Saw web used for both cutting and grinding

A saw blade and dual-purpose technology, applied in the field of steel and wood cutting equipment, can solve the problem of poor surface flatness and profile verticality, increased operator working time, surface knife marks, chipping or burrs, etc. problems, to achieve the effect of low cost, improved impact resistance, not easy to deform or break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

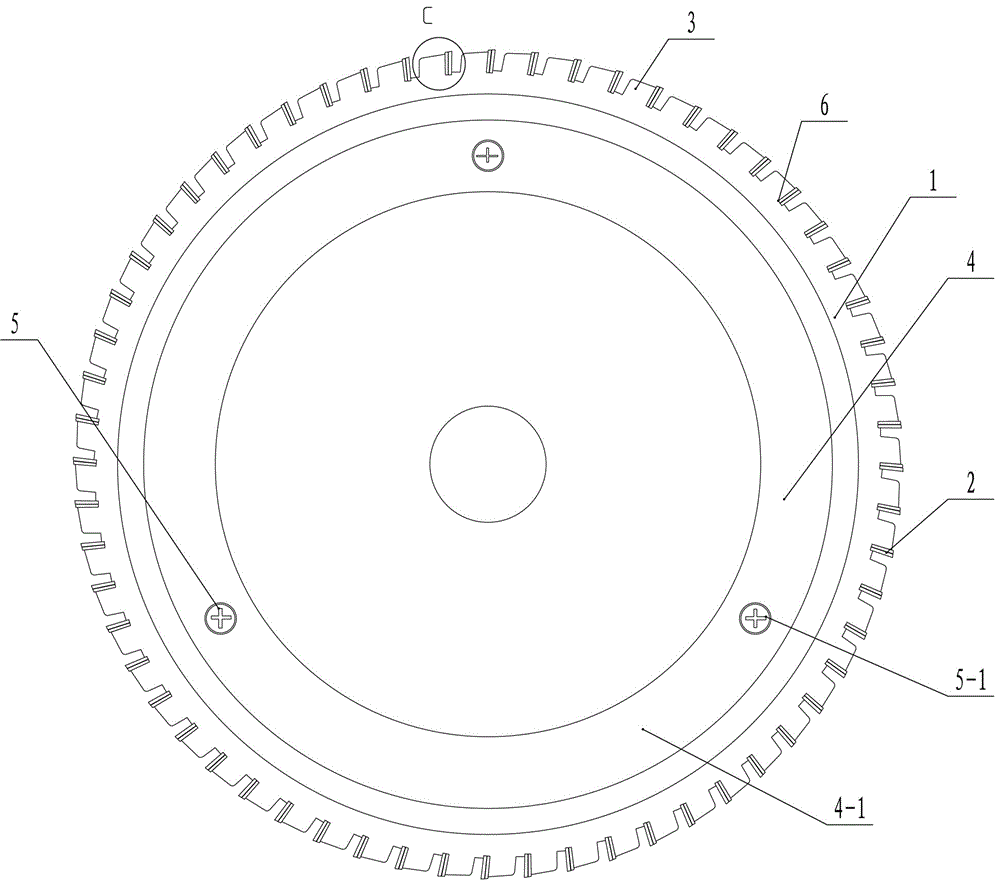

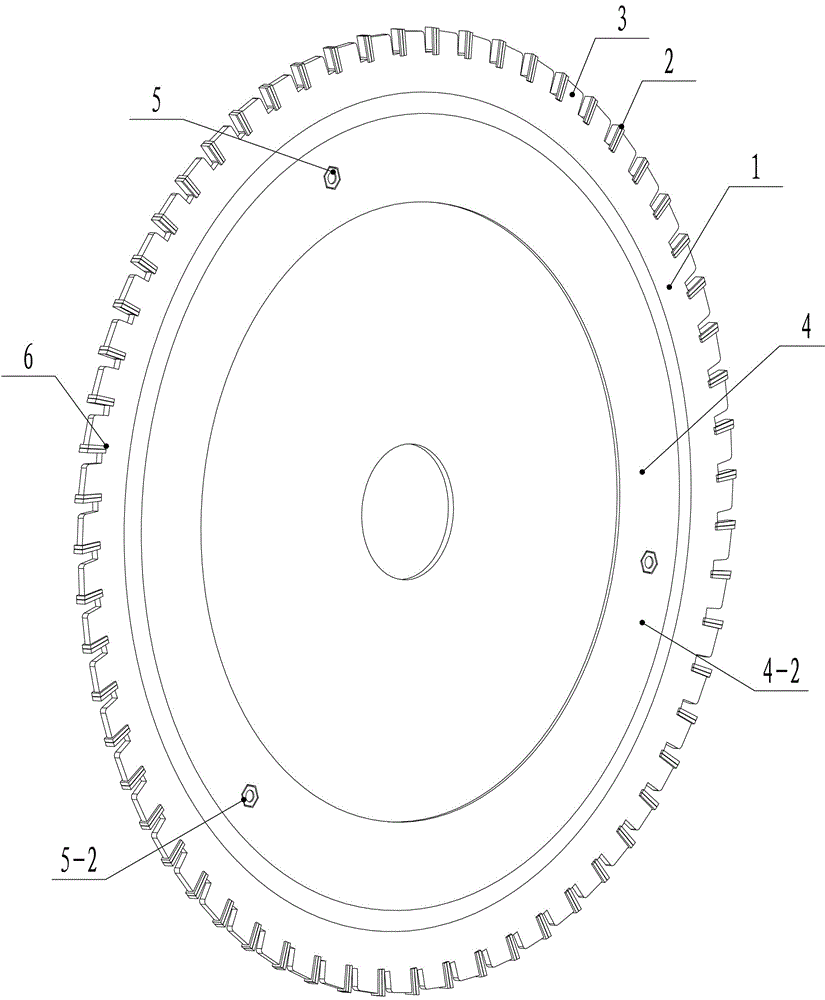

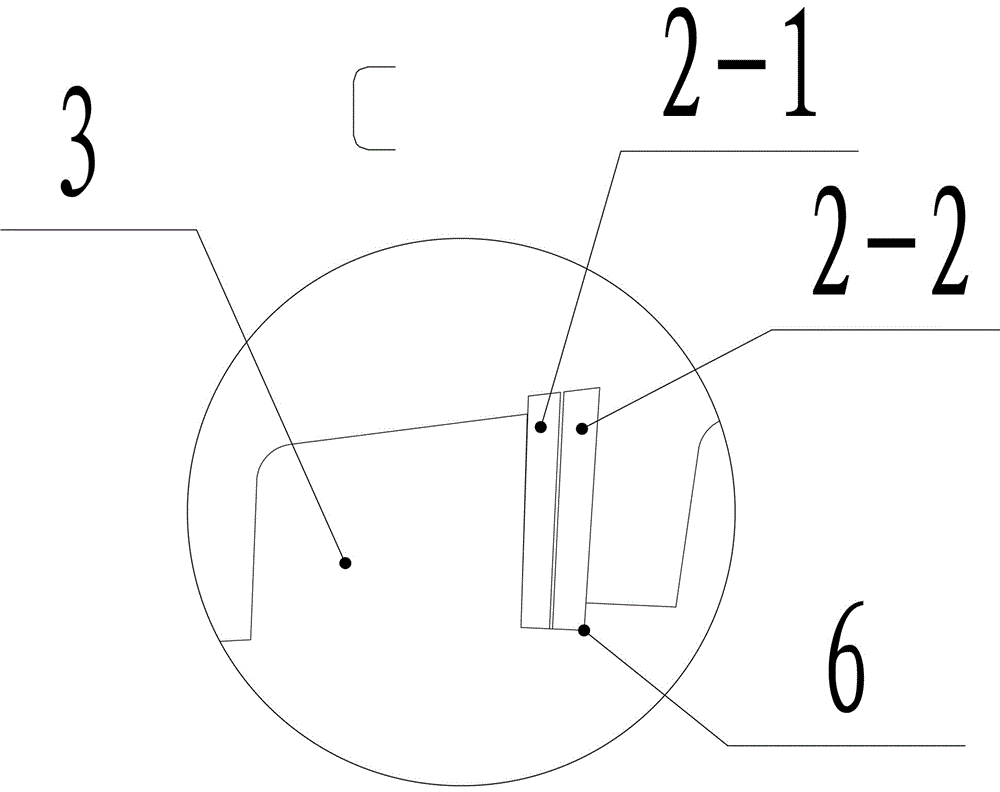

[0027] Such as Figure 1-5 As shown, the present invention includes a saw blade body 1, a double-layer cutter head 2, a tooth back 3 and a grinding wheel 4. On the saw blade body 1, a concave hole is provided on the same side of each tooth back 3. Groove 6, that is, all the grooves 6 are attached to the relative left side of the tooth back 3 or all the grooves 6 are attached to the relative right side of the tooth back 3. From another angle, it can also be said that all the grooves 6 are all attached to the opposite front side of the tooth back 3 or all the grooves 6 are attached to the opposite rear side of the tooth back 3, forming a structure in which both sides of the groove 6 correspond to the tooth back 3, double-layer The cutter head 2 is fixed in the groove 6 by welding, thus, the double-layer cutter head 2 is embedded in the groove 6, and the inventive embedded welding of the present invention greatly improves the cutting material of the saw blade during the cutting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com