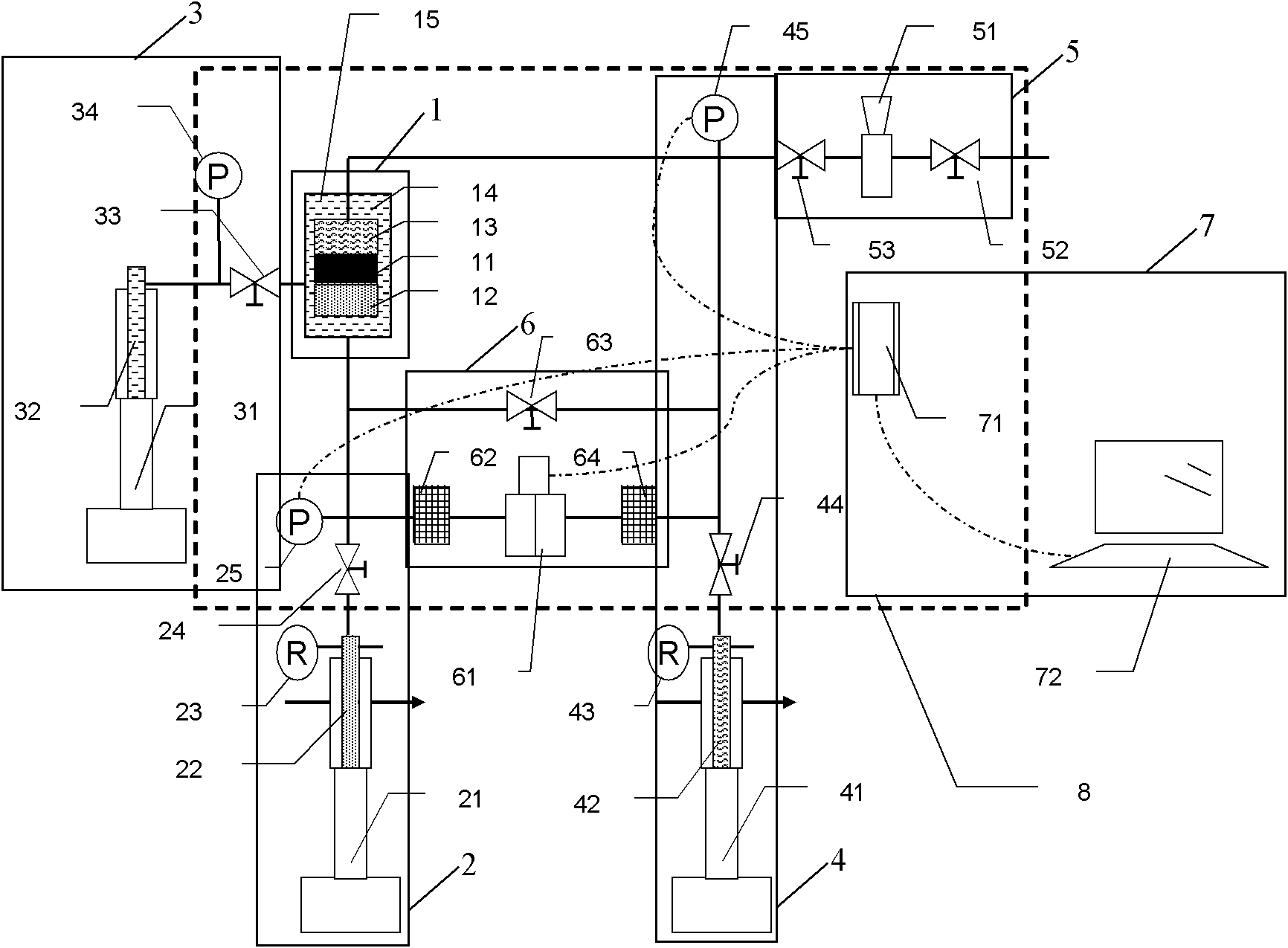

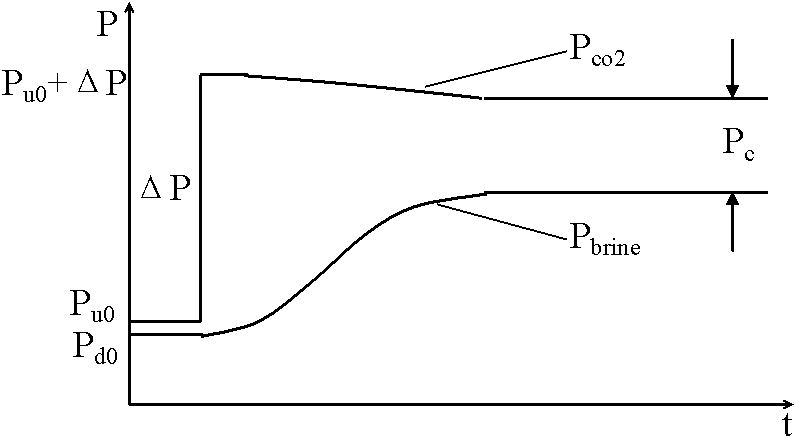

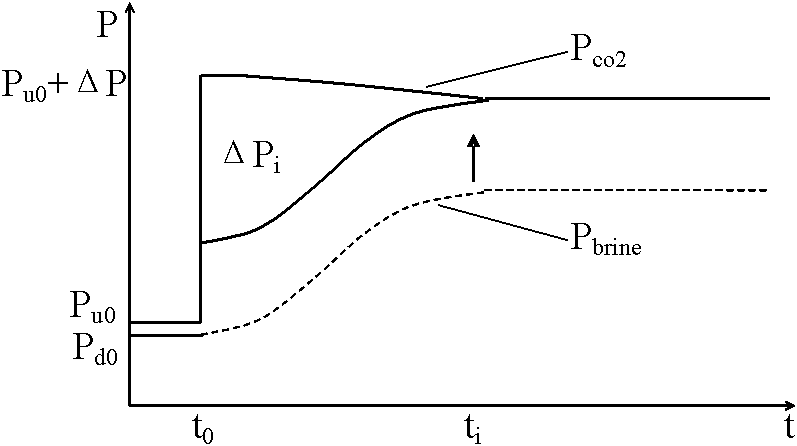

Method and device for measuring breakthrough pressure of porous medium material

ActiveCN102183448AMeet the measurement requirementsAdaptableEarth material testingPermeability/surface area analysisEngineeringPorous medium

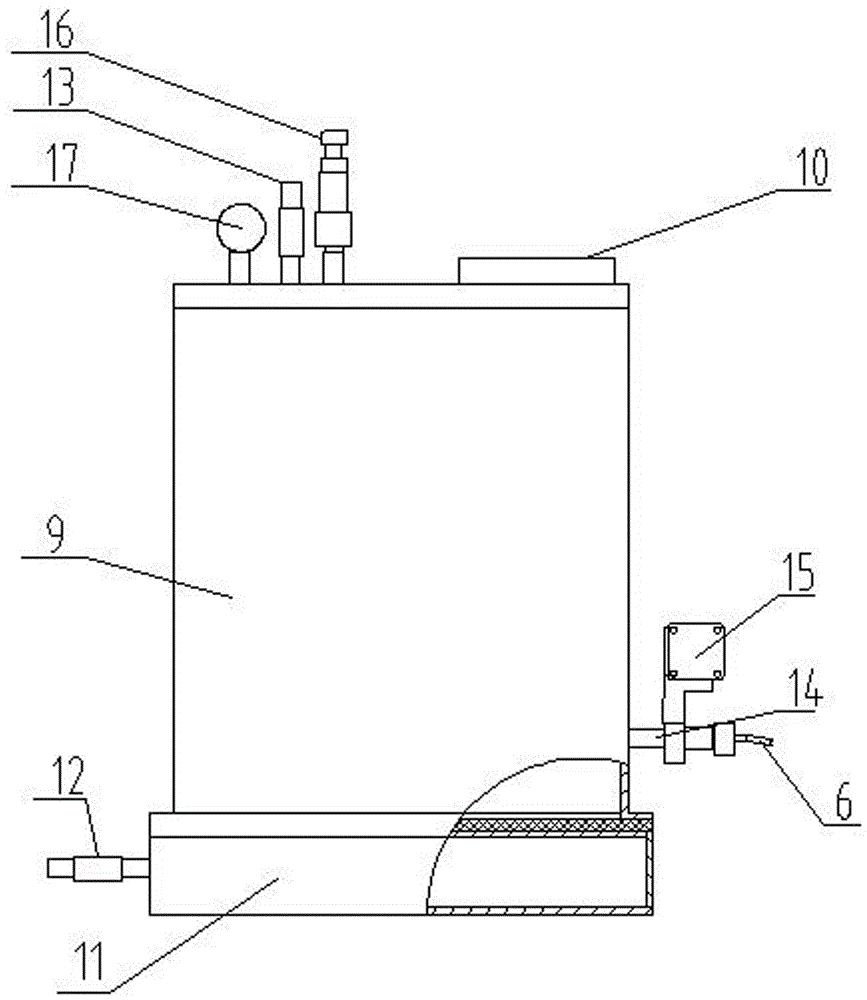

The invention discloses a method and a device for measuring a breakthrough pressure of a porous medium material. The method comprises the following steps of: A, placing a saturated infiltration phase tested piece into a holder, and loading a confining stress to the tested piece; B, shutting off an upstream emptying valve, a downstream emptying valve and a backpressure emptying valve, and vacuumizing; C, when the device is in a stable vacuum state, making the device pass through an upstream non-infiltration phase injection system and a downstream infiltration phase injection system; and D, simultaneously performing test on the breakthrough pressure and the permeability coefficient. The holder is connected with a confining stress control valve through a pipeline; the upstream is connected with an upstream control valve and an upstream pressure meter through pipelines; the downstream is connected with a downstream control valve, a downstream pressure meter and a backpressure control valve respectively through pipelines; a communicating valve is connected with an upstream non-infiltration phase and a downstream infiltration phase respectively through pipelines; a data acquisition cardis connected with the upstream pressure meter through a data wire. The invention is easy in operation, stable in performance and reliable in measurement, and applicable to simultaneous, quick, efficient and precise measurement of the breakthrough pressure and the permeability coefficient of the porous medium material.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

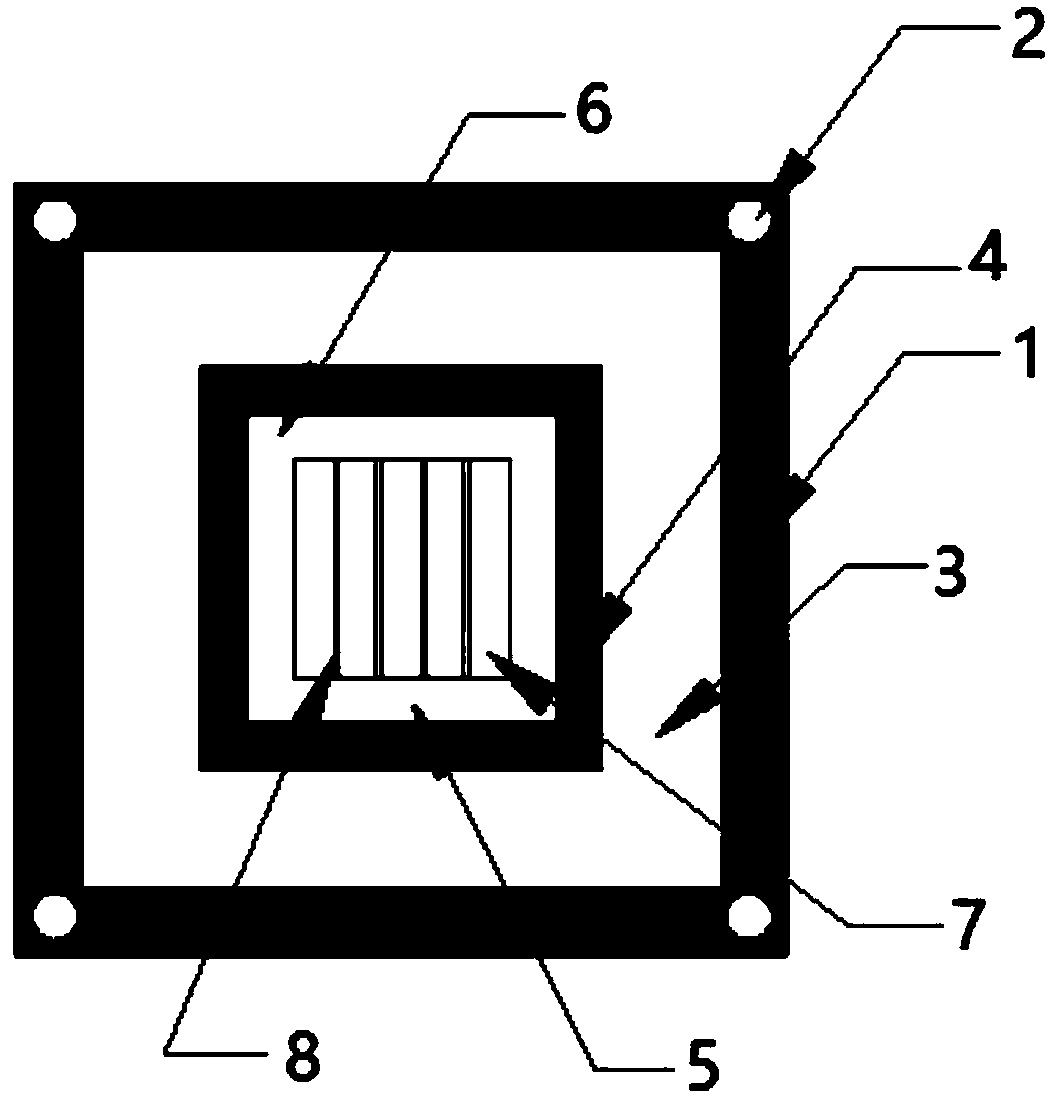

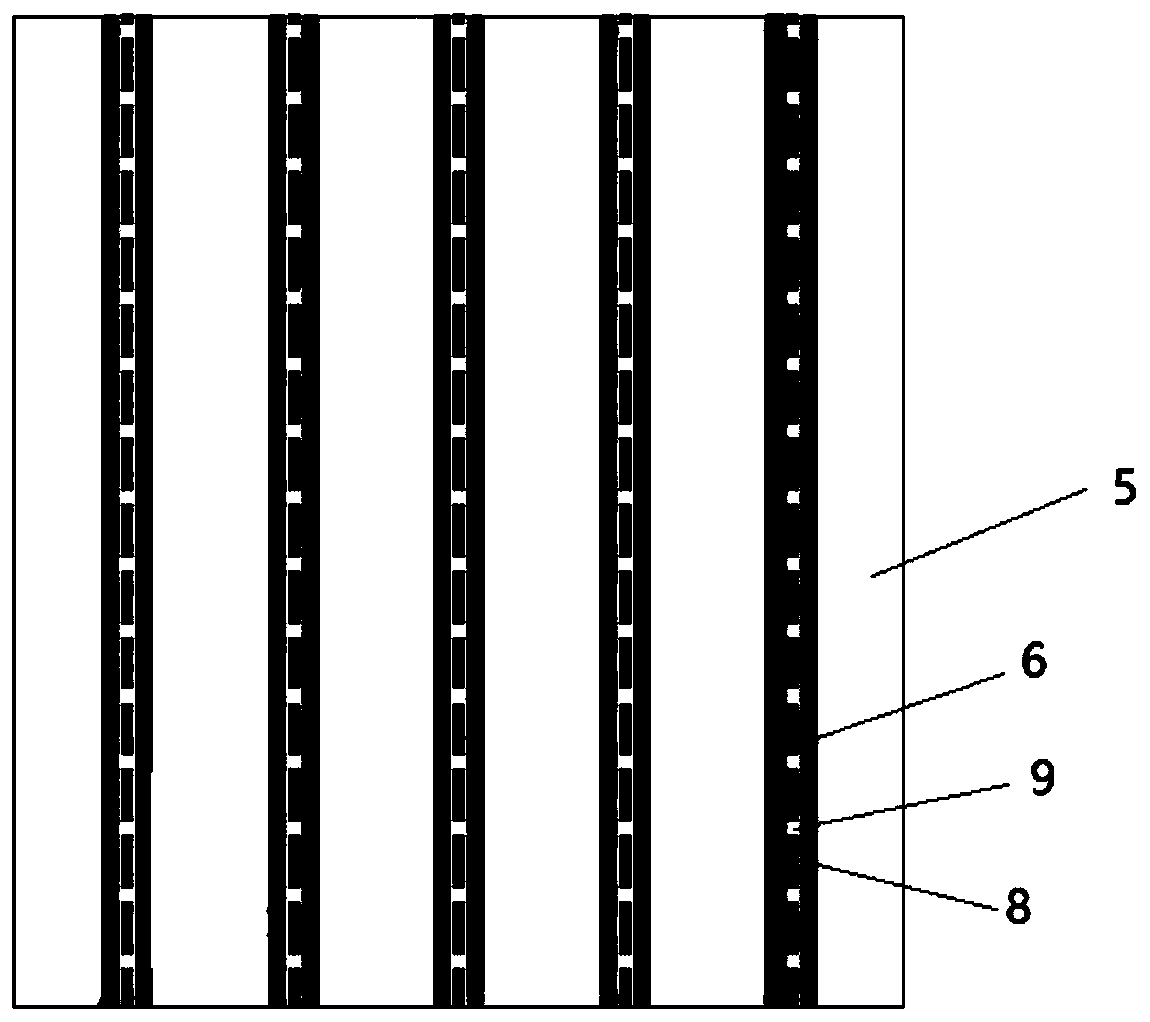

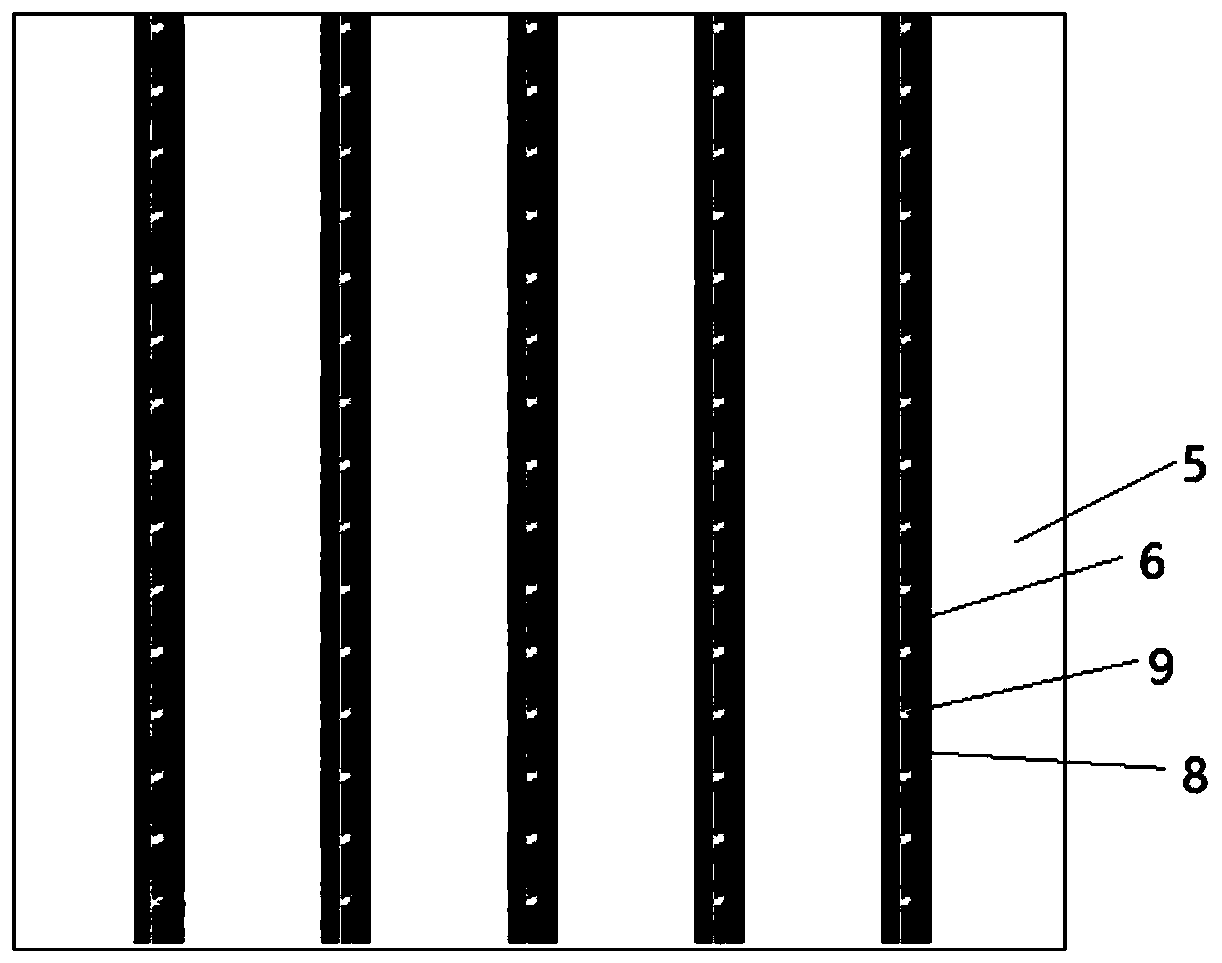

Manufacturing method of metal alloy composite screen plate

InactiveCN110039883ALow elongationGood dimensional stabilityPlate printingFoil printingDouble supportPuncture resistance

The invention discloses a manufacturing method of a metal alloy composite screen plate. The manufacturing method comprises the following specific steps of 1) carrying out net pulling compounding; 2) manufacturing an alloy sheet pattern outer contour; 3) preparing a film layer; 4) coating an adhesive layer; 5) coating a film; 6) drying; 7) laser; 8) cleaning; and 9) detecting and packaging. In thisway, according to the manufacturing method of the metal alloy composite screen plate, a metal alloy sheet is adopted to replace traditional mesh cloth, and the manufacturing method has low elongationrate, better dimensional stability, printing resistance, puncture resistance, double supports of the metal alloy sheet and the film layer are adopted, the service life of the bonding strength far beyond a silk-screen and the film layer can be improved by 30% or above, and under the action of a high-molecular adhesive, the adhesion force of the high-molecular composite layer is extremely high, theplate making yield is greatly improved, the production cost is saved, the printing is good, the line type is good, and the efficiency of a battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

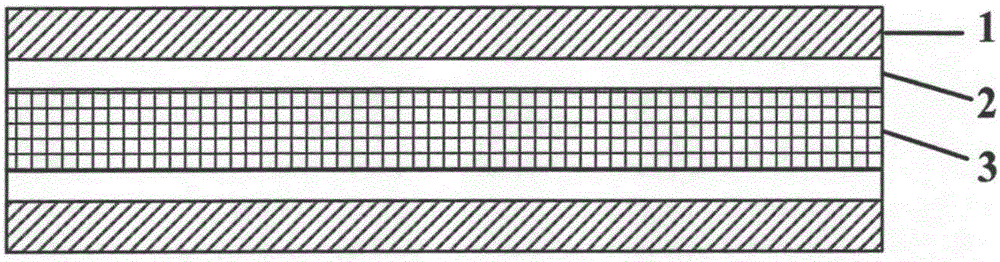

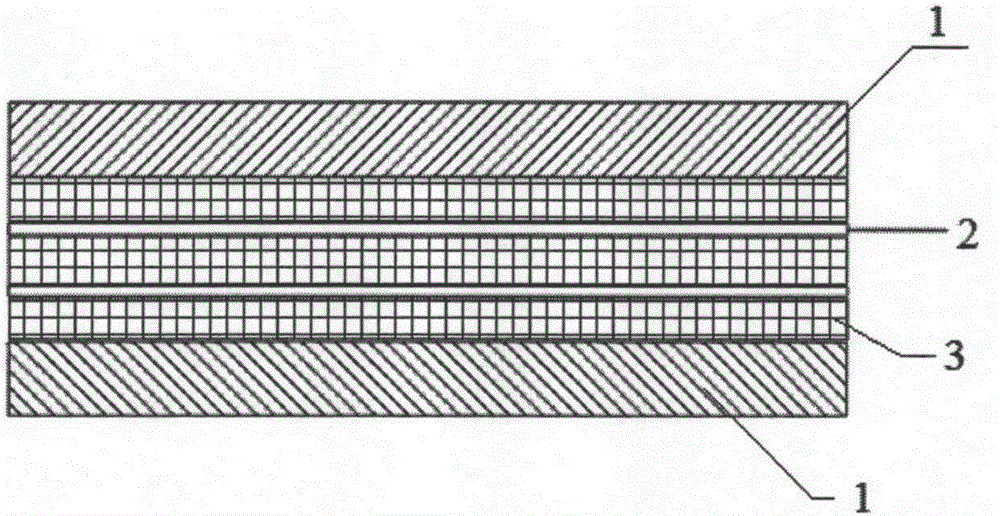

Flexible stretchable electromagnetic shielding fabric and preparation method thereof

ActiveCN106012553AGood flexibilityIncrease elasticityFibre treatmentComposite filmElectromagnetic shielding

The invention provides a flexible stretchable electromagnetic shielding fabric and a preparation method thereof. The method for preparing the flexible stretchable electromagnetic shielding fabric comprises the following steps: selecting a spandex stretch fabric as an elastic adhesion matrix, applying a certain tension to two ends of the fabric, stretching the fabric to a certain elongation and fixing, and coating a layer of liquid elastic adhesives on the surface of the elastic adhesion matrix; performing pressure dipping on a flexible nano electromagnetic shielding composite film on the liquid elastic adhesives, coating a layer of liquid elastic adhesives on the upper side of the flexible nano electromagnetic shielding composite film, allowing the composite film to be adhered to another spandex stretch fabric, and curing the adhesives under a certain conditions; releasing the tension applied to the elastic adhesion matrix so as to drive the flexible nano electromagnetic shielding composite film to retract, thereby obtaining the flexible stretchable electromagnetic shielding fabric. The flexible stretchable electromagnetic shielding fabric disclosed by the invention has the characteristics of high elasticity, high elongation, excellent electromagnetic shield property and the like.

Owner:DONGHUA UNIV

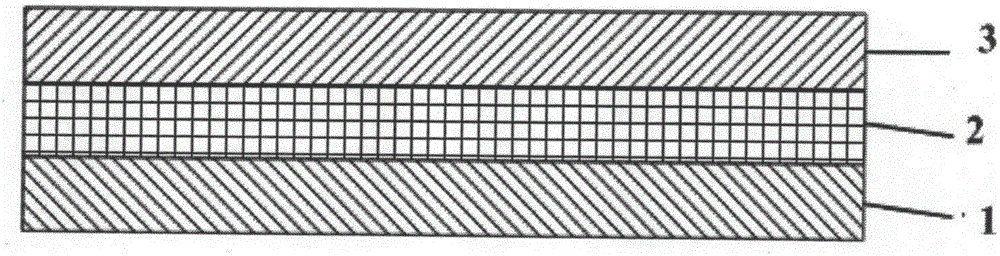

Flexible stretchable electromagnetic shielding film and preparation method thereof

InactiveCN106003888AGood flexibilityIncrease elasticityLamination ancillary operationsMagnetic/electric field screeningEngineeringElectromagnetic shielding

The invention provides a flexible stretchable electromagnetic shielding film and a preparation method thereof. The preparation method of the flexible stretchable electromagnetic shielding film comprises the following steps: selecting an elastic membrane as an elastic adhesion matrix, stretching the elastic membrane to a certain elongation, then fixing the elastic membrane, and coating a liquid elastic adhesive layer on the surface of the elastic membrane; crushing a flexible nano electromagnetic shielding complex film on the liquid elastic adhesive layer, coating resin with protective effect at the upper side of the flexible nano electromagnetic shielding complex film to form a resin layer, and curing the liquid elastic adhesive and the resin under certain conditions; and releasing a tensile force applied onto the elastic adhesion matrix, so as to drive the flexible nano electromagnetic shielding complex film to retract, namely the flexible stretchable electromagnetic shielding film is obtained. The prepared flexible stretchable electromagnetic shielding film has good elasticity, high elongation (20-50%) and excellent electromagnetic shielding property (electromagnetic wave absorptivity is more than or equal to 99% at the frequency of 1-5GHz) and can bear certain bending and compression deformation.

Owner:DONGHUA UNIV

Opening and closing device for mould and mould using the same

The present invention provides an opening and closing device for die. It includes a guide pin and a guide pin liner. The described guide pin has a straight bar portion into which the guide pin line can be inserted, on the described straight bar portion a containing hole is set, in the described containing hole a spring and a rigid ball are contained, on end of the described spring is fixed in the bottom portion of said containing hole, its another end is connected with the rigid ball. When the spring is being in natural state, the partial rigid ball is exposed from the containing hole, and the inner wall of the described guide pin liner is equipped with a recessed groove which can be used for containing the above-mentioned partial exposed rigid ball after the die is closed. Said invention also provides a die using said opening and closing device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

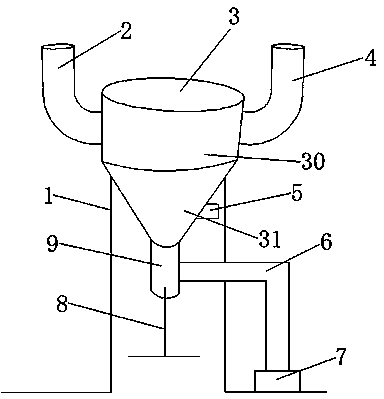

Bead stringing machine capable of stringing different beads and working method of bead stringing machine capable of stringing different beads

The invention discloses a bead stringing machine capable of stringing different beads. The bead stringing machine comprises a bracket, a hopper on the bracket, a first feeding pipe on the left side of the hopper, a second feeding pipe on the right side of the hopper, a bead dropping pipe below the hopper, an air pipe connected to the bead dropping pipe, a fan at the end part of the air pipe, a bead stringing rod below the bead dropping pipe and a gravity sensor on the right side of the hopper, wherein the hopper includes an upper hopper and a lower hopper, and a first partition board is arranged between the upper hopper and the lower hopper; a second partition board is arranged in the bead dropping pipe, and an air outlet hole is formed in the right side face of the bead dropping pipe; a sensor is arranged on the second partition board; the air outlet hole is communicated with the air pipe; a conical lever head is arranged on the bead stringing rod, a threading hole is formed in the conical lever head and a fixed plate is arranged at the bottom end of the bead stringing rod. The bead stringing machine capable of stringing the different beads, disclosed by the invention, has the advantages of good service performance, low labor intensity, good processing quality, simple structure and long service life.

Owner:ZHONGSHAN JUCHANG AUTOMATION EQUIP TECH CO LTD

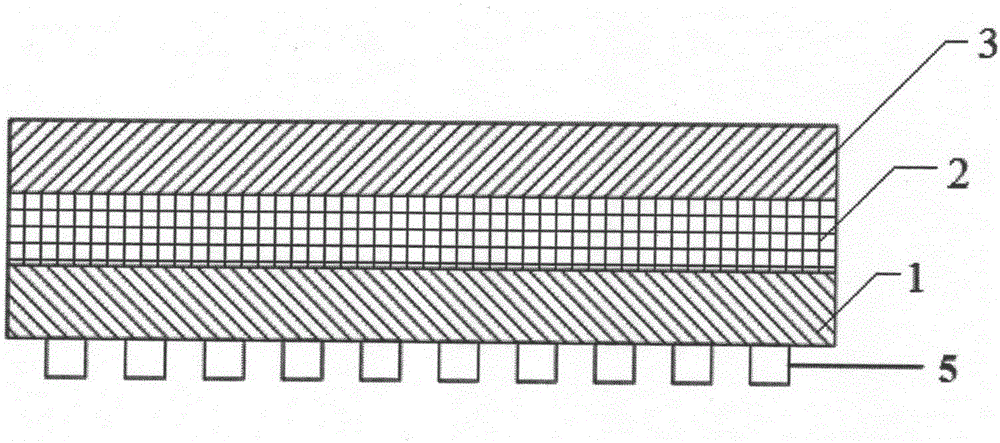

Manufacturing method of composite screen printing plate

InactiveCN110039882ANot easy to wear and tearIncreased printing lifePlate printingFoil printingLine widthEngineering

The invention discloses a manufacturing method of a composite screen printing plate. The manufacturing method comprises the following steps of 1) screen pulling and compounding; 2) film layer manufacturing; 3) coating an adhesive layer; 4) coating a film; 5) drying; 6) laser; 7) cleaning; and 8) detection and packaging. By means of the mode, the manufacturing method of the composite screen plate has the advantages that when the screen printing plate is used, the film layer is not easy to wear and break, the printing life is prolonged by one time or more, the printing life of a conventional plate-making screen printing plate is averagely increased by about 50 thousand, the average energy of the screen printing life prepared by the method can reach 100 thousand or above and even higher, theprinting line at the later stage is not expanded, and the efficiency of the battery piece is obvious; and the manufactured screen printing plate is better in ink permeability, so that the limitation of the high-precision narrow line width can be greatly reduced, on the basis of the same type of ink printing, the width of the designed line can be compressed by 2-5 microns, the printing is good, theline type is good, and therefore the efficiency of the battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Chip and carrier self-contrapositioning soft soldering method under gas protection

ActiveCN1666839ASimple structureReduce manufacturing costSoldering auxillary devicesShielding gasEngineering

The invention relates to the self-contraposition soldering of the chip and the carrier under gas protection. It uses the gas protection, the minimum surface energy principle, the precise control of carrier size to realize the self-contraposition. It is characterized in that the method put the carrier, the chip the soldering sheets and the operational tools in the glove-operation box with protective gas, the heating table and the worktable to implement the process. The invention has high soldering efficiency and low damaging rate of the chip.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

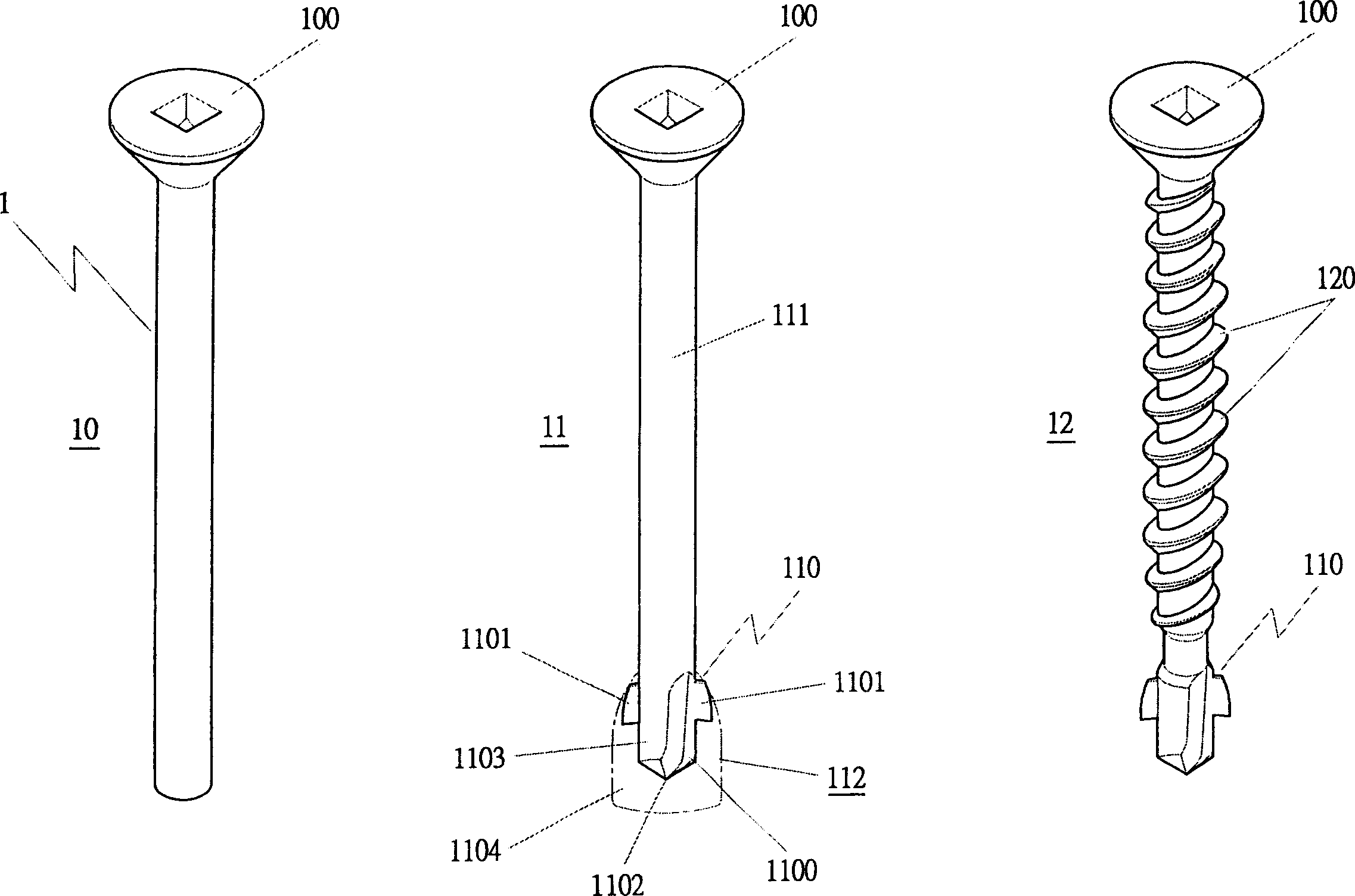

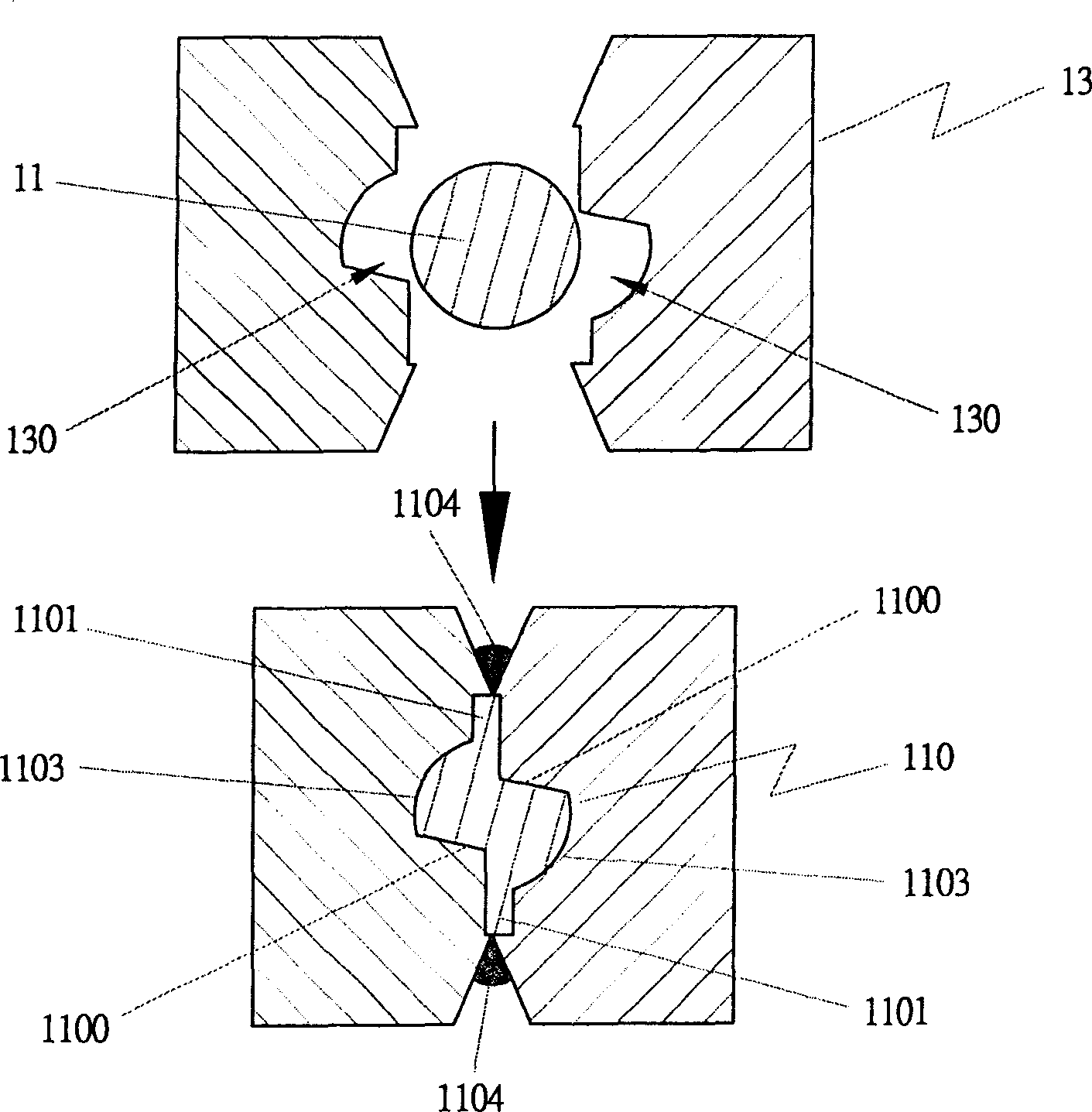

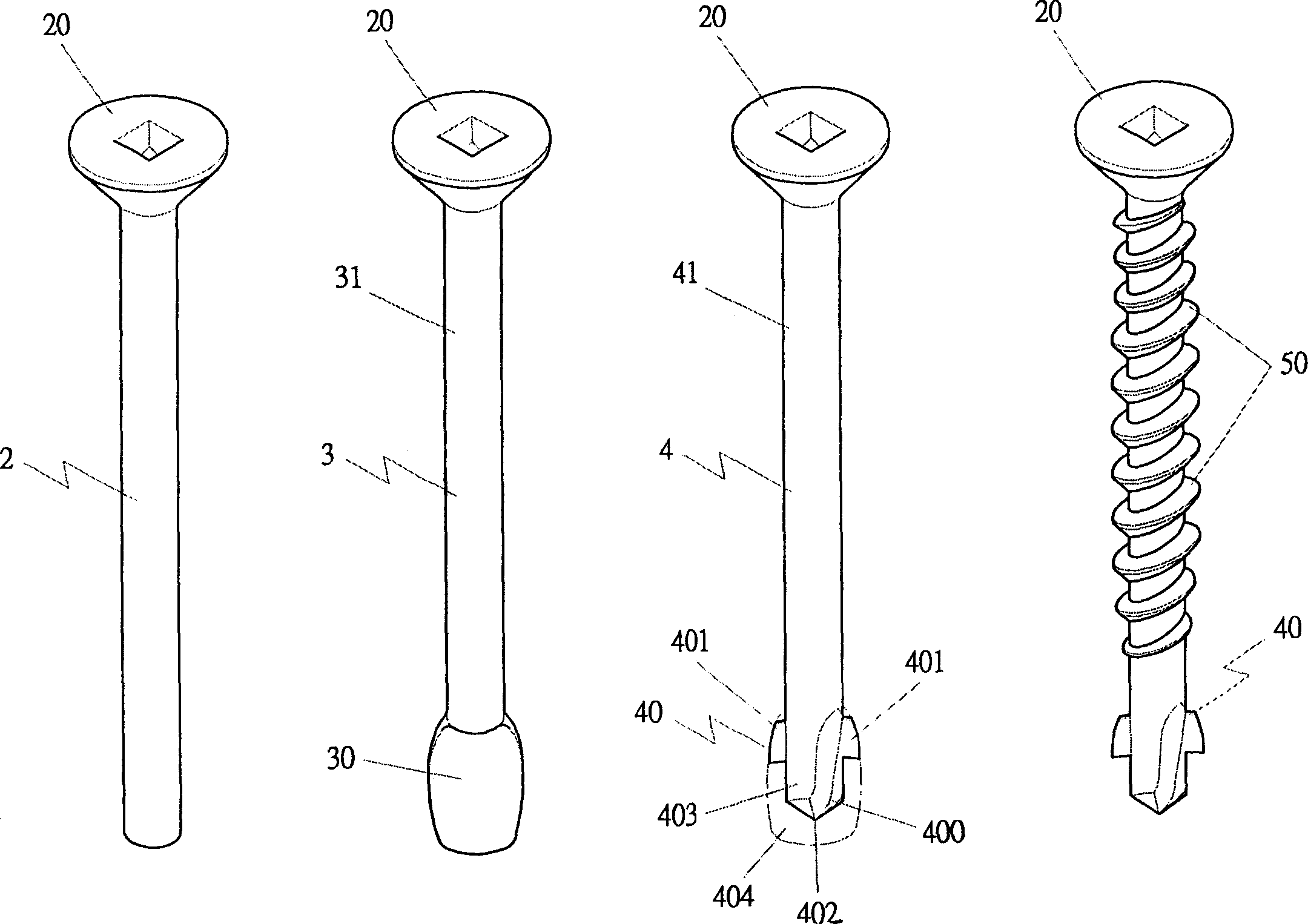

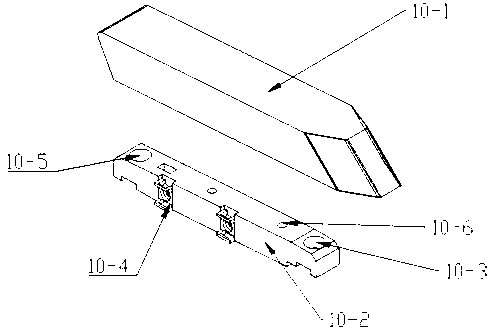

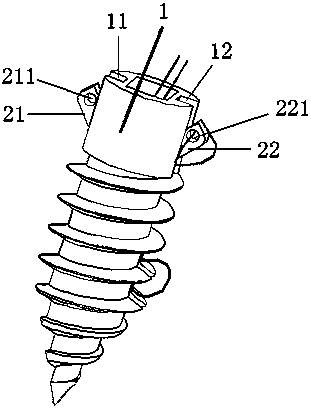

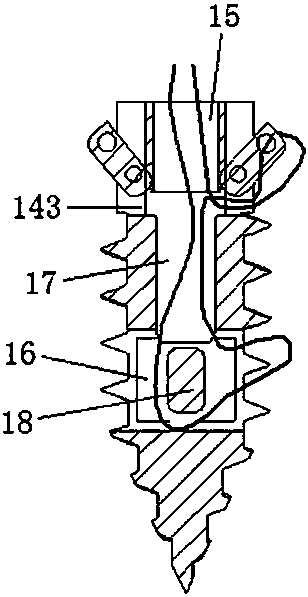

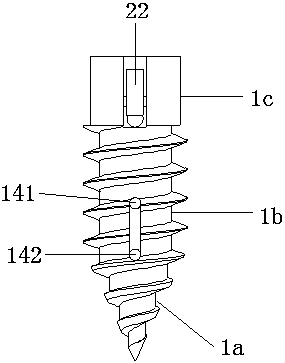

Tapping screw making method

InactiveCN1827291ASolution to short lifeSolve easy wear and tearGear teethScrew threadMaterials science

The invention relates to a method for preparing self-taping screw which can reduce the mold consumption, increase the mold service life, and reduce the producing cost, which comprises following steps: initial blank preparation, cap molding, tail molding, cutting part molding, and screw molding. Wherein, the cap molding step is that arranging the initial blank into the first molding mold to punch the cap to attain the first blank with cap; the tail molding step is that: arranging the first blank into the second molding mould and using the second molding mould to punch another end of first blank to form the second blank with tail; the cutting part molding step is that: arranging the tail of second blank into the third molding mould to punch the tail to form the third blank with cutting part; and the screw molding step is that: via the thread rolling of forth molding mould on the rod of third blank, forming the screw rod with screw thread and removing the burr of cutting part.

Owner:陈河田

Soil gas flux detector and determination method

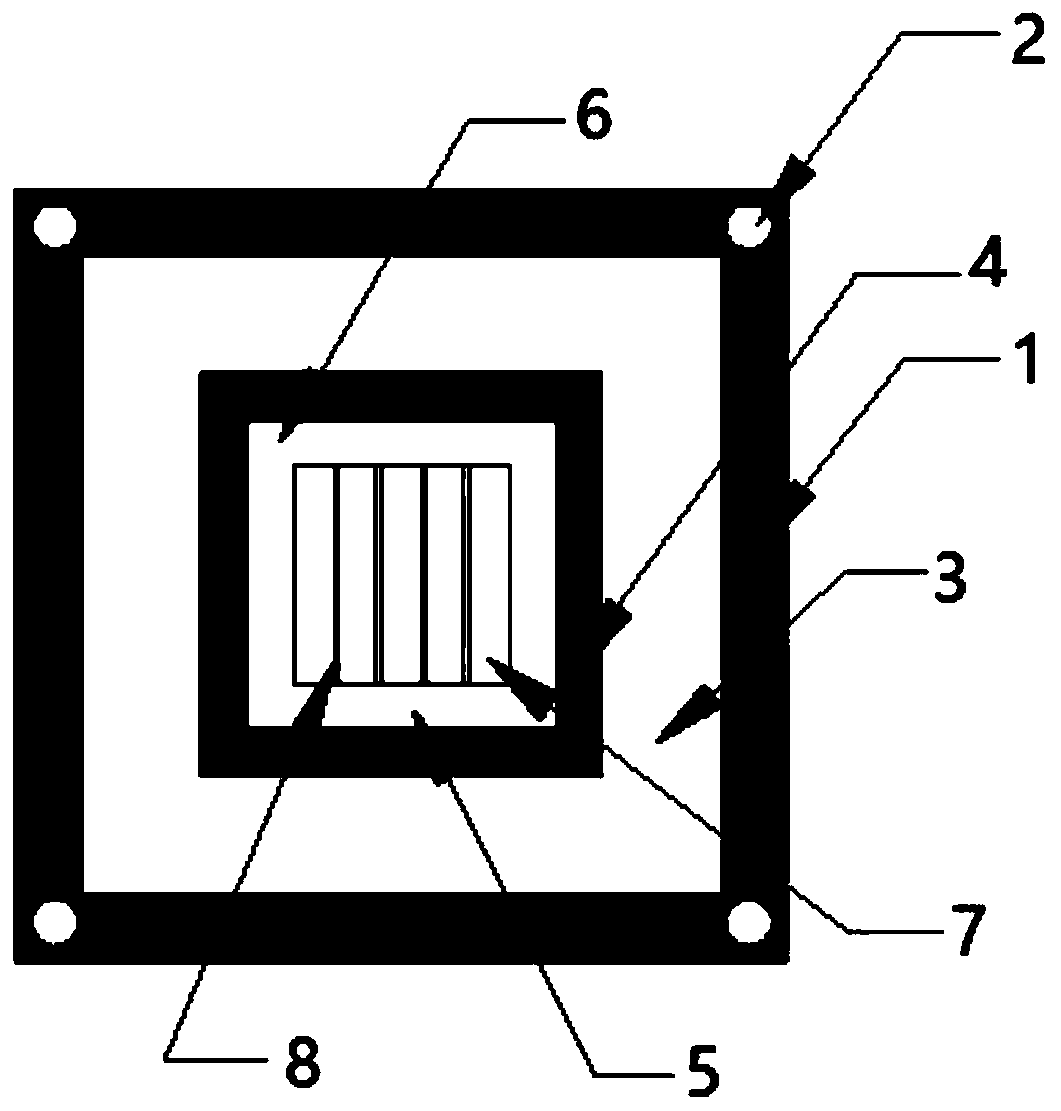

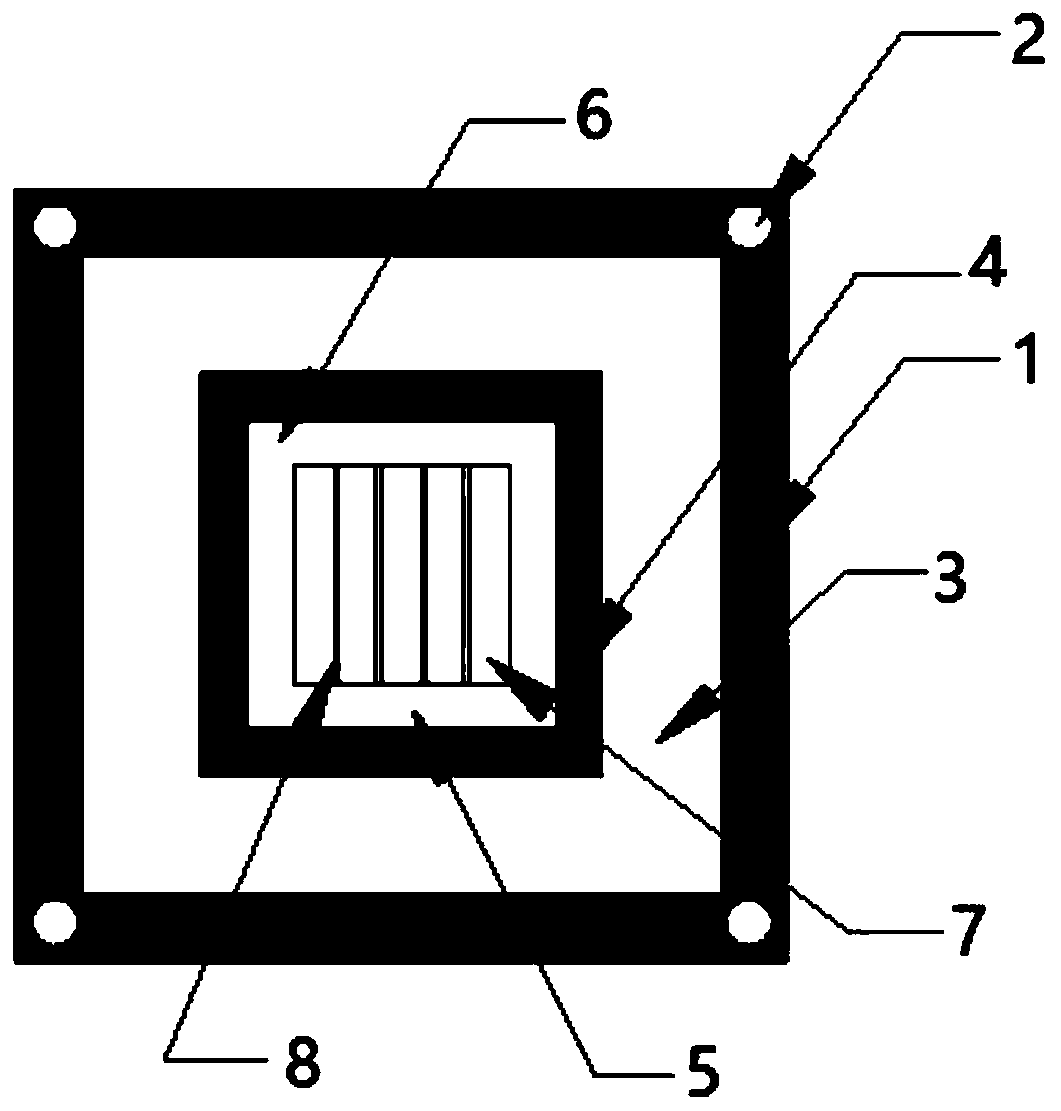

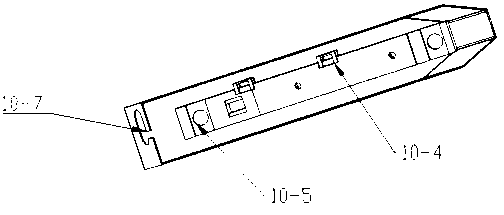

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

Manufacture method of multi-angle or zero-angle screen printing plate

InactiveCN110039884AClear and smooth outlineEasy to shapePlate printingFoil printingScreen printingLaser etching

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

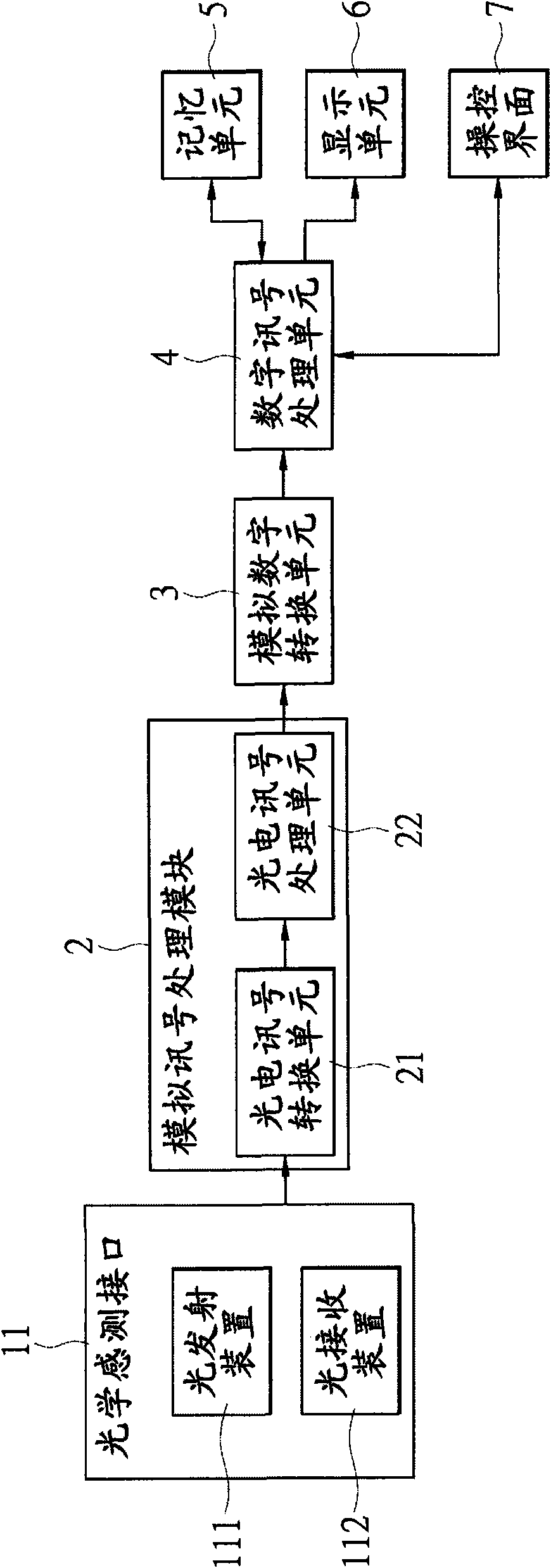

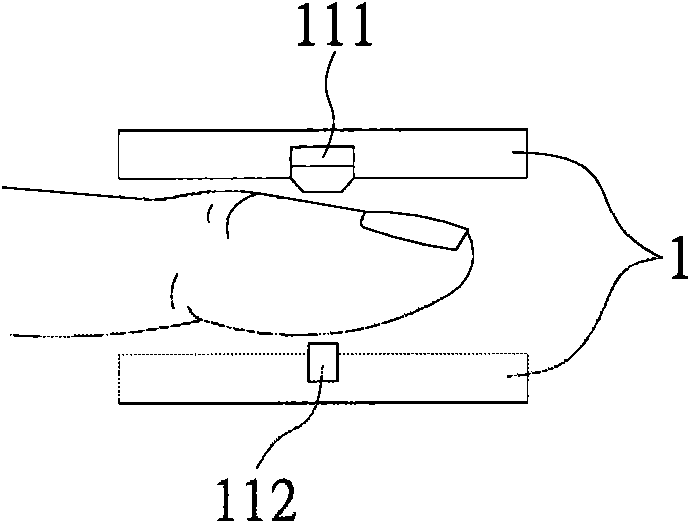

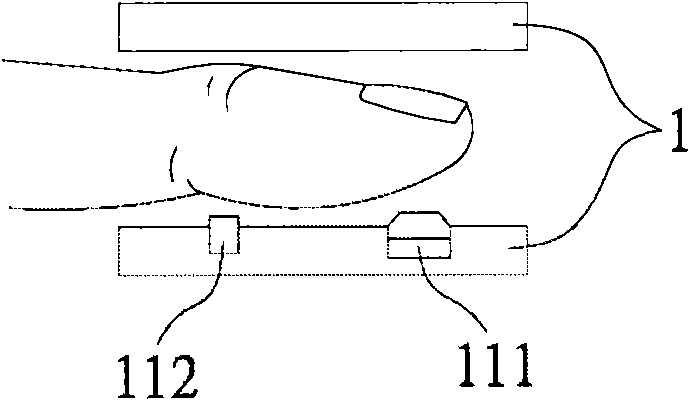

Physiological signal detecting system and method

InactiveCN101773389ASolve easy wear and tearWon't get dirtyMeasuring/recording heart/pulse rateRR intervalMeasurement device

The invention provides a physiological signal detecting system and a physiological signal detecting method. The physiological signal detecting system comprises a measuring device, an analog signal processing module, an analog-digital conversion unit and a digital signal processing unit, wherein the measuring device is provided with an optical sensing interface which retrieves optical plethysmogram signals of testees; the analog signal processing module is electrically connected with the optical sensing interface and the analog-digital conversion unit; the optical plethysmogram signals are converted into a digital format by the analog-digital conversion unit; the digital signal processing unit is electrically connected with the analog-digital conversion unit; and the digital signal processing unit senses characteristic points of the optical plethysmogram signals in the digital formats, so that the interphase of the characteristic points and heart rate variability parameters of the testees are calculated. Therefore, users can conveniently sense the heart rate variability parameters per se to achieve the health early warning effect.

Owner:AVITA

Abrasion-resistant tire special for tractor

InactiveCN105602025AThe material formula is simpleSolve easy wear and tearSpecial tyresStearic acidAir tightness

The invention relates to an abrasion-resistant tire special for a tractor. The tire is manufactured with, by weight, 20-25 parts of natural rubber, 5-7 parts of sulfur powder, 1-2 parts of nano-crystalline cellulose whiskers, 6-8 parts of zinc oxide, 6-8 parts of a vulcanizing agent, 4-5 parts of stearic acid, 5-8 parts of a wear-resisting agent, 5-8 parts of a rubber air tightness enhancing agent, 8-12 parts of octyl-phenolic tackifying resin, 2-3 parts of plasticity polyurethane elastomer (TPU) and 5-8 parts of high-performance long aramid fibers. According to the tire special for the tractor, a material formula is simple and reasonable, the problem that a tire of the tractor is abraded easily can be effectively solved, and the service life of the tire of the tractor is prolonged.

Owner:LIUZHOU LIUPIN TECH

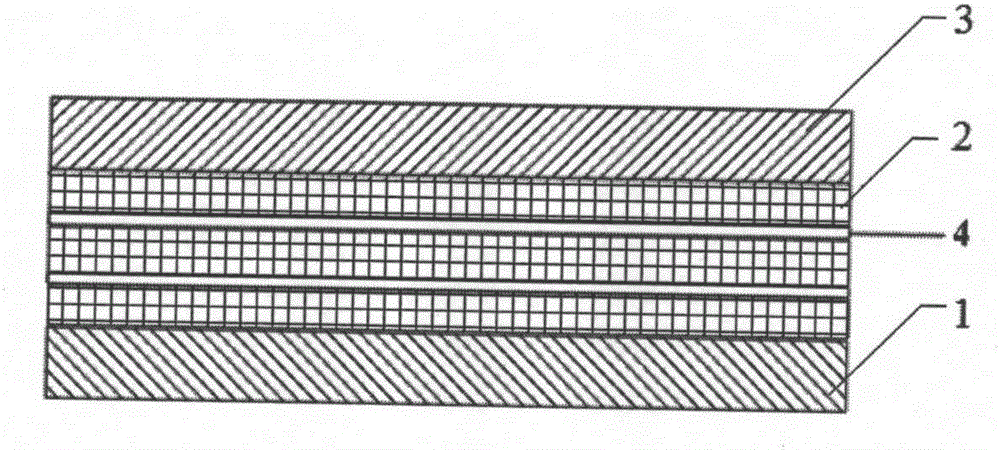

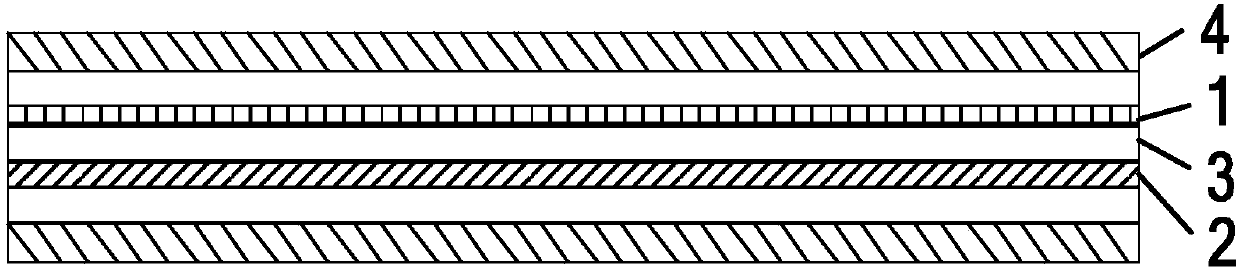

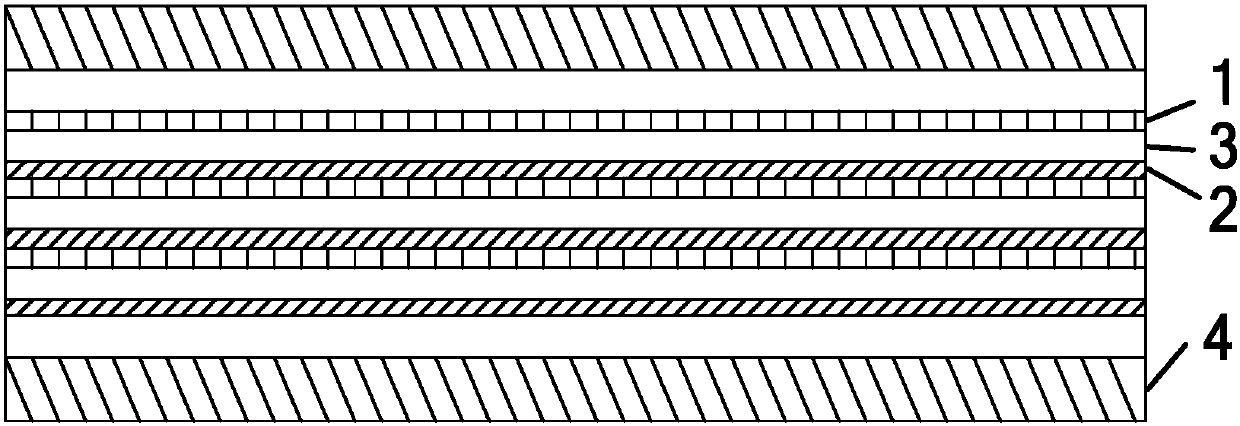

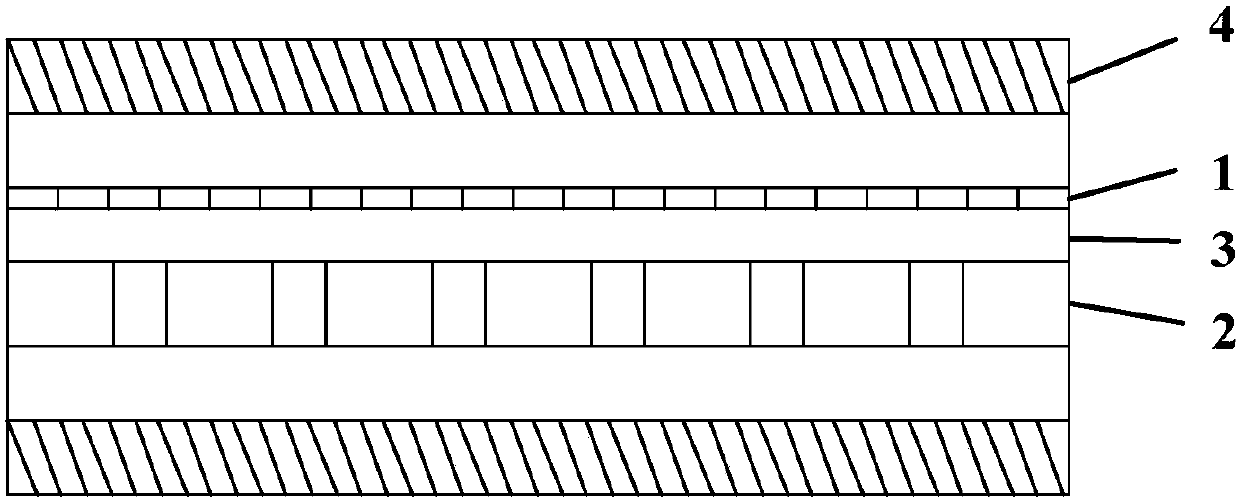

A kind of electromagnetic shielding composite fabric and its preparation and application

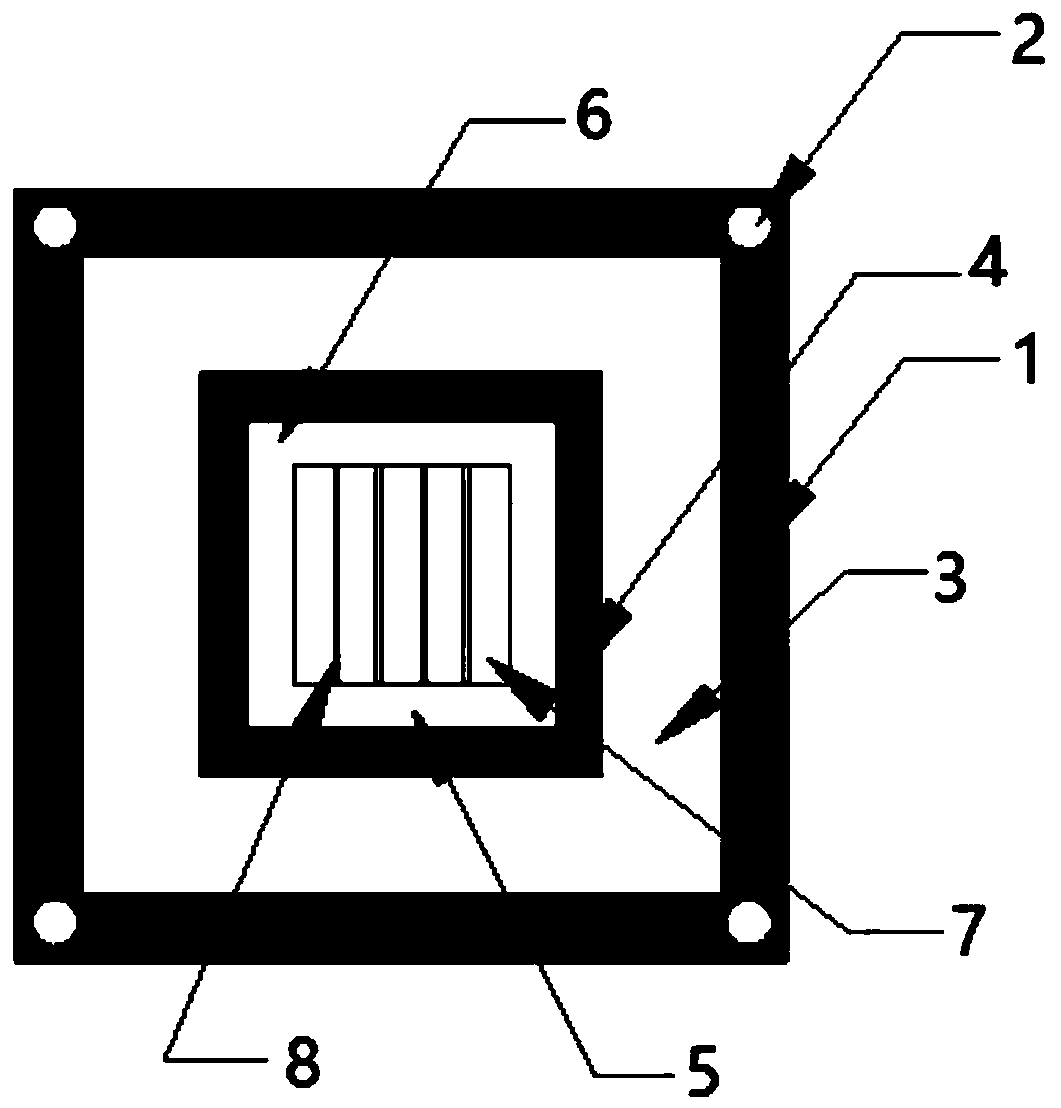

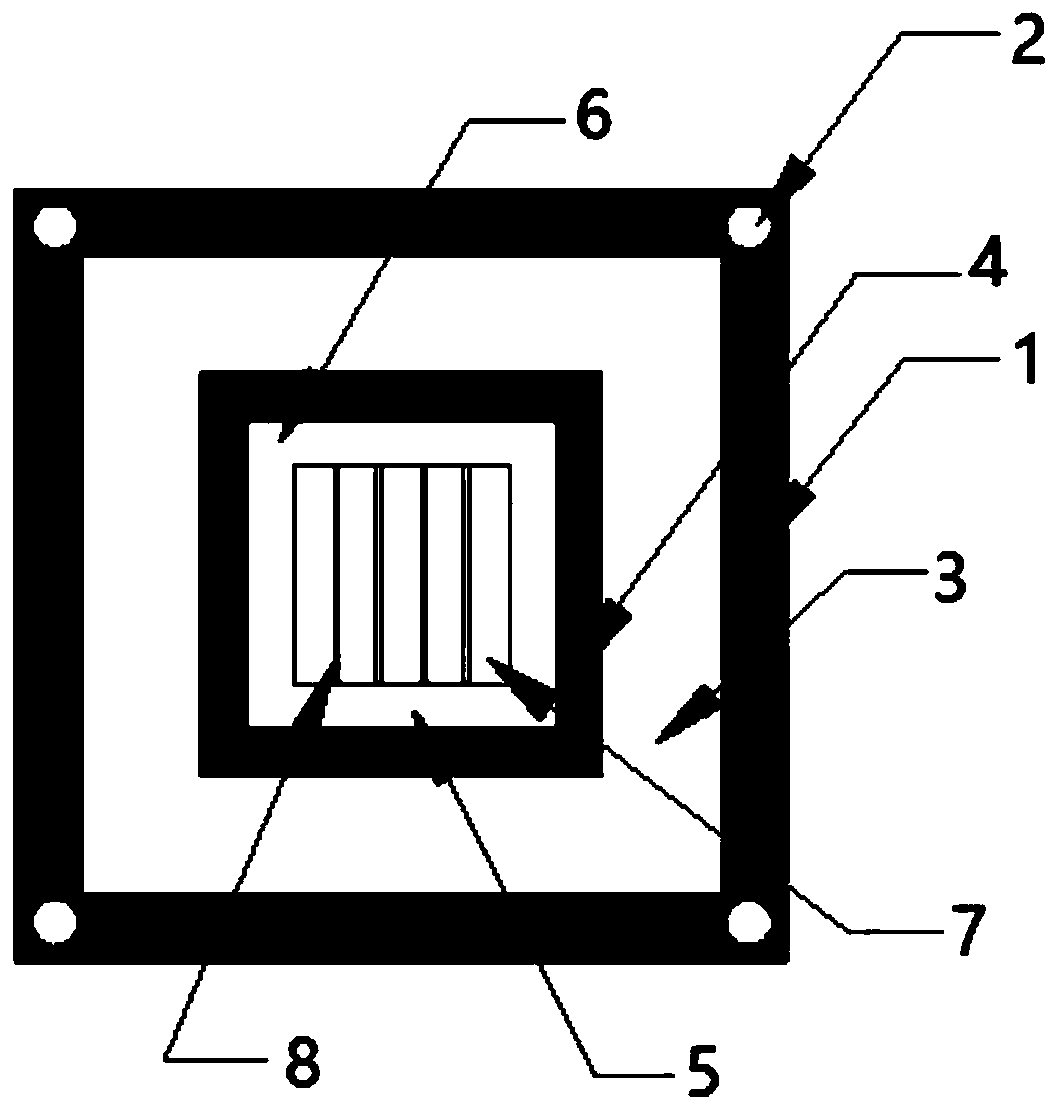

InactiveCN106183211BHas usage directionDirectionalSynthetic resin layered productsConstructions elementsComposite filmCarbon nanotube

The invention relates to an electromagnetic shielding composite fabric as well as preparation and application thereof. The electromagnetic shielding composite fabric comprises: a carbon nanotube / graphene composite film (1), a polyaniline thin film (2), a binding agent (3) and a base fabric (4), wherein graphene in the carbon nanotube / graphene composite film is compounded on the upper surface of a carbon nanotube film; the polyaniline thin film is adhered to the lower surface of the carbon nanotube film through the binding agent. The preparation comprises: depositing a graphene suspension solution on one layer of a carbon nanotube thin film and naturally airing at room temprature to obtain a graphene / carbon nanotube composite film; adhering the polyaniline thin film on the lower surface of the carbon nanotube thin film through the binding agent to obtain a carbon nanotube / graphene / polyaniline composite film; the base fabric is adhered to the surface of the carbon nanotube / graphene / polyaniline composite film through the binding agent and then is cured to obtain the product. The electromagnetic shielding composite fabric prepared by the invention has a good electromagnetic shielding performance and can also keep the characteristics of air permeability, flexibility, foldability, binding property and the like of a fabric material.

Owner:DONGHUA UNIV

Rotary welding tool for friction welding and welding method

ActiveCN110524105ASolve easy wear and tearSolve the problem of breakingNon-electric welding apparatusButt jointSpot welding

The invention relates to a rotary welding tool for friction welding and a welding method, which achieve welding by friction of a rotary welding tool on the surface of a workpiece. The welding tool forrealizing the friction welding method consists of a core material and a support body. The core material is a consumable material and is composed of a cylinder or a prism made of the same material asa to-be-welded material. One end of the support body is sleeve-shaped and is in close fit with the core material; and the other end is a common knife handle connected with a motor spindle. The supportbody is a non-consumable part, and the material strength of the support body is higher than that of to-be-welded materials. Compared with common linear friction welding and rotary friction welding, butt joint, lap joint and spot welding of plates can be welded through mutual friction of homogeneous materials, and the friction welding method is not limited to workpieces with specific section shapes any more. Compared with common friction stir welding, a non-consumable stirring tool is not needed to serve as a welding tool any more, and the problem that a stirring head is prone to abrasion andbreakage is fundamentally solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Compressor

PendingCN109372744AGuaranteed sealing performanceSolve wear and tearRotary piston pumpsRotary piston liquid enginesInternal pressureEngineering

The invention discloses a compressor. The compressor comprises an air inlet cavity, a compression cavity, a middle pressure cavity, a high-pressure buffering cavity and a back pressure adjusting mechanism, wherein the compression cavity is formed between a movable vortex disc and a fixed vortex disk, the compression cavity comprises a first compression cavity and a second compression cavity, the inner pressure of the first compression cavity is larger than the inner pressure of the second compression cavity; the back pressure adjusting mechanism controls the middle pressure cavity to be in communication with the first compression cavity or the second compression cavity. On the basis of an existing scroll compressor structure, the back pressure adjusting mechanism is arranged, the adjustingstructure is used for controlling the pressure of the middle pressure cavity in the back of the fixed disk and the switching between the first compression cavity and the second compression cavity according to the pressure difference between the exhaust pressure and the suction pressure or directly the exhaust pressure, so that the sealing of a pump body under the light-load working condition is guaranteed, and the problem of back abrasion of the fixed vortex disk under heavy load working conditions is avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

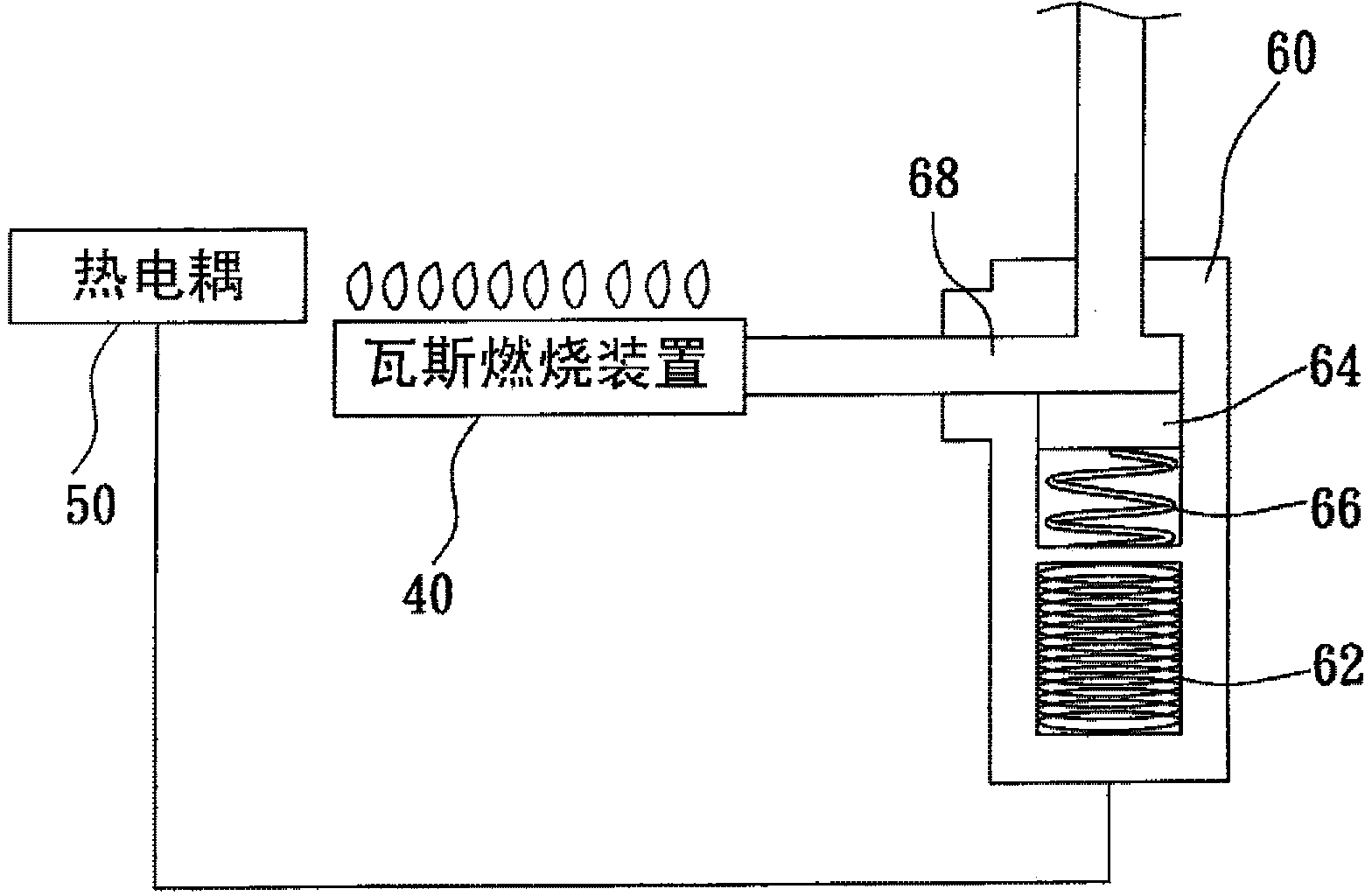

Hypoxia protection device

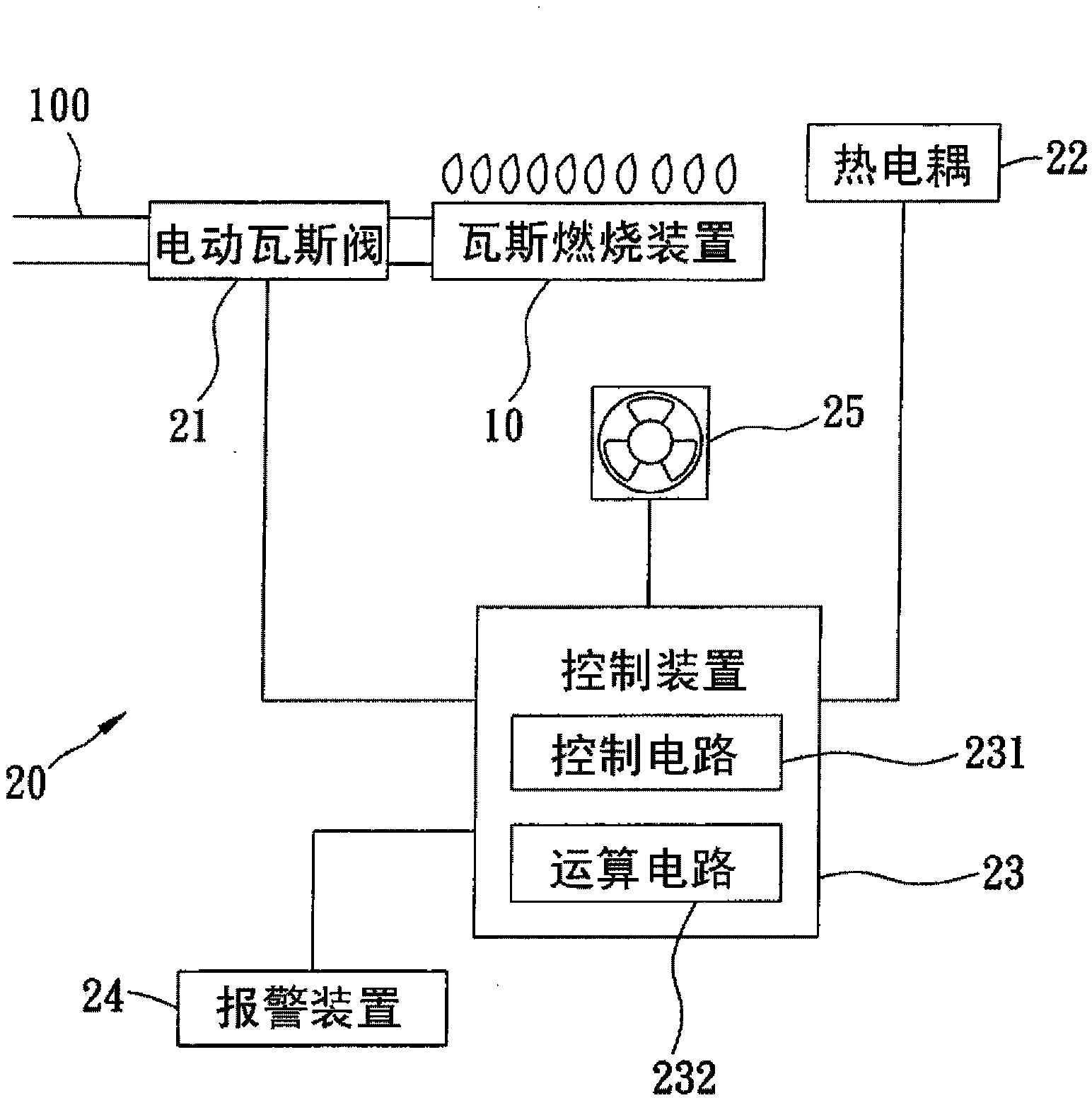

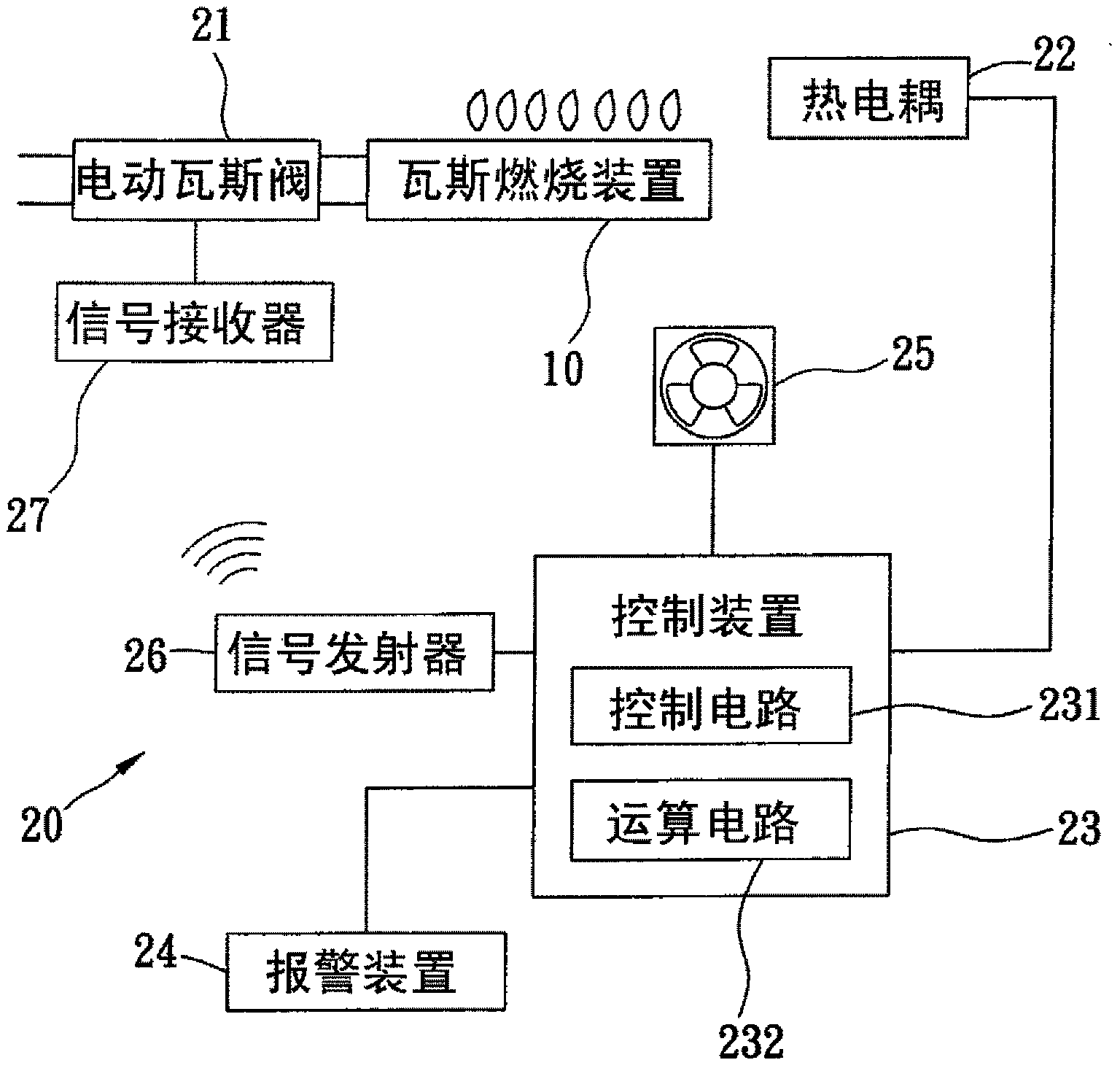

InactiveCN103836802ASolve easy wear and tearImprove accuracyFluid heatersDomestic stoves or rangesThermal energyOxygen

A hypoxia protection device is used for regulating supplied gas quantity when oxygen concentration around a gas burning device is lower than a preset value and comprises an electric gas valve, a thermal couple and a controller, wherein the electric gas valve is used for controlling gas flow supplied to the gas burning device. The thermal couple is arranged nearby the gas burning device and outputs thermoelectric force according to thermal energy generated by the gas burning device. The controller is electrically connected with the electric gas valve and the thermal couple and used for receiving the thermoelectric force, calculating whether the oxygen concentration around the gas burning device is lower than the preset value according to the thermoelectric force and generating an electric signal to control the electric gas valve to regulate gas supplied to the gas burning device when the oxygen concentration is lower than the preset value.

Owner:GRAND MATE

Textile technology of blending textiles

Provided is a textile technology of blending textiles. The technological process is that purified cotton piled yarns and cotton yarns added with conductive wires are twisted into piled yarns by a twisting device, a sectional warping machine is used, the piled yarns are arranged in a warp beam according to arraying of two conductive wires per inch, a high-speed rapier loom is used for weaving, procession inspection is conducted on an arranging workshop, dyeing is conducted according to technological requirements during dyeing, after dyeing and coloring, a softener is added according to the technology, and testing, inspecting, preshrinking and sizing processing are conducted. By means of fabrics which are produced according to the requirement of the textile technology of the blending textiles, the overall effect of the surfaces of the fabrics is smooth and flat, the grade of the fabrics is improved, wearing is comfortable, the using range is wide, the function and effect are better, and the functions of resisting mildew and bacteria, absorbing moisture, ventilating, preventing ultrasonic rays, preventing static electricity, being good in draping, eliminating the fact that the yarns can be worn and broken easily in the using process and the like are achieved.

Owner:荆日占

Spinning technology of textile

InactiveCN103510224ARaise the gradeComfortable to wearBiochemical fibre treatmentHeating/cooling textile fabricsEnzymeWoven fabric

The invention discloses a spinning technology of a textile. The spinning technology of the textile comprises the steps that plied yarn twisted by twisting equipment for pure-cotton plied yarn and cotton yarn with static wires is arranged on a beam by means of a sectional warping machine in a mode that two strands of static wires are added into per inch of the piled yarn, weaving is carried out by means of a loom, the piled yarn is sorted and checked in a workshop according to a corresponding technique, and the filed yarn is boiled firstly with soft water containing a scouring agent in a proportion of 2-8g / L for 10 hours during sorting, wherein the temperature of the water is 50-80 DEG C; then soft water is reinjected, wherein the bath ratio is 1:15, and the temperature is 40-70 DEG C; biological enzymes are added and processing is carried out for 40-60 min, wherein the pH of an acid enzyme is 4-5 and the pH of a neutral enzyme is 6-7; dewatering, drying and printing according to the technique are carried out in sequence, and then testing, checking, preshrinking and shaping are carried out in sequence. Fabric manufactured with the technology has the advantages of being high in grade, comfortable when the fabric is worn, wide in application range, resistant to mould and bacteria, capable of absorbing moisture, breathable, capable of preventing ultraviolet rays and static electricity, and good in drapability. Fracture, caused by abrasion, of the yarn can not occur easily in use.

Owner:赵翠萍

Single-air-cylinder switchover type air intake valve

ActiveCN103697191AMake up for the defect of unreliable switchingConvenient power sourceOperating means/releasing devices for valvesMultiple way valvesAir compressionInlet valve

The invention discloses a single-air-cylinder switchover type air intake valve which is simple in structure, good in air impermeability, low in cost and capable of achieving a quick, flexible and reliable air channel switchover function through a single peripheral air cylinder. The single-air-cylinder switchover type air intake valve comprises a valve body provided with an inner cavity, a valve sleeve, a valve rod and a valve plate, wherein the valve sleeve, the valve rod and the valve plate are arranged in the inner cavity of the valve body. The valve body comprises an air inlet and two air outlets, wherein the air inlet and the air outlets are communicated with the inner cavity. The valve sleeve is tightly matched with the inner wall of the valve body, a plurality of through holes for enabling the inner cavity of the valve body and one air outlet to be communicated are formed in the valve sleeve, the valve plate is connected to the head portion of the valve rod, and the rail portion of the valve rod is connected with the peripheral air cylinder. When the peripheral air cylinder is pushed into or pulled back, the valve plate blocks an air channel between the air inlet and one air outlet and enables the air inlet and the other air outlet to be communicated. The single-air-cylinder switchover type air intake valve can be applied to the field of air compression.

Owner:ZHUHAI HECA PURIFICATION TECH

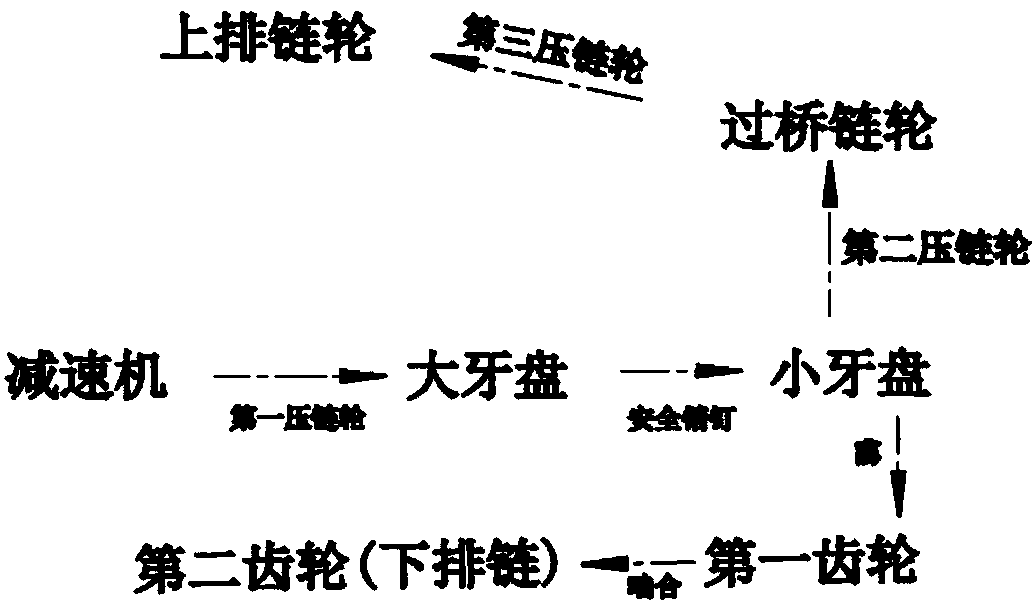

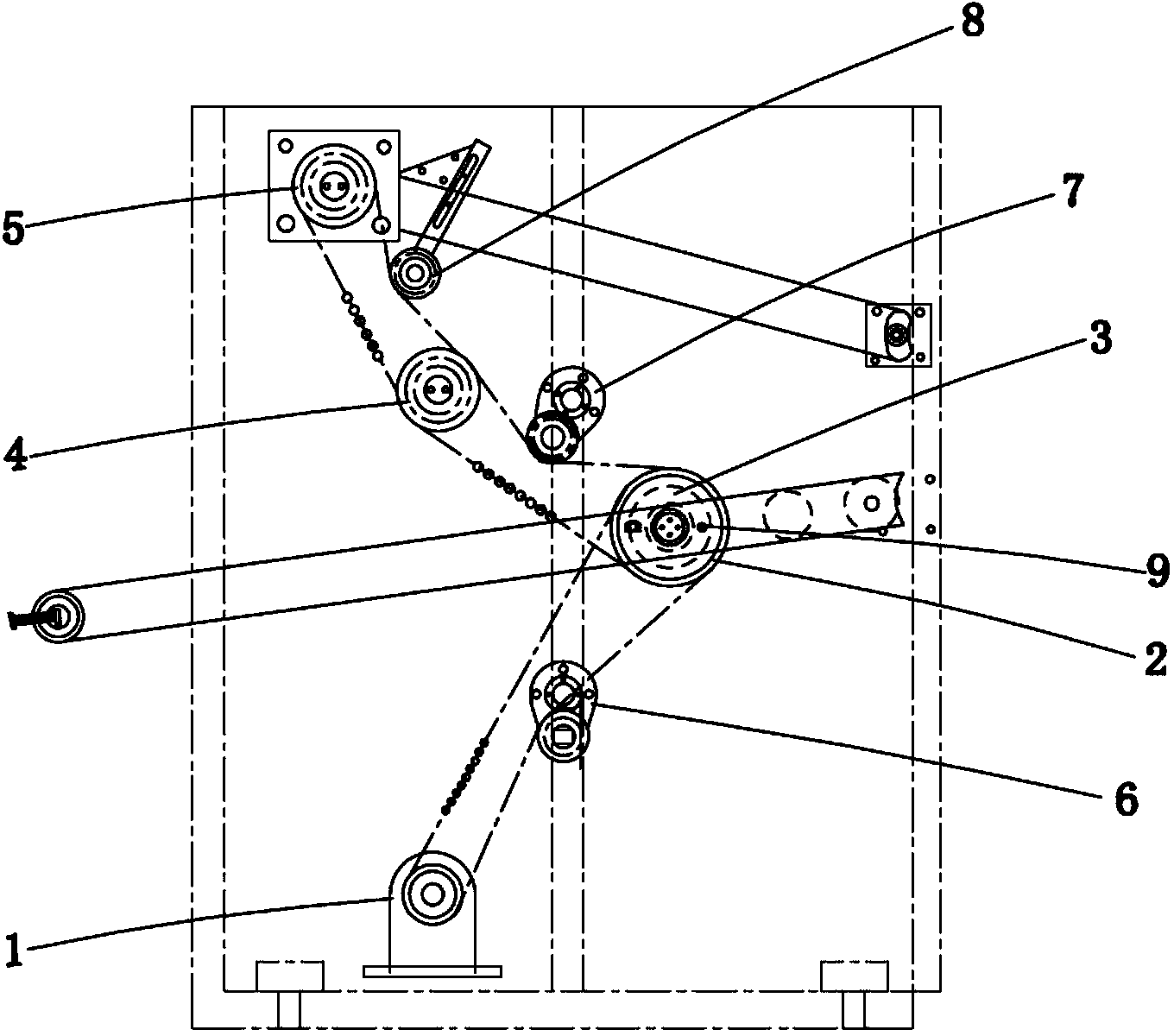

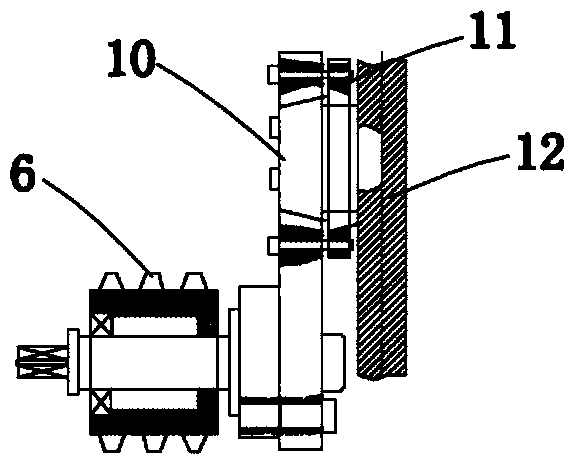

Wire cutter chain transmission tensioning assistance device

The invention discloses a wire cutter chain transmission tensioning assistance device. A wire cutter chain transmission mechanism is characterized in that a chain wheel on a speed reducer output shaft is connected with a big crankset through a chain, the big crankset is coaxially connected with a small crankset through a safety pin, a first gear is mounted on the small crankset through a key and meshed with a second gear to transmit power to a lower row chain wheel, a first chain pressing wheel is arranged on the chain between a speed reducer and the big crankset, a second chain pressing wheel is arranged on a chain between the small crankset and a bridging crankset, and a third chain pressing wheel is arranged on a chain between the bridging crankset and an upper row chain wheel. A lifting and lowering adjustment mechanism provided with the first chain pressing wheel and a tensioning mechanism provided with the third chain pressing wheel can freely adjust a tensioning device without stopping running or producing to guarantee stable working and normal running of a transmission system.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Powder coating equipment and coating technology

ActiveCN106076688APrevent flutteringSolve the floating phenomenonLiquid surface applicatorsMovable spraying apparatusImpellerHigh pressure

The invention provides a piece of powder coating equipment which comprises a spraying gun part, wherein the spraying gun part comprises a powder outlet which is disposed in a conical manner; an impeller is installed in the powder outlet; a powder circulation gap is disposed between the impeller and the powder outlet; a mixing chamber is disposed on the upper part of the impeller and installed at the powder outlet; the mixing chamber is located above the back face of the impeller and disposed in an annular manner; and the mixing chamber comprises a chamber wall, a channel communicating with the mixing chamber is formed in the chamber wall, and a power supply pipeline is connected to the channel. According to the invention, the high-voltage powder chamber is used as a powder supply source; a powder floating rate is increased by 15%-20%; and centrifugal effects generated from impeller rotation are used to solve the uniformity problem existing in powder fluidization.

Owner:WEIFANG EAST PIPE IND TECHNICAL CO LTD

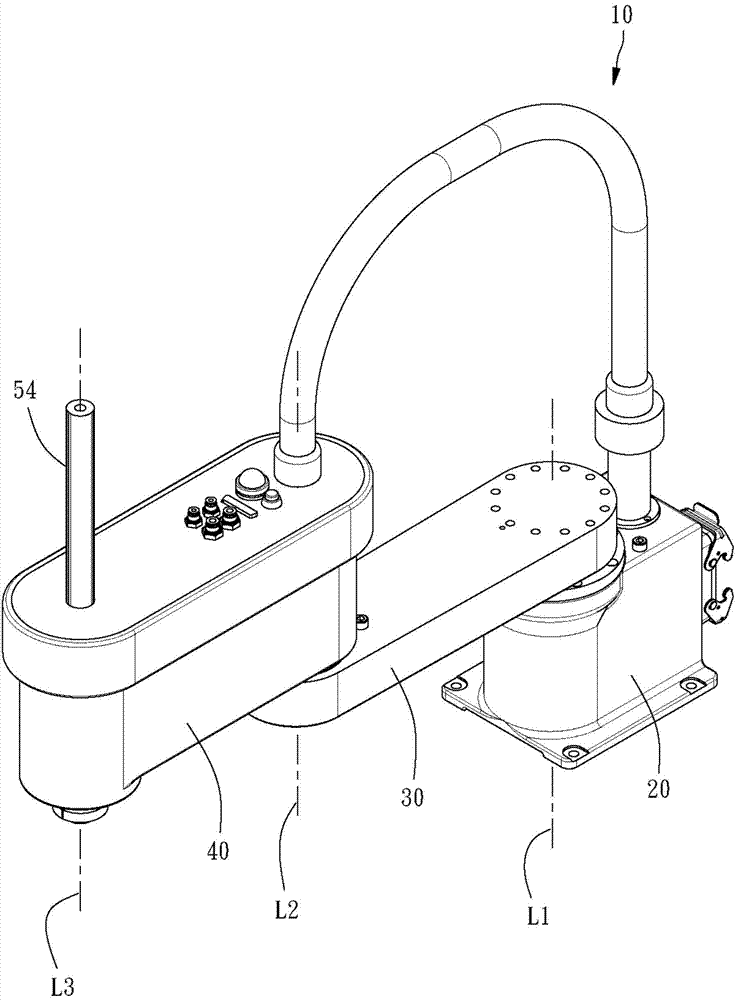

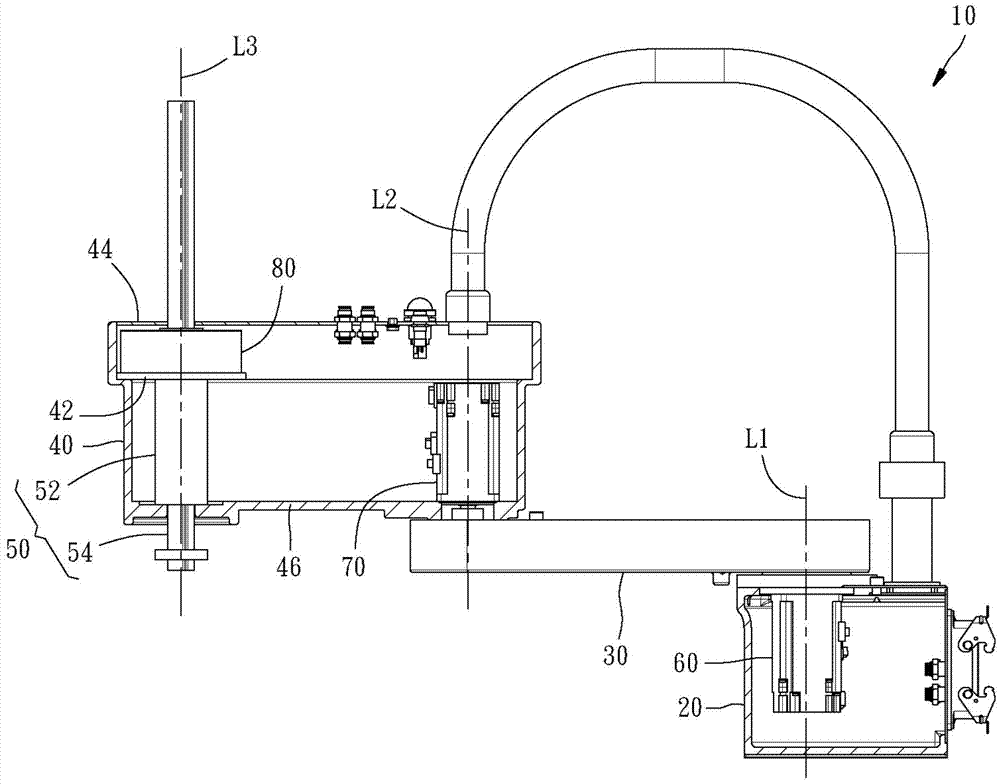

Selective compliance assembly robot

InactiveCN104708620AAvoid offsetSolve easy wear and tearProgramme controlProgramme-controlled manipulatorRobotic armCantilever

The invention provides a selective compliance assembly robot. The selective compliance assembly robot comprises a base, a first cantilever arranged on the base and capable of rotating with a first hypothetical axis as the center relative to the base, a second cantilever arranged on the first cantilever and capable of rotating with a second hypothetical axis as the center relative to the first cantilever, a shaft motor and rotary motors. The shaft motor comprises a fixing piece arranged on the second cantilever and a shaft rod capable of moving along a third hypothetical axis relative to the fixing piece. The first hypothetical axis, the second hypothetical axis and the third hypothetical axis are substantially parallel to one another. The rotary motors are arranged on the second cantilever and capable of driving the shaft rod to rotate with the third hypothetical axis as the center. In this way, according to the selective compliance assembly robot, the shaft rod is high in drive efficiency, stable in drive and capable of being controlled easily and precisely, and the maintenance cost is lower due to the fact that parts are not prone to damage.

Owner:HIWIN TECH

Alloy bit

InactiveCN103769582AStrong hardnessStrong toughnessTurbinesOther manufacturing equipments/toolsManganeseTitanium

The invention discloses an alloy bit. The alloy bit is characterized in that the alloy bit is manufactured by processing magnesium, titanium, chromium, manganese, iron, and aluminum through a compressing an sintering process according to a certain weight percentage, wherein the alloy bit comprises components of, by mass, 5.9%-8.1% of the magnesium, 20.5%-27.4% of the titanium, 13.5%-19.6% of the chromium, 31.6%-38.9% of the iron, 22.1%-25.7% of the magnesium, and 10.1%-13.8% of the aluminum. According to the alloy bit, by means of the manner, various kinds of sound metal is compressed and sintered to manufacture the alloy bit, so that the alloy bit has the advantages of being high in hardness and tenacity, difficult to abrade and fracture, long in service life, and capable of greatly improving production efficiency, and saving production costs.

Owner:SUZHOU KAIYE METAL PROD

Anchor bolt with line

The invention discloses an anchor bolt with a line. The anchor bolt comprises an anchor bolt body and two supporting wings, and the two supporting wings are arranged at the tail end of the anchor boltbody; grooves are formed in the positions, corresponding to the two supporting wings, of the anchor bolt body respectively; the near end of each supporting wing is pivoted in the corresponding groove, and each supporting wing can rotate around the pivot to enable the far end of the supporting wing to extend out of the groove or enter the groove; each supporting wing is provided with a first threading hole, and the two supporting wings are oppositely arranged. The anchor bolt with the line is provided with the supporting wings, and the supporting wings are expanded and fixed under the action of drawing force generated by a surgeon or movement after the anchor bolt with the line is implanted so that the drawing force can be better adjusted and controlled.

Owner:SHANGHAI KINETIC MEDICAL

Mold core for molding glass

InactiveCN1772664AInhibit growthReduce chemical abrasivenessGlass pressing apparatusTectorial membraneMaterials science

The present invention discloses mold core for molding glass, and the mold core includes base material and protecting film on the base material and containing M1 and C, where M1 is the noble metal Pd, Au, Ir, Ru, Re, Ta, Pt, Rh, Os or their combination. The protecting film has one precise molding surface far from the base material for molding and has thickness greater than 5 microns.

Owner:东莞信泰光学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com